To calculate soap yield before production, multiply your total oil weight by 1.3-1.4 to account for lye and water. For example, 32 oz of oils typically yields about 42 oz of finished soap. Factor in a 10-15% weight loss during curing from water evaporation. Use a lye calculator to determine precise NaOH amounts based on your oils' SAP values, and adjust your recipe for your specific mold dimensions. Master these calculations to achieve consistent, predictable results every time.

How to Calculate Soap Yield Before Production

Before diving into soap production, calculating your expected yield helps you plan materials and assess profitability effectively.

Start by determining the molar mass of your oils and sodium hydroxide, as these values form the foundation of your stoichiometric calculations.

Calculating molar mass first provides the essential framework for all subsequent soap production calculations.

Identify your limiting reactant—the ingredient that will be consumed first—as this determines the maximum amount of soap you can produce.

Once you've identified this constraint, you can calculate the theoretical yield based on the chemical reaction.

Ensure all ingredient percentages in your formula total 100% to maintain proper balance. This precision is essential when you later calculate the percent yield using the formula: (actual yield ÷ expected yield) × 100%.

Accurate measurements throughout this process will give you reliable predictions before you begin making your soap.

Understanding Saponification Ratios in Traditional Soap Making

To make properly balanced soap, you'll need to calculate the precise amount of lye required for your chosen oils by multiplying each oil's weight by its SAP value (like palm oil's 0.141g NaOH per gram).

Understanding individual fat SAP values prevents creating either harsh soap from excess lye or greasy soap from insufficient lye.

When adjusting your water discount, you'll modify the water-to-lye ratio without changing the essential oil-to-lye calculation that determines your final soap yield.

Lye-Oil Balance Basics

The foundation of successful soap making lies in achieving the perfect balance between oils and lye. To calculate this essential lye-oil balance, you'll need to understand saponification values—the amount of lye required to convert 1 gram of a specific oil into soap.

Your basic formula is straightforward: multiply your oil weight (in grams) by its saponification value to determine the necessary lye amount. For recipes with multiple oils, calculate each oil separately, then add the results together.

Don't forget to incorporate superfatting—typically 5-10% less lye than the theoretical requirement—which guarantees your soap remains moisturizing and free from excess lye.

For precision and safety, use a lye calculator that automatically factors in your desired superfatting percentage based on your total oil weight.

Fat SAP Values

Now that you've grasped the lye-oil balance concept, let's examine the specific SAP values that make precise calculations possible.

SAP values represent the exact amount of sodium hydroxide (in milligrams) needed to saponify one gram of a particular fat or oil. Each oil has its unique SAP value.

For example, coconut oil's SAP value is approximately 0.183, meaning you'll need 183mg of sodium hydroxide to saponify each gram of coconut oil. To calculate lye requirements for your recipe, simply multiply the weight of each fat by its corresponding SAP value.

Understanding these ratios is essential for your soap's quality. Using too little lye results in unsaponified oils, while excess lye creates harsh soap that irritates skin.

Mastering SAP values guarantees your soap has the perfect balance of cleansing power and moisturizing properties.

Water Discount Effects

While calculating the precise amount of lye is essential for proper saponification, understanding water discount effects can dramatically transform your soap's quality and production timeline.

When you apply a water discount, you're strategically reducing the water-to-lye ratio from the standard 2:1 to as low as 1:1. This reduction yields firmer soap bars that cure faster, helping you bring products to market sooner.

However, be cautious—less water means a more concentrated lye solution, which accelerates trace and gives you less working time for intricate designs.

Your soap yield calculations must account for these water adjustments. A higher discount produces harder initial bars with potentially stronger cleansing properties.

Always balance your water discount against your design needs and desired final soap characteristics.

Essential Components of Soap Yield Formulas

When calculating your soap yield, you'll need to determine the precise ratio of base oils required for your desired soap properties.

You can adjust your water discount to control the curing time and final hardness of your soap bars, with lower water amounts typically resulting in firmer soaps that cure faster.

Don't forget to account for fragrance weight adjustments, typically ranging from 3-6% of your total oil weight, as these additives will affect both your final yield and the soap's sensory qualities.

Base Oils Ratio Calculations

The foundation of any successful soap recipe lies in understanding and properly calculating your base oils ratio. When formulating your recipe, aim for a balance that totals 100%, such as the common 30% palm oil, 30% coconut oil, 30% olive oil, and 10% sweet almond oil combination. Each oil contributes unique properties—coconut creates lather while olive moisturizes.

