Wood ashes create perfect lye because they're naturally rich in potassium and sodium minerals, which react with water to form strong hydroxides. When you burn hardwoods like hickory or sugar maple, you'll get higher concentrations of these essential minerals compared to softwoods. The complete combustion process leaves behind pure mineral residues that, when leached with water, produce the ideal chemical composition for lye. Understanding the specific minerals and process will help you master this ancient craft.

The Chemistry Behind Wood Ash Composition

When wood burns completely, it leaves behind a complex mixture of inorganic minerals that serve as the foundation for traditional lye production.

Wood ash contains vital inorganic minerals that, when properly processed, create the essential lye needed for traditional soap-making.

You'll find that these wood ashes contain high concentrations of sodium and potassium, which are essential elements in creating an effective lye solution.

During the burning process, organic materials oxidize, and what remains are mineral-rich residues containing alkali metals.

These metals, primarily in oxide form, transform into hydroxides when they meet water.

The type of wood you use matters greatly – hardwoods like hickory and maple will give you more minerals than softer varieties.

When you mix the ashes with water, you'll notice the lye solution naturally separates and rises to the top, making it easy to collect for soap-making and other practical applications.

Essential Minerals in Hardwood Species

The mineral profile of hardwood species sets them apart as superior sources for lye production. When you burn hardwoods like hickory, sugar maple, and ash, you'll find they're packed with essential minerals, particularly sodium and potassium, that create effective wood ash lye.

| Hardwood Type | Key Minerals |

|---|---|

| Hickory | Sodium, Potassium |

| Sugar Maple | Potassium, Calcium |

| Ash | Sodium, Magnesium |

| White Oak | Potassium, Sodium |

During combustion, these minerals become highly concentrated as the wood mass reduces to ash. You'll get more bang for your buck with hardwoods because they contain higher mineral concentrations than softwoods. When you mix these mineral-rich ashes with water, they form potassium carbonate and sodium hydroxide – the key components needed for soap making through saponification.

Traditional Methods of Ash Collection

When gathering ashes for lye production, you'll want to focus on broad-leaved hardwoods like hickory and sugar maple, which provide the richest mineral content for high-quality lye.

You should wait until the wood has burned completely, ensuring all chunks have turned to fine ash before collection.

Once cooled, you'll need to sift the ashes through a flour sifter to separate the pure white ash from any remaining unburnt pieces, storing the filtered material in a dry, non-metallic container.

Hardwood Selection Guidelines

Selecting the right hardwoods stands as a crucial first step in traditional lye production. You'll want to focus on specific trees like hickory, sugar maple, ash, beech, and buckeye, as they contain higher concentrations of potassium and sodium – fundamental elements for creating effective lye.

To maximize your hardwood ashes' potential, you'll need to properly season your wood before burning. Dried wood burns more thoroughly, producing finer ash that'll yield better results.

When you're burning the wood, maintain high temperatures to guarantee complete combustion, as this creates more concentrated lye solution. Remember to sift through your ashes carefully, removing any unburnt pieces that could hinder the leaching process.

Sifting Pure White Ash

After burning your selected hardwood completely, sifting the resulting ash marks a critical phase in traditional lye-making.

You'll need to use a flour sifter to remove any unburnt wood pieces and carbon deposits, which can compromise your lye's quality.

As you sift, carefully examine the ashes to verify they're purely white without any dark specks.

High-quality hardwoods like hickory and sugar maple yield mineral-rich white ash that's essential for potent lye production. The sodium and potassium content in these ashes creates the most effective solution when mixed with water.

Store your sifted ashes in a clean container to prevent contamination from outside materials.

This careful separation speeds up the clarification process and guarantees you'll produce the purest lye possible for your traditional soap-making endeavors.

Creating the Perfect Leaching Setup

To create an effective lye leaching setup, you'll need a wooden or steel barrel with drainage holes positioned off the ground.

Place a collection trough underneath to catch the liquid lye as it drips through. Before adding your hardwood ashes, layer the barrel's interior with pebbles and straw, leaving a small space at the top for water flow. This natural filtration system prevents clogging and guarantees peak lye concentration.

Select premium hardwoods like hickory, sugar maple, ash, beech, or buckeye for the best results. These species produce higher concentrations of sodium and potassium in your final lye solution.

Once you've added the ashes, pour water slowly over the top and let it gradually seep through the layers. This process may take several hours or even days, but your patience will be rewarded with high-quality lye.

