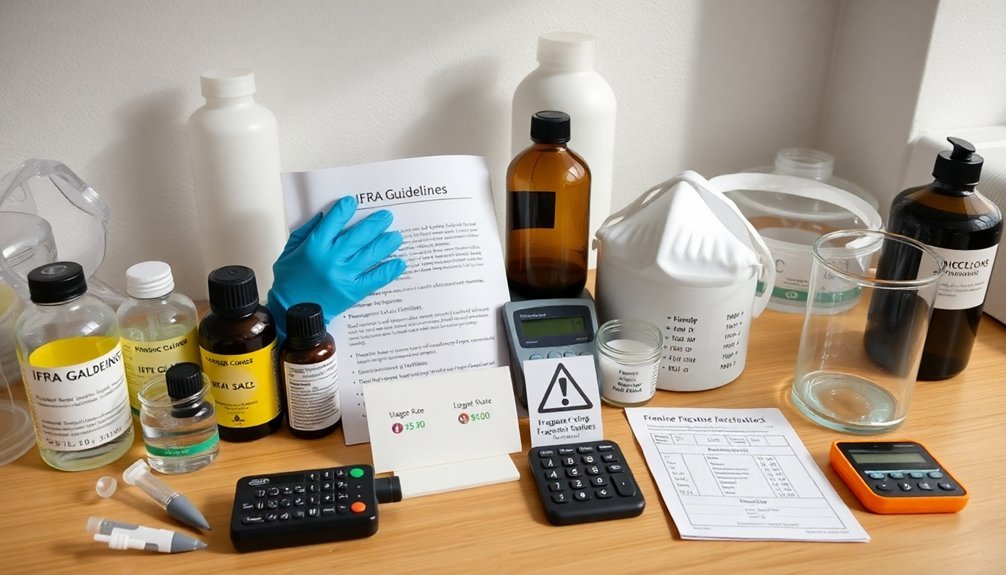

To protect yourself when adding fragrances to soap, always wear nitrile gloves, safety goggles, and consider a respirator for strong scents. Guarantee proper ventilation with open windows or exhaust fans. Follow IFRA guidelines for safe usage rates (typically 0.1-5%) and test new fragrances in small batches first. Store oils in dark glass containers away from heat and sunlight. Keep safety data sheets nearby for emergencies. The right precautions will transform your crafting experience from potentially hazardous to confidently creative.

Numeric List of 12 Second-Level Headings

Every successful soap maker needs to master several essential safety practices when working with fragrances.

When crafting your soap-making workflow, consider these critical areas for protection:

- Understanding Fragrance Oil Composition

- Proper Ventilation Requirements

- Personal Protective Equipment

- Calculating Safe Usage Rates

- Temperature Management Techniques

- Fragrance Oil Storage Solutions

- Scent Fixative Applications

- Testing Procedures for New Fragrances

- Documentation of Formulations

- Allergen Awareness and Labeling

- Equipment Cleaning Protocols

- Emergency Response Planning

Following these guidelines helps you work safely with fragrance oils while creating beautiful, aromatic products.

Remember to test each new scent in small batches before committing to larger production runs, and always respect the recommended usage rate for each specific fragrance.

Essential Safety Gear for Handling Soap Fragrances

Working with fragrance oils requires proper protective equipment, including gloves to prevent skin irritation, safety goggles to shield your eyes from splashes, and a respirator to avoid inhaling harmful fumes.

You'll need to establish adequate ventilation in your workspace as your top priority, since it helps disperse volatile organic compounds that can cause respiratory issues.

Keep your safety data sheets accessible for quick reference about the specific hazards associated with each fragrance you're using in your soap-making process.

Protective Equipment Essentials

Safety precautions shouldn't be overlooked when handling fragrance oils for soap making, as these concentrated substances can cause serious skin irritation and health issues.

Your protective equipment arsenal should include nitrile or latex gloves to create a barrier between your skin and potentially irritating fragrance oils.

