To master trace control and prevent soap seizing, you'll need to manage temperature, mixing techniques, and ingredient selection. Keep oils and lye below 110°F, blend in short bursts, and choose slow-moving oils like olive or sunflower. Beware of trace-accelerating additives like cinnamon or clove oils. Adjust your water-to-lye ratio to slow the process, aiming for a 1:1 ratio for better control. These strategic adjustments will transform your soaping experience from frustrating to predictable.

9 Second-Level Headings

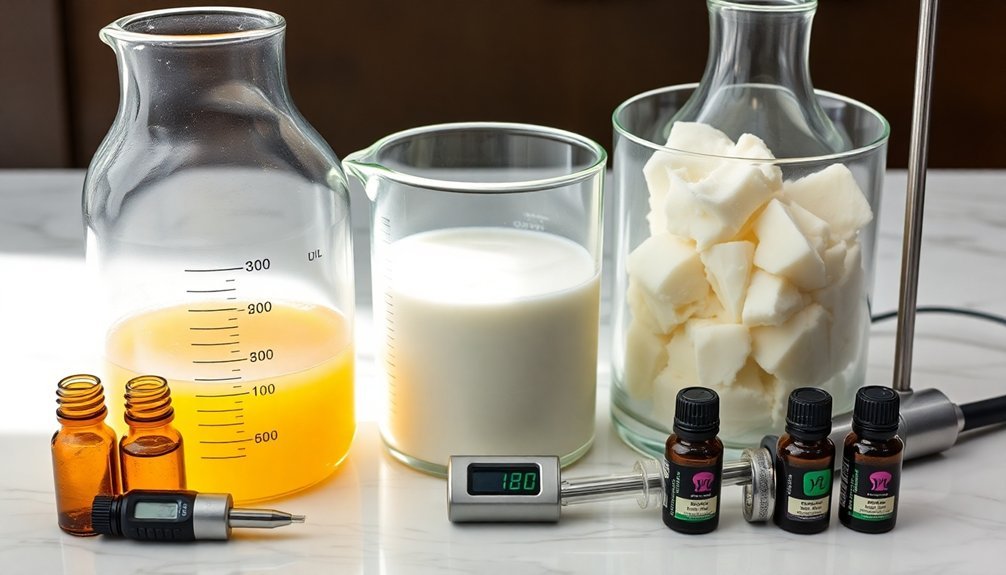

When your soap mixture suddenly turns into "soap on a stick," you're experiencing one of the most frustrating challenges in soapmaking—seizing. This rapid thickening can derail your creative process and ruin intricate designs.

Temperature Control

Keep your oils and lye solution below 110°F to slow saponification and maintain workable trace longer.

Ingredient Management

Certain fragrance and essential oils (especially clove and cinnamon) accelerate trace dramatically.

Start with smaller amounts or blend with milder options.

Mixing Technique

Use your stick blender in short bursts, alternating with hand stirring.

This gives you better control over how quickly your soap thickens.

Rescue Methods

If seizing begins, quickly add small amounts of reserved liquid to regain fluidity, without exceeding the 2:1 water-to-lye ratio.

What Exactly Is Trace and Why Does It Matter?

Trace is your soap batter's transformation from separated oils and lye to an emulsified mixture that will eventually become solid soap.

You'll recognize it when your mixture thickens, holds patterns on the surface, or leaves trails when drizzled from your spatula or stick blender.

Mastering trace recognition and control gives you power over your soap's design possibilities and helps prevent common pitfalls like false trace or acceleration that can ruin your carefully planned creations.

Definition of Trace

The magical moment in cold process soap making occurs when your oils and lye solution transform from separate entities into a unified mixture—this is trace.

You'll recognize it when your soap batter begins to thicken, showing that the oils have successfully emulsified with the lye solution.

Trace comes in different stages—light trace resembles heavy whipping cream, while thick trace looks more like pudding.

As a soap maker, you'll want to understand these variations because they determine what designs you can create and when to add your fragrances and colorants.

If you're working with intricate swirls, aim for light trace; for textured tops, wait for a thicker consistency.

Mastering trace timing gives you control over your soap's appearance and prevents frustrating issues like seizing or false trace.

Visual Recognition Signs

Recognizing trace with certainty separates novice soap makers from experienced artisans. As you develop your soap making skills, learn to identify visual cues that indicate different stages of trace to maintain control over your batch.

