When testing your soap's essential oil blend, always adhere to the 3% rule—never exceed this concentration to prevent skin irritation. For a 1-pound batch, use approximately 270 drops total, spreading them across your selected oils. Measure with a calibrated digital scale for accuracy, and document every test batch. For sensitive skin formulations, reduce to 1% and choose gentler oils like lavender or chamomile. Test small batches first and allow blends to mature 48 hours before final evaluation.

Understanding the 3% Essential Oil Rule for Soap Making

Three key factors make the 3% essential oil rule crucial for soap makers.

First, it's a safety threshold that helps prevent skin irritation and allergic reactions that can occur with excessive concentrations.

Second, this guideline aligns with IFRA regulations, which set maximum usage rates for various cosmetic applications including soap products.

To apply this rule, simply multiply your total base oils weight by 0.03.

For example, if you're using 32 ounces of oils (coconut, olive, shea), you'd add 0.96 ounces of essential oils maximum.

Remember that individual oils have different safety limits.

While lime and sweet marjoram can be used at the full 3%, cinnamon leaf should stay below 0.5%, and ylang ylang under 1.4%.

Always prioritize these specific limitations when creating your blends.

Measuring by weight not volume provides the most accurate results for ensuring your essential oil percentages remain within safe limits for soap making.

Converting Weight to Drops: Precise Measurements for Your Blends

When formulating essential oil blends, you'll need a reliable drop measurement chart to convert weight measurements to drop counts for different oils.

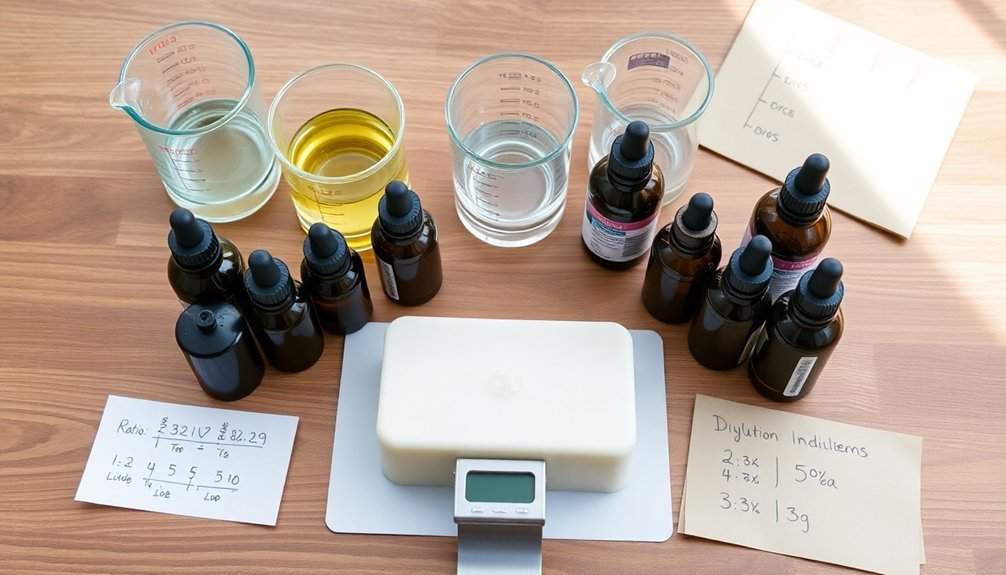

Your digital scale should be calibrated regularly to guarantee accuracy down to 0.01 grams, especially for potent oils where precision matters.

Remember that viscosity affects drop size—thicker oils like patchouli yield fewer drops per gram than thinner oils like citrus varieties. Understanding the proper dilution rates is crucial for safety when creating blends, particularly for children or those with sensitive skin.

Drop Measurement Chart

Although many essential oil recipes call for a specific number of drops, converting between weight and drops can be challenging due to the variability in drop sizes.

For most practical purposes, you can use these standard conversions: 600 drops equal approximately 1 fluid ounce (30ml) of essential oil. This means about 20 drops per milliliter, though this varies based on the oil's viscosity and your dropper type.

For soap making, aim for a 2-4% dilution rate. Remember that for a 2% dilution you would need approximately 12 drops per 5ml of carrier oil.

Calculate this by determining your total soap weight, then measuring the corresponding amount of essential oil. For example, in a 1-pound (454g) batch, a 3% dilution would require 13.6g of essential oil—roughly 270 drops.

Scale Calibration Tips

Accurate scale calibration forms the foundation of successful essential oil blending. To guarantee precision, test your scale with objects of known weight and adjust as needed using the calibration mechanism.

Choose a scale that measures in increments of at least 1 gram or 0.1 ounce. For essential oils, you'll need even greater precision—a jeweler's scale is ideal for measuring tiny amounts accurately.

