Soap oils may not mix properly due to temperature mismatches between your lye solution and oils (aim for 100-120°F), insufficient stick blending, incorrect water-to-lye ratios, or fragrance oil incompatibility. You'll recognize problems when you see separation, ricing, or false trace instead of true emulsification. Always measure ingredients accurately, blend in short bursts until reaching true trace, and maintain consistent temperatures. Understanding these factors will transform your soap-making experience from frustrating to flawless.

Numeric List of 11 Second-Level Headings

These eleven critical issues can affect your soap oil mixing success. When your oils and lye refuse to emulsify properly, check:

- Temperature imbalance (100-120°F is ideal)

- Insufficient stick blender mixing time

- Incorrect water-to-lye ratio

- Incompatible oil combinations

- Poor quality or rancid ingredients

- Premature addition of additives

- Environmental factors (humidity/temperature)

- Disproportionate soft oils to hard oils

- Incorrect measurement techniques

- Lye solution preparation errors

- Inadequate trace identification

Each issue can greatly impact your mixture's ability to properly emulsify.

For example, when temperatures exceed 120°F, oils may separate despite vigorous blending.

Similarly, using insufficient mixing power won't create the necessary molecular bonds between your oils and lye solution.

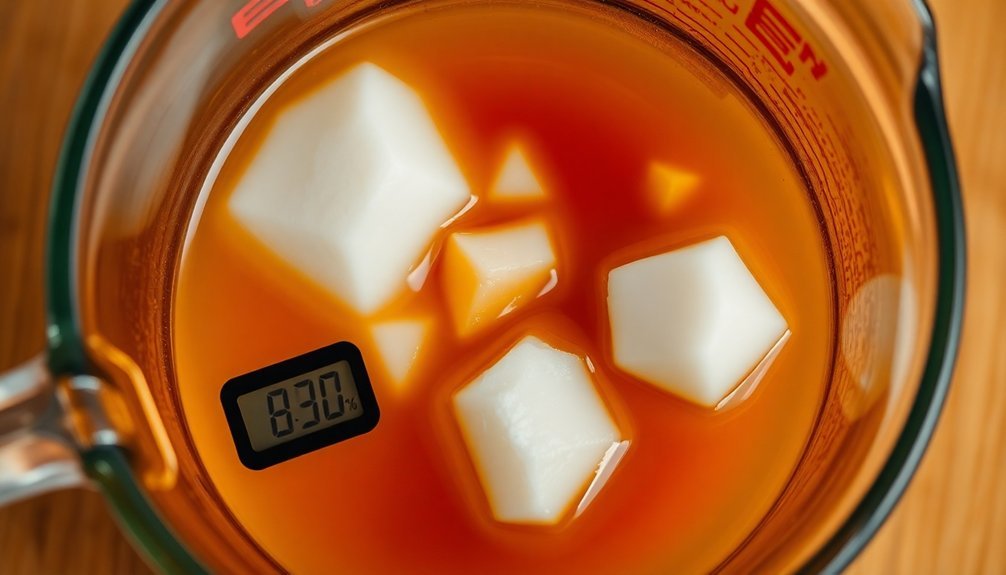

Temperature Discrepancies Between Oils and Lye Solution

Temperature discrepancies between your oils and lye solution rank among the most common culprits when soap batches fail.

When these components aren't within a compatible range (ideally 100-120°F), you'll likely face improper mixing issues that prevent proper emulsification.

If your lye solution is too cool compared to warmed oils, it won't fully integrate, resulting in a lumpy soap batter. Conversely, when your lye solution overheats, it can accelerate trace too quickly, making pouring and molding difficult.

For successful saponification, both elements need to blend smoothly without shocking the mixture.

Consistently measuring temperatures before combining prevents these issues. Always monitor both components carefully—this simple step guarantees your oils and lye solution will cooperate rather than compete, leading to that perfect creamy soap texture you're aiming for.

Insufficient Stick Blending Technique

While properly measured ingredients matter, your stick blending technique ultimately determines whether your soap achieves proper emulsification. If you're noticing a gritty soap mixture or separation issues, you're likely not blending enough to reach a proper trace.

