Victorian soap makers used specialized equipment to meet rising consumer demand during an era when cleanliness became increasingly important. You'll find cutting implements like high-carbon steel knives and wire frames enabled uniform production, while wooden molds and metal dies created distinctive branded shapes. Precision measuring tools guaranteed consistent quality, and hand-powered machinery improved efficiency. These innovations transformed soap making from artisanal craft to industrial process, making soap accessible to more social classes. Discover how these tools revolutionized an entire industry.

Essential Cutting Implements in Victorian Soap Workshops

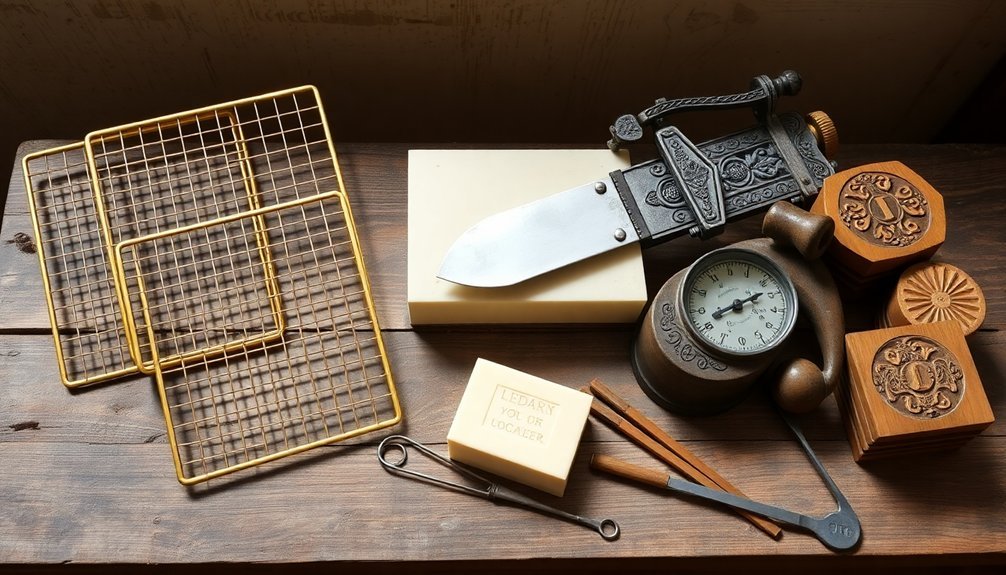

Three essential cutting implements defined the Victorian soap workshop's efficiency and output quality. You'd find soap makers wielding high-carbon steel knives, durably crafted to slice through thick, hardened soap blocks with precision.

The soap cutter—a wooden frame with taut wires—revolutionized production by creating uniform bars, ensuring consistent quality and pricing for commercial soaps.

Wire cutters completed this trio of specialized tools, allowing artisans to divide large soap blocks into manageable sections before final shaping.

The design and functionality of these cutting implements directly influenced workshop productivity, enabling faster processing and more affordable products.

As demand for soap grew throughout the Victorian era, these tools became increasingly sophisticated, reflecting the industry's evolution from small-scale craftsmanship to commercial manufacturing that could meet the rising consumer market.

The Evolution of Soap Cutting Technology From 1800-1900

The Victorian soap industry underwent remarkable technological transformation throughout the nineteenth century, shifting from basic manual implements to sophisticated mechanical systems.

If you'd visited an early 1800s workshop, you'd have seen craftsmen wielding simple knives and wire cutters, meticulously slicing soap by hand.

By mid-century, mechanical devices revolutionized this process, allowing for consistent cuts essential to brand identity in the competitive Victorian era.

The late 1800s introduced the first true soap cutting machines, dramatically increasing production capacity for manufacturers.

As steam power became widespread, these technologies handled ever-larger soap volumes.

Wire Frames and Guillotine Cutters: Precision in Production

As Victorian soap production expanded beyond small workshops into industrial manufacturing, wire frames and guillotine cutters emerged as revolutionary tools that transformed the soap-making process.

Wire frames allowed you to create perfectly uniform bars with consistent dimensions—a significant development for efficient packaging and retail sales.

Meanwhile, guillotine cutters sliced large soap blocks into precise pieces, dramatically reducing waste while speeding up production.

These innovations came at the perfect moment during the Industrial Revolution when soap manufacturers needed to scale operations to meet soaring consumer demand.

