Store your hot process soap batches in a cool, dry space at 55-68°F with consistent humidity between 40-60%. You'll need to use airtight containers while maintaining proper ventilation, and keep bars spaced 1 inch apart on elevated racks. Turn bars regularly, monitor pH levels weekly, and protect essential oils by storing in dark conditions. Track hardness changes through regular testing, and document your findings to perfect your aging process. Our detailed guide explores these techniques in depth.

Optimal Storage Conditions for Hot Process Batches

Three key environmental factors determine the success of storing your hot process soap batches: temperature, humidity, and light exposure.

For ideal aging, maintain temperatures between 55-68°F (12-20°C) in a cool, dry space. You'll want to protect your soap from direct sunlight, as UV rays can damage both the fragrance and color.

Storage conditions play a significant role in preserving your hot process soap's quality. Use airtight containers while ensuring sufficient air circulation to prevent mold growth.

You'll need to strike a balance between sealing the soap to limit air exposure and allowing enough ventilation for even aging. Keep humidity levels consistent to avoid texture problems – too much moisture can soften the bars, while excessive dryness can make them brittle.

Choose a dedicated storage area that meets these requirements for the best results.

Temperature Control During the Aging Period

While proper storage conditions set the foundation for aging, maintaining precise temperature control throughout the aging period determines your hot process soap's final quality.

You'll want to keep your aging hot process soap between 55-68°F (12-20°C) to achieve ideal results. This temperature range allows the soap to develop properly without risking any quality issues.

To prevent fluctuating temperatures from causing texture problems or separation, store your batches in a well-ventilated area away from direct sunlight.

You'll need to monitor the temperature regularly, as readings above 70°F can speed up curing and affect your final product.

Remember that cooler temperatures work in your favor by slowing down saponification, which helps your soap develop more complex characteristics over time.

Moisture Management Techniques

Successful moisture management during hot process soap aging begins with proper pouring and storage techniques. You'll want to focus on water discounting in your lye solution to achieve firmer soap and reduce excess moisture. Place your soap in a well-ventilated area during cooling to promote proper moisture evaporation.

| Stage | Action | Benefit |

|---|---|---|

| Pouring | Use ventilated molds | Prevents condensation |

| Mixing | Reduce water content | Creates firmer texture |

| Environment | Monitor humidity (40-60%) | Prevents sweating |

| Cooling | guarantee air circulation | Reduces trapped moisture |

| Storage | Use breathable wrapping | Regulates moisture levels |

For best results, wrap your finished bars in muslin or parchment paper. This approach allows your soap to maintain proper moisture balance while protecting it from environmental humidity and contaminants.

Air Circulation Requirements

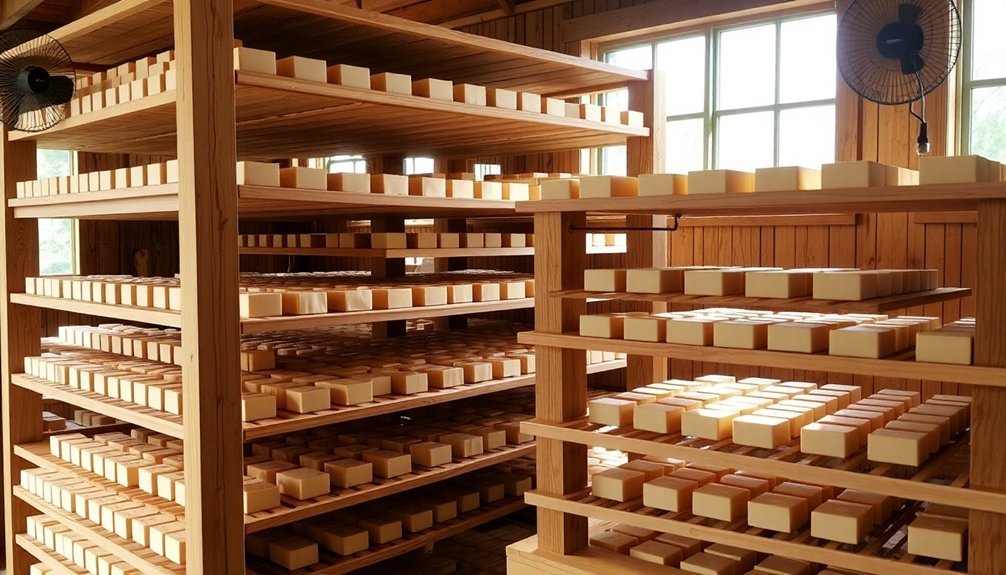

Your hot process soap batches need proper ventilation throughout the curing process, so position your drying racks in a well-ventilated area away from humid spaces.

