Temperature and humidity directly impact how long your soap batches take to cure. You'll get ideal results when you maintain temperatures between 70-85°F and humidity levels of 50-70%. Higher temperatures speed up curing but risk separation, while colder conditions extend curing time. Too much humidity slows evaporation, and too little causes rapid drying that can compromise quality. Mastering these environmental factors will help you achieve the perfect batch every time.

Understanding Temperature's Role in Soap Curing

When making soap, temperature plays an essential role in how quickly and effectively your bars will cure. Just like concrete curing requires specific conditions, your soap needs the right temperature environment to achieve ideal results.

You'll find the sweet spot between 70°F and 85°F, where saponification occurs most efficiently.

While higher temperatures can speed up your curing process, you'll want to be careful not to let things get too hot. Excessive heat can cause your mixture to separate or overheat, compromising the final product.

Conversely, if your curing area's too cold, you're looking at extended curing times and potential quality issues. Maintaining steady temperature conditions is vital, as fluctuations can affect both humidity levels and moisture evaporation, ultimately impacting your soap's texture and durability.

Optimal Humidity Levels for Batch Processing

Just as temperature influences curing time, maintaining proper humidity levels is crucial for successful batch processing.

You'll want to keep humidity between 50% and 70% to guarantee your batches retain the right amount of moisture for proper hydration.

When you maintain ideal humidity levels, you're creating perfect conditions for the curing process, resulting in stronger and more durable concrete.

High humidity works to your advantage by slowing down evaporation, which gives your concrete extended hydration time and reduces cracking risks.

If you're working in low-humidity environments, you'll need to implement additional moisture-retention strategies like water sprays or wet coverings.

Consider using water-reducing admixtures to help maintain workability while reducing the overall water content needed to achieve ideal humidity levels during curing.

The Science Behind Environmental Curing Factors

Understanding curing factors starts with heat transfer mechanisms, where temperature directly influences the concrete's hydration rate and can make or break your final product's strength.

You'll find that humidity works alongside temperature through moisture regulation, as proper water content enables the essential chemical reactions needed for ideal concrete development.

When you're setting up environmental control systems, you'll need to balance both temperature and humidity carefully – keeping temperatures between 50°F and 90°F while maintaining adequate moisture levels through techniques like wet burlap or fogging systems.

Heat Transfer Mechanisms Explained

The complex interplay between temperature and humidity during concrete curing relies on two primary heat transfer mechanisms: conduction and convection. You'll find that concrete temperature changes as heat moves through the matrix via conduction, while airflow around the surface facilitates convection. These mechanisms directly impact how Humidity Affects the curing process.

| Parameter | Low Level | High Level | Effect |

|---|---|---|---|

| Temperature | <50°F | >85°F | Affects hydration rate |

| Relative Humidity | <50% | >80% | Controls moisture loss |

| Air Movement | Stagnant | Active | Distributes heat |

| Heat Transfer | Minimal | Ideal | Guarantees even curing |

Understanding these mechanisms helps you control the curing environment. When relative humidity is too low and temperatures are high, you'll need to manage moisture loss carefully to prevent compromising the concrete's strength and durability.

Humidity's Impact on Curing

While concrete strength depends on multiple factors, humidity plays a vital role in determining the success of the curing process. You'll find that higher humidity levels are beneficial, as they slow down evaporation and allow for better hydration, resulting in stronger concrete structures.

When you're working in low-humidity environments, you'll need to be extra vigilant. The increased evaporation rate can quickly rob your concrete of essential moisture, leading to weakened structural integrity and potential cracking.

To combat this, you can employ various moisture-retention techniques like water sprays or wet burlap coverings.

Understanding your local climate is important, as humidity levels will directly impact how you manage the curing process. You'll need to adapt your approach and implement appropriate moisture-control strategies to guarantee the best concrete strength development.

Optimizing Environmental Control Systems

Successfully managing concrete curing requires precise control of both temperature and humidity through well-calibrated environmental systems.

You'll need to maintain air temperature between 50°F and 90°F while keeping humidity levels at 40-70% for ideal results.

To achieve these conditions, you can employ water sprays or fogging systems that help regulate moisture levels around your concrete.

These systems are particularly essential when you're dealing with challenging climate conditions that could otherwise compromise the curing process.

You'll find that maintaining proper humidity slows down evaporation, allowing for better hydration and stronger concrete development.

Remember that your environmental control strategy should adapt to local weather patterns.

Whether you're working in a dry or humid climate, you'll need to adjust your approach to guarantee consistent curing conditions.

Managing Air Circulation During Curing Phases

Proper air circulation stands as a cornerstone of effective concrete curing, playing a vital role in maintaining consistent humidity levels and preventing uneven drying patterns.

During hot weather conditions, you'll need to carefully monitor the amount of water retention, as excessive air movement can accelerate moisture loss.

You can optimize your curing process by implementing controlled ventilation systems or strategically placed fans. These tools help balance temperature differences while ensuring even moisture distribution across all concrete surfaces.

