In soapmaking, essential oil guidelines revolve around concentration, safety, and scent retention. You'll need to keep usage rates between 0.5-5% depending on the specific oil, with cinnamon leaf at 0.5% and citrus oils at 2-3%. Always weigh oils by weight, not volume, and store in dark glass bottles away from heat. Blending top, middle, and base notes helps combat scent fade. Understanding these principles guarantees your soaps remain both safe and fragrant throughout their shelf life.

What Essential Oil Guidelines Matter In Soapmaking?

When crafting your homemade soaps, understanding essential oil usage rates stands as the foundation of both safety and effectiveness.

Most formulations require concentrations between 5-30%, with experts typically recommending 30-35g of essential oils per 1kg of base oils for cold process soap.

Always check IFRA guidelines for maximum usage rates of specific oils—some, like cinnamon leaf, shouldn't exceed 0.5% due to potential skin reactions.

For lasting scent retention, create essential oil blends that combine middle and base notes, and consider how your chosen base oils might affect fragrance strength.

Measure by weight rather than volume for precise results, especially in larger batches.

Don't overlook allergen information on your packaging—this attention to safety standards protects your customers and demonstrates your professionalism as a soapmaker.

Understanding Essential Oil Concentration Limits

When working with essential oils in soap, you'll need to observe maximum usage rates that typically range from 5% to 30% of your total formula, with most soapmakers following the guideline of no more than 30-35 grams per kilogram of base oils.

Calculate your essential oil percentages by weight rather than volume for consistency and accuracy, especially since specific oils like cinnamon leaf (0.5%) and ylang ylang (1.4%) have different safety thresholds.

You can consult IFRA guidelines to guarantee you're using correct concentrations, as exceeding these limits may result in skin irritation or quality issues in your finished soap.

Maximum Usage Rates

Three critical factors govern essential oil usage in soapmaking: safety, effectiveness, and compliance with industry standards. As a soapmaker, you'll need to follow maximum usage rates that typically range from under 1% to 5%, depending on each oil's safety profile. For cold process soap, aim for 30-35 grams of essential oils per kilogram of base oils (3-5%).

| Essential Oil | Max Rate | Primary Concern | Safe Usage |

|---|---|---|---|

| Standard Oils | 3-5% | Effectiveness | 30-35g/kg |

| Cinnamon Leaf | 0.5% | Skin Irritation | 5g/kg |

| Citrus Oils | 2-3% | Oxidation | 20-30g/kg |

| Spice Oils | 1-2% | Sensitization | 10-20g/kg |

Always consult IFRA guidelines before creating your essential oil blend. Exceeding recommended usage rates may cause adverse skin reactions and compromise your soap's quality.

Calculating Oil Percentages

Precise calculation of essential oil percentages forms the foundation of safe soapmaking. When formulating your soap recipe, you'll need to calculate the finished percentage of each essential oil to guarantee you're within maximum usage levels.

For most applications, maintain concentration of oils between 5-30% of your total soap formula, with an upper limit of 30-35 grams per kilogram of base oils.

Always measure essential oils by weight rather than volume, especially for larger soap batches, as this provides greater accuracy.

Refer to IFRA guidelines for specific limitations—cinnamon leaf oil shouldn't exceed 0.5%, while ylang ylang can go up to 1.4%. Exceeding these recommendations risks skin safety issues like allergic reactions or compromised soap quality.

Remember that proper calculation isn't just about fragrance strength—it's primarily about creating products that are gentle and safe for skin.

Blending Notes: Top, Middle, and Base Oils for Lasting Scent

Creating a perfectly balanced soap fragrance requires understanding the essential oil classification system of notes.

When formulating your soap making blends, combine all three note types for complexity and staying power.

Top notes like citrus essential oils provide immediate impact but fade quickly if used alone. They're what you'll smell first, but need anchoring.

Middle notes, including lavender and rosemary, form the heart of your fragrance and blend well with both top and base components. They bridge the gap between initial impression and final character.

For lasting aroma, incorporate base notes such as patchouli or cedarwood. These slower-evaporating oils guarantee your soap's scent lingers long after use.

The ideal essential oil to use ratio is typically a balance of all three categories for a well-rounded, enduring fragrance.