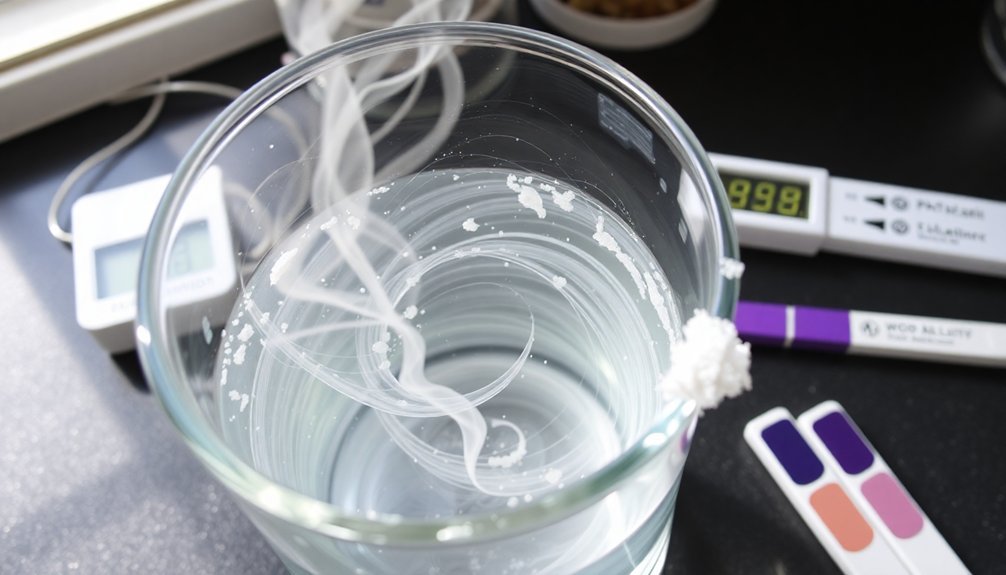

Water Quality and Temperature Effects

You'll find that water quality plays a pivotal role in lye extraction, with rainwater's purity and soft water's low mineral content producing superior results compared to hard tap water.

The temperature of your leaching water matters too – warm (but not boiling) water increases the solubility of potassium and sodium hydroxides, leading to more efficient extraction than cold water methods.

Your careful attention to both water quality and temperature control helps maintain ideal pH levels throughout the leaching process, ensuring you get the most potent lye solution from your wood ashes.

Optimal Ph for Extraction

Proper lye extraction from wood ashes depends critically on maintaining ideal pH levels between 12-14, while carefully considering both water quality and temperature.

You'll achieve the best pH for lye extraction by using soft rainwater, which doesn't contain minerals that could interfere with the process.

When you're mixing your ashes with water, stick to a ratio of 1 part ashes to 2-3 parts water to get the right concentration.

You'll want to keep the temperature elevated during leaching, as this helps dissolve the alkaline compounds more effectively.

Monitor your solution's pH regularly as you extract the lye.

If you're careful with these measurements and maintain consistent conditions, you'll avoid unwanted chemical reactions and produce a high-quality lye solution that's perfect for soap making and other applications.

Hot Vs Cold Leaching

While both hot and cold leaching methods can extract lye from wood ashes, hot leaching proves considerably more efficient for producing concentrated solutions.

When you use heated water, you'll notice the lye compounds dissolve faster and yield higher concentrations compared to cold water extraction.

If you're planning to make lye water, you'll want to use soft rainwater rather than hard water, as it's free from minerals that could interfere with the extraction process.

The pH of your water source matters too – you'll get better results using water that's neutral to slightly alkaline.

While cold leaching can still work, you'll need to wait longer and accept a weaker solution.

Mineral Content Impact

The mineral composition of wood ashes directly influences the strength and quality of your lye solution. When you're using hardwoods like hickory or sugar maple, you'll get a higher concentration of essential minerals, particularly sodium and potassium, which are vital for creating effective lye.

You'll achieve the best results by using rainwater in your leaching process, as it's free from chemicals that could interfere with the mineral extraction. The temperature of your water matters too – warmer water will help dissolve these minerals more efficiently, creating a more potent solution.

If you're working with hardwood ashes, you'll notice they produce more lye than softwoods due to their denser mineral content. This higher mineral concentration leads to stronger hydroxides during the leaching process, ultimately giving you a more effective lye product.

Testing Lye Concentration Naturally

Natural methods for testing lye concentration have stood the test of time, relying on simple yet effective visual indicators.

When testing lye concentration, you'll find that the floating egg method offers reliable results – an egg sinking halfway indicates ideal strength, while a quarter-sized circle should appear on the water's surface.