Don't forget eye protection—safety goggles are essential to shield your eyes from accidental splashes or spills. A lab coat or apron provides an additional layer of protection for your clothing and skin.

Proper ventilation is vital; work near an open window or use a fan to redirect fumes away from your breathing zone.

If you're working with particularly potent fragrance oils, consider wearing a mask or respirator to prevent respiratory irritation and long-term sensitivity issues.

Ventilation Matters Most

The environment you work in plays a critical role in your safety when handling fragrance oils. Proper ventilation prevents respiratory irritation and allergic reactions that can occur when these potent substances become airborne. Set up your workspace near an open window or install an exhaust fan to efficiently disperse fumes while mixing.

- Always wear safety goggles to shield your eyes from accidental splashes of concentrated fragrance oils.

- Supplement ventilation with an N95 respirator when working with particularly strong fragrances.

- Use nitrile gloves to protect your skin from direct contact with potentially sensitizing ingredients.

Don't underestimate the importance of airflow—even mild fragrances can cause issues in confined spaces. Your respiratory health depends on creating an environment where harmful compounds don't linger in your breathing zone.

Understanding IFRA Guidelines for Fragrance Usage Rates

When formulating soap, you'll need to follow IFRA guidelines that specify maximum safe percentages for each fragrance oil, typically ranging from 0.1% to 5% depending on the specific ingredients.

These standards aren't arbitrary—they're designed to prevent skin irritation, sensitization, and allergic reactions that can occur when fragrance concentrations exceed recommended thresholds.

You should always check the IFRA classification and Safety Data Sheet for each fragrance before adding it to your soap formula, paying special attention to ingredients known to cause sensitivity in certain individuals.

Maximum Safe Percentages

Three critical factors determine how much fragrance you can safely add to your soap: the specific oil's composition, IFRA guidelines, and your product type.

Most fragrance oils have maximum safe percentages between 3-5% for cold process soap, but these rates vary greatly depending on the chemicals present in each oil.

- Never exceed IFRA guidelines – they're established to prevent skin sensitization and allergic reactions

- Check each fragrance individually – safe usage rates can range from as low as 0.1% to as high as 30%

- Document your formulations – keeping records guarantees consistency and safety compliance

Always consult the manufacturer's safety data sheet before adding any fragrance to your soap.

Following these maximum safe percentages isn't just about regulations—it's about protecting your customers and the reputation of your handcrafted products.

Skin Sensitivity Considerations

Understanding individual skin sensitivity extends beyond simply following maximum percentage limits for fragrance oils. When creating soap, you're crafting products that will have direct contact with diverse skin types, each with unique reactions to fragrance ingredients.

IFRA guidelines account for these variations by establishing safety thresholds based on extensive research into skin sensitization potential. Remember that certain fragrances require considerably lower usage rates than others due to their higher allergenicity.

Always reference the most current IFRA standards, as these undergo regular updates reflecting new dermatological research. For your own protection and that of your customers, conduct patch tests with new fragrance blends before full production.

Consider that personal factors like pre-existing skin conditions can amplify sensitivity reactions even within IFRA-compliant formulations, making a conservative approach to fragrance loading the wisest choice.

Proper Ventilation Requirements in Your Soap Studio

A well-ventilated workspace forms the foundation of safe soap-making practices. When working with fragrance oils, especially those with low flashpoints, you'll need proper ventilation systems to disperse harmful fumes.

Aim for at least six air changes per hour in your studio to maintain healthy air quality and protect yourself from volatile organic compounds.

- Install exhaust fans or keep windows open during soap production

- Consider a dedicated fume hood when working with strong fragrances

- Use air purifiers with activated carbon filters to reduce airborne contaminants

Don't underestimate the importance of wearing a respirator designed for organic vapors during mixing and pouring stages.

This added protection, combined with good ventilation, will greatly reduce your exposure to potentially harmful fumes throughout the soap-making process.

