Temperature greatly affects how quickly your soap reaches trace. Higher temperatures (120-130°F) accelerate saponification, while cooler temperatures slow it down. Your lye solution and oils should be within 10°F of each other for stability. Ambient room temperature, water-to-lye ratio, mixing methods, and oil selection all impact trace development. Using infrared thermometers helps maintain control, while strategic cooling techniques like ice baths can extend working time. Master these temperature factors for more intricate soap designs.

7 Ways Temperature Controls Soap's Trace Time

When making handcrafted soap, temperature serves as the primary catalyst controlling how quickly your mixture reaches trace. Higher temperatures between 120-130°F accelerate the saponification process, giving you faster trace, while temperatures below 100°F might cause false trace or ricing issues in your soap.

For successful soaping, maintain your lye solution and oils within 10 degrees of each other. This temperature consistency promotes stable emulsion before reaching trace.

When working with hard oils and butters, warmer temperatures guarantee complete melting, preventing premature thickening during mixing.

Your water-to-lye ratio also influences trace time—higher water content typically speeds trace. For precise temperature control, use an infrared thermometer to monitor ingredients and adjust your process to achieve your desired trace consistency.

The Science Behind Temperature's Effect on Saponification Speed

The faster molecular movement at higher temperatures increases collision rates between lye and oils, dramatically accelerating the saponification reaction according to Molecular Collision Theory.

You'll notice that heat acts as a catalyst during soap-making, breaking chemical bonds more efficiently and converting your ingredients into soap in less time.

This catalytic effect explains why your soap reaches trace quickly at 120°F but might take twice as long at 90°F, giving you predictable control over your working time.

Molecular Collision Theory

Diving into the molecular world reveals why temperature dramatically affects trace time in soap making. When you increase temperature in cold process soaps, you're actually boosting the kinetic energy of your ingredients, causing more frequent collisions between lye and soap making oils.

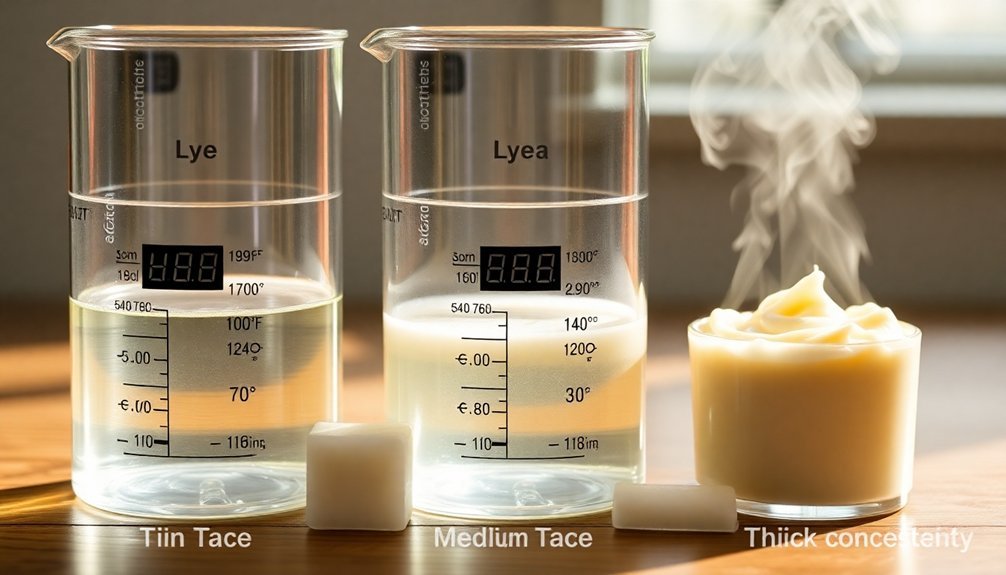

| Temperature | Effect on Trace |

|---|---|

| High (110-130°F) | Faster trace, quicker emulsification |

| Medium (90-110°F) | Moderate saponification process |

| Low (70-90°F) | Delayed trace occurs, potential separation |

These molecular interactions follow collision theory principles—higher temperatures help molecules overcome activation energy barriers more easily. When your lye temperatures rise, molecules move more vigorously, creating more effective collisions. This is why hot process soap reaches trace faster than cold lye methods. Understanding this science lets you control trace timing for different design needs.

