Hand-cutting your soap bars connects you to time-honored artisanal traditions while giving you complete control over quality and design. You'll achieve precise cuts, stunning swirls, and intricate patterns that machines simply can't replicate. With manual cutting, you can customize sizes, preserve natural textures, and maintain ideal temperatures between 110°F and 120°F for perfect results. When you embrace this traditional craft, a world of creative possibilities and sustainable practices unfolds before you.

The Artisan's Connection to Traditional Soap Making

When artisans choose to cut soap bars by hand, they embrace a time-honored tradition that connects them deeply to their craft. Just as a mixologist carefully crafts each cocktail with precision, soap artisans pour their expertise into every bar they create, guaranteeing each piece tells its own unique story.

You'll find that handcrafted care products stand apart from mass-produced alternatives, as artisans take pride in maintaining traditional methods that showcase their creativity. Each soap bar features distinctive swirls and patterns that you won't find in factory-made versions.

The careful hand-cutting process allows artisans to preserve the integrity of premium ingredients while creating products that reflect their dedication to quality. This personal touch guarantees that when you choose hand-cut soap bars, you're not just buying a product – you're investing in authentic craftsmanship.

Benefits of Manual Cutting Techniques

Three key advantages make manual soap cutting techniques superior to machine-based methods.

When you opt for hand-cut bars, you'll notice greater precision and consistency in size, which greatly enhances the soap's visual appeal. The manual process preserves the soap's texture and intricate designs, allowing delicate swirls and patterns to remain intact.

You'll appreciate how hand-cutting enables artisans to maintain a personal connection with each bar they create, resulting in products that feel more unique and special.

This method also offers unmatched customization possibilities – you can request specific sizes and shapes that match your preferences.

Unlike mechanical alternatives, manual cutting gives craftspeople complete control over the final product, ensuring that every bar meets their exacting standards while maintaining the artistic integrity of their work.

Essential Tools for Hand-Cutting Soap

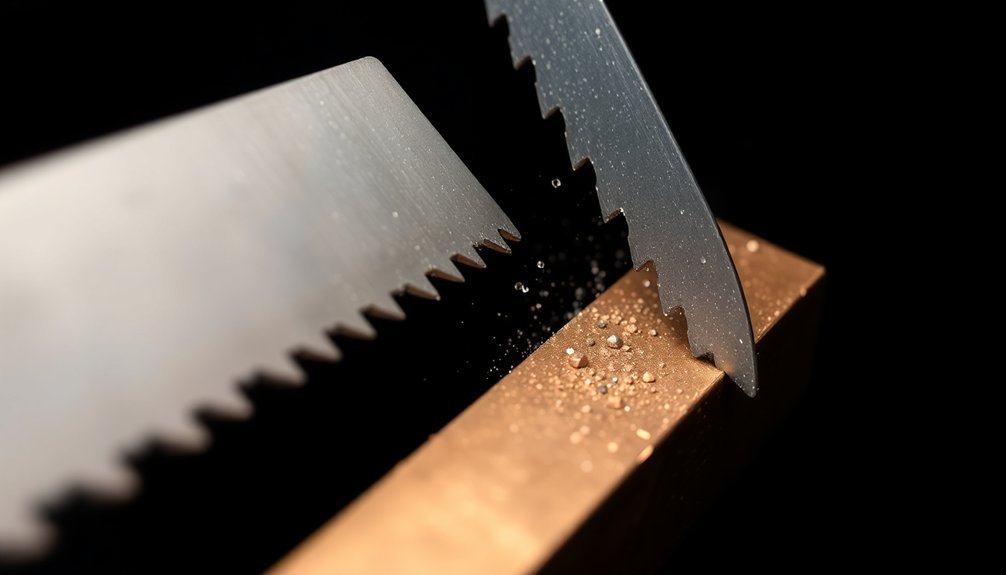

Successful hand-cutting of soap relies on a carefully selected set of essential tools. When you're ready to cut your cold process soap, you'll need a wavy cutter for effortless straight cuts and a specialized soap cutting box that guarantees consistent sizing.

Unlike ice cubes that melt away, your soap needs permanent shaping solutions, which is why a silicone-lined mold is vital for even bar formation.

To maintain perfect rectangles while working with essential oils and other ingredients, you'll want to secure bulldog clips to your molds. Don't forget to utilize your cutting box's front stop – it's your best friend for achieving uniform dimensions.

With these tools at your disposal, you'll be able to transform a single log into nine precisely sized bars, showcasing true artisanal craftsmanship.

Precision and Control in Custom Shapes

While mastering hand-cutting techniques takes practice, the ability to create custom shapes offers unparalleled creative freedom in soap making.