Signs of Fragrance Sensitivity and Allergic Reactions

How will you know if you're experiencing a negative reaction to fragrance oils? Your body will typically alert you through skin irritation, redness, itching, or rashes shortly after exposure to scented products.

These are common indicators of fragrance sensitivity. More serious allergic reactions may manifest as hives, swelling, or respiratory issues requiring immediate medical attention.

With fragrance allergies affecting approximately 1-3% of the population and increasing, you shouldn't ignore these warning signs. Always conduct a patch test before incorporating new fragrance oils into your soap formulations, especially if you've experienced sensitivities previously.

Apply a small amount to your skin and monitor for reactions. Following IFRA guidelines for safe usage levels will also help minimize potential allergic responses in both yourself and your customers.

Safe Storage Practices for Essential and Fragrance Oils

Proper storage of your fragrance materials serves as the foundation for both safety and product quality. Your essential oils require specific conditions to maintain their potency and prevent potentially harmful degradation.

Store oils in dark glass containers with airtight lids in cool, dry locations away from direct heat and sunlight.

- Always label containers with the oil name, purchase date, and expiration date to track freshness

- Consider refrigeration for delicate oils that are particularly volatile or sensitive

- Check storage practices regularly as essential oils typically last only 1-3 years

Implementing these storage practices won't just extend your oils' lifespan—it'll guarantee your soap making remains safe while delivering consistent fragrance quality in your finished products.

How to Conduct Patch Testing Before Full Production

Before committing your fragrances to full soap production, performing thorough patch testing stands as your first line of defense against potential allergic reactions.

Apply a small amount of your finished soap to the inner forearm and wait 24 hours to observe any redness or irritation.

For fragrance oils specifically, create a diluted version using one drop per teaspoon of carrier oil to assess sensitivity more accurately.

Document all results, noting reactions to particular fragrances to build a valuable reference guide for future projects.

If possible, test on diverse skin types, as sensitivity varies widely among individuals.

Always adhere to IFRA guidelines regarding usage limits for each fragrance oil.

This systematic approach to patch testing guarantees you'll create safer products while building confidence in your fragrance selections.

Preventing Chemical Burns When Working With Concentrated Scents

Three critical safety measures stand between you and potential chemical burns when handling concentrated fragrance oils.

Always wear appropriate protective gear including gloves and goggles before touching any concentrated scents. These oils can cause severe irritation or burns when they come into direct contact with your skin or eyes.

- Always dilute concentrated fragrance oils in carrier oils before application

- Perform a patch test with diluted fragrance on a small skin area first

- Read the safety data sheets for specific handling instructions

Never work with fragrances in poorly ventilated areas, as inhaling concentrated fumes can irritate your respiratory system.

When you're handling multiple scents, make sure you're aware of each oil's specific safety requirements, as potency and reactivity vary greatly between products.

Documenting Fragrance Information for Future Reference

Systematically tracking how fragrance oils behave in your soap recipes will save you from repeating costly mistakes.

Create detailed reference cards for each scent, noting acceleration tendencies, discoloration patterns, and ideal usage rates based on your experiences.

Your documentation should include customer feedback on scent performance, allowing you to continually refine your fragrance selections and application techniques.

Recording Fragrance Behaviors

Recording your fragrance experiences diligently can save you from repeating costly mistakes and help you recreate successful formulations. As soap makers know, each fragrance oil can behave differently when introduced to your soap batch.

Document whether the fragrance accelerates trace, causes ricing, or remains well-behaved at various temperatures. Note the exact temperature of your oils and lye solution when adding the fragrance, as this greatly impacts scent retention in the final product.

- Track acceleration, ricing, or separation issues with specific brands and scent types

- Document temperature effects on fragrance performance and stability

- Record post-cure scent strength and longevity for future batch adjustments

This systematic approach transforms your personal experiences into valuable reference data, helping you anticipate potential issues and reproduce your most successful scented creations.

