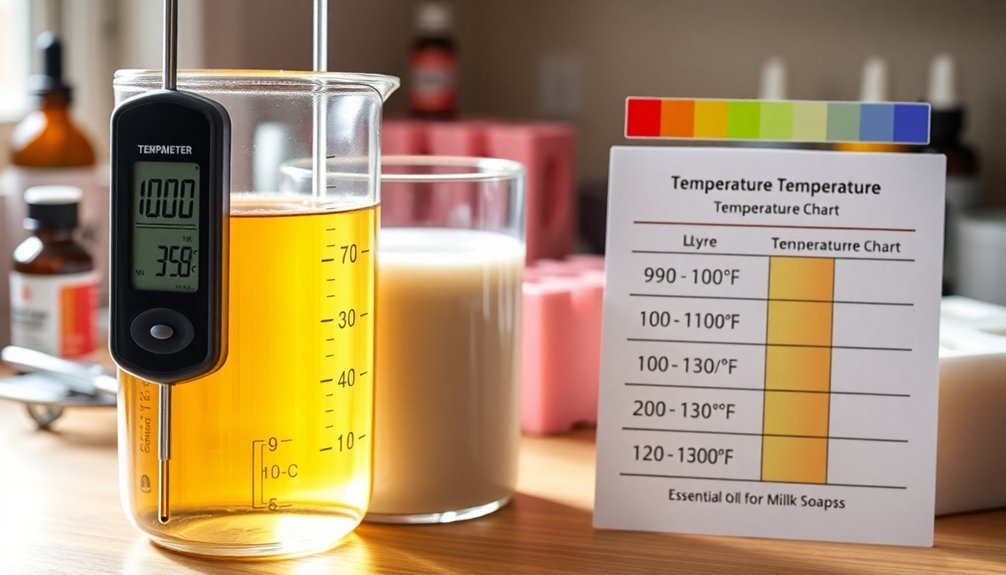

For proper saponification, maintain your lye solution between 120-130°F before mixing with oils at a similar temperature (within 10 degrees). Higher temperatures cause rapid thickening or false trace, while temperatures below 70°F can prevent proper emulsification. Use a reliable thermometer like a non-contact IR device to monitor consistently. Cool hot lye solutions (which can reach 200°F) before combining with oils. Master these temperature controls and you'll avoid common soap-making pitfalls.

The Science Behind Water Temperature in Saponification

While many soapmakers focus on oil temperatures, the water temperature you choose for dissolving lye plays an equally essential role in the saponification process.

When mixing lye with water, a vigorous chemical reaction occurs, generating heat that can push temperatures up to 200°F.

For ideal temperature management, cool your lye solution to 120-130°F before combining it with your soap making oils. Higher water temperatures intensify the exothermic reaction, potentially causing rapid thickening or false trace, which can ruin your batch.

In cold process soap making, using water below 120°F strategically slows saponification, giving you more working time for intricate designs.

This careful control prevents issues like soda ash and guarantees all oils fully incorporate into your soap, resulting in a smoother, more consistent product.

Optimal Temperature Ranges for Cold Process Soap Making

Although temperature management might seem technical, mastering it will dramatically improve your cold process soap results. For successful saponification, aim to keep both your oil mixture and lye solution within 120-130°F—the ideal soaping temperature range.

Always maintain these temperatures within 10 degrees of each other to prevent false trace issues. Remember that your lye solution initially reaches about 200°F through exothermic reactions, so you'll need to cool it before combining with oils.

If you're working with heat-sensitive fragrance oils, consider cooler temperatures (100-110°F) to avoid gel phase. Conversely, higher temperatures (131-160°F) enhance color vibrancy and reduce soda ash formation.

Ensure all oils are completely melted and clear at your chosen temperature to prevent premature solidification during mixing.

How Water Temperature Affects Lye Reactions

When mixing lye into water, you'll need to maintain temperatures below 120°F to prevent dangerous exothermic reactions that can cause your soap batter to overheat and thicken prematurely.

Your lye solution should cool to 120-130°F before combining with oils, while ensuring the solution temperature stays within 10-15°F of your oils' temperature for proper emulsification.

Too cold water can leave undissolved caustic lumps in your mixture, while excessive heat can accelerate saponification unpredictably, potentially causing volcano-like eruptions if temperatures reach 200°F.

Cold Process Temperature Range

Because lye reactions are highly sensitive to temperature variations, maintaining your solution within the perfect range of 120-130°F is critical for successful cold process soap making.

This ideal temperature range guarantees effective saponification while preventing false trace or accelerated reactions.

You'll need to cool your lye water after mixing, as it will initially reach temperatures well above 130°F.

Match your lye temperature to within 10-15°F of your oils to promote a smooth blending process.

If your lye solution is too hot, saponification will accelerate too quickly; too cold, and your fats may solidify upon contact, failing to properly emulsify.

Consistent monitoring of temperatures throughout your soap-making process is essential for controlling reaction dynamics and ultimately determining your final soap quality.

Precision at this stage establishes the foundation for successful saponification.

Heat Acceleration Effects

The initial water temperature you select plays an essential role in controlling the entire lye reaction process.

Water temperature directly influences how lye dissolves and affects the exothermic reaction that follows. Proper temperature control guarantees both lye safety and ideal soap quality.

- Hot water (180-200°F) – Accelerates the exothermic reaction, generating excessive heat that can speed up saponification but risks dangerous temperature spikes.

- Lukewarm water (100-120°F) – Creates a balanced lye solution with moderate heat generation, supporting controlled saponification.

- Cold water (35-50°F) – Slows the exothermic reaction but risks insufficient dissolution, potentially leading to gritty texture.