Keep individual soap bars at least an inch apart on your curing racks to guarantee air flows freely around each bar, preventing moisture buildup and promoting even aging.

The height of your rack placement matters too – elevate them off the ground and away from walls to maximize airflow from all directions.

Proper Ventilation During Curing

Although hot process soap is ready to use immediately, proper ventilation during the curing period remains crucial for achieving excellent quality and longevity.

You'll need to set up your curing area in a space with consistent airflow to prevent moisture buildup and ward off potential mold growth.

Keep your soaps in a temperature-controlled environment between 65-75°F, placing them on open racks or shelves rather than in sealed containers.

Don't forget to turn your soap bars regularly to guarantee even drying on all sides.

If you're working in a humid climate, you'll want to add a dehumidifier or fans to maintain ideal conditions.

Spacing Between Soap Bars

Building on proper ventilation practices, the specific spacing between your soap bars plays a major role in the aging process.

You'll need to maintain at least 1 inch of space between each bar to guarantee proper air circulation throughout your batch. This critical spacing prevents moisture from becoming trapped, which could otherwise lead to mold growth and irregular curing.

To maximize airflow, place your soap bars on wire racks or ventilated shelving instead of solid surfaces.

Don't stack your bars directly on top of each other, as this will impede the hardening process. If you're using storage containers, make sure they've adequate ventilation holes to prevent condensation buildup.

These spacing requirements aren't just suggestions – they're essential for achieving consistently high-quality results in your hot process batches.

Rack Position Matters

The three key factors of rack positioning – height, location, and design – directly impact air circulation during the soap aging process.

You'll want to place your soap racks in areas where air flows freely, avoiding enclosed spaces or corners where stagnant air can accumulate.

Position your racks at a comfortable height that allows air to move both above and below the bars.

Select racks with slatted designs, as they're vital for promoting proper airflow around each soap bar.

When setting up your aging area, verify there's adequate ventilation to maintain ideal humidity levels.

Don't place racks against walls or in tight spaces where air movement becomes restricted.

Proper Spacing and Arrangement Methods

Proper spacing and arrangement play a vital role in successfully aging hot process soap batches. You'll need to guarantee adequate spacing between each bar to promote peak airflow and prevent unwanted moisture retention.

Place your bars in a single layer on your curing racks, avoiding the temptation to stack them on top of each other. Keep your bars from touching during the aging process, as contact between them can lead to uneven curing and texture issues.

You'll want to maintain your storage area's temperature between 55-68°F and monitor humidity levels closely. A well-ventilated space is essential for consistent results.

Testing Hardness Throughout Aging

You'll want to check your soap's hardness weekly by gently pressing the surface with your finger, looking for minimal to no indentation as a sign of proper aging.

Track changes in firmness over several weeks by cutting small test pieces from the corners, which lets you compare texture and consistency from different parts of the batch.

Remember to pair these physical tests with pH measurements between 7-10, confirming both complete saponification and ideal hardness development.

Measuring Bar Firmness Weekly

Monitoring your hot process soap's firmness throughout aging provides essential data about its curing progress.

You'll want to establish a consistent weekly testing routine to track your soap's hardness development accurately.

Start by using your finger to press gently into the soap's surface, noting how much resistance you feel and whether it leaves an indentation. For more precise measurements, consider investing in a penetrometer to get consistent, comparable data.

Your soap should gradually become firmer over 4-6 weeks until it resists light pressure without denting.

Keep detailed records of your weekly firmness tests to understand how your specific recipe develops over time. This documentation helps you identify when your bars have reached ideal hardness and determine the perfect aging period for future batches.

Soap Indentation Test Methods

Testing your soap's hardness through indentation checks serves as a reliable way to track the curing process.

You'll want to conduct your first indentation test after the soap has cooled for 24 hours, then continue weekly assessments throughout the aging period.

To perform the test, make certain your soap bar is at room temperature, then press your finger gently into its surface. A well-cured bar will quickly bounce back with minimal marks, while softer soaps leave visible imprints, indicating they need more curing time.

Keep detailed records of your findings to understand how your soap's hardness changes over time. These observations will help you determine the ideal aging period for your specific recipe.

Always test under consistent temperature conditions to maintain accurate results.

Tracking Hardness Over Time

Building on basic indentation tests, an extensive hardness tracking system helps perfect your hot process soap batches.

Start by performing a zap test after 48 hours of cooling to guarantee your soap's safety and proper curing. You'll want to monitor your batches of soap weekly by cutting small edge samples to observe texture changes.

