For handmade soap curing, you'll find three reliable rack materials: wire mesh, bamboo, and coated metal. Wire mesh provides ideal air circulation and easy cleaning between batches. Bamboo offers natural antimicrobial properties with up to 99.8% bacterial inhibition while remaining sustainable. Coated metal racks deliver industrial strength with protective layers preventing chemical reactions with your soap. Each option balances durability with functionality, ensuring your handmade bars cure evenly and efficiently. Discover which material best suits your specific production needs.

Wire Mesh: The Breathable Classic for Even Curing

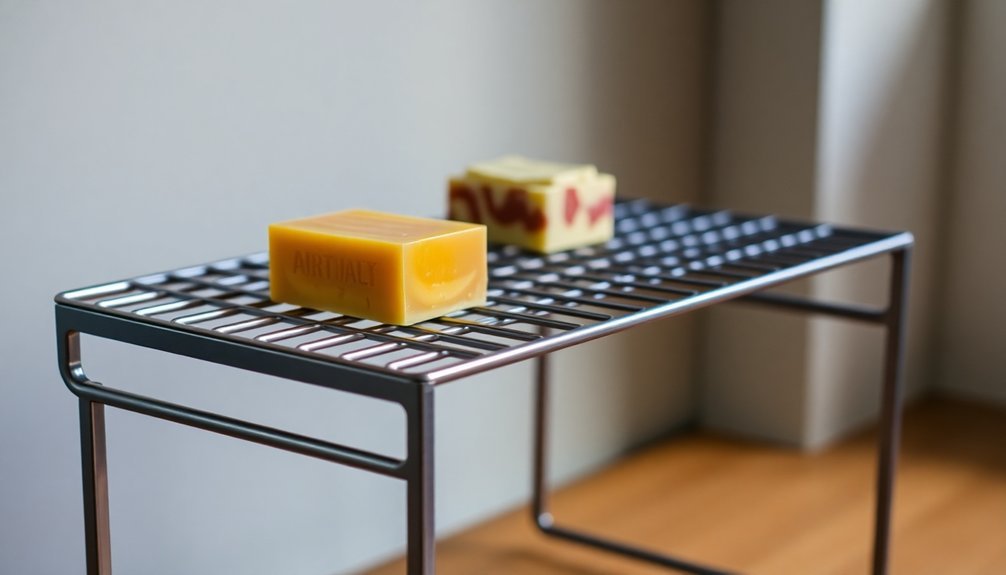

When you're seeking the perfect material for soap curing racks, wire mesh stands out as an exceptional choice. Its open structure allows air to circulate freely around your handmade bars, ensuring even curing from all sides.

Wire mesh offers remarkable durability while remaining cost-effective in the long run. You'll appreciate how easily these racks can be cleaned between batches, minimizing downtime in your production process.

Invest once in wire mesh racks and enjoy years of easy cleaning and efficient soap production.

The interwoven structure provides secure placement for your bars, preventing accidents and product damage. For specialized needs, you can opt for custom configurations or stainless steel options that meet hygiene requirements.

Wire racks also maximize your workspace through vertical stacking capabilities while maintaining visibility for monitoring your products. With minimal maintenance and straightforward installation, wire mesh delivers reliable performance for years to come.

Bamboo Materials: Sustainable and Naturally Antimicrobial

Bamboo curing racks represent a powerful alternative to wire mesh for eco-conscious soapmakers.

These racks harness bamboo's natural antimicrobial properties, with studies showing up to 99.8% bacterial inhibition thanks to the bio-agent bamboo kun, which fights bacteria and fungi without additional treatments.

You'll appreciate bamboo's exceptional durability and breathability, creating ideal conditions for even soap curing.

Unlike synthetic materials, bamboo maintains its antimicrobial effectiveness even after repeated use and cleaning.

It's also hypoallergenic and biodegradable, reducing your ecological footprint throughout its lifecycle.

Cost-effectiveness makes bamboo particularly attractive for small businesses.

The material requires minimal maintenance, resists moisture damage, and adds aesthetic appeal to your production space.

For reliable performance with environmental benefits, bamboo curing racks deliver compelling advantages.

Coated Metal Options: Durability Meets Non-Reactivity

Coated metal racks offer the perfect blend of industrial strength and chemical inertness for serious soap makers. These racks typically feature steel cores with protective vinyl, powder, or epoxy coatings that prevent unwanted reactions with your soap ingredients.

| Feature | Benefit |

|---|---|

| Rust resistance | Extends rack lifespan in humid environments |

| High weight capacity | Accommodates large soap batches without sagging |

| Adjustable shelving | Customizable for different soap sizes and quantities |

| Easy cleaning | Maintains hygiene standards between batches |

You'll find options like the heavy-duty AWT Rack-It with its powder-coated finish or the Flinn Scientific Drying Rack with vinyl coating. For budget-conscious crafters, repurposed metal storage units can serve as effective alternatives, while custom fabrication lets you tailor specifications to your specific workflow.

Frequently Asked Questions

How Long Do Different Curing Rack Materials Typically Last?

You'll find metal racks last several years, plastic ones a few years, wooden racks endure if properly sealed, and cardboard boxes typically manage just one or two uses before needing replacement.

Can Curing Racks Affect the Scent of My Soap Bars?

Yes, curing racks can affect your soap's scent. Some materials absorb fragrances, while proper airflow helps preserve scents. You'll want to avoid plastic racks and keep different scented soaps separated during curing.

What Materials Work Best for Extremely Humid Environments?

For extremely humid environments, you'll find stainless steel and recycled plastic most effective. They won't corrode or warp in high moisture. Consider powder-coated or chrome finishes for additional protection against humidity damage.

Are Pvc-Based Materials Safe for Soap Curing?

PVC-based materials aren't ideal for soap curing as they may release chemicals when exposed to moisture. You'll find safer alternatives in bamboo, stainless steel, or powder-coated metal that won't react with your soap's alkalinity.

How Do I Prevent Soap Bars From Sticking to Rack Surfaces?

To prevent soap bars from sticking, cover your rack with parchment paper, guarantee surfaces are dry before placing soaps, use non-porous materials like food-grade polyethylene, and rotate bars regularly during curing.

In Summary

When selecting your curing rack material, you'll find each option offers unique benefits. Wire mesh provides ideal airflow, bamboo combines sustainability with antimicrobial properties, and coated metals deliver long-lasting performance without chemical interactions. Choose based on your specific soap-making needs, budget, and environmental values. You're now equipped to make an informed decision that'll enhance your handmade bar curing process.

Leave a Reply