Calculating Proper Usage Rates by Weight

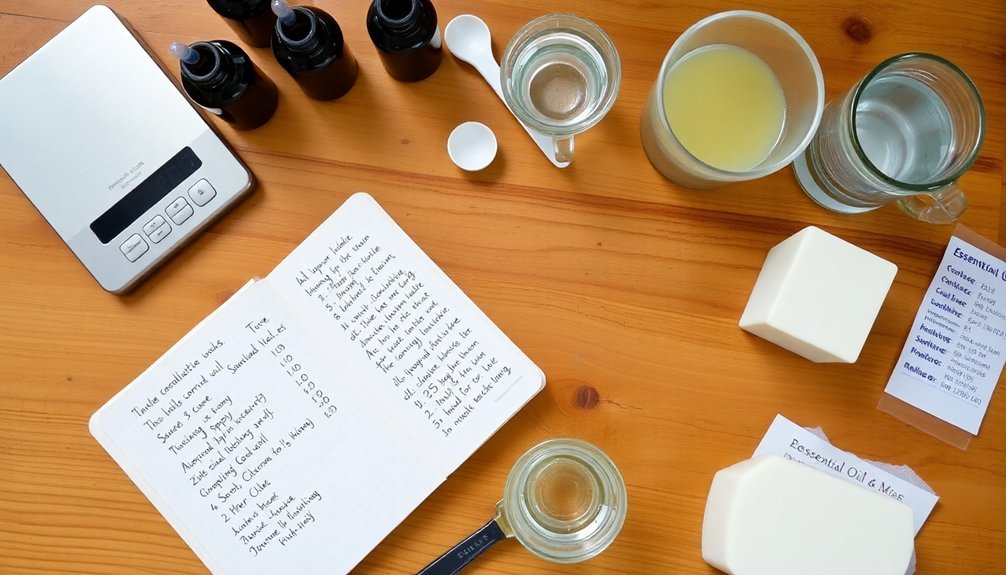

When making soap with essential oils, you'll need to weigh them precisely using a scale rather than measuring by volume since different oils have varying densities.

Your total essential oil percentage should typically range between 3-5% of your base oil weight, or approximately 30-35 grams per kilogram for cold process soap.

Always check IFRA guidelines for specific oils, as some like cinnamon leaf have much lower maximum usage rates (0.5%) to guarantee your finished product remains skin-safe.

Measuring With Precision

Although many hobbyists rely on volume measurements, accurate essential oil usage in soapmaking depends on precise weight calculations.

When you're crafting soap, you'll need to measure essential oils by weight rather than teaspoons, especially for larger batches. The standard usage rate ranges from 30-35g of essential oils per 1kg of base oils in cold process soap.

Remember that each essential oil has specific IFRA guidelines—cinnamon leaf shouldn't exceed 0.5%, while ylang ylang can go up to 1.4%. Exceeding these limits risks skin irritation and other adverse reactions.

Always calculate the finished percentage of essential oils in your final soap formulations to guarantee compliance with safety standards. While teaspoons might work for small projects, investing in a quality scale provides the precision necessary for consistent, safe soap products.

IFRA Standards Matter

Precise measurements form just one part of safe soapmaking—you'll also need to understand the specific limits for each essential oil you use.

The IFRA documents establish maximum usage rates that prevent skin irritation and adverse reactions in your finished soap products.

When making cold process soap, follow these critical guidelines:

- Always limit essential oils to approximately 3% (30-35g per 1kg of oils) unless IFRA documents specify lower rates.

- Reference specific limits for each oil—cinnamon leaf's 0.5% differs dramatically from ylang ylang's 1.4%.

- Measure by weight, not volume, to guarantee accurate compliance with safety standards.

- Verify your formulations meet IFRA guidelines if selling in the UK or EU, where compliance isn't optional—it's the law.

Understanding these standards protects both your customers and your soapmaking business.

Soap-Specific Calculation Methods

Calculating essential oil usage rates correctly stands as your first defense against potential skin reactions in finished soap products. For cold process soap, aim for 30-35 grams of essential oils per kilogram of base oils—this typically falls within the recommended 3-6% range that guarantees both fragrance effectiveness and safety compliance.

Always measure your essential oils by weight, not volume. Using a scale provides precision that teaspoons simply can't match, especially when creating larger batches or complex essential oil blends.

Remember that timing matters too—add essential oils after the cooking phase in hot process soap to prevent evaporation at high temperatures.

Regardless of your soap making method, cross-check your calculations against IFRA guidelines to verify your products remain safe for use in your region.

Preventing Skin Irritation: Safety Standards and Testing

When creating handcrafted soaps with essential oils, you'll need to prioritize skin safety through proper dilution rates and testing protocols. Always maintain concentration levels between 3-5% of total soap weight, while following IFRA maximum guidelines for specific oils like cinnamon leaf (0.5%) to prevent skin irritation.

- Conduct patch tests before launching new formulations to identify potential allergic reactions that could damage your reputation and harm customers.

- Follow regional labelling requirements for allergens exceeding 0.01% concentration, particularly important in the UK and EU markets.

