To test your handmade soap's pH, use alkaline-specific pH strips or a calibrated digital meter. Create a solution with 1g soap dissolved in 99g distilled water. For cold process soap, wait 4-6 weeks before testing; hot process soap can be tested after 7 days. Safe soap should register between pH 7-10, with 9 being ideal. Regular testing maintains consistency and skin safety. Discover the complete protocol to confirm your soap meets proper standards.

Testing Your Handmade Soap: Proper Ph Guide

Quality control begins with proper pH testing of your handmade soap. For safe skin use, your soap pH should fall between 7 and 10. To get accurate readings, create a paste by mixing your soap with distilled water before testing.

Timing matters – test cold process soap about 12 hours after pouring, while hot process soap can be checked once it develops a waxy appearance.

Standard pH strips often provide unreliable results, so invest in high-quality pH strips or a digital pH meter for precision.

Continue testing throughout the curing process to monitor consistency and quality. This regular assessment guarantees your handmade soap maintains the safe pH range that's effective yet gentle on skin, giving you confidence in your finished product.

Understanding the Ph Scale and Its Importance in Soapmaking

The pH scale forms the foundation of successful soapmaking – without understanding it, you'll struggle to create products that are both effective and safe.

This numerical range from 0 to 14 indicates whether your handmade soap is acidic (below 7), neutral (7), or alkaline (above 7).

Properly balanced pH levels are critical for your skin care products because:

- Handmade soap naturally has an alkaline pH between 8-10, ensuring effective cleansing while remaining gentle

- pH testing confirms complete saponification process, guaranteeing your soap is safe to use

- Levels above 11 can damage skin's protective barrier, causing irritation and moisture loss

- Regular quality control through pH testing helps maintain consistency across batches

Understanding these principles empowers you to create soaps that cleanse effectively while respecting your skin's natural balance.

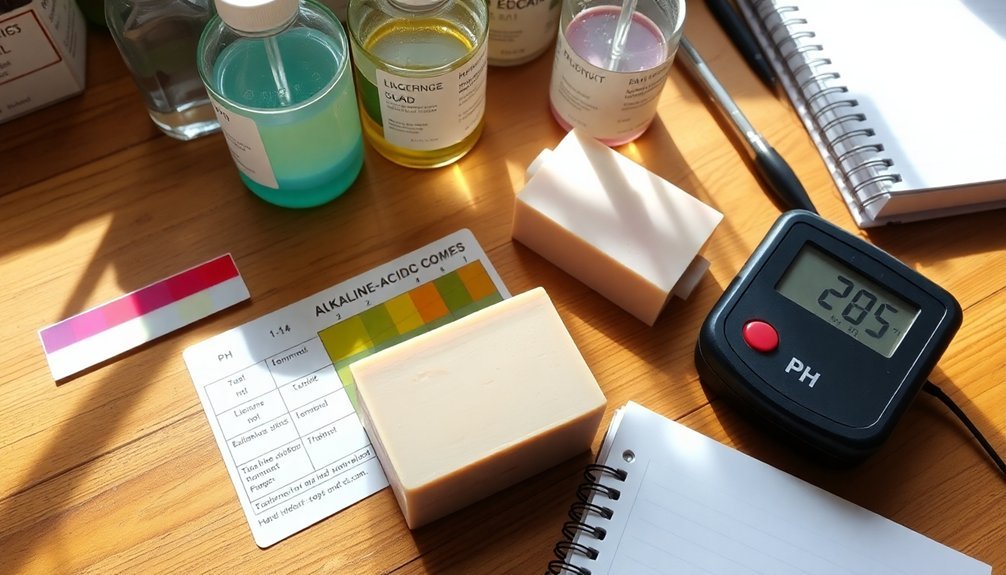

Essential Equipment for Accurate Ph Testing of Handmade Soap

Accurate testing equipment serves as your first line of defense against potentially harmful soap products. When measuring the pH of saponified oils, you'll need pH test strips designed specifically for alkaline products or digital pH meters calibrated with buffer solutions. Always use distilled water when creating your soap solutions to prevent contaminants from skewing results.

| Equipment | Purpose | Ideal Specifications |

|---|---|---|

| pH Test Strips | Quick assessment | Lab-grade, alkaline range (8-10) |

| Digital pH Meter | Precise measurement | Calibrated, 0.01 resolution |

| Digital Scale | Proper soap to water ratio | Accurate to 0.1g for 1:99 ratio |

Maintain clean measuring equipment and disposable supplies to guarantee soap molecules don't contaminate subsequent tests. For an accurate reading, mix 1g soap with 99g distilled water to create the proper testing solution.

Step-by-Step Guide to Testing Your Cold Process and Hot Process Soaps

With the right tools in hand, you're ready to establish a reliable testing protocol for your handmade soaps.

Remember that timing matters—cold process soap requires a 4-6 week curing period before accurate readings, while hot process soap needs less than 7 days.

For your pH test:

- Create a soap paste by mixing 1 gram of soap with 99 grams of distilled water, letting it sit for 12 hours for cold process soap.

- For hot process soap, verify it has a waxy appearance before creating the same solution.

- Use pH testing strips or a digital meter to check if your soap falls within the safe 7-10 pH range.

- Always prioritize safety by wearing protective gear and testing in a well-ventilated space.

Interpreting Ph Results: What Safe Soap Readings Look Like

Understanding pH results forms the cornerstone of successful handmade soap making. When you test your creations, you'll want to see readings within the pH range of 7 to 10, which indicates safe soap suitable for skin contact.

Your handmade soap is ideally positioned around pH 9—this sweet spot balances effective cleansing with skin-friendliness. If your pH test reveals values below 7, you're dealing with acidity that won't properly cleanse. Readings above 10 signal excessive alkalinity, which can irritate skin and compromise soap quality.

Regular pH testing throughout the curing process helps you monitor your soap's development. By watching these numbers carefully, you'll guarantee your final product maintains the proper balance, giving your customers confidence in your handmade soap's safety and effectiveness.

Frequently Asked Questions

How to Test Ph Levels in Homemade Soap?

You'll need to mix a small amount of solidified soap with distilled water to form a paste. Then use pH strips or a digital meter to test if it's within a safe range (7-10).

What Is a Good Ph Level for Soap?

A good pH level for your handmade soap is between 8 and 10. You'll want to aim for around 9, which balances effective cleansing with skin gentleness. Avoid levels above 11, which can cause irritation.

What Is the Ph of Pure Hand Soap?

Pure hand soap typically has a pH between 9 and 11, making it alkaline. This is natural because of the saponification process that uses lye and fatty acids to create the cleansing product you're using.

How to Test Ph of Body Wash?

Dilute your body wash with distilled water (1% concentration), then use pH test strips or a digital meter to measure it. You'll want a reading between 4.5-6.5 to match your skin's natural pH.

In Summary

You'll find knowing your soap's pH is essential for creating safe, high-quality products. By using the proper testing equipment and following the steps outlined, you're now equipped to measure your creations accurately. Remember, ideal handmade soap typically falls between 8-10 on the pH scale. Don't skip this important step—your customers' skin health and your reputation as a soapmaker depend on it.

Leave a Reply