The precision these tools provided wasn't just about aesthetics; it delivered vital quality control benefits. Evenly cut bars were less prone to cracking during handling and storage.

This mechanization perfectly exemplified the Victorian era's push toward standardization in manufacturing processes.

Wooden Molds and Metal Dies for Distinctive Soap Shapes

In Victorian soap manufacturing, you'll notice wooden molds and metal dies served as the industry's first branding tools, creating distinctive shapes that distinguished one producer from another.

These tools balanced artistic expression with production efficiency, allowing manufacturers to craft decorative soaps with repeatable precision in larger batches than hand-cutting alone could achieve.

The functional design of these molds and dies reflected the Victorian era's dual commitment to craftsmanship and industrial progress, transforming simple soap bars into marketable products with unique identities.

Victorian Branding Through Design

Three distinct elements converged during the Victorian era to transform soap from a mere cleansing agent to a branded commodity: wooden molds, metal dies, and artistic design sensibility.

You're witnessing the birth of modern branding when examining Victorian soap making techniques. Manufacturers cleverly used ornate molds to create unique shapes like flowers and animals, instantly distinguishing their products in a competitive marketplace. This craftsmanship wasn't merely decorative—it communicated quality and luxury to the emerging middle class.

As consumer goods became more commercialized, soap makers recognized that visual identity created brand recognition and loyalty. The aesthetic appeal of these molded soaps directly connected to Victorian values of cleanliness and refinement.

Advertisements prominently featured these distinctive designs, cementing the relationship between a soap's appearance and its perceived quality.

Batch Production Efficiency

Victorian soap manufacturers revolutionized their industry through specialized production tools that balanced artistry with efficiency. The introduction of wooden molds enabled them to create uniform soap bars in distinctive shapes while maintaining consistent quality across large batches.

You'll find these manufacturing innovations particularly noteworthy in their contribution to mechanization during the Industrial Revolution. Soap manufacturers could produce considerably more product with less labor by employing wooden molds for shaping and metal dies for imprinting logos and branding. This systematic approach to batch production dramatically reduced costs while increasing output.

The standardized shapes created by these tools offered additional benefits beyond aesthetics. Manufacturers could optimize packaging and transportation, improving distribution networks and expanding their market reach—a critical advantage in Victorian Britain's competitive consumer landscape.

Form Follows Function

While functionality remained paramount, Victorian-era wooden molds and metal dies transformed ordinary soap into distinctive works of art. You'd find these tools created uniformity in soap production while elevating the humble bar of soap to new aesthetic heights.

Skilled artisans crafted wooden molds in rectangular, oval, and decorative forms, ensuring consistent sizing that improved transportation, storage, and production efficiency.

When metal dies entered the scene, manufacturers could impress intricate patterns onto each bar, notably enhancing their visual appeal and marketability.

This combination of practicality and craftsmanship reflected broader Victorian values—even utilitarian items deserved beautiful presentation.

As soap making evolved from basic necessity to branded consumer good, these specialized tools helped manufacturers distinguish their products in an increasingly competitive market, turning everyday cleansing into a luxury experience.

Measuring and Marking Tools for Consistent Soap Bars

Victorian soap makers' success hinged on their meticulous use of precision measuring devices like scales, graduated jugs, and thermometers to guarantee perfect ingredient ratios during saponification.

You'll notice these craftspeople employed marking tools such as patterned molds and cutting guides to produce uniform soap bars that built brand recognition in the competitive marketplace.

These standardized measuring practices weren't merely for consistency—they represented the emerging scientific approach to manufacturing that would transform soap making from a casual household task to a respected commercial enterprise.

Precision Measuring Devices

As the soap industry evolved during the 19th century, precision measuring devices became indispensable for creating consistent, high-quality products.

You'd find Victorian soap makers meticulously weighing lye and fats with accurate scales, ensuring the chemical reactions occurred properly every time. Without this precision, soap batches could fail entirely.

Standardized measurements transformed soap making from an imprecise craft to a reliable manufacturing process. Using graduated cylinders for liquids and calibrated scales for solids, producers maintained consistency across thousands of bars—crucial as consumer expectations rose alongside mass production.

The Industrial Revolution accelerated this need for precision. As you expanded production beyond small workshops, quality control depended on these measuring tools.

Calipers and rulers complemented the process, enabling uniform sizing that satisfied both merchants and customers alike.