Use short bursts rather than continuous stick blending to guarantee oils incorporate evenly without accelerating thickening too quickly. A light trace typically develops within minutes, indicating successful emulsification has begun.

Working at lower temperatures (100-120°F) promotes smoother blending and prevents the batter from seizing.

Be consistent with your blending technique—insufficient mixing won't properly emulsify your ingredients, while over-blending causes premature thickening that makes pouring difficult.

Finding that sweet spot where your batter shows slight thickening without becoming too thick is key to successful soap making.

Water-to-Oil Ratio Imbalances

Despite careful selection of soap ingredients, an incorrect water-to-oil ratio can undermine your entire batch. The standard 2:1 water-to-lye ratio exists for good reason—deviate from it, and you'll encounter mixing issues that affect your final soap quality.

When your mixture contains too much water, you're facing high water content that delays the saponification process, leaving you with sticky soap as oils fail to properly emulsify.

Conversely, insufficient water creates a batter too thick to blend thoroughly, leading to separation and uneven texture.

Your best defense? Accurate measurements. Always use a lye calculator to determine the proper ratios based on your recipe size.

Hard Oils Solidifying Prematurely

Even when you've mastered your water-to-oil ratios, hard oils can throw another wrench into your soap-making process by solidifying before they're fully incorporated.

Coconut and palm oils, in particular, may re-solidify at temperatures above their melting point, disrupting proper emulsification. To prevent this, heat your hard oils to approximately 120°F before mixing with liquid oils. This guarantees they remain fluid long enough for complete blending.

Your recipe's hard-to-soft oil ratio greatly impacts this process. Higher percentages of hard oils require more careful temperature control to avoid a lumpy soap batter.

When mixing, use your stick blender in short, controlled bursts rather than continuous blending. This technique helps incorporate the oils thoroughly without causing them to seize prematurely, giving you the smooth, well-emulsified mixture that's essential for successful soap making.

Incompatible Fragrance Oil Reactions

Because fragrance oils contain complex chemical compounds, they can dramatically impact your soap's texture and consistency when combined with certain base oils.

When you notice ricing or separation in your soap batter, your fragrance oil might be the culprit. Florals and spices often accelerate trace, giving you little time to mix thoroughly before the batter thickens.

High vanillin content fragrance oils can cause discoloration and unpredictable reactions with your base formula. Always check if your fragrance is compatible with cold process soapmaking before full-scale production.

A helpful technique is mixing your fragrance oil with an equal amount of liquid oils and slightly warming this mixture before adding it to your soap batter. This simple temperature adjustment improves compatibility and helps avoid those frustrating last-minute reactions that ruin your batch.

Incorrect Measurement of Base Ingredients

While many soapmakers focus on oil combinations and additives, precise measurement of base ingredients forms the foundation of successful soap making.

Accurate measurement of sodium hydroxide is non-negotiable—insufficient lye prevents proper saponification, causing oils to separate instead of transforming into soap.

Always use a reliable, calibrated scale for weighing ingredients. When adjusting recipe quantities, make sure you're maintaining the correct water-to-lye ratio (typically 2:1) to achieve consistent results.

Don't guess—use a lye calculator to determine the exact amount needed for your specific oil combination, as each oil requires different amounts of lye to saponify properly.

Finally, store your sodium hydroxide in an airtight container to prevent moisture absorption, which can alter its potency and throw off your soap mixture's chemistry, leading to mixing failures.

Soap Batter Seizing and Ricing Phenomena

When you're carefully mixing your soap ingredients, unexpected chemical reactions can quickly derail your project through phenomena known as seizing and ricing. These issues often occur when fragrance oils, particularly floral or spicy scents, interact with your soap batter during the mixing process.

| Issue | Cause | Solution |

|---|---|---|

| Seizing | Fragrance oils causing rapid thickening | Blend fragrance with warm oils first |

| Ricing | Fragrance binding with harder oils | Use stick blending to smooth lumps |

| High Temperature | Heat accelerating reactions | Keep batter at 100-120°F |

| Thick Batter | Advanced seizing/ricing | Consider rebatching the soap |

To prevent these problems, incorporate your fragrance oils into your warm base oils before adding the lye solution. This promotes proper emulsification and gives you more control over the critical mixing phase.