Heat-Activated Catalyst Effect

Beyond simple molecular collisions, temperature functions as a powerful catalyst in soapmaking chemistry, fundamentally altering reaction pathways.

When you combine oils and lye at temperatures above 110°F, you're harnessing this heat-activated catalyst effect to manipulate trace timing. The exothermic nature of saponification means your soap batter generates heat naturally, but controlling your starting temperatures gives you remarkable power over the process.

At ideal temperatures (120-130°F), your soap moves smoothly through trace stages, allowing precise control over designs and additives. Conversely, cooler temperatures can lead to false trace—where your mixture thickens without true saponification occurring.

Remember that every 10°F increase dramatically accelerates reaction rates. By understanding this temperature-catalyst relationship, you'll gain mastery over one of soapmaking's most essential variables, ensuring consistent results every time.

How Oil Temperature Influences Trace Development

You'll notice that working with cooler oils (120°F or below) can greatly delay trace, giving you more time for intricate designs and swirl techniques.

Conversely, heating your oils above 130°F accelerates the chemical reactions between lye and fats, causing soap batter to thicken more rapidly.

Finding your ideal temperature range—typically 120-130°F for balanced formulations—will help you control trace development predictably while ensuring complete saponification without false trace issues.

Cold Oils Slow Trace

When your oils are too cold during the soapmaking process, you'll notice a significant slowdown in trace development, giving you extended working time but potentially creating complications.

Oils below the recommended soaping temperature of 110°F can trigger false trace—a deceptive thickness that hasn't properly saponified.

Cold temperatures cause fatty acids to solidify, preventing smooth emulsions and creating a grainy texture that mimics trace but lacks stability.

While this slowdown can benefit soap makers attempting intricate designs, it's important to ascertain oils are fully melted before combining with lye.

Consider using oils with lower melting points, like olive oil, to maintain a controlled, slower trace.

Always monitor your temperatures carefully—cold oils may extend working time, but they can compromise the saponification process if not managed properly.

Heat Accelerates Reactions

While cold oils slow the trace, heat acts as the chemical accelerator in soapmaking. When you work with oils at higher temperatures (110-130°F), you'll notice trace happens considerably faster. Your soap mixture responds dramatically to temperature changes, especially when you're working with hard oils above their melting point.

- Stick blending generates additional heat, further helping to accelerate trace when combined with already warm oils.

- Maintaining oil temperatures above 100°F but below 130°F gives you ideal control trace without risking premature gel phase.

- Thoroughly melting all hard oils prevents false trace issues that soap calc formulations can't predict.

Remember that the relationship between your oil and water temperature matters too—keeping oils slightly warmer than your lye solution creates perfect conditions for even saponification without shocking the mixture into thickening too quickly.

Optimal Temperature Ranges

Finding the sweet spot for your oil temperatures directly influences how your soap develops trace. For most soap making recipes, maintaining oils between 120-130°F creates perfect conditions for consistent trace development. This ideal temperature range promotes even saponification without rushing the process.

When your oils drop below 100°F, you risk false trace, where the mixture looks thick but hasn't properly saponified, resulting in grainy soap. Conversely, temperatures exceeding 130°F accelerate trace too quickly, limiting your working time.

Recipes high in solid oils need warmer temperatures for complete melting, while those with more liquid oils can work at cooler temperatures for slower trace.

For a smooth mixing process, verify your lye solution temperature matches or slightly exceeds your oil temperature, preventing any unwanted solidification during combination.

Lye Solution Temperature: Finding the Sweet Spot

Because lye undergoes an exothermic reaction with water, its temperature management sits at the heart of successful soap making. Your lye solution can reach 200°F, but you'll need to cool it to 120-130°F before combining with oils to prevent false trace and guarantee proper saponification.

