The top heat-resistant materials for soap molds include HDPE with resistance up to 200°F, stainless steel for professional durability, high-temperature silicone that withstands up to 446°F, PVC for cost-effective temperature control, and wooden molds for natural insulation. You'll find each material offers unique benefits – from HDPE's easy cleaning to silicone's non-stick properties. Understanding these options' specific features will help you create the perfect soaps for your needs.

Understanding HDPE Molds and Their Superior Heat Properties

When choosing materials for soap making, HDPE molds stand out as a top performer due to their exceptional heat resistance and durability.

Unlike silicone molds, HDPE plastic can withstand temperatures up to 200°F (93°C), making them perfectly suited for both cold and hot process soap making.

HDPE molds excel in both cold and hot process soap making, handling temperatures up to 200°F while maintaining structural integrity.

You'll find that HDPE plastic offers significant advantages over other heat resistant materials.

These molds won't break down when exposed to essential oils or fragrances, and they're remarkably easy to clean after use.

Whether you're making small batches or large production runs, you can count on HDPE molds to maintain their shape and integrity.

They're available in various styles, from loaf to slab configurations, giving you the flexibility to create different soap designs while ensuring consistent results batch after batch.

Stainless Steel Molds for Professional-Grade Heat Resistance

For professional soapmakers seeking ultimate durability and heat resistance, stainless steel molds represent the gold standard in soap making equipment.

You'll find these professional-grade molds can handle temperatures up to 200°F, making them perfect for both melt and pour and cold process methods.

Unlike their plastic counterparts, stainless steel molds won't deteriorate when exposed to essential oils or fragrances, ensuring your investment lasts longer.

While they're more expensive initially, their superior performance and reliability make them cost-effective in the long run.

However, you'll need to evaluate proper insulation since stainless steel conducts heat efficiently – this helps maintain even saponification throughout your soap batch.

For serious soapmakers who demand consistent quality and durability, these molds deliver exceptional heat resistance and longevity that justify their higher price point.

High-Temperature Silicone Molds and Their Applications

High-temperature silicone molds stand as a versatile powerhouse in modern soap making, offering exceptional heat resistance from -40°F to 446°F. You'll find these soap molds particularly valuable for their non-stick properties and flexibility, making demolding effortless while preserving your soap's intricate details.

| Feature | Benefit |

|---|---|

| Heat Resistance | Suitable for cold process and melt-and-pour methods |

| Flexibility | Easy demolding without damaging finished soaps |

| Durability | Long-lasting performance with repeated use |

| Chemical Resistance | Withstands essential oils and fragrances |

| Versatility | Works for soaps, bath bombs, and confections |

The resilience of silicone molds extends beyond soap making, as you can use them for various crafting projects. Their reusable nature and ability to maintain shape during saponification make them a cost-effective choice for both hobbyists and professional soap makers.

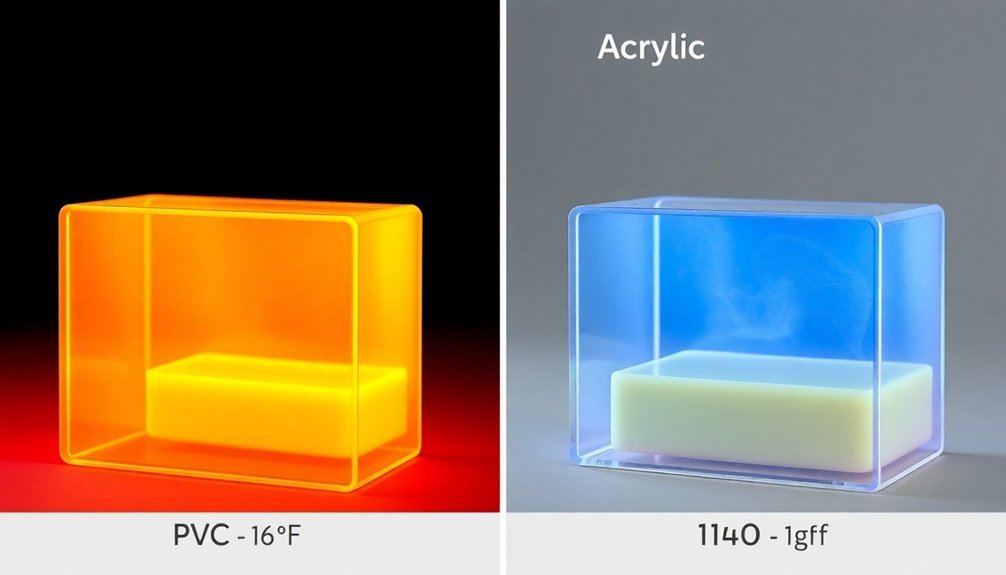

PVC and Acrylic Options for Temperature Control

Though more traditional than silicone alternatives, PVC and acrylic molds offer unique advantages for temperature-controlled soap making.

PVC molds are made to withstand temperatures up to 200°F, making them versatile for various soap recipes while keeping your costs down. You'll need to take into account lining these plastic soap molds depending on your formula.

Acrylic soap molds provide excellent visibility during the creation process and work well for detailed designs. However, you'll want to avoid high-temperature formulations, as excess heat can damage these molds. While they don't require lining, they're more susceptible to cracking when exposed to essential oils.

Both options need careful handling and proper storage to maintain their longevity.

You'll find PVC more durable for regular use, while acrylic excels in creating visually appealing designs at lower temperatures.

Heat-Safe Wooden Molds With Proper Insulation Methods

Wooden molds stand out as a reliable choice for temperature-controlled soap making, offering natural insulation properties that plastic alternatives can't match.

When you're working with heat-safe wooden molds, you'll need to line them with grease-proof paper to prevent sticking and guarantee your soap releases easily.

To maximize your mold's effectiveness, implement proper insulation methods by wrapping them in blankets or towels during the saponification process.

You'll find that non-treated pine works best for these molds, and you can customize their size to fit your specific batch requirements.

Remember to maintain your wooden molds regularly to prevent warping from heat and moisture exposure.

For added convenience, choose molds with detachable bottoms or sides – they'll make removing your finished soap much easier while still maintaining excellent heat retention during curing.

Frequently Asked Questions

What Is the Best Material for Soap Molds?

You'll find HDPE molds are your best choice for soapmaking. They're highly durable, resist temperatures up to 200°F, won't degrade from oils, and they're more cost-effective than other materials like stainless steel.

What Is the Heat Resistant Silicone for Mold?

You'll find that heat-resistant silicone for molds can withstand temperatures from -40℉ to 446℉. It won't stick to your soap, won't break down from oils, and it's perfect for detailed designs.

Can Soap Molds Go in the Oven?

Yes, you can put certain soap molds in the oven. Silicone molds withstand up to 446°F, and HDPE molds handle up to 200°F. Don't use acrylic molds, though – they'll crack under high heat.

Can I Use Parchment Paper to Line My Soap Mold?

Yes, you can use parchment paper to line your soap mold. It's heat-resistant up to 420°F, won't stick to your soap, and makes removal easier. Just be sure it's not waxed parchment paper.

In Summary

You've now got the knowledge to select the perfect heat-resistant mold for your soap making journey. Whether you choose HDPE's durability, stainless steel's professional quality, silicone's flexibility, PVC's affordability, or wooden molds' traditional appeal, you'll be able to create beautiful soaps safely. Remember to always match your mold material to your specific soap making process and temperature requirements.

Leave a Reply