The Impact of Environmental Humidity on Mixing

Environmental humidity represents an often overlooked factor that can greatly impact your soap-making process.

When humidity levels are high, your oils can absorb moisture, undermining proper emulsification during mixing. You'll notice this problem when glycerin beads form on your soap's surface, signaling that environmental moisture is interfering with your batch.

Humidity also affects the temperature of your oils, making it challenging to maintain the ideal 100-120°F range needed for successful mixing. Without proper temperature control, your oils won't blend effectively into the lye solution, potentially causing separation or ricing in your soap batter.

Experienced soap makers recommend working in well-ventilated areas with controlled humidity levels.

This environmental management helps guarantee consistent emulsification and prevents the frustrating consistency issues that can derail your carefully crafted soap recipe.

Recognizing False Trace vs. True Emulsification

Many novice soap makers fall victim to false trace, mistakenly believing their oils and lye have properly emulsified when they haven't. This deceptive phenomenon occurs when your mixture appears slightly thickened but hasn't actually reached true emulsification, often resulting in separation later.

To distinguish between false trace and true emulsification:

- Observe consistency – True emulsification produces a thicker, creamy mixture that maintains a stable texture, while false trace remains thin despite appearing thickened.

- Check for trailing – Properly traced soap leaves distinct trails on the surface that momentarily hold their shape.

- Monitor temperatures – Keep your mixture between 100°F-120°F while blending to promote proper combination of oils and lye.

You'll achieve consistent texture and quality in your final product by patiently blending until reaching genuine trace rather than rushing the process.

Troubleshooting Separation After Molding

Despite your best efforts during mixing, you might occasionally discover an unpleasant surprise after pouring your soap into molds – separation of ingredients. This frustrating issue typically stems from several common factors that disrupt proper emulsification.

| Problem | Cause | Solution |

|---|---|---|

| Oil pooling | Insufficient trace | Mix longer until stable trace forms |

| Layering | Temperature imbalance | Keep oils and lye between 100-120°F |

| Curdling | Problematic fragrance | Test fragrances before full batch |

| Weeping | Excess water | Adjust water-to-oil ratio |

When you notice separation, you have options. For minor separation, remix immediately after discovery. If oils have notably pooled on top, rebatching may be your best salvation method. Always verify thorough mixing to true trace and maintain consistent temperatures between your oils and lye solution to prevent these issues in future batches.

Frequently Asked Questions

Why Is My Oil Separating in My Soap?

Your oil's separating due to insufficient mixing, improper temperature (aim for 100-120°F), excess liquid in your recipe, or incompatible ingredients. You'll need to blend thoroughly until you reach light trace for proper emulsification.

Why Are My Soap Layers Not Sticking Together?

Your soap layers aren't sticking because you're likely pouring at different temperatures, not allowing proper timing between pours, or over-thickening the first layer. Try pouring when both layers are 100-120°F for better adhesion.

What Is the Biggest Mistake First Time Soapmakers Make?

The biggest mistake you'll make as a first-time soapmaker is inaccurately measuring ingredients, especially sodium hydroxide and water. This critical error disrupts proper saponification, resulting in inconsistent texture and potentially unsafe soap. Always measure precisely!

Why Is My Soap Not Emulsifying?

Your soap isn't emulsifying because you're likely not mixing long enough, using inconsistent temperatures, adding too much water, including incompatible additives, or measuring lye incorrectly. Keep blending until you reach light trace.

In Summary

You'll find that most soap mixing issues stem from either temperature problems, inadequate blending, or poor formulation. By adjusting your temperatures, improving your stick blending technique, and balancing your water-to-oil ratios, you'll create successful batches consistently. Don't be discouraged when mistakes happen—they're valuable learning opportunities. Keep detailed notes of your process, and you'll soon develop an intuition for perfect soap emulsification every time.

Leave a Reply