Maintaining a 1:1 lye-to-water ratio helps control trace speed, as higher water content leads to quicker thickening of your batter.

- Keep your lye solution temperature within 10 degrees of your oil temperature to achieve even trace and prevent solidified fats

- Test small batches at different temperatures to determine what works best for your specific soap recipes

- Watch for false trace when lye solution temperatures drop below 100°F, as this indicates premature thickening without proper saponification

Environmental Factors: Room Temperature and Trace Control

Beyond lye solution temperatures, your working environment plays a key role in determining how quickly your soap reaches trace. When you're working in higher ambient temperatures (above 70°F), your soap batter can heat up faster, accelerating saponification and shortening your working time.

To gain more control over intricate design techniques, maintain a cooler environment in your soap making space. This helps preserve the ideal viscosity of your mixture, allowing better incorporation of colorants, essential oils, and additives.

A cooler room temperature gives you precious extra minutes before trace sets in—critical when working with fragrance oils known to accelerate hardening.

Don't underestimate the importance of monitoring temperature throughout your workspace. By controlling this environmental factor, you'll avoid false trace and enjoy more consistent results in your soap making adventures.

Strategic Temperature Management for Intricate Soap Designs

When crafting intricate soap designs, strategic temperature management becomes your most powerful ally. Maintaining your lye solution and oils between 120-130°F promotes smoother trace development, while cooler temperatures (100-110°F) help prevent unwanted gel phase when working with delicate designs.

You'll gain more control over trace speed by adjusting your water-to-lye ratio to approximately 1:1. This water discount provides extended working time for complex patterns.

- Alternate between stick blending and hand stirring to monitor temperature and prevent sudden acceleration

- Use an infrared thermometer to guarantee consistent temperature readings throughout your soap mixture

- Consider your workspace temperature as an additional variable that affects trace development

These temperature-focused techniques give you precise control over trace timing, allowing your artistic soap designs to shine without racing against rapidly thickening batter.

Cooling Techniques to Extend Working Time

Mastering temperature control gives you significant power over soap trace development. By cooling both oils and lye solution below 100°F, you'll dramatically extend trace time, allowing for more complex designs and swirls.

Create an ice bath for your lye solution before combining it with oils to maintain lower temperatures throughout the initial mixing phase.

Incorporate slow moving oils like olive oil in your recipe, as they resist solidification at cooler temperatures and delay trace development.

Consider slightly reducing your water content while ensuring adequate hydration for saponification. This strategic adjustment helps slow the chemical reaction without compromising the final product.

Replace your stick blender with hand mixing when possible to minimize heat generation during blending. This simple technique prevents unnecessary temperature increases that accelerate trace development.

Frequently Asked Questions

How Do You Make Soap Trace Faster?

You'll make soap trace faster by using coconut oil, adding colorants like indigo, maintaining higher temperatures (110-130°F), reducing water in your lye solution, and using a stick blender in short bursts.

How Does Temperature Affect Soap?

Temperature greatly affects your soap's behavior. Higher temperatures (110-130°F) promote even emulsification and faster trace, while cooler temperatures below 100°F can cause false trace or ricing in your mixture.

What Temperature Is a Soap Trace?

You'll achieve ideal soap trace at 120-130°F. This temperature range guarantees your oils and lye mix properly without false trace issues or accelerated saponification. It's the sweet spot for consistent, predictable results.

What Is the Effect of Temperature on the Saponification Reaction?

Higher temperatures (110-130°F) speed up your saponification reaction, while lower temperatures can cause false trace. You'll get more even saponification when you keep your lye and oils within 10°F of each other.

In Summary

By mastering temperature's influence on your soap's trace time, you'll gain precise control over your creative process. Whether you're aiming for complex designs requiring extended working time or quick-setting formulations, these temperature management techniques put you in the driver's seat. Remember, it's not just about oil and lye temperatures—your environment matters too. With practice, you'll confidently manipulate this critical variable for consistently beautiful results.

Leave a Reply