When you're managing airflow, it's important to avoid both extremes – too much circulation can cause rapid drying, while insufficient airflow creates stagnant pockets that hinder proper curing.

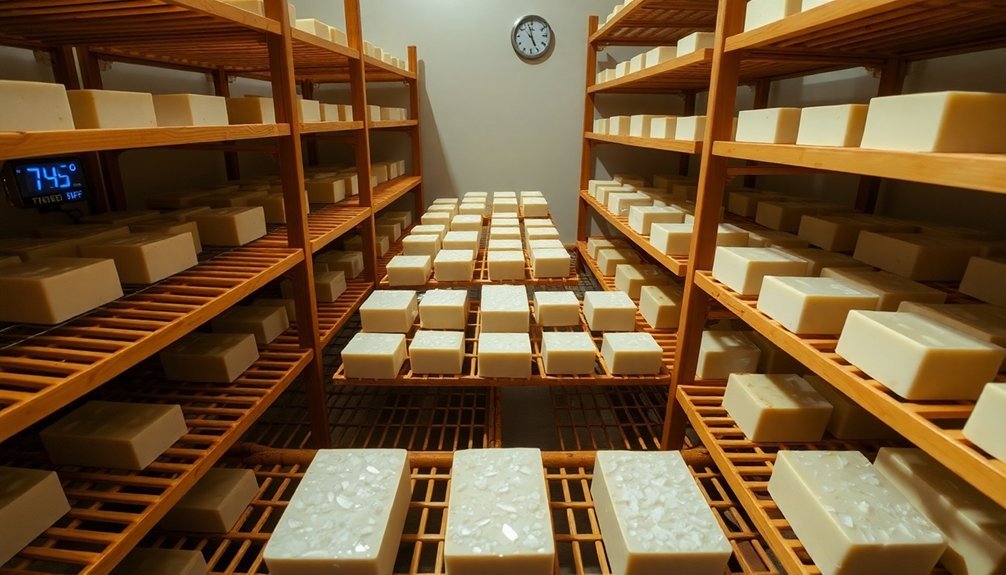

Storage Area Requirements and Conditions

Your storage area must maintain temperatures between 50°F and 90°F to guarantee proper concrete curing and prevent premature moisture loss.

You'll need to keep humidity levels above 50% while implementing moisture-retaining methods like wet coverings or fogging systems in drier environments.

When setting up your storage space, prioritize adequate ventilation to prevent heat buildup that could compromise the concrete's strength and durability.

Optimal Storage Temperature Ranges

When storing concrete materials, maintaining temperatures between 50°F and 90°F is crucial for ideal curing results.

You'll want to monitor your storage area closely, as temperatures outside this range can greatly impact your concrete's performance.

If your storage temperatures rise above 90°F, you'll notice accelerated curing times that can weaken the concrete's final strength and make it harder to work with.

Conversely, if temperatures drop below 50°F, the curing process will slow down considerably, and you'll need to implement additional measures to maintain proper moisture and temperature levels for hydration.

You'll need proper ventilation to regulate both temperature and humidity in your storage space.

This helps prevent condensation and guarantees your concrete materials maintain their quality throughout the curing process.

Moisture Control Best Practices

Maintaining precise moisture control in concrete storage areas requires careful attention to both environmental conditions and protective measures.

You'll need to keep your storage facility between 50°F and 85°F with humidity levels under 70% to prevent premature hydration. Use waterproof bags or silos for cement storage, and implement proper ventilation to prevent condensation that could compromise your materials.

- Don't let your hard work go to waste – protect your materials with moisture-retaining covers like wet burlap or plastic sheeting to shield them from sunlight and wind.

- Stay ahead of potential problems by regularly checking aggregate moisture content – it's vital for achieving the perfect water-to-cement ratio.

- Take control of your storage environment – proper ventilation isn't just helpful, it's essential for preventing costly material degradation and mix integrity issues.

Seasonal Changes and Their Impact on Curing

As seasons shift throughout the year, the curing process for concrete requires careful adaptation to changing environmental conditions. You'll need to adjust your curing strategies to combat temperature and humidity fluctuations that can make or break your project's success.

| Season | Challenges | Solutions |

|---|---|---|

| Summer | Rapid evaporation | Use fogging systems |

| Spring | High humidity | Reduce water content |

| Fall | Variable conditions | Monitor moisture levels |

| Winter | Slow hydration | Extend curing time |

| Changeover | Unpredictable weather | Daily adjustments |

During summer's heat, you'll face accelerated evaporation rates that demand increased moisture retention efforts. Winter's cold temperatures will slow down the hydration process, requiring longer curing periods. Spring's humid conditions can actually work in your favor by naturally slowing evaporation, while fall's drier air might necessitate additional moisture control measures. You'll need to stay vigilant and adjust your methods based on these seasonal variations.

Measuring and Monitoring Environmental Parameters

To effectively manage seasonal variations in concrete curing, you'll need precise measurement tools and monitoring systems. By using dry bulb temperature probes, you'll get accurate ambient air readings, while wet bulb probes with saturated cloth will help you track humidity levels.

