A lye and oil ratio calculator helps you create balanced soap formulations by calculating precise amounts of sodium or potassium hydroxide needed for your chosen oils. Each oil has a specific saponification (SAP) value—olive oil requires 0.134g NaOH per gram while coconut oil needs 0.190g. For beginners, maintain a 2:1 water-to-lye ratio and 5% superfat level. Always weigh ingredients rather than measure by volume for consistent results. The perfect soap formula awaits in these calculated proportions.

Lye and Oil Ratio Master Calculator Guide

When creating homemade soap, achieving the perfect balance between lye and oils is essential for both safety and quality. The Lye and Oil Ratio Master Calculator eliminates guesswork by precisely determining the amount of lye needed for your specific recipe ingredients.

To use this soap making tool effectively, you'll need to:

- Select your lye type (sodium hydroxide or potassium hydroxide)

- Input your oils and fats accurately by weight

- Choose your desired super-fatting level (typically 0-10%)

The calculator works with average saponification values to recommend proper lye-to-water ratios—generally 2:1 for solid soaps and 3:1 for liquid formulations.

Remember to measure your total batch weight precisely, as this directly impacts the calculator's recommendations.

You can also resize batches while maintaining perfect proportions for consistent results every time.

Understanding Saponification Values for Common Soap Oils

You'll need to grasp fatty acid compositions to understand why different oils require specific amounts of lye in your soap recipes.

The SAP values vary considerably among common soap-making oils, with coconut oil (0.190) requiring more lye than olive oil (0.134) or shea butter (0.128) per unit weight.

When working with oil blends, you can calculate the total lye requirement by multiplying each oil's weight by its SAP value and then adding these amounts together.

Fatty Acid Composition Basics

Although many novice soapmakers begin their journey with simple recipes, understanding the science behind saponification values is essential for formulating balanced, high-quality soaps.

Each oil's unique fatty acid profile directly influences your soap's properties.

When using a lye calculator, you'll notice that oils high in oleic acid (like olive oil with a SAP value of 0.134) create mild, moisturizing bars.

Meanwhile, oils rich in lauric acid (like coconut oil at 0.190) produce abundant lather but can be drying.

Stearic-rich oils and fats contribute to hardness and stability.

Oil-Specific SAP Values

Every successful soap formula begins with precise saponification values that determine exactly how much lye you'll need for your chosen oils.

Understanding these SAP values is essential when you calculate the lye requirements for your recipe.

Different oils require varying amounts of lye to transform into soap. For instance, olive oil has a SAP value of 0.134, meaning you'll need 0.134g of NaOH per gram of oil.

Coconut oil demands more lye with its higher 0.183 SAP value, which creates a more cleansing bar. Meanwhile, castor oil's lower 0.128 SAP value contributes moisturizing properties and improved lather.

Remember that SAP values can vary based on extraction methods and purity.

Always reference reliable, up-to-date sources when formulating your soap to guarantee perfect saponification every time.

Blend Calculation Methods

Now that we've established individual oil SAP values, let's examine how to calculate lye requirements for oil blends in your soap recipes.

When working with multiple oils, you'll need to perform calculations for each oil separately. Multiply the weight of each oil to use by its specific saponification value, then add these figures to determine your total lye requirement.

For example, if your recipe contains 500g of olive oil (SAP 0.134) and 300g of coconut oil (SAP 0.190), you'd need 67g and 57g of lye respectively, totaling 124g.

Most soapmakers rely on a lye calculator to perform these calculations automatically. Simply input the total weight of each oil in your blend, and the calculator will determine the precise lye amount needed based on accurate saponification values.

The Science Behind Lye-to-Oil Ratios in Soap Making

You'll need to understand saponification values (SAP values) to calculate the precise amount of lye required for each oil in your soap recipe.

These values vary considerably between oils—coconut oil requires more lye than olive oil for the same weight—which directly impacts your final soap's qualities.

Maintaining proper water-to-lye ratios (typically 2:1) guarantees your soap mixture dissolves the lye completely while providing enough time for thorough mixing before the batter thickens.

Saponification Value Essentials

At the heart of successful soap making lies the saponification value, a critical number that determines precisely how much lye is needed to transform oils into soap.

Every oil has its unique SAP value—olive oil's 0.135 means you'll need 0.135g of lye per gram of oil in your soap recipes.

These values aren't arbitrary; they're based on each oil's fatty acid composition.

When you're creating your own formulations, using a lye calculator is vital to guarantee proper lye-to-oil ratios.

Without these calculations, you risk creating soap that's either caustic from excess lye or ineffective from too little.