Don't rely on drop measurements; they're inconsistent and unreliable. Instead, weigh your essential oils directly. Your scale should toggle between metric and English units for flexibility with different recipes.

Confirm your scale surface is at least 6 inches square to safely measure caustic materials like lye.

Clean and calibrate regularly to maintain accuracy for all your soap making measurements.

Understanding the volume-to-weight conversion for each essential oil is critical as they vary significantly, with oils like Lavender measuring 3.5g per teaspoon while Tea Tree is only 3g.

Adjusting Concentrations for Sensitive Skin Applications

For those with sensitive skin, proper dilution of essential oils becomes even more critical in soap making. While standard formulations can handle 3% concentration, you'll need to reduce this to just 1% for sensitive skin applications—approximately 22 drops per 100g soap bar instead of 66.

Choose gentler oils like lavender, chamomile, geranium, and rose rather than potentially irritating citrus, mint, or eucalyptus varieties. These milder options provide therapeutic benefits without triggering reactions. Creating these gentle blends 48 hours beforehand allows the oils to harmonize before being incorporated into your soap base.

Enhance your sensitive skin formula with soothing additives such as oat flour, raw honey, and jojoba oil. These ingredients complement the essential oils while providing additional skin benefits.

Always test new blends on a small area first, and remember that essential oils should never contact skin in their undiluted form.

Balancing Single Oils vs. Complex Blends in Soap Recipes

When crafting soap recipes, you'll need to choose between the clarity of single essential oils and the nuanced complexity of blends.

Single oils like lavender or tea tree offer straightforward, recognizable scents that let specific therapeutic properties shine through without competition.

Complex blends, however, can create depth and intrigue by combining top, middle, and base notes for a more sophisticated fragrance experience that evolves over time. Experienced soap makers typically aim for a 3% usage rate when incorporating essential oils, though this can vary depending on the strength of specific oils.

Single Note Simplicity

The elegance of a single essential oil in soap making can't be overlooked, despite the allure of complex blends. When you work with just one oil, you'll experience its true character and therapeutic benefits without competing aromas.

| Oil Type | Example | Usage Rate |

|---|---|---|

| Top Note | Lemon | 3-5% |

| Top Note | Lime | 3-5% |

| Middle Note | Lavender | 3-6% |

| Base Note | Cedarwood | 2-4% |

| Base Note | Patchouli | 2-4% |

Simplicity offers advantages for beginners and experts alike. You'll find it easier to measure and adjust concentrations, with 22 drops equaling approximately 1g of oil. Start with lower percentages (around 1%) for sensitive skin formulations. Though single notes lack complexity, they provide consistency and predictability that blends sometimes can't match. Always remember that undiluted essential oils should never come into direct contact with skin, making proper dilution in your soap base crucial for safety.

Complexity Versus Clarity

While single note essential oils offer simplicity, complex blends create depth and character that many soapmakers find irresistible. However, this complexity comes with challenges.

When blending oils, limit yourself to three varieties to maintain clarity in your scent profile. Remember that your total essential oil concentration shouldn't exceed 3% of your soap's weight, regardless of how many oils you combine. Small adjustments in ratios can dramatically change your blend's character.

Always test your blends before committing them to a full batch. Allow your blend to mature for at least 48 hours, then evaluate how the top, middle, and base notes interact. Consider how quick-fading oils like citrus might affect the longevity of your scent. When creating fragrance combinations, some suppliers suggest 50/50 ratios for balanced blends, though individual oil strengths should inform your final proportions.

You'll need to balance your creative desires with practical considerations of scent clarity and safety.