- Remember that essential oils are highly concentrated plant extracts that can cause severe adverse effects when misused.

- Adjust your formulations based on customer feedback and evolving safety standards to maintain product integrity.

Anchoring Techniques to Improve Scent Retention

Despite the initial vibrancy of essential oils in soap batches, their fragrance often fades during curing without proper anchoring techniques. To enhance scent retention, focus on incorporating middle and base notes in your essential oil blends, as these provide depth and staying power to your fragrance profile.

The carrier oils you select matter—natural butters like shea can absorb and alter scents in cold process soap.

Try adding fixatives such as arrowroot powder or cornstarch to anchor your essential oils during the saponification process.

Don't overlook your lye solution strength; optimizing it alongside your base oil selection can greatly impact how fragrances perform.

For best results, create well-rounded essential oil blends combining various notes—this balanced approach creates more stable scents that withstand the chemical changes of soapmaking.

Combating Scent Fade in Cold and Hot Process Methods

Soapmakers face distinct challenges with scent retention in both cold and hot process methods. Understanding the science behind scent fade helps you create longer-lasting fragrances in your soap making projects.

For maximum fragrance longevity:

- Select essential oil blends with strong base notes for cold process soap—pair fleeting citrus oils with anchoring companions like litsea cubeba.

- Check flashpoints carefully—choose oils that can withstand 160-200°F gel phase temperatures to prevent premature evaporation.

- Add essential oils after cooking in hot process soap to protect their aromatic compounds from heat degradation.

- Adjust natural butter content thoughtfully—shea and cocoa butters can mask or diminish your carefully crafted scent profile.

Remember that well-rounded essential oil combinations with middle and base notes consistently outperform single-note fragrances in resisting scent fade over time.

Managing Discoloration From Natural Essential Oils

Just as scent requires careful consideration, color presents another fascinating aspect of your soap artistry. When formulating your recipes, remember that darker essential oils like patchouli often cause discoloration, typically resulting in yellow or pale tan hues in your final appearance.

You'll find that essential oils generally cause less discoloration than fragrance oils, making them preferable when you're aiming for color consistency. For minimal color impact, select light oils whenever possible. If you're using folded orange essential oil, expect a light yellow to peach tint—noticeably less dramatic than what darker essential oils produce.

Contrary to what you might expect, a darker essential oil actually indicates minimal discoloration potential. Savvy soapmakers leverage this knowledge when planning soap formulations, strategically selecting oils based on their desired aesthetic outcome.

Handling and Storage Practices for Potency Preservation

Three critical factors determine whether your essential oils maintain their potency in soapmaking: light exposure, temperature control, and proper sealing. Your valuable oils require protective measures to preserve their therapeutic properties and fragrance quality.

- Shield from UV light – Always store essential oils in dark glass bottles to protect them from degradation that diminishes their effectiveness in your soap formulations.

- Monitor temperature – Keep your oils in a cool, dry area away from heat sources that accelerate oxidation and evaporation.

- Seal properly – Tightly close bottles after each use to prevent air exposure that compromises potency.

- Track expiration dates – Label containers with purchase and expiration dates, as most oils remain viable for only 1-3 years.

Never use plastic containers, as they risk contamination and reduce your oils' efficacy.

Frequently Asked Questions

What Is the 30/50/20 Rule for Essential Oils?

The 30/50/20 rule suggests you'll create balanced soap fragrances by using 30% top notes (immediate scents), 50% middle notes (body), and 20% base notes (long-lasting depth). This combination guarantees your scents remain pleasant throughout use.

What Essential Oils Should Not Be Used in Soap?

You shouldn't use phototoxic citrus oils (bergamot, lime), wintergreen (toxic when absorbed), cinnamon bark (severe irritant), pennyroyal, wormwood, and sassafras in soap. They're either dangerous or regulated due to toxicity concerns.

Which Essential Oil Is Good for Soap Making?

You'll find lavender, lemon, patchouli, peppermint, and May Chang essential oils excellent for soap making. They offer appealing aromas and good scent retention at recommended usage rates between 1.5% and 5% of total soap weight.

What Is the Ratio of Essential Oils to Soap Making?

You'll want to use essential oils at 3-5% of your soap's total oil weight, typically 30-35 grams per kilogram. Always check IFRA guidelines for specific oils, as some require lower percentages for skin safety.

In Summary

When making soap with essential oils, you'll need to respect concentration limits, balance your notes, and calculate weights precisely. Don't skip safety testing for potential irritants. Remember to use anchors for scent retention and adopt specific techniques to fight scent fade. Watch for discoloration from natural oils, and store your ingredients properly. Follow these guidelines, and you'll create beautiful, fragrant soaps that delight the senses safely.

Leave a Reply