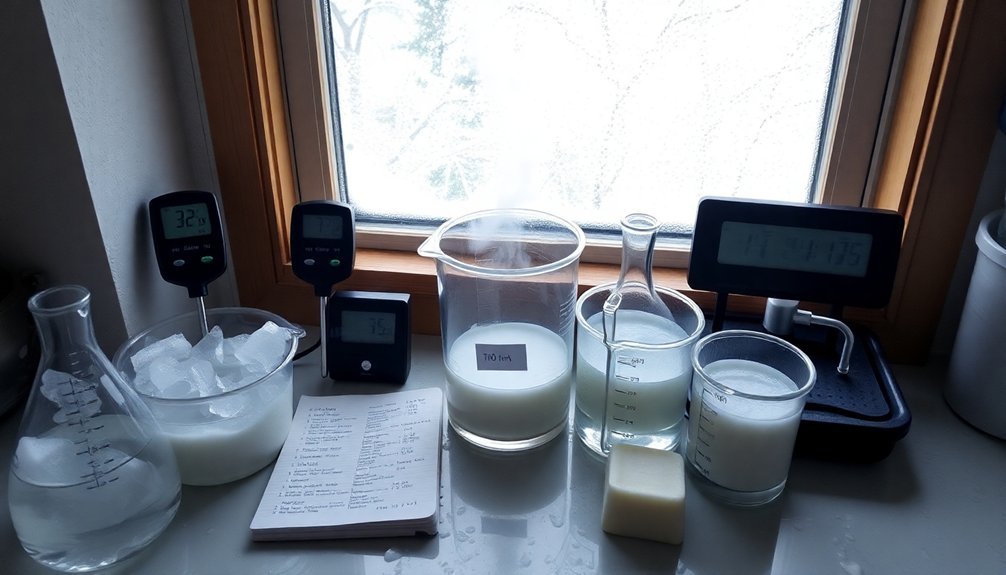

When making soap in cold weather, you'll need to maintain proper temperatures. First, warm your workspace to 70-80°F using heating pads or space heaters. Second, keep your oils and lye solution between 120-130°F to prevent false trace. Third, insulate your soap molds with towels or a gelling box after pouring. These temperature control strategies guarantee successful saponification even during winter months. Let's explore how these techniques transform your cold-weather soap making experience.

Warming Your Workspace: Setting the Stage for Successful Winter Saponification

While summer soap making often proceeds without climate concerns, winter crafting demands more attention to your environment. Maintaining ideal temperatures between 70-80°F in your workspace prevents common cold-weather problems like false trace when combining lye and oils.

Position heating pads strategically near your soap-making area to keep solid oils and butters melted properly before mixing.

Don't forget to pre-warm your mixing containers with hot water rinses to maintain consistent temperatures throughout the process.

Monitor ambient temperature closely as you work, making adjustments when necessary.

Once poured, insulating molds with towels or using a gelling box will retain heat during the critical saponification process. This extra warmth guarantees better color development and proper curing, even when winter temperatures try to interfere with your soap-making success.

Oil Temperature Management: Preventing False Trace in Cold Environments

Because winter temperatures can dramatically affect your soap's chemistry, maintaining proper oil temperatures becomes crucial for successful cold-weather batches.

In colder environments, oil temperature management becomes your first line of defense against false trace—that misleading thickening that occurs when solidified fatty acids masquerade as true saponification.

To prevent false trace during cold weather soap making:

- Keep both oils and lye within the ideal soaping temperature range of 120-130°F

- Confirm oils appear clear, not cloudy, indicating they're properly melted

- Allow hot lye solutions (which can reach 200°F) to cool to 120-130°F before mixing

- Monitor your workspace temperature, making adjustments as needed to maintain warmth

Lye Solution Temperature Control: Balancing Chemistry in Chilly Conditions

Just as oil temperatures require attention in winter soap making, your lye solution demands equally careful monitoring to achieve soap-making success.

When cold weather strikes, controlling your lye solution temperature becomes vital for proper saponification.

Though the exothermic reaction can push temperatures up to 200°F, you'll need to cool your lye solution to 120-130°F before combining with oils. This prevents premature solidification and false trace issues.

However, don't let it cool too much—excessively cold lye can cause oils to harden on contact, resulting in graininess.

For best results, maintain both lye and oils within 10 degrees of each other.

Consider preparing your lye solution 1-3 hours before soaping to achieve ideal temperature balance. This timing strategy helps you navigate the challenges of cold weather soap making with confidence.

Frequently Asked Questions

What Temperature Should Cold Process Soap Be Mixed At?

You should mix your cold process soap at temperatures between 120-130°F for both oils and lye solutions. Keep them within 10 degrees of each other to guarantee proper saponification and prevent mixing problems.

How Do You Make Cold Process Soap More Conditioning?

To make your cold process soap more conditioning, use oils rich in oleic acid like olive and avocado, increase superfat percentage to 5-10%, add honey or oatmeal, and maintain proper saponification temperatures of 120-130°F.

What Is the Cold Method of Making Soap?

You'll make cold process soap by mixing lye solution and oils at 100-130°F, allowing saponification to occur naturally without additional heat. It creates moisturizing soap that retains glycerin and allows for creative designs.

How Can I Speed up the Curing of Cold Process Soap?

You can speed up cold process soap curing by insulating molds with towels, using a low-temperature oven method, maintaining 120-130°F temperatures, increasing lye concentration to 33%, and utilizing hot lye solution to melt oils thoroughly.

In Summary

You've now mastered three essential temperature control techniques for cold weather soap making. By warming your workspace, managing your oil temperatures, and controlling your lye solution properly, you'll avoid the common winter pitfalls of false trace and improper saponification. Don't let chilly conditions discourage you—with these strategies, you'll create beautiful, high-quality soaps regardless of the thermometer reading outside.

Leave a Reply