You can assess lye potency through these traditional methods:

- Floating egg test – observe how deep the egg sinks

- Surface circle measurement – look for quarter-sized rings

- Chicken feather dissolution – stronger lye dissolves feathers

- Multiple ash runs – first run produces strongest concentration

Remember that when lye is used in soap making, proper concentration matters greatly.

These visual cues help you adjust your recipe accordingly, ensuring you achieve the right strength for successful soap production.

Safety Protocols for Handling Lye

Handling lye safely requires strict adherence to essential protective measures since this highly alkaline substance can cause severe chemical burns.

Always wear rubber gloves and protective goggles before working with lye, and keep vinegar nearby as a neutralizing agent in case of accidental contact with your skin.

When mixing or using lye, work in a well-ventilated space to avoid inhaling dangerous fumes.

Don't forget to mix carefully to prevent harmful splashback.

You'll need to store your lye in clearly labeled, airtight containers away from children and pets to avoid dangerous exposure.

If you have leftover lye, make sure you dispose of it properly according to your local hazardous waste guidelines – this protects both people and the environment from potential harm.

Storing and Preserving Wood Ash Lye

Since wood ash lye's potency depends heavily on proper storage, you'll need to keep it in clearly labeled, airtight containers that prevent moisture absorption.

When storing homemade lye, mason jars work exceptionally well for preserving crystallized lye, offering a reliable moisture-proof barrier for long-term use.

To maintain your lye's effectiveness, follow these essential storage guidelines:

Proper storage ensures lye maintains its potency – follow key guidelines to preserve its effectiveness for all your soap-making projects.

- Store containers in a cool, dry location away from direct sunlight

- Check regularly for signs of moisture or clumping

- Keep containers sealed tightly between uses

- Prepare small batches to guarantee consistent potency

Remember to monitor your stored lye's condition periodically, as exposure to air can weaken its strength over time.

If you notice any degradation, dispose of the lye properly and create a fresh batch for your soap-making needs.

Seasonal Variations in Ash Quality

The quality of your wood ash varies dramatically throughout the year, with several seasonal factors affecting its potency for lye production.

You'll find that late winter and early spring provide the best ash for making lye, as seasoned wood burned during these months yields higher mineral concentrations.

To make lye effectively, you'll want to use ash from dry, well-seasoned hardwoods like hickory or sugar maple, which contain more potassium carbonate.

The burning conditions during different seasons also impact your results – winter's typically drier air promotes hotter fires and more complete combustion, creating superior ash.

Be aware that moisture levels in freshly cut wood can reduce ash quality, so avoid using green wood.

Additionally, you'll need to protect your collected ash from weather exposure, as rain and snow can leach away valuable minerals.

Historical Techniques and Modern Applications

You'll find that traditional lye-making methods from wood ashes remain effective today, as the basic chemistry behind the process hasn't changed since our ancestors first discovered it.

When you combine hardwood ashes with water, you're recreating the same potassium-based chemical reaction that generations before you used to create soap and process foods.

While you'll need to follow modern safety protocols when handling lye, you can still employ historical testing methods like the floating egg technique to gauge your solution's strength, connecting you to centuries of practical knowledge.

Traditional Methods Still Work

While modern chemical processes have largely replaced traditional lye-making methods, time-tested techniques for producing lye from wood ashes remain effective and relevant today.

You can still create high-quality lye from ashes using the same principles your ancestors relied on for making soap.

The traditional barrel-leaching method offers a reliable way to extract lye from hardwood ashes, particularly when you're using:

- Hickory or sugar maple ashes for ideal potassium content

- Simple water filtration through layered ash

- Traditional egg-floating tests to measure concentration

- Natural settling and skimming techniques

These time-honored methods don't just work—they're particularly valuable if you're interested in natural soap-making processes.

The potassium carbonate from wood ashes creates an excellent base for saponification, proving that sometimes the old ways are just as effective as modern alternatives.

Chemistry Behind Ancient Knowledge

Understanding the chemistry behind traditional lye-making reveals why these ancient methods were so effective. When you burn wood at high temperatures, you're actually performing a complex chemical transformation that converts organic materials into mineral-rich ashes. The key component, potassium carbonate, creates lye when it meets water through the leaching process.

You'll find that while modern soap makers prefer sodium hydroxide for its consistency, our ancestors knew exactly what they were doing. They discovered that wood ashes contained essential minerals like sodium and potassium, which they could extract through boiling or using leaching barrels.

