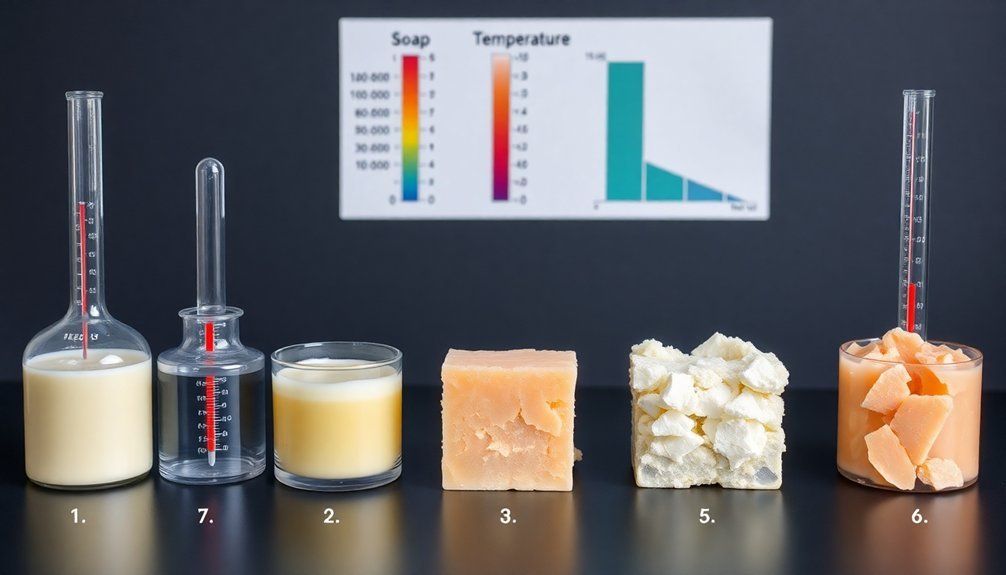

Temperature plays an essential role in your soap-making success. For ideal results, keep both oils and lye solution between 120-130°F, with neither component more than 10 degrees apart. Too cold (below 100°F) and you'll risk false trace with grainy texture; too hot (above 140°F) and you'll face rapid saponification with potential defects. Your careful temperature management directly impacts texture, appearance, and quality of your final product. The following sections reveal exactly how to master this vital variable.

Numeric List of 5 Second-Level Headings

Several key temperature considerations impact your soap-making success. When crafting cold process soap, maintaining precise temperatures prevents common pitfalls and guarantees quality results.

- Optimal Oil and Lye Temperature Range (120-130°F) – Prevents false trace and guarantees smooth mixing.

- Managing Trace Acceleration (110°F+) – Higher temperatures speed up trace in your soap batter.

- Low Temperature Benefits (100-110°F) – Prevents gel phase, ideal for heat-sensitive additives.

- Preventing Overheating Soap Disasters (Below 160°F) – Avoids alien brains and soap volcanoes.

- Lye Solution Temperature Management – Cooling to 120-130°F prevents oil solidification.

These temperature guidelines apply to standard recipes, but you'll need adjustments for high water soaps or specialized formulations.

Monitoring your soap making oils and lye solution temperatures throughout the process gives you greater control over the final product.

The Science Behind Heat and Saponification

Understanding how temperature catalyzes the saponification process reveals why precise heat management is crucial for successful soap making.

When your lye temperatures and oil mixture meet in the ideal 120-130°F range, they create the perfect environment for oils and alkali to transform into soap.

If you're working below 100°F, your soap batter may experience false trace—a premature thickening that creates grainy, inconsistent results.

Conversely, temperatures exceeding 140°F accelerate saponification too rapidly, causing structural defects.

Your soap's water content also influences temperature sensitivity.

High water soap requires careful monitoring during the gel phase to prevent overheating, while low water soap formulations can tolerate higher temperatures without compromising quality.

For best results, maintain your lye solution around body temperature (98.6°F) to guarantee smooth integration with oils.