To calculate the exact amount of each oil needed, multiply your mold's capacity by the corresponding percentage. For example, in a 50 oz. mold with 34 oz. oil capacity, you'd need 10.2 oz. each of palm, coconut, and olive oils (30% × 34 oz.), plus 3.4 oz. of sweet almond oil (10% × 34 oz.).

Always convert these measurements to grams or ounces for precision. These careful base oils ratio calculations guarantee your soap achieves the desired hardness, lather, and moisturizing qualities.

Water Discount Considerations

Understanding water discount greatly impacts your final soap yield calculations and product quality.

When you apply water discounting in your soap making process, you're intentionally reducing the amount of water in your lye solution to create harder bars with improved efficiency.

A typical water discount ranges from 25-30% of the calculated water amount.

To determine your new water measurement, multiply your original water amount by the remaining percentage (70-75% if using a 25-30% discount). For example, if your recipe calls for 10 oz of water, a 30% discount would mean using only 7 oz instead.

Remember that while your lye and oil amounts stay constant, your total soap yield will decrease slightly due to the reduced water content, resulting in firmer bars that cure faster.

Fragrance Weight Adjustments

Beyond water calculations, fragrance additions play a significant role in determining your final soap yield. When planning your recipe, you'll need to account for these fragrance weight adjustments to guarantee proper balance and accurate yield calculations.

Most soapmakers use essential oils or fragrance oils at 3-5% of total oil weight. For example, if you're making a 1kg batch of soap and want to use 4% fragrance, you'll need 40g of fragrance oil.

- Fragrances don't participate in saponification but affect total yield

- Calculate fragrance separately from base oils for accurate lye calculations

- Typical usage rates range from 3-5% of total oil weight

- Adding fragrances requires recalculating other oil percentages to maintain 100% total

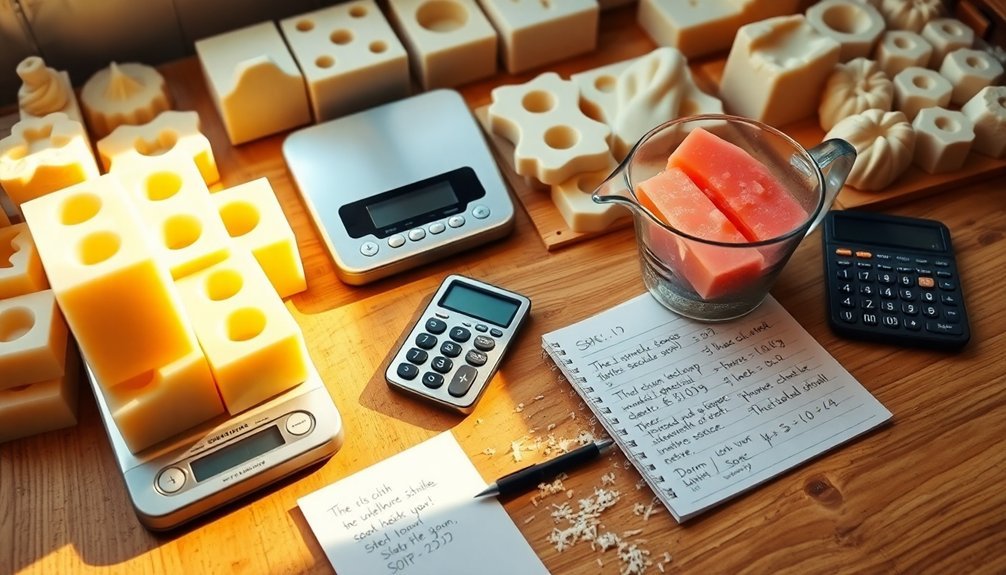

Determining Oil Weights for Your Target Batch Size

Three critical steps form the foundation of calculating your soap recipe's oil weights. First, decide your total batch weight including oils, lye, and additives. This total weight determines your final yield. Next, convert your oil percentages to actual weights by multiplying each percentage by the total batch weight. Finally, incorporate your superfat percentage to guarantee proper lye-to-oil ratio.

| Oil Type | Percentage | Weight in 50oz Batch |

|---|---|---|

| Palm Oil | 30% | 15 oz |

| Olive Oil | 40% | 20 oz |

| Coconut | 20% | 10 oz |

| Shea | 10% | 5 oz |

| Total | 100% | 50 oz |

Always use a lye calculator to verify your measurements. Remember, your oil percentages must total exactly 100% to maintain proper formulation balance and achieve your desired yield.

The Role of Lye Concentration in Final Soap Yield

Now that you've determined your oil weights, lye concentration becomes the next key factor affecting your soap yield. The amount of sodium hydroxide you use directly impacts both the quantity and quality of your final product.