Creating Reference Cards

A well-organized reference card system transforms chaotic fragrance experimentation into methodical soap making. For each fragrance oil, document the supplier, IFRA maximum usage rates, and behavioral characteristics like acceleration or ricing tendencies.

Detail each scent profile by breaking down the top, middle, and base notes, providing valuable insight for future blending projects. Record previous batch outcomes, noting any issues like seizing or discoloration that occurred during processing.

Include a section for recommended additives that enhance scent longevity. Note which fragrances benefit from anchoring agents like kaolin clay or other fixatives that improve retention.

These extensive reference cards become your personalized fragrance encyclopedia, saving time and materials while helping you consistently create successful, beautifully scented soaps with confidence.

Emergency Protocols for Fragrance Spills and Exposures

Accidents happen quickly when working with fragrance oils, so you'll need to know exactly how to respond. Always keep your MSDS handy for each fragrance oil you use, as they contain specific emergency procedures for different substances.

Wearing personal protective equipment like gloves and goggles is your first line of defense against potential exposures.

If an incident occurs despite precautions:

- For skin contact: Immediately wash with soap and water for at least 15 minutes to prevent irritation or allergic reactions

- For eye exposure: Rinse thoroughly with clean water for 15 minutes and seek medical help if irritation continues

- For inhalation: Move to fresh air immediately and get medical assistance if breathing becomes difficult

Temperature Considerations When Adding Fragrances

Temperature plays a significant role in how fragrances behave when added to your soap mixture. For ideal scent retention, you'll want to monitor both oil and lye solution temperatures carefully.

Add your fragrances when the soap has cooled to 100°F-130°F, especially with essential oils that have low flashpoints below 200°F. High temperatures during the gel phase (160°F-200°F) can cause essential oils to evaporate or alter their scent profiles.

Fragrances known to accelerate trace should be added at lower temperatures to maintain control over the mixing process. This prevents rapid thickening and potential "soap volcanoes."

If you anticipate a gel phase, leave your soap at room temperature after adding fragrances. This temperature consideration helps preserve aromatic properties and prevents unwanted chemical reactions that could diminish your soap's scent.

Child and Pet Safety Measures for Soap Making Areas

Keeping your soap making area secure should be a top priority, especially when children and pets are in the household.

Create a designated space with a door that can be closed while working with potentially harmful ingredients like lye and fragrance oils. Always store your supplies in child-proof containers and place them out of reach when not in use.

- Verify proper ventilation in your workspace to prevent respiratory issues from fragrance inhalation

- Wear protective gear (gloves and goggles) even when you think children and pets aren't nearby

- Educate older children about safety measures, allowing supervised participation only when appropriate

Frequently Asked Questions

Is Fragrance in Soap Safe?

Fragrance in soap can be safe if you're using proper concentrations. You'll need to follow IFRA guidelines, source from reputable suppliers, and conduct patch tests to avoid skin irritation or allergic reactions.

Should You Wear a Mask When Making Soap?

Yes, you should wear a mask when making soap to protect yourself from inhaling irritating fragrance oils and essential oil vapors. This is especially important if you're sensitive to chemical fumes during mixing.

What Happens if You Put Too Much Fragrance in Soap?

If you put too much fragrance in soap, you'll risk skin irritation, soap seizing during production, overheating, poor scent retention, and possible separation of ingredients, resulting in an unusable or problematic final product.

When to Add Fragrance When Making Soap?

Add fragrance at trace for even distribution. You can also try mixing it with oils before lye if you're concerned about scent retention. Test different timing methods as each fragrance behaves uniquely in your soap.

In Summary

When handling fragrances in soapmaking, you're protecting not just yourself but others who'll use your products. Don't skip safety gear, proper ventilation, or documentation steps. Always respect temperature guidelines, follow IFRA standards, and keep your workspace secure from children and pets. By developing these responsible habits, you'll guarantee your creative process remains safe and enjoyable while producing soap that's both beautiful and responsibly crafted.

Leave a Reply