Understanding the relationship between these measurements is essential, as it directly affects moisture retention and evaporation rates in your concrete.

- You'll feel more confident knowing your concrete's strength is developing properly when you maintain consistent monitoring practices.

- You'll reduce anxiety about project outcomes by catching environmental fluctuations early.

- You'll gain peace of mind from having reliable data to support your curing decisions.

Remember that high humidity slows moisture evaporation, while proper temperature control guarantees ideal curing conditions.

Regular monitoring helps you avoid strength inconsistencies and durability issues in your finished product.

Common Temperature and Humidity Challenges

When you're working with concrete in varying weather conditions, you'll encounter several critical temperature and humidity challenges that can impact the curing process. High temperatures can speed up curing but risk rapid moisture loss and cracking, while low humidity accelerates surface drying and may compromise strength. You'll need to monitor these conditions carefully and adjust your techniques accordingly.

| Condition | Challenge |

|---|---|

| High Temperature | Rapid moisture evaporation, increased cracking risk |

| Low Temperature | Slower chemical reactions, extended setting time |

| High Humidity | Slower evaporation, longer curing period needed |

| Low Humidity | Quick surface drying, inadequate hydration |

To address these challenges, you'll often need to implement specific curing methods like wet coverings or fogging systems to maintain ideal moisture levels throughout the process.

Best Practices for Climate Control

While achieving ideal concrete curing requires careful attention to environmental conditions, you'll need to implement specific climate control measures to maintain peak temperatures and humidity levels.

Successful concrete curing demands precise environmental control through targeted measures that optimize temperature and humidity throughout the process.

You can actively control your curing environment by installing temperature monitoring systems and humidity gauges to track conditions in real-time. When you notice deviations, quickly adjust your climate control systems to maintain the 70-80°F sweet spot and humidity levels above 50%.

- Don't let your concrete fail – install fogging systems or water sprays to maintain consistent moisture levels and prevent devastating surface cracks.

- Take control of your environment – use wet burlap covers during low humidity conditions to protect your investment.

- Stay vigilant – monitor local weather patterns and adapt your curing methods to guarantee your concrete reaches its full strength potential.

Equipment and Tools for Environmental Control

Three vital types of equipment form the backbone of effective concrete curing: environmental control systems, moisture retention tools, and monitoring devices.

You'll need HVAC systems and dehumidifiers to maintain ideal temperature and humidity levels throughout the batch curing process.

For moisture retention, you can deploy curing blankets and wet burlap to prevent rapid water evaporation, while water sprays and fogging systems help extend the concrete's hydration period.

These tools work together to enhance strength development during curing.

To guarantee precise environmental control, you'll want to implement automated monitoring systems that track temperature and humidity in real-time.

Don't forget to regularly calibrate your thermometers and hygrometers – accurate measurements are vital for adjusting conditions and achieving ideal curing times.

Adapting Curing Times to Different Climates

Since concrete curing times vary dramatically across different climates, you'll need to adjust your approach based on local conditions.

In hot weather, you'll find curing times decrease as evaporation accelerates, while cold environments require longer durations to guarantee complete hydration. High humidity levels naturally slow down evaporation, giving you extended hydration periods for ideal strength development.

- Don't let your hard work go to waste in dry, arid conditions – protect your concrete using wet burlap or curing compounds to prevent moisture loss.

- Watch out for cold weather challenges that can compromise your concrete's integrity if you rush the curing process.

- Take advantage of humidity's natural benefits in moist climates, but stay vigilant to avoid over-saturation.

Remember to monitor environmental conditions consistently and adjust your curing strategy accordingly for the best results.

Frequently Asked Questions

How Does Humidity Affect Curing?

When you're curing concrete, high humidity slows evaporation and promotes stronger concrete through extended hydration. You'll notice that low humidity causes rapid moisture loss, which can lead to cracking and weaker structures.

How Does Temperature Affect Curing Time?

You'll notice that higher temperatures speed up your concrete's curing time, while cooler temperatures slow it down. For ideal results, you should maintain temperatures between 50°F and 86°F during the curing process.

Is 70% Humidity Too High for Curing?

No, 70% humidity isn't too high for curing concrete. It's actually beneficial as it helps maintain moisture and promotes proper hydration. You'll want to monitor the surface carefully though to guarantee proper finishing.

What Is the Best Temperature and Humidity for Curing Meat?

You'll want to maintain temperatures between 34-38°F (1-3°C) and keep humidity at 70-80% for ideal meat curing. These conditions guarantee proper enzymatic activity while preventing spoilage and promoting even moisture distribution.

In Summary

You'll get the best curing results by maintaining temperature between 65-80°F and relative humidity at 45-55%. Don't forget to check your storage area's ventilation and use proper monitoring tools to track conditions. When your environment isn't ideal, you'll need to adjust curing times accordingly. Remember, consistent conditions are more important than perfect ones, so focus on stability over exact numbers.

Leave a Reply