Size Standardization Equipment

Beyond simple measurement, Victorian soap makers utilized specialized standardization equipment to create perfectly uniform bars. You'd find measuring cups and scales in every successful soap workshop, as they guaranteed consistent quality throughout the saponification process.

By precisely weighing fats, lye, and additives, manufacturers prevented dangerous variations that could ruin entire batches. Marking tools played an equally crucial role, creating distinctive shapes that differentiated products in the competitive soap industry.

This standardization revolutionized production processes during the Victorian era by enabling efficient packaging and predictable pricing. When soap bars maintained consistent size and weight, consumers developed brand loyalty, allowing manufacturers to scale their operations effectively.

The introduction of these tools transformed soap making from a cottage craft into a thriving commercial enterprise.

Hand-Powered Machinery That Revolutionized Soap Production

While manual soap making had existed for centuries, the introduction of hand-powered machinery during the Victorian era transformed this ancient craft into a more efficient and precise industry.

You'd find mechanical saponification processes greatly improving soap consistency and quality by controlling temperature and mixing speed. Lever and crank systems enabled you to efficiently blend fats and oils with alkalis, cutting labor time considerably.

Soap-making machines like the soap press guaranteed uniformity in size and weight—critical for commercial sales and packaging.

These innovations also improved the extraction process, increasing yields and reducing waste. The shift to hand-powered machinery marked the beginning of industrialized soap production, with soap factory operations expanding to meet growing consumer demand, ultimately setting the foundation for mass production techniques still influencing manufacturing today.

Specialized Equipment for Luxury and Scented Soap Varieties

The refinement of soap manufacturing extended beyond simple production to include artistic and sensory elements that defined Victorian luxury. You'd find specialized equipment like saponification kettles enabling precise control over the soap-making process, ensuring consistent quality in both luxury soaps and scented varieties.

| Tool | Purpose | Result |

|---|---|---|

| Molds & Cutting Wires | Shape formation | Intricate shapes and designs |

| Scenting Apparatus | Fragrance incorporation | Distinctive aromatic profiles |

| Spatulas & Spoons | Layering and swirling | Visually striking patterns |

| Mechanical Mixers | Blending ingredients | Smoother textures and uniform scent |

Late Victorian mechanical mixers and homogenizers revolutionized production by improving the blending ingredients process, creating smoother textures with evenly distributed fragrances—transforming ordinary soap into coveted luxury items for discerning Victorian consumers.

From Craftsman's Workshop to Industrial Manufacture: Transitional Tools

As Britain's Industrial Revolution gained momentum, traditional soap-making craftsmen found themselves at a crossroads between time-honored manual methods and emerging mechanized production.

You'd witness remarkable changes in their workshops as new industrialized equipment replaced hand tools, dramatically improving production efficiency.

By 1850, soap manufacturing had transformed fundamentally, with output soaring to over 157 million pounds annually.

The incorporation of steam-powered machinery, precise scales, and industrial soap molds allowed makers to produce consistent quality with less manual labor.

Mechanized processes for lye production and fat rendering further revolutionized the industry.

These transformative tools of the Victorian era weren't merely about production—they democratized access to soap, turning what was once a luxury item into a household staple available to people across all social classes.

Frequently Asked Questions

What Did Victorians Use for Soap?

You'd find Victorians using commercial and homemade soaps. They'd purchase bar soaps made from animal fats and lye, or make their own using cauldrons, wooden paddles, and molds for household cleaning and bathing.

What Was Used for Soap in the 1800S?

In the 1800s, you'd find soap made from animal fats like tallow or lard, combined with alkalis such as soda ash or potash. These ingredients underwent saponification to create various washing and scented soaps.

What Was the Old Way of Making Soap?

You'd make soap the old way by mixing wood ash lye with animal fats in a cauldron over fire, stirring with wooden paddles, then pouring into molds to cure for weeks before use.

What Was Soap Used for in the Bronze Age?

During the Bronze Age, you'd find soap primarily used for cleaning wool and doing laundry, not personal hygiene. You're looking at practical applications that valued soap's cleansing properties for textiles rather than bodies.

In Summary

You've seen how Victorian soap makers relied on their specialized equipment to transform production from an artisanal craft to an industrial process. Their wire frames, guillotine cutters, and wooden molds weren't just practical—they enabled consistent quality and distinctive designs that consumers demanded. As you explore these historical implements, you'll appreciate how they bridged traditional craftsmanship with emerging manufacturing techniques, establishing the foundation for modern soap production we take for granted today.

Leave a Reply