Keep in mind that your recipe's oil composition greatly impacts hardness – coconut and palm oils create firmer bars compared to olive or castor oils.

While hot process soap reaches most of its hardness within 48 hours after pouring, you'll notice continued firmness development over 4-6 weeks.

Document your findings at consistent intervals to identify patterns and make informed adjustments to future batches. This systematic approach helps you maintain quality control and achieve your desired texture consistently.

Essential Oil Retention Strategies

When working with essential oils in hot process soap making, proper retention techniques can make the difference between a boldly scented bar and a faintly fragrant one.

You'll want to add your essential oils after the cooking phase to prevent unnecessary evaporation, keeping the temperature around 160°F for ideal preservation.

To enhance scent longevity during aging, increase your essential oil concentration slightly above standard recommendations, as some loss is inevitable.

Mix the oils gradually into your hot process soap to guarantee even distribution throughout the batch. Don't rush this step – slow incorporation leads to better results.

Once you've completed your batch, store it in a cool, dark place during the aging process. This controlled environment helps stabilize the essential oils and allows their aromatic properties to develop fully over time.

Handling Large-Scale Batch Storage

Proper storage facilities can make or break your large-scale hot process soap production. When handling large batches, you'll need to use non-reactive containers made of stainless steel or food-grade plastic to protect your soap's integrity during the aging process.

Keep your storage area's temperature between 55-68°F to guarantee ideal batch development. You'll want to use airtight containers to prevent oxidation, which can compromise your soap's quality.

Don't forget to label each container with batch dates, ingredients, and specific aging notes for easy tracking and quality control.

For efficient storage management, consider using slab molds, as they'll provide uniform thickness across your batches. This uniformity guarantees even aging and makes it easier to handle your soap during the storage phase.

Monitoring Ph Levels While Aging

Three essential pH readings during your soap's aging process will determine its final quality and safety.

You'll want to monitor your soap's pH levels weekly during the first month to guarantee they stay between 8 and 10, which is the ideal range for skin compatibility.

Using pH strips or a digital pH meter, you can accurately track any changes in your soap's chemistry.

If you notice a significant pH drop, it's vital to investigate immediately, as this could signal incomplete saponification or bacterial contamination.

These issues require prompt attention to maintain your product's quality.

To support stable pH levels during the aging process, keep your soap batches in a temperature-controlled environment and protect them from moisture.

This consistent storage approach helps maintain the chemical balance you've worked hard to achieve.

Curing Room Setup and Organization

Since successful hot process soap aging depends heavily on environmental conditions, establishing an organized curing room with precise temperature and humidity control is essential. You'll need to maintain temperatures between 55-68°F and a humidity level of 40-60% while ensuring proper ventilation throughout the space.

| Feature | Requirement |

|---|---|

| Temperature | 55-68°F (12-20°C) |

| Humidity | 40-60% |

| Airflow | Continuous ventilation |

| Storage | Spaced shelving units |

Set up your shelving units to maximize air circulation around each soap batch. You'll want to label every batch with production dates and ingredient details to track aging progress effectively. Remember, your curing room's environment directly impacts your soap's final quality, so monitoring these conditions consistently will help you achieve excellent results.

Frequently Asked Questions

How to Age Hot Sauce?

Store your hot sauce in a dark, cool space at 55-68°F. You'll want to keep it in breathable containers for 2-12 months, checking regularly for spoilage. Make certain peppers stay submerged for best results.

Why Is My Hot Process Soap Still Soft?

Your hot process soap's softness could be due to insufficient lye, high water content, incomplete cooking time, premature unmolding, or too many soft oils. You'll need proper curing time and balanced ingredients for firmness.

How to Speed up Barrel Aging?

You'll speed up barrel aging by using smaller barrels, maintaining warmer temperatures, implementing micro-oxygenation, and regularly rotating your barrels. The increased wood contact and oxygen exposure will accelerate flavor development considerably.

Is Hot Process Soap Better Than Cold Process Soap?

You'll find that neither hot nor cold process soap is definitively "better." They each have unique advantages – hot process offers quicker use and more control, while cold process provides smoother texture and traditional appeal.

In Summary

You'll find aging hot process batches becomes easier once you've mastered these storage and monitoring techniques. Keep your temperature stable, maintain proper moisture levels, and guarantee good air circulation. Don't forget to check pH levels regularly and organize your curing space efficiently. With consistent attention to these details, you'll achieve perfectly aged soap batches that retain their essential oils and quality characteristics.

Leave a Reply