- Light trace appears like heavy whipping cream—the batter leaves a faint trail on the surface that quickly disappears, perfect for intricate swirl designs.

- Medium trace resembles cake batter—sustains slight peaks and allows enough working time for simple decorative techniques.

- Thick trace looks like pudding—holds its shape well and works best for textured tops or soap frosting.

- Accelerated trace occurs when the mixture suddenly thickens rapidly—a warning sign that you're losing control of your process.

Mastering these visual signals helps you anticipate timing and avoid the frustration of soap seizing unexpectedly.

Impact on Soapmaking

When you understand the chemistry behind trace, you'll grasp why it represents the cornerstone of successful soapmaking. It marks the critical moment when oils and lye begin emulsifying, signaling that saponification is underway and your soap batch is transforming.

Trace directly affects every design choice you make. Light trace allows for intricate swirls and layers, while thick trace works better for textured tops and chunky embeds. Your oil choices greatly influence how quickly trace develops—coconut oil will accelerate trace while olive oil slows it down.

Maintaining control prevents disastrous outcomes like seizing soap, where your mixture suddenly becomes too thick to pour.

The Science Behind Saponification and Emulsion Stages

During soap making, you'll witness saponification—the exothermic reaction between oils and lye that generates heat while forming soap and glycerin.

You can better manage your soap's consistency by recognizing emulsion (when oils and lye first combine) before it progresses to thin, light, or thick trace stages.

Understanding factors that accelerate trace, such as high temperatures or over-mixing, will help you maintain control during the critical window for adding colorants and creating intricate designs.

Chemical Reactions Explained

The magic of soapmaking lies in its fundamental chemical reaction: saponification. When you combine oils with sodium hydroxide, they transform into soap and glycerin while generating heat. This saponification process accelerates as temperature plays a more significant role, potentially rushing you to trace faster than anticipated.

Understanding what happens chemically helps you control when trace happens:

- Saponification is exothermic – the reaction produces heat that can further speed up the process

- Emulsification precedes trace – this is when oils and lye become a stable suspension

- Fatty acid profiles determine speed – saturated fats in solid oils accelerate trace

- Temperature acts as your timing tool – cooler temperatures give you more working time

Accelerating Trace Factors

Several key factors can dramatically influence how quickly your soap reaches trace, giving you either luxurious working time or rushing you to pour before you're ready.

Temperature plays an essential role—keep your oils and lye solution below 110°F to slow the reaction and maintain control.

Your oil choices matter greatly. Solid oils like coconut accelerate trace, while olive oil provides a more forgiving pace.

The water-to-lye solution ratio directly impacts speed; a 1:1 ratio offers better control over the process.

Be mindful of fragrance selections—clove and cinnamon oils are notorious trace accelerators due to their chemical composition.

Finally, your mixing technique matters. Use your stick blender in short bursts rather than continuous blending to prevent sudden thickening, especially when creating intricate designs.

Monitoring Emulsion Timeline

Understanding emulsion stages gives you precise control over your soap's development before it reaches trace. When oils and lye first combine, they create an emulsion—a uniform consistency that precedes trace but signals your soap batter is properly incorporating.

To master this critical timeline:

- Watch for the disappearance of oil streaks, indicating your emulsion has formed—it should resemble thin custard.

- Avoid over-mixing, which can trigger false trace and limit your design options.

- Recognize that proper emulsion provides a stable foundation for intricate techniques.

- Adjust your mixing intensity based on how quickly you want the soap batter to thicken.

Recognizing Different Trace Stages Before Seizing Occurs

While guiding through the soap-making process, you'll encounter various stages of trace that signal how your soap batter is progressing toward solidification. Learning to identify these trace stages helps you maintain control over your formulation.

Start by recognizing emulsion—when oils and lye water have combined with no visible streaking.

Light trace resembles whipping cream, perfect for intricate designs. As you progress to medium trace, you'll notice a pudding-like consistency that still pours but holds simple patterns.

Thick trace stands up on its own, ideal for textured tops but challenging for detailed work.

Watch carefully for "soap on a stick"—the rapid thickening that precedes seizing. This often happens with certain fragrance oils that accelerate saponification.

Temperature Management: The Key to Predictable Trace

Temperature management stands at the heart of maintaining predictable trace timing. By keeping your oils between 110-120°F, you'll gain better control over how quickly your soap batter thickens.

Cooling your lye solution below 120°F considerably slows saponification, giving you precious extra minutes to work before trace occurs.