Water-Lye Balance Fundamentals

While crafting successful soap requires precise oil measurements, understanding the water-lye relationship forms an equally critical foundation of your soapmaking process.

When you calculate the amount of water needed, remember that the absolute minimum water:lye ratio is 1:1, though this leaves little room for error.

For beginners, start with a 2:1 water:lye ratio for solid soaps and up to 3:1 for liquid formulations. This guarantees proper dissolution and prevents unsaponified lye pockets.

Your lye solution's concentration directly impacts curing time, bar hardness, and overall soap quality.

Be cautious—too little water (below 1:1) risks separation and "volcano" effects, while excessive amounts extend curing time unnecessarily.

The water-lye balance you choose affects your soap's moisturizing properties and cleansing ability, making proper calculation vital for consistent results.

Calculating Superfat Percentages for Balanced Formulations

Understanding superfat percentages is essential when formulating soap that balances cleansing power with moisturizing properties.

When you're using lye calculators, you'll find a superfatting setting that allows you to determine how much extra oil remains unsaponified in your final product.

For standard formulations, aim for 5% superfat, though you can adjust between 0-10% depending on your desired outcome.

To calculate this correctly, set your lye calculator's superfat slider to your chosen percentage before determining your oil weight requirements.

For specialty soaps, consider adding precious oils at trace. For example, in a 1.3 kg batch, adding 65 grams of argan oil can enhance moisturizing properties without disrupting saponification.

Remember that skin type matters—limit superfat to 3% for acne-prone teenage skin, while dry skin benefits from higher percentages.

Water-to-Lye Ratios: Finding Your Perfect Combination

Water-to-lye ratios directly impact your soap's trace time, with higher concentrations accelerating the process and lower concentrations allowing more working time.

As a beginner, you'll want to stay within the 1.5:1 to 2:1 water-to-lye range, while experienced soapmakers often use more concentrated solutions to speed curing.

If you're working with hard water, you'll need to adjust your calculations or consider using distilled water to prevent unwanted reactions with minerals that could affect your soap's quality.

Concentration Affects Trace Time

As you mix lye solution with oils, the concentration of your lye greatly influences how quickly your soap reaches trace. The water to lye ratio you choose directly impacts your soapmaking process timeline and consistency.

With lower ratios (less water), your mixture will trace faster, creating a thicker soap that sets up quickly. Many solid soap makers prefer the 2:1 ratio as it balances workability with efficiency.

If you're making liquid soap, try a 3:1 ratio for smoother pouring.

Remember not to reduce water below a 1:1 ratio – this can leave dangerous pockets of unsaponified lye in your final product.

Finding the right amount of lye to use requires experimentation. You'll discover your perfect balance between trace time and texture as you gain experience.

Beginners vs. Advanced Ratios

While we've seen how concentration affects trace time, your experience level should guide your choice of water-to-lye ratio.

Beginners should stick to a safer 1.5:1 to 2:1 water-to-lye ratio, which provides more forgiveness during the learning process. As you gain confidence, you can gradually adjust ratios using a soap calculator to optimize your results.

- Beginners: Use 1.5-2 times the weight of lye in water to reduce the risk of unsaponified lye pockets

- Intermediate: Try the standard 2:1 ratio for solid soaps; 3:1 for liquid soaps

- Advanced: Experiment with lower ratios (as low as 1:1) for faster saponification

- Expert: Fine-tune your water amounts based on oil types for maximum saponification efficiency

Remember that while experienced soap makers can work with less water, it leaves less margin for error.

Hard Water Considerations

Hard water introduces significant challenges to your soap-making process that can dramatically affect your final product's quality. When working with hard water, you'll need to adjust your water ratio to counteract the minerals that interfere with lathering and saponification.

| Water Type | Recommended Ratio | Effect on Soap |

|---|---|---|

| Hard Water | 1.75:1 – 2:1 | Reduced lather, potential scaling |

| Medium Hard | 1.5:1 – 1.75:1 | Variable results, some mineral interference |

| Soft Water | 1:1 – 1.5:1 | Better lather, cleaner finish |

| Distilled Water | 1:1 – 3:1 | Ideal results, full customization |

For best results, use distilled water regardless of your local water quality. This eliminates variables and guarantees your lye dissolves completely. Remember, never use less than a 1:1 water-to-lye ratio to prevent unsaponified lye pockets.