To optimize your soap yield while maintaining safety:

Finding the sweet spot in your lye ratio ensures maximum yield without sacrificing your soap's gentleness or safety.

- Use a lye calculator to determine the precise sodium hydroxide concentration needed for your specific oil blend.

- Remember that higher lye concentrations can increase yield efficiency but risk creating a harsh product.

- Consider that different oils require different amounts of lye to saponify completely.

- Avoid excess lye which, while potentially increasing initial yield, can result in harmful unsaponified lye remaining.

Striking the perfect balance with your lye concentration guarantees you'll maximize yield without compromising the quality or safety of your handcrafted soap.

Accounting for Water Evaporation During Curing

While calculating the initial soap weight is straightforward, you'll need to factor in water evaporation to determine your true final yield.

During the 4-6 week curing process, your soap will typically lose 10-15% of its weight as water evaporates. This water loss varies based on your recipe's initial water content and environmental conditions like humidity and temperature.

For example, if your batch begins at 1,000 grams with 50% water content, expect to lose approximately 100-150 grams by the end of curing.

To accurately predict your final yield, monitor the weight of your soap bars throughout the curing period. Keep a record of these measurements to refine your future recipes and yield calculations.

This practical approach helps you set realistic expectations for how much sellable product you'll have when curing is complete.

Calculating Additive Percentages for Precise Formulations

Precision matters when incorporating additives into your soap formulations. To calculate additive percentages correctly, multiply the desired percentage by your total soap base weight. For example, if you want 3% Green Tea Extract in a 4 oz base, you'll need 0.12 oz (3.5 ml) of extract.

When working with additives, remember to:

- Adjust all ingredient weights to maintain a total of 100% in your final formulation

- Recognize that extracts don't count toward oil or water content

- Use a precise scale for measuring both base and additives

- Apply the same percentage calculations for liquid soap, accounting for density differences

Always verify your calculations before production to guarantee consistent quality and predictable yield in your finished soap products.

Converting Between Volume and Weight Measurements

Creating consistent soap batches requires mastering both precision calculation and proper measurement conversion.

When converting between volume and weight measurements, remember that each ingredient has a unique density. This means 1 oz of palm oil (weighing 25.5 grams) occupies a different volume than 1 oz of another oil.

To convert accurately, multiply weight in ounces by 29.57 ml/oz, then adjust for the ingredient's density. For example, palm oil's 0.89 g/ml density means 1 oz by weight equals about 33.2 ml by volume.

Always use scales for solids and measuring cups for liquids. For tiny amounts of essential oils or additives, consider using droppers or syringes for precision.

Your soap's quality depends on maintaining correct ratios through proper measurement conversion.

Adjusting Recipes for Different Mold Dimensions

Switching mold dimensions presents a common challenge for soap makers who need to adjust their tried-and-true recipes accordingly.

To correctly resize your batch size, first calculate the total volume of your new mold in ounces or milliliters, which determines how much oil you'll need.

- Calculate the ratio between your original and new mold sizes (new mold volume ÷ original mold volume)

- Multiply all your original oil amounts by this ratio to maintain proper proportions

- Use a lye calculator to recalculate the correct amount of lye for your new oil weight

- Double-check that your ingredient percentages still total 100%

For example, if you're moving from a 50 oz. mold to a 25 oz. mold, you'll need to halve all ingredient amounts while preserving their original ratios to guarantee your soap maintains its quality.

Frequently Asked Questions

How to Calculate the Theoretical Yield of Soap?

To calculate the theoretical yield of soap, you'll need to convert your fatty acid's mass to moles, apply the stoichiometric ratio from your balanced equation, then multiply by the soap's molar mass.

How to Calculate Actual Yield Without Percent Yield?

To calculate actual yield without percent yield, you'll need to weigh your final soap product after production. This measured weight is your actual yield, independent from theoretical calculations based on limiting reactants.

What Is the Calculation for Soap Making?

To calculate soap yield, you'll need to determine expected yield using reactant molar masses, identify your limiting reactant, apply stoichiometric ratios, and then compare your actual production weight to calculate percent yield.

How Many Bars of Soap Does 10 Lbs Make Per?

To calculate how many bars 10 lbs makes, you'll need to determine your bar size first. For 4 oz bars, you'll get 40 bars (160 oz ÷ 4 oz), while 3 oz bars yield about 53.

In Summary

Calculating soap yield beforehand guarantees you'll maximize materials and meet production goals. You've now mastered saponification values, water discounts, and additive percentages—all essential for consistent batches. Don't forget to account for curing shrinkage when planning your projects. With these calculations in your toolkit, you're ready to scale recipes confidently, adjust for different molds, and create precisely formulated soaps every time you craft.

Leave a Reply