You'll get superior slicing performance from steel cutting frames thanks to their exceptional strength-to-weight ratio and precision-engineered components. Their lightweight nature makes handling easier, while advanced safety features protect you during operation. The frames' resistance to moisture and pests reduces maintenance needs, and their design flexibility allows for innovative cutting solutions. Discover how their laser-guided systems and specialty blade technologies can transform your cutting experience.

Understanding Steel Frame Construction and Benefits

While traditional building materials have their merits, steel frame construction stands out as a superior choice for cutting frames due to its exceptional strength-to-weight ratio and versatility.

You'll find that metal frames deliver unmatched precision when cutting, guaranteeing clean and accurate results every time.

The lightweight nature of steel frames makes them easier to handle during installation, yet they don't compromise on structural integrity.

You're getting the best of both worlds: durability and maneuverability.

When you're working with steel frames, you'll notice they resist environmental challenges like moisture and pests, which means less maintenance and longer-lasting performance.

Plus, their design flexibility allows you to create innovative cutting solutions that wouldn't be possible with conventional materials.

The strength of steel construction guarantees your frame maintains stability even under significant stress.

Key Features of Professional-Grade Cutting Systems

You'll find professional-grade cutting systems equipped with advanced blade technology that integrates carbide-tipped or specialty steel components for superior durability and cutting efficiency.

Your cutting operations benefit from precise control mechanisms that allow you to adjust speeds and settings based on material specifications.

These systems incorporate essential safety features, including robust frames and cooling systems, which protect both the operator and maintain peak cutting performance throughout extended use.

Advanced Blade Engineering Technology

Three key innovations in advanced blade engineering have revolutionized professional steel cutting systems.

You'll find specialty tooth designs that deliver smoother cuts and minimize splintering when you're working with steel frames. The saw blades feature European micro-grained carbide construction, giving you exceptional durability and resistance to breakage compared to standard options.

These cutting-edge systems operate at low RPMs, which is essential when you're slicing through dense steel materials. The optimized tooth count allows you to control chip formation while maintaining ideal cutting speeds.

To get the most from your investment, you'll want to maintain these advanced blades regularly. With proper lubrication and care, they'll deliver extended performance and prove more cost-effective for your high-volume steel cutting operations.

Precision Control Safety Features

Professional-grade steel cutting systems incorporate multiple safety features that work together to protect operators and guarantee precise control.

You'll find advanced technologies designed to enhance both safety and accuracy while reducing operator fatigue.

Key precision control and safety features include:

- Laser-guided alignment systems paired with adjustable cutting speeds for clean, accurate cuts

- Automatic shut-off mechanisms and emergency stop buttons that instantly halt operations when needed

- Ergonomic handles with vibration dampening technology to maintain steady control

These integrated safety measures work alongside specialized cooling systems that prevent overheating and extend blade life.

The combination of precision control features and protective elements assures you'll achieve professional results while maintaining a secure working environment.

When you're working with steel frames, these safety innovations give you confidence and control throughout the cutting process.

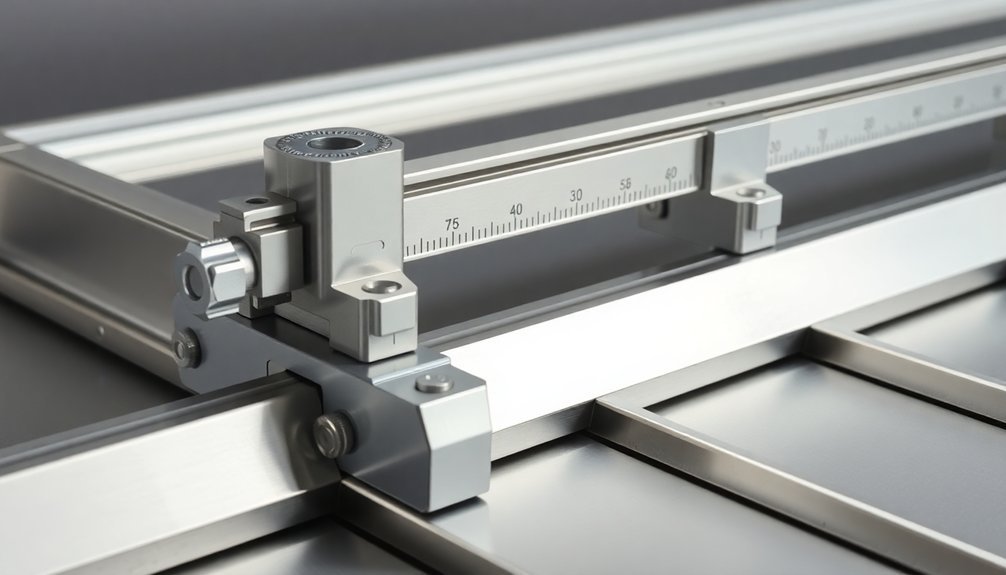

Precision Control and Safety Mechanisms

You'll find that modern steel cutting frames offer exceptional precision through advanced blade control systems that maintain consistent cutting depth and alignment throughout the slicing process.