They even developed reliable testing methods, like the floating egg technique, to measure lye concentration. Though perhaps less refined than today's methods, these chemical processes demonstrate how practical knowledge often predates scientific understanding.

Modern Safety Meets History

Although our ancestors mastered the art of making lye from wood ashes, today's practitioners must balance these time-tested techniques with modern safety protocols.

When you're making lye soap, you'll need to combine historical wisdom with current safety standards to guarantee both quality and protection.

The essential safety measures you'll need for working with lye include:

- Chemical-resistant gloves to prevent skin contact

- Safety goggles to protect your eyes from splashes

- Well-ventilated workspace to avoid harmful fumes

- Precise measuring tools for accurate concentrations

While historical methods like the floating egg test demonstrated remarkable ingenuity, modern safety demands more precise controls.

You'll find that traditional hardwood ash leaching techniques still work effectively, but you'll need to implement these protective measures to safely create your lye soap.

This combination of old and new guarantees you're preserving valuable heritage while maintaining contemporary safety standards.

Troubleshooting Common Lye Problems

Since creating lye from wood ashes requires precise measurements and careful monitoring, several common problems can arise during the process.

When your lye solution appears cloudy or contains sediment, you'll need to allow extra settling time before proceeding with soap making.

If your soap turns out greasy, you can carefully add more lye water to balance the recipe, but be cautious to avoid making it too caustic.

You can test your lye's strength using the floating egg method, which helps determine if your solution needs adjustment.

If you're getting inconsistent results, check your wood source – hardwoods like hickory and sugar maple produce better-quality lye due to their higher mineral content.

When your lye solution is too weak, try multiple leachings of the ashes to increase concentration.

Environmental Benefits of Wood Ash Lye

When you choose wood ash lye over commercial alternatives, you're making a significant environmental impact. This sustainable approach to soap making and cleaning supports a circular economy while reducing your ecological footprint.

By reusing wood ashes, you're helping return valuable nutrients to the environment.

The environmental advantages of wood ash lye extend beyond waste reduction:

- Improves soil fertility by recycling potassium and calcium

- Creates biodegradable cleaning products that minimize water pollution

- Enhances compost quality by balancing pH levels and adding minerals

- Reduces reliance on synthetic chemicals and non-renewable resources

Your choice to use wood ash lye contributes to a healthier ecosystem by promoting sustainable practices.

This natural alternative not only supports self-sufficiency but also helps protect aquatic environments from harmful chemical runoff while fostering better soil health.

Best Practices for Sustainable Production

Creating sustainable wood ash lye starts with selecting the right materials and methods.

You'll want to focus on hardwoods like hickory, sugar maple, and ash, as they contain higher concentrations of sodium hydroxide and potassium, making them ideal for DIY soap making.

Set up a leaching barrel system to maximize your yield while conserving resources.

This method allows rainwater to slowly filter through your ashes, creating a potent lye solution without waste.

Always collect pure rainwater for this process, avoiding tap water that might contain unwanted minerals.

Don't forget to prioritize safety by wearing protective gear, and test your lye's strength using the floating egg method.

This guarantees you're producing the right concentration for your soap making needs while maintaining sustainable practices throughout the process.

Frequently Asked Questions

Why Does Wood Ash Make Lye?

When you mix wood ash with water, you're creating lye because the ash's sodium and potassium compounds dissolve, forming hydroxides. This chemical reaction happens as water leaches these minerals from the burnt wood.

Why Is Wood Ash Alkaline?

When wood burns, it creates mineral oxides, mainly potassium and sodium carbonates. These compounds react with water to form hydroxides, which is why you'll find wood ash is naturally alkaline in nature.

Does Wood Ash Contain Sodium Hydroxide?

You'll find wood ash contains very little sodium hydroxide naturally. Instead, it's primarily made of potassium carbonate, though when mixed with water, both sodium and potassium oxides can transform into their hydroxide forms.

What Happens When You Mix Wood Ash, and Water?

When you mix wood ash and water, you'll create a highly alkaline solution. The water transforms the sodium and potassium oxides in the ash into hydroxides, forming lye. You'll see sediment settle after several hours.

In Summary

You'll find wood ash creates perfect lye because it's naturally rich in potassium hydroxide and other essential minerals. When you properly collect, store, and leach hardwood ashes, you're tapping into centuries of traditional soap-making wisdom. By controlling water temperature and quality while following sustainable practices, you'll produce effective, environmentally-friendly lye that's ideal for both modern and historical applications.

Leave a Reply