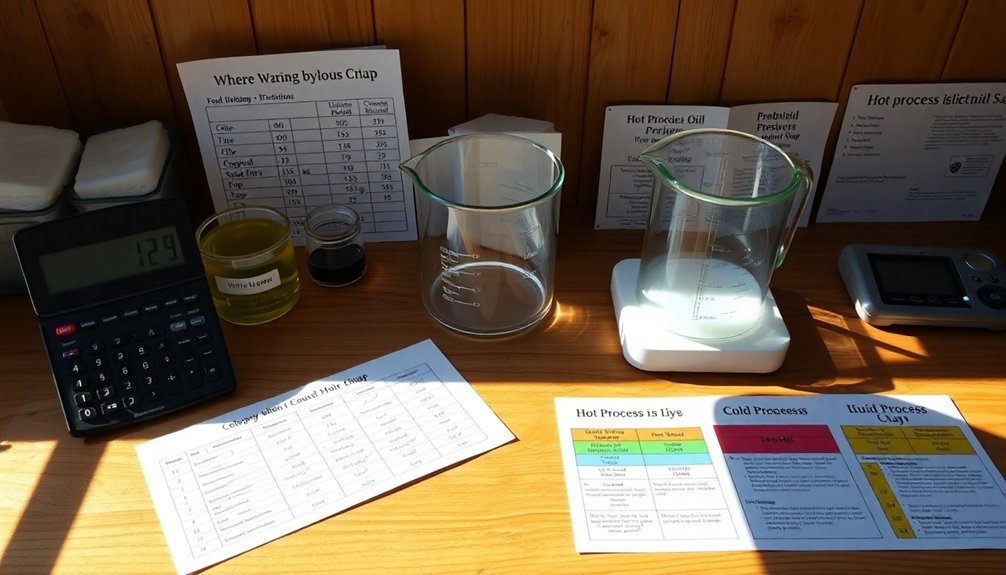

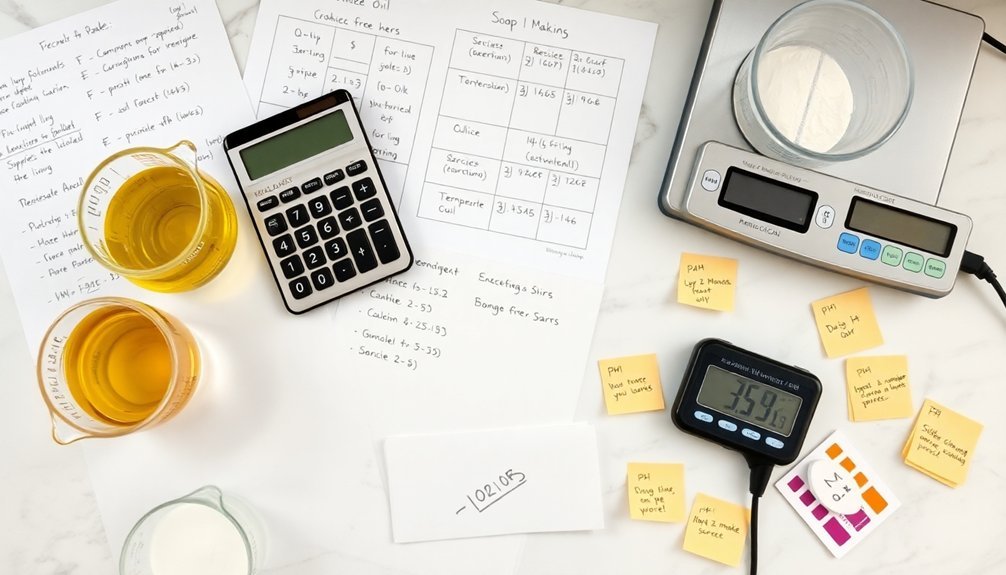

Converting Volume Measurements to Weight for Precision

When shifting from volume to weight measurements in soapmaking, you'll discover a significant improvement in your recipe's precision and consistency. Your lye calculator requires exact measurements to produce safe, quality soap.

Since oils have different densities—olive oil weighs about 28.35 grams per fluid ounce while coconut oil is roughly 27 grams—volume measurements simply can't provide the accuracy needed.

- Invest in a quality kitchen scale that measures in both grams and ounces

- Remember that each oil has a unique density, making direct volume conversions unreliable

- Use online calculators specifically designed to convert volume to weight for soapmaking oils

- Always weigh your ingredients directly into your soaping container to eliminate transfer loss

This weight-based approach eliminates guesswork and guarantees your soap recipes are reproducible every time.

Essential Oil Blending Ratios and Safe Usage Rates

Creating the perfect essential oil blend for your soap requires both artistry and scientific precision. For most formulations, aim for essential oils to comprise about 3% of your total oil weight, though you can adjust between 0.75% and 8% depending on scent strength desired.

When blending, limit yourself to 3-5 different essential oils to create harmonious scent profiles without overwhelming complexity.