The integrated safety lock mechanisms protect you from accidents by incorporating automatic shut-offs and blade guards, ensuring your workspace remains secure during operation.

These precision and safety features work together to give you ideal control while minimizing risks, especially when you're handling thicker materials or performing extended cutting sessions.

Precise Blade Control Systems

Modern steel cutting frames rely heavily on precise blade control systems to deliver accuracy and safety during operation.

These systems let you adjust cutting speeds and angles to match different steel thicknesses while maintaining ideal cut quality. With computer numerical control (CNC) technology, you'll achieve consistent, repeatable results while minimizing errors in your cutting process.

When you're working with these advanced frames, you'll notice three key features that enhance performance:

- Tension adjustment mechanisms that keep blades rigid and reduce vibration

- Integrated monitoring systems that alert you when blades need maintenance

- Automatic safety features, including blade guards and emergency shutoffs

These precise blade control systems work together to guarantee you're getting clean cuts while maintaining a safe working environment.

You'll appreciate how these features help prevent unexpected equipment failures and maintain cutting efficiency.

Safety Lock Mechanisms

Safety lock mechanisms represent the next frontier in steel cutting frame technology, building upon the precision control systems that guide blade movement.

You'll find these mechanisms incorporate trigger locks and blade guards that prevent unexpected blade activation while you're working.

Modern safety lock mechanisms require your deliberate action to disengage, ensuring you maintain complete control throughout the cutting process.

You can adjust the cutting speed to match your material's specifications, resulting in cleaner, more precise cuts. This feature proves especially valuable when you're working with varying thicknesses of steel.

These protective features do more than just keep you safe – they're essential for maintaining cut quality.

Material Compatibility and Performance Standards

When selecting a steel cutting frame, matching the right blade and material specifications is essential for achieving precise cuts and prolonging equipment life.

Material compatibility directly impacts tool life, as specialized blades with European micro-grained carbide work best with steel's unique properties.

For peak performance, you'll want to take into account these key standards:

- Lower blade speeds than wood-cutting counterparts, guaranteeing cleaner cuts through dense steel

- Blade thickness capacity up to 1/2 inch or more, depending on your specific cutting needs

- Specialized metal-cutting blades that prevent splintering and maintain durability

You'll find that proper matching between your frame and blade specifications not only improves cutting efficiency but also guarantees safer operation and better results when working with steel materials.

Maintenance Requirements and Longevity Factors

Building on proper material and blade compatibility, maintaining your steel cutting frame demands consistent attention to detail.

You'll need to clean the blades after each use and regularly inspect them for cracks or damage to guarantee peak performance.

Key longevity factors include using specialized European micro-grained carbide blades, which offer superior durability and break resistance.

European micro-grained carbide blades deliver exceptional longevity and resistance, making them essential for professional-grade steel cutting operations.

Don't forget to apply proper lubrication, such as wax sticks or aerosol lubricants, during cutting operations. This reduces friction and extends blade life while improving cut quality.

To meet essential maintenance requirements, you'll want to maintain appropriate cutting speeds and use tools specifically designed for metal.

Rather than attempting to sharpen dull blades, it's more effective to replace them promptly.

These practices will maximize your frame's efficiency and guarantee consistent, high-quality results.

Speed Settings and Optimal Operating Conditions

To achieve precise cuts in steel materials, you'll need to operate your cutting frame at considerably lower speeds than those used for wood. The right speed settings make a significant difference in cut quality and blade longevity, while proper lubrication keeps your equipment running smoothly.

To maintain ideal cutting conditions, remember these key factors:

- Adjust your feed rate based on the steel's thickness, ensuring steady progression without forcing the blade.

- Select blades with appropriate tooth count for steel, which reduces friction and heat buildup during operation.

- Apply lubricant consistently to keep temperatures down and enhance cutting efficiency.