Mastering the Heat Transfer Method for Perfect Soap

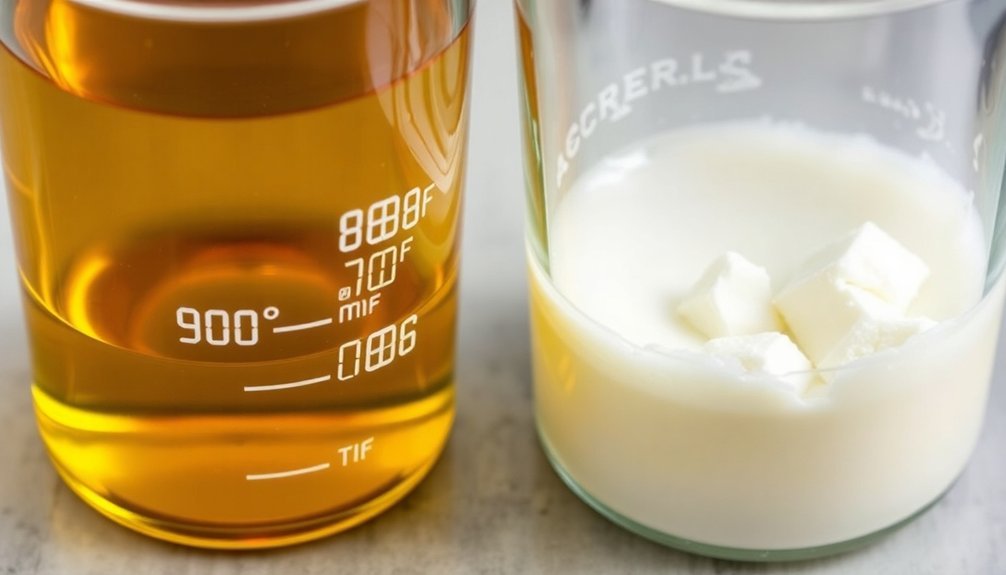

Why struggle with temperature management when the Heat Transfer Method offers a simpler approach to soap making? This technique leverages the heat from your hot lye solution to melt solid oils, creating a smooth mixture that prevents false trace issues.

For effective implementation, weigh your oils first, then add the lye solution while gently stirring until everything melts. Keep temperatures between 120-130°F to guarantee proper saponification.

This method works particularly well with soap recipes containing soft or liquid oils alongside moderately hard oils.

To optimize your results, pay attention to the melting points of your ingredients and adjust water levels accordingly. By monitoring these variables, you'll achieve consistent batches every time.

The Heat Transfer Method simplifies temperature control while enhancing the quality of your finished soap.

Preventing False Trace: Temperature Warning Signs

While the Heat Transfer Method simplifies temperature management, recognizing the warning signs of false trace remains a vital skill for every soap maker.

You'll know you're at risk when your oils appear cloudy at soaping temperature—this indicates solidified fatty acids that can create a deceptive, grainy thickness. To prevent this, verify oils are fully melted and homogenized before adding your lye solution.

Aim to maintain your lye solution at 120-130°F, which is slightly higher temperature than body heat. Your oils should stay within 10 degrees of your lye temperature. Lower temp soaping invites false trace, especially when water temperature drops too quickly.

Monitoring both components throughout your process is essential. If you notice premature thickening with a grainy appearance, you're likely experiencing false trace rather than true saponification.

Hot vs. Cold: Temperature Guidelines for Different Processes

Although both cold and hot process methods create beautiful soaps, they demand distinctly different temperature approaches for success.

Cold process soap making typically requires oils and lye between 120-130°F, with both components within 10 degrees of each other to prevent separation when trace occurs.

Hot process soap operates at higher temperatures, accelerating saponification without the cooling period needed in cold process. If you're avoiding gel phase for pastel colors, aim for cooler temperatures (100-110°F) before pouring into soap molds. Conversely, hotter temperatures (131-160°F) promote gel phase, enhancing color vibrancy and reducing soda ash formation.

Monitoring temperatures throughout either process is essential—too hot can cause soap volcanoes, while too cold may result in unsaponified lye or aesthetic issues.

Your temperature choices directly impact your soap's appearance, texture, and quality.

Frequently Asked Questions

How Does Temperature Affect Soap?

Temperature affects your soap by influencing trace time, oil/lye interaction, and final texture. When you maintain 120-130°F and keep components within 10° of each other, you'll prevent false trace and guarantee proper saponification.

What Causes Soap to Break?

Your soap breaks when you mix it at extremely high temperatures. You'll see cracking or puffiness if overheating occurs during saponification. Low temperatures can cause false trace, while improper thermal management creates defects like alien brains.

What Happens When Soap Is Heated?

When your soap is heated, it can enter gel phase, enhancing texture but risking defects like alien brain formation. You'll see issues such as cracking, puffiness, and volcanoes if temperatures exceed 160°F during saponification.

How to Prevent Soap From Overheating?

To prevent soap from overheating, you'll need to monitor initial mixing temperatures (120-130°F), use the heat transfer method, adjust water content, insulate appropriately, and watch for warning signs like puffiness during the gelling phase.

In Summary

You've discovered how temperature impacts every stage of your soapmaking journey. Whether you're creating hot process bars or cold process formulations, monitoring and adjusting heat levels remains essential to your success. By understanding saponification science and recognizing warning signs like false trace, you'll consistently achieve smooth, properly cured soap. Remember, it's not just about following recipes—it's about mastering the thermal dance that makes or breaks your creations.

Leave a Reply