Always consult Safety Data Sheets (SDS) for each oil to identify potential skin sensitivities or contraindications before combining them.

Perform a patch test with your blended essential oil mixture before full-scale production, especially for soap intended for sensitive skin.

Be particularly cautious with citrus oils, which can cause photosensitivity when skin is exposed to sunlight after use.

Scaling Recipes Up or Down While Maintaining Proportions

Successfully scaling soap recipes requires meticulous attention to proportional relationships between ingredients, whether you're preparing a small test batch or ramping up for commercial production.

To accurately scale, you'll need to recalculate your formulation while preserving the vital balance between oils and lye.

- Always use a reliable lye calculator to determine the proper amount of lye needed for your adjusted recipe size.

- Maintain your original superfatting percentage (e.g., 5%) to guarantee consistent quality across different batch sizes.

- Preserve the water-to-lye ratio (2:1 for solid soap, 3:1 for liquid soap) to avoid consistency problems.

- Verify that your ingredient percentages still total 100% after scaling to confirm balanced proportions.

When scaling recipes, remember that precision matters—even small miscalculations in proportions can affect your soap's quality and safety.

Adjusting Formulations for Different Soap Making Methods

Different soap-making methods require specific formulation adjustments to achieve ideal results.

When crafting solid soap bars with NaOH, you'll want to maintain a 2:1 water-to-lye ratio for proper saponification.

Switch to liquid soap with KOH? Increase to a 3:1 ratio for smoother consistency and easier mixing.

Don't overlook superfatting levels—5% works well for most formulations, providing moisturizing benefits without excess oil.

However, you might adjust this percentage depending on your chosen method and desired properties.

Remember that each oil has a unique saponification value, requiring precise calculations for your specific oil blend.

Whether you're hot processing, cold processing, or creating liquid soap, always use a reliable lye calculator to recalculate your formula when changing methods or ingredients to guarantee both safety and quality.

Specialty Oil Incorporation: Ratios for Luxury Additives

While luxury oils can transform ordinary soap into extraordinary creations, they require careful calculation to maintain proper saponification. When working with specialty additives, you'll need to use a lye calculator to determine the precise amount of sodium hydroxide based on each oil's unique saponification values.

- Keep luxury oils like argan, avocado, and jojoba at about 5% superfatting to maximize benefits without sacrificing cleansing power.

- Limit conditioning oils such as shea or cocoa butter to 25% of total weight of oils to prevent overly soft bars.

- Aim for a 50/50 balance between liquid and solid oils for ideal texture and lather.

- Remember that 100g of oils with an average SAP value of 0.137 requires approximately 13.7g of sodium hydroxide.

Troubleshooting Common Ratio Miscalculations

Even experienced soap makers encounter calculation errors that can transform a promising batch into a disappointing result.

When your soap fails, first check if you've included non-saponifiable additives in your oil weight calculations, which throws off your lye amount.

If your soap is too harsh, you've likely underestimated your superfat percentage—aim for 5% to balance moisturizing and cleansing properties.

Inconsistent results often stem from outdated saponification values for oils, so verify these before calculating.

Watch your water-to-lye ratio carefully. Never use less than a 1:1 ratio, as this can leave dangerous lye pockets.

Conversely, if your soap won't reach trace, you've likely used too much water, slowing the saponification process.

Adjust this ratio for ideal consistency in future batches.

Frequently Asked Questions

How Much Lye to Oil Ratio?

You'll need a 10% lye to oil ratio for most solid soaps, but always use a lye calculator to determine exact amounts based on your specific oils and desired superfatting level.

How to Calculate Water to Lye Ratio?

To calculate water to lye ratio, multiply your lye weight by your desired ratio (1.5-2 for beginners, 1:1 minimum). For example, if using 100g lye with a 2:1 ratio, you'll need 200g water.

What Temperature Do You Combine Lye and Oil?

You'll want to combine your lye and oils when both have cooled to between 95°F and 105°F. Using a thermometer helps guarantee they're at similar temperatures, preventing separation issues during saponification.

What Is the Formula for the Lye Solution?

You'll combine NaOH with water at a ratio of 1:1 to 1:2 (lye:water). For beginners, use water that's 1.5-2 times your lye weight. A 30% strength solution works well for solid soap.

In Summary

You've now mastered the art of soap making calculations! By understanding lye-to-oil ratios, saponification values, and water proportions, you're equipped to create perfectly balanced soaps every time. Remember, precision matters—even small miscalculations can affect your final product. Don't be afraid to experiment with your newfound knowledge, but always double-check your numbers before mixing. Happy soaping with confidence and creativity!

Leave a Reply