For ideal trace speed control, consider:

- Using an infrared thermometer to verify exact temperatures of both oils and lye solution

- Maintaining a 1:1 water-to-lye ratio to regulate the saponification process

- Lowering overall temperatures when working with acceleration-prone additives

- Ensuring consistent temperatures across all ingredients before combining

Remember that hotter temperatures accelerate trace, while cooler temperatures extend your working time.

This temperature balance becomes especially critical when creating complex soap designs requiring longer manipulation time.

Strategic Mixing Techniques to Maintain Control

Once you've mastered temperature management, your mixing technique becomes the next critical factor in controlling trace development.

Use your stick blending in short, controlled bursts rather than continuous running. This gives you time to observe how quickly your soap batter is thickening between pulses.

For ultimate control, consider hand mixing with a whisk or spatula, which lets you closely monitor each stage of trace development.

When adding fragrance oils, incorporate them into your warmed base oils first before introducing the lye mixture—this simple step can prevent unexpected seizing.

Different recipes respond uniquely to mixing intensity, so experiment with varying durations and techniques.

Always avoid extended high-speed blending, which generates excess heat and accelerates trace beyond your control.

Choosing Slow-Moving Oils for Extended Working Time

Your oil selection forms the foundation of trace control, complementing your mixing techniques.

When you're aiming for intricate designs in soap making, incorporating slow-moving oils gives you valuable working time before the batter thickens.

The ideal candidates for extended trace time include:

- Olive oil – creates a 100% olive oil formula for the slowest possible trace

- Sunflower oil – high in unsaturated fatty acids that resist quick thickening

- Sweet almond oil – provides excellent slow trace properties for detailed work

- Rice bran oil – another excellent option with similar slow-moving characteristics

Water Ratio Adjustments to Modify Trace Development

While oil selection provides your foundation, water ratios serve as your timing mechanism in soap making.

Contrary to common belief, decreasing your water content can actually slow down trace speed, giving you more time to execute complex designs before your soap batter thickens.

For ideal control, maintain a 1:1 water-to-lye ratio.

If you're seeking even more working time, experiment with water discounts using a 25% to 33% lye solution concentration. This adjustment directly impacts the saponification process, allowing you to dictate how quickly your soap reaches trace.

Remember that excessive water beyond standard ratios may unexpectedly accelerate trace rather than delay it.

Problematic Additives That Trigger Sudden Acceleration

Despite your best efforts with oil selection and water ratios, certain additives can sabotage your carefully planned soap design by triggering unexpected acceleration.

Understanding which ingredients accelerate trace can help you avoid soap seizure disasters.

Fragrance oils, particularly florals and spices, are notorious for causing rapid saponification. Always research and test these problematic additives in small batches before committing to larger projects.

- Essential oils containing eugenol (like clove and cinnamon) dramatically accelerate trace, making intricate designs challenging.

- Sugar-rich additives such as honey and fruit purees raise batch temperatures and speed up reactions.

- Hard oils, especially coconut oil, reach trace faster than liquid oils like olive.

- Certain colorants including fermented indigo and some clays can trigger sudden thickening.

Frequently Asked Questions

Why Does My Soap Keep Seizing?

Your soap seizes due to fragrance oils containing eugenol, high temperatures above 110°F, excessive stick blending, insufficient soft oils like olive oil, or additives such as sugars or alcohols in your lye solution.

How Do You Save Seized Soap?

To save seized soap, you can gently reheat it in a crock pot, manually stir it with a spoon, or add small amounts of liquid. If it's still too thick, try rebatching by grating and remelting it.

Which Essential Oils Cause Soap to Seize?

Essential oils that cause soap to seize include clove, cinnamon, thyme, oregano, and others high in eugenol or phenols. You'll want to blend these with carrier oils first and test small batches before full production.

Why Is My Soap Not Hardening?

Your soap isn't hardening likely due to excess water, too many soft oils, improper lye balance, or insufficient mixing. Try adjusting your oil-to-lye ratio and using more hard oils in your next batch.

In Summary

You're now equipped with the knowledge to master trace control. By understanding the science, recognizing warning signs, managing temperature, using strategic mixing techniques, selecting slow-moving oils, adjusting water ratios, and avoiding problematic additives, you'll enjoy complete control over your soap's working time. Remember, practice builds confidence—soon you'll predict and adjust trace with expertise, turning potential disasters into beautiful, successful batches every time.

Leave a Reply