Testing Methods for Essential Oil Stability in Different Bases

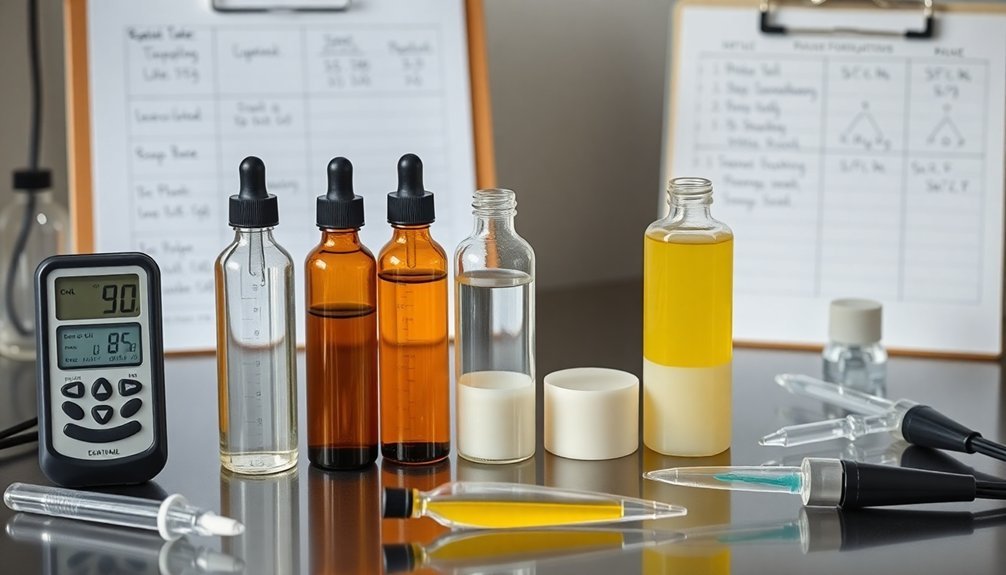

Because essential oils behave differently in various soap bases, you'll need reliable testing methods to verify their stability and performance.

Begin with solubility tests to verify your oils properly dissolve in your chosen base without separation issues.

Conduct compatibility testing between your essential oils and other soap ingredients to prevent unexpected chemical reactions. Check how your blend responds to the pH level of your base—some oils degrade quickly in highly alkaline environments.

Don't forget to evaluate how your oils affect lather quality through small test batches.

For thorough stability assessment, perform accelerated degradation tests by exposing small samples to controlled heat, light, and moisture conditions.

This simulates aging and helps you predict how your scent will perform over time in real-world conditions.

Consider employing the Foaming Ability Test to ensure your essential oil blend doesn't compromise the soap's lathering performance that consumers expect.

Documenting Your Blend Experiments for Consistent Results

Successful soapmakers recognize that meticulous documentation forms the backbone of repeatable success with essential oil blends.

You'll need precision tools—scales, thermometers, and pH meters—to capture accurate measurements of your experiments.

Maintain a dedicated logbook where you record consistent ratios for each blend, noting supplier information and specific usage rates.

Follow the SOAP note principles: standardized format, accurate details, concise language, and thorough proofreading.

Schedule testing at regular intervals throughout the curing process. Document how your soap performs over time by tracking lather quality, hardness, weight loss, and fragrance retention.

Pay special attention to the saponification process, noting how different oils affect your final product's characteristics. Remember that while saponification completes within 24 hours, the full curing process takes significantly longer for optimal soap performance.

This systematic approach transforms your creative experiments into repeatable formulas you can confidently recreate time after time.

Safety Considerations When Testing New Oil Ratios

As you perfect your soap formulations through careful documentation, prioritizing safety becomes equally important when experimenting with essential oil ratios. Always maintain dilution rates between 1-2% for topical applications to prevent skin irritation and sensitization. For reference, remember that 20 drops equals approximately 1 ml of essential oil when calculating your formulations.

| Safety Measure | Why It Matters |

|---|---|

| Patch testing | Identifies potential allergic reactions before full use |

| Proper dilution | Prevents skin irritation and sensitization |

| Ingredient listing | Alerts users to potential allergens |

| Protective gear | Keeps you safe during the formulation process |

Remember that certain oils like cinnamon and citrus varieties are more likely to cause reactions. Store your oils properly, follow safety instructions on labels, and consult safety data sheets before working with unfamiliar oils. Your customers' safety depends on your diligence when testing new ratios.

Frequently Asked Questions

Can Essential Oils Change Soap Color During Curing?

Essential oils can subtly change your soap's color during curing. You'll notice this happens when they interact with other ingredients, though it's minimal compared to the impact of natural colorants and pH levels.

How Do Seasonal Temperature Changes Affect Essential Oil Performance?

Seasonal temperature changes directly impact your essential oils' performance. You'll notice reduced potency in hot weather as volatile compounds evaporate faster. Cold temperatures can preserve oils longer but may alter their scent profiles.

Which Essential Oils Last Longest in Cold Process Soap?

Base notes like patchouli and ylang ylang last longest in cold process soap. You'll also get good longevity from lavender and peppermint. Try using these at 3% of your oil weight for best results.

Do Essential Oils Affect Soap's Lathering Properties?

No, essential oils don't directly affect your soap's lathering properties. They're added primarily for scent and therapeutic benefits. Your lather quality depends on the base oils you choose in your soap recipe.

Can I Substitute Fragrance Oils for Essential Oils?

Yes, you can substitute fragrance oils for essential oils. They're generally longer-lasting and less expensive, but you'll lose the therapeutic benefits of essential oils. Both require proper concentration for skin safety.

In Summary

You've learned the essential principles of oil ratios for soap making—from the 3% rule to precise measurements and safety considerations. Now it's time to test your blend! Start with small batches, document everything, and adjust based on results. You'll soon create perfectly balanced soaps tailored to your skin's needs. Remember, successful soap making combines science with creativity. Keep experimenting and refining your craft.

Leave a Reply