- Ideal temperature (120-130°F) – Promotes complete dissolution while maintaining a homogeneous mixture that properly integrates with oils.

Temperature Safety Thresholds

Understanding safety thresholds for water temperature represents a critical expansion of our heat management principles. When you prepare lye solution, you're initiating an exothermic reaction that can reach up to 200°F—a potentially dangerous level. You must cool this solution to 120-130°F before introducing oils to prevent splashing hazards.

| Temperature (°F) | Effect | Safety Consideration |

|---|---|---|

| >200 | Dangerous eruptions | High risk of burns |

| 120-130 | Safe mixing range | Appropriate for combining with oils |

| 98.6 (body temp) | Ideal integration | Best saponification reaction |

| 70-80 | Risk of solidifying | May cause false trace |

| <70 | Excessive cooling | Prevents proper emulsification |

Water temperature directly impacts your soap making success. Too hot, and you'll accelerate heat buildup causing soap volcanoes; too cold, and you'll experience solidifying oils, leading to incomplete saponification reaction.

Balancing Oil and Water Temperatures for Perfect Trace

You'll need to maintain both oils and lye water between 120-130°F for perfect trace, with no more than a 10-15°F difference between them.

When your temperatures are mismatched, watch for false trace where the soap batter thickens prematurely before complete saponification occurs.

If you encounter temperature-related issues, guarantee oils are fully melted without cloudiness and cool your lye solution adequately from its initial 200°F heat before combining with oils.

Optimal Temperature Ranges

Achieving perfect trace in your soap making process depends greatly on maintaining proper temperature balance between your oils and lye solution.

For successful cold process soaping, you'll need to monitor these temperatures carefully to guarantee proper saponification.

- Preferred range: Keep both lye solution and oils between 120-130°F for ideal saponification and to prevent false trace issues.

- Temperature difference: Maintain oils and lye solution within 10 degrees of each other to avoid solidification or accelerated trace.

- Cool temperatures (100-110°F): Help prevent gel phase and glycerin rivers, preferred for delicate designs.

- Hot temperatures (131-160°F): Promote vibrant colors and reduce soda ash, but require careful monitoring.

Remember that your lye solution will initially reach up to 200°F, so allow proper cooling before combining with your oils.

Troubleshooting Temperature Issues

When your soap suddenly seizes or exhibits false trace, temperature imbalances are often the culprit. Your lye solution and oil temperatures should remain within 10-15°F of each other to achieve consistent saponification.

If you're working with lye that's too hot (exceeding 200°F), cool it to 120-130°F before combining with your oils to prevent accelerated trace occurs.

Check both components with a reliable temperature gun before mixing. If your soap mixture thickens prematurely, immediately assess your temperature in cold process soap making.

Hot lye can cause rapid saponification, while insufficiently heated oils may appear melted but contain microscopic solid particles that create graininess.

When troubleshooting, remember that properly balanced temperatures result in predictable trace development, giving you adequate working time and ensuring your final soap achieves proper chemical reaction.

Troubleshooting Temperature-Related Soap Making Issues

Temperature control stands at the heart of successful soap making, as even slight deviations can lead to frustrating results.

When your lye solution becomes too hot or cold, the entire saponification process can be compromised. Experienced soap makers know that temperature is key when adding the lye to water and combining it with oils.

- If your soap batter thickens unexpectedly, you may be experiencing false trace caused by cooler temperatures – verify your lye water solution has cooled to 120-130°F before proceeding.

- Monitor temperatures closely to prevent gel phase issues like alien brain formation.

- Use hot water initially, but allow proper cooling time to avoid accelerated saponification.

- Keep your lye and oil temperatures within 10-15°F of each other for ideal results.

Essential Tools for Precise Water Temperature Measurement

Precise water temperature measurements form the backbone of consistent soap making success. A reliable non-contact IR thermometer like the eT650D allows you to monitor your lye solution without risking safety through direct contact.

Since proper saponification requires keeping your lye and oils within 10-15°F of each other, investing in a calibrated thermometer rated for high temperatures is crucial. Your thermometer should accurately measure up to 200°F, as lye-water reactions can reach these extreme temperatures.

For efficient soap-making, choose a digital thermometer with quick response time to help you track temperature changes in real-time. Regular temperature checks of both your water and lye solution prevent overheating or excessive cooling that can lead to false trace and compromised soap quality.

This vigilance guarantees your saponification process proceeds smoothly.

Frequently Asked Questions

What Is the Best Temperature for Saponification?

The best temperature for saponification is between 120-130°F. You'll want to keep your oils and lye solution within this range, and within 10 degrees of each other, to guarantee successful soap making.

What Is the Best Temperature for Curing Soap?

For curing soap, you'll want to maintain temperatures between 70°F and 90°F. This ideal range promotes proper moisture evaporation without compromising your soap's structure. Keep humidity low and allow 4-6 weeks for complete curing.

What Temperature Should Lye Water Be?

You should keep your lye water between 120-130°F for ideal soap making. This temperature guarantees effective saponification without causing false trace, while preventing oils from solidifying when they're mixed together.

How Does Temperature Affect the Rate of Saponification?

Higher temperatures speed up your soap's saponification rate, while cooler temperatures slow it down. You'll get faster trace at 120-130°F, but you'll have more working time if you soap at 100-110°F.

In Summary

You've now mastered the essential relationship between water temperature and successful saponification. Remember, you'll get consistent results when you monitor temperatures precisely and adjust according to your recipe's needs. Don't worry if you've experienced temperature-related failures—they're valuable learning opportunities. By maintaining proper temperature control, you'll create beautiful, well-structured soaps with predictable trace times and avoid common pitfalls. Your soap making journey just got considerably more reliable!

Leave a Reply