Your oils need time to cure soap because they're undergoing a gradual chemical transformation called saponification. During this 4-6 week process, the oils continue reacting with lye while excess water evaporates, resulting in a harder, milder bar with better lather. Different oils cure at varying rates – olive oil takes months while coconut oil cures faster. Proper curing conditions and patience will guarantee your handmade soap reaches its full potential.

The Science Behind Oil-Based Soap Curing

When oils transform into soap through saponification, they don't become fully cured the moment you unmold your bars. The process continues as your soap matures, typically requiring 4-6 weeks before saponification is complete. During this time, the chemical reaction between your oils used and the lye solution gradually finalizes.

Soap needs time to fully transform – even after unmolding, the saponification process continues developing for several weeks.

You'll notice that proper air circulation plays an essential role as water evaporation occurs, removing excess moisture from your soap bars.

Different oils require varying curing times – for instance, olive oil soap might need several months to reach ideal hardness, while recipes with castor oil often cure faster.

The environment where you cure your soap matters greatly; temperature and humidity levels will affect how quickly your bars harden and develop their final properties.

Essential Oil Properties During the Curing Phase

Although essential oils add delightful fragrances to soap, their properties evolve considerably during the curing phase. During this time, volatile compounds within the essential oils stabilize, creating richer and more complex scent profiles in your final product.

You'll notice that the curing process enhances both aromatic qualities and therapeutic properties of these oils.

The extended curing period serves another vital purpose: it guarantees complete saponification, neutralizing any remaining lye and making your soap safe for skin contact. This is particularly important when you're working with essential oils that might cause skin sensitivity.

If you're using oils with higher flash points, you'll need to allow for longer curing times to maintain their beneficial properties. As a result, you'll experience improved lather quality and enhanced skin benefits in your finished soap.

Time Requirements for Different Oil Combinations

Since different oil combinations react uniquely during saponification, you'll need to adjust your curing times accordingly.

Your soap recipe's balance of hard oils and soft oils directly impacts how long your cold process soap needs to cure. When working with high olive oil content, you're looking at extended curing times of up to a year for ideal results.

- Combining coconut or palm oils with softer oils can reduce your curing time to 4-6 weeks

- High olive oil content requires longer curing time to avoid slimy texture

- Reducing water content in your recipe can speed up the hardening process

Your soap making success depends on matching the lye needed to your chosen oils and adjusting curing times based on the blend.

While personal preference plays a role, proper curing guarantees your soap develops the best possible hardness and lather quality.

Optimal Curing Conditions for Oil-Infused Soaps

To achieve the highest quality soap, you'll need to maintain specific environmental conditions throughout the curing process.

The ideal curing conditions for oil-infused soaps require temperatures between 60°F to 80°F, which promote proper evaporation and chemical reactions.

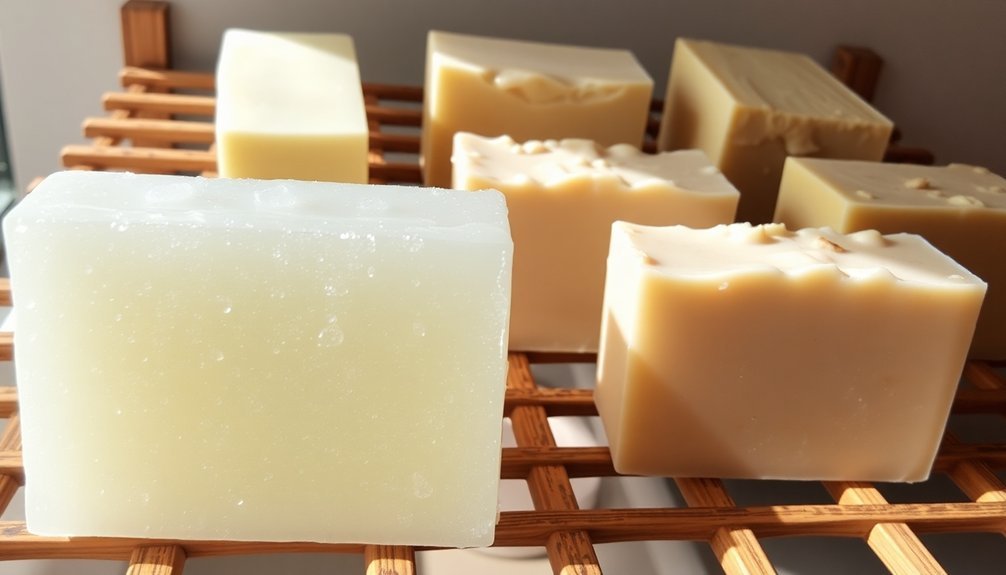

You'll want to guarantee good air circulation by placing your soaps on wire racks or trays, which helps prevent mold and supports even drying.

Store your soaps in a cool, dry area away from direct sunlight to prevent quality issues.

While most soaps need 4 to 6 weeks to cure, allowing excess moisture to evaporate into a harder soap bar, some oils require longer periods.

For instance, olive oil's unique properties may extend the curing process to several months before reaching ideal results.

Monitoring Oil Development Throughout the Cure

When making soap, you'll need to carefully track how different oils develop during the curing phase to guarantee ideal quality. As excess water evaporates and saponification continues, you'll notice significant changes in your soap's characteristics.

- The texture shifts from soft to firm as oils interact with lye concentration.

- Environmental factors like temperature and humidity affect how quickly oils cure.

- Different oils require varying cure times – olive oil needs months, while blended oils cure faster.

Monitor your soap's development by checking its hardness regularly.

You'll want to observe how environmental factors impact the curing process, as these conditions can speed up or slow down oil development.

The soap's texture should become increasingly firm as excess water evaporates.

When properly cured, your soap will demonstrate improved lather and longevity, indicating successful oil development.

Frequently Asked Questions

Why Do You Have to Wait for Soap to Cure?

You'll need to wait for soap to cure because it allows moisture to evaporate, making the bar harder and longer-lasting. The process also guarantees the lye's neutralized and creates better lather quality through continued saponification.

What Happens if You Don't Let Soap Cure?

If you don't let soap cure, you'll end up with a softer bar that dissolves quickly, may cause skin irritation, and won't lather well. The soap's quality will suffer without proper curing time.

How Long Should I Let My Soap Cure?

You'll need to cure your soap for 4-6 weeks minimum in a cool, dry place. If you're using high olive oil content, extend the cure to 6-12 months for best results and quality.

Can I Use Cold Process Soap Right Away?

While you can technically use cold process soap after 48 hours, you shouldn't. Wait 4-6 weeks for proper curing to guarantee your soap develops better lather, becomes harder, and lasts longer with peak performance.

In Summary

You'll find that proper curing time is essential for your oil-based soaps to reach their full potential. During this waiting period, excess water evaporates, pH levels stabilize, and oils undergo complete saponification. Don't rush the process – allowing 4-6 weeks of curing creates harder, milder bars with better lather. Check your soap's progress by monitoring weight, hardness, and scent development throughout the cure.

Leave a Reply