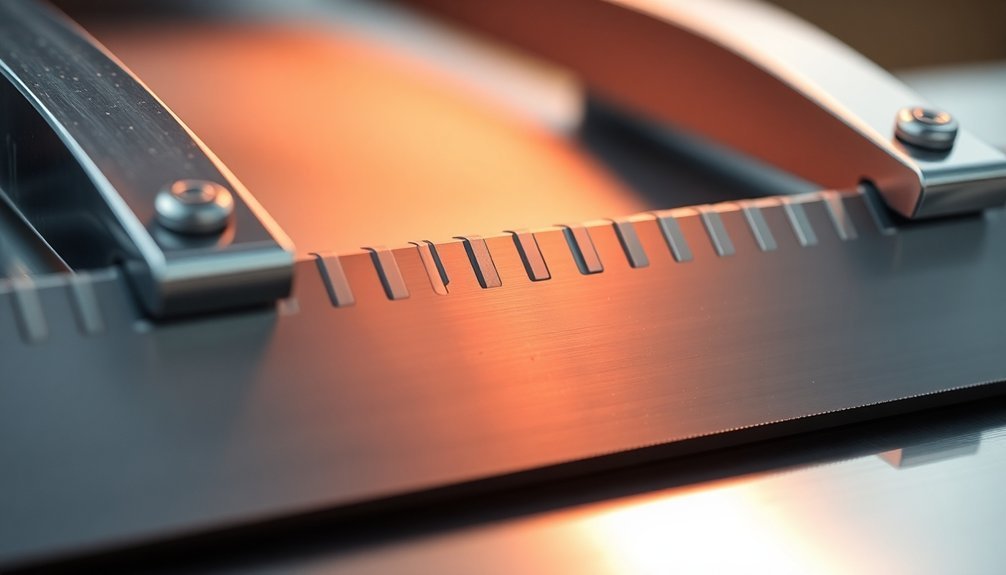

Design Elements That Enhance Cutting Accuracy

Since precision is paramount in steel cutting operations, modern cutting frames incorporate several essential design elements that maximize accuracy.

You'll find precision-engineered components that reduce vibrations and maintain stability while cutting metal, ensuring your cuts remain true. The frames feature adjustable clamps that lock materials firmly in place, preventing unwanted movement during operation.

To enhance cutting accuracy, these frames utilize specialized blades that produce clean cuts with minimal heat generation.

You'll benefit from advanced features like laser guides and measuring systems that help you align cuts perfectly. The frame's rigid construction distributes force evenly, eliminating flex that could compromise precision.

These design elements work together to deliver consistently accurate results, making steel cutting frames an invaluable tool for professional-grade metal cutting tasks.

Tool Adaptability and Replacement Components

Modern steel cutting frames offer remarkable versatility through their modular design. You'll find that their tool adaptability allows you to switch between various cutting tasks effortlessly, while replacement components guarantee you're always equipped with the right blade for your specific needs.

When working with these frames, you can expect:

- Quick-change blade systems that let you shift between thick and thin materials in seconds

- Adjustable speed and depth settings to match your material's properties perfectly

- Multiple attachment points for specialized accessories that expand your cutting capabilities

You'll appreciate how these frames are engineered specifically for metal applications, which means your tools will last longer and deliver cleaner cuts.

The wide availability of specialized replacement components guarantees you're never limited in your metalworking projects.

Technical Specifications and Usage Guidelines

Steel cutting frames come with precise technical requirements that guarantee peak performance and safety during operation.

When you're doing metal work, you'll need to maintain slower cutting speeds compared to woodworking to prevent excessive heat buildup and extend blade life.

For ideal results, you should use specialized A.G.E. steel cutting blades featuring European micro-grained carbide construction.

These blades work best on materials between 1/8 inch and 1/4 inch thick.

Don't forget to apply proper lubrication using a wax stick or specialized cutting fluid during operation – this reduces friction and improves cut quality.

The frame's design specifically accommodates the density and hardness of steel, making your cuts smoother and more efficient than what you'd achieve with general-purpose blades in standard frames.

Frequently Asked Questions

What Makes Metal Easier to Cut?

You'll find metal easier to cut when it has lower carbon content, thinner dimensions, and proper lubrication. Using specialized cutting blades and techniques like plasma or laser cutting also makes the process more manageable.

What Is the Best Way to Cut Through Steel?

You'll get the best results using a plasma cutter or gas cut-off saw for precise steel cuts. For thicker steel, use a portable bandsaw. Always maintain proper cutting speed and secure clamping for safety.

What Is the Best Tool for Cutting Metal Frames?

You'll get the best results using a portable bandsaw for cutting metal frames. It delivers clean, precise cuts with minimal heat buildup. If you can't access one, a plasma cutter's another excellent choice.

What Is the Best Material for Cutting Steel?

You'll get the best results using high-speed steel (HSS) or carbide-tipped blades for cutting steel. They maintain hardness at high temperatures, resist wear effectively, and won't dull quickly during your cutting operations.

In Summary

Steel cutting frames give you superior slicing performance through their rigid construction, precise alignment, and vibration control. You'll find they maintain better blade tension and provide smoother cutting action than other materials. They're more durable, resist warping, and deliver consistent results across various materials. When you invest in a steel frame system, you're getting professional-grade accuracy and reliability that'll serve you well for years.

Leave a Reply