When you're working with luxurious ingredients like shea butter and olive oil, you'll want to guarantee each bar meets your exact specifications. Your hands-on approach allows you to precisely control the dimensions and thickness of every bar made using your preferred cutting tools.

You'll discover that hand-cutting enables you to craft unique designs, including intricate swirls and patterns that enhance your soap's visual appeal.

Whether you're using a wavy cutter or traditional blade, you can maintain consistent quality across your entire production. This intimate connection with the craft means you're able to spot and address any imperfections immediately, guaranteeing each bar meets your high standards.

Creating Unique Patterns Through Hand-Cut Methods

Through hand-cutting techniques, you'll discover how skilled artisans create mesmerizing swirls and intricate patterns that make each soap bar unique.

You can achieve stunning layered designs by carefully controlling the angle and pressure of your cuts, allowing colors and textures to blend seamlessly.

Your ability to guide the pattern flow becomes more refined with practice, as you'll learn to manipulate the cutting tools to reveal the artistic potential within each soap block.

Swirls Through Precise Cuts

Precise hand-cutting techniques reveal limitless possibilities for creating stunning swirl patterns in handmade soap. When you hand-cut soap, you'll discover how each slice discloses unique designs that machines simply can't replicate.

Make sure you maintain control over the blade to achieve the intricate swirls and patterns that reflect your artistic vision. You'll appreciate how adjusting the thickness of each cut creates varying textures and visual dimensions throughout your soap bars.

By hand-cutting, you're not just crafting soap – you're creating individual works of art. The process even allows you to salvage trimmings for future soap designs, making your creative process more sustainable.

As you perfect your cutting technique, you'll find that each precisely executed slice contributes to the distinctive character that makes hand-cut soaps so desirable.

Layered Designs By Hand

By mastering hand-cut techniques, you'll reveal the ability to create mesmerizing layered designs that transform ordinary soap into stunning works of art.

Your skilled hands can control the thickness and alignment of each layer, producing visually striking patterns that mass production simply can't match.

You'll discover how to blend different colors and textures by carefully layering various soap mixtures, making each bar uniquely yours.

As you develop your craft, you'll create intricate swirls and shapes that showcase your artistic vision.

The tactile nature of hand-cutting lets you make real-time adjustments, ensuring perfect layer alignment and visual harmony.

Unlike machine-made soaps, your hand-cut creations will stand out in the market as true one-of-a-kind pieces that reflect your creativity and dedication to the artisan's craft.

Controlling Pattern Flow

When you master hand-cutting techniques, you'll gain unprecedented control over your soap's pattern flow, allowing you to craft designs that tell a unique visual story.

Through careful manipulation of your cutting tools, you can direct swirls and colors in ways that mass production simply can't match.

You'll find that different cutting implements, from wavy cutters to straight blades, create distinct textures that enhance your soap's visual appeal.

As you cut, you're able to precisely control the size and shape of each bar, ensuring consistency while maintaining artistic freedom.

The hands-on approach lets you feel the soap's texture and adjust your technique accordingly, resulting in intricate patterns that showcase your creativity.

Each cut becomes an opportunity to reveal hidden color combinations and create stunning visual effects that make your handcrafted soaps truly one-of-a-kind.

Temperature and Timing for Perfect Cuts

Temperature and timing make or break the quality of hand-cut soap bars. You'll need to master these elements to achieve professional results like artisans do. The sweet spot for cutting cold process soap lies between 110°F and 120°F, when it's firm enough to hold shape yet soft enough to slice cleanly.

| Temperature | Timing | Result |

|---|---|---|

| Too Hot >120°F | Too Early | Sticky, messy cuts |

| 110-120°F | Just Right | Clean, even edges |

| <110°F | Too Late | Crumbly, rough bars |

When using a wavy cutter, timing becomes even more critical. You'll want to maintain a consistent environment during the curing process to guarantee your soap reaches the ideal cutting temperature. This control helps you achieve those distinctive, professional-looking patterns without compromising the bar's structural integrity.

Preserving Natural Properties Through Manual Methods

Manual cutting techniques do more than just shape your soap – they protect the valuable natural properties that make handcrafted bars superior to mass-produced versions.

When you cut soap by hand, you'll preserve the natural glycerin created during saponification, enhancing your soap's moisturizing benefits. You won't need harsh treatments or artificial additives that are common in industrial production. Instead, you'll maintain the integrity of skin-nourishing ingredients while ensuring each bar has its own unique character.

The precision of hand-cutting allows you to control the size and shape precisely, leading to even curing that locks in beneficial properties.

There's also a deeper connection to your craft when you cut by hand. You'll develop an intimate understanding of the materials and techniques, resulting in bars that showcase true artisanal quality.

Storage and Curing of Hand-Cut Bars

You'll want to set up your drying area in a cool, ventilated space where hand-cut soap bars can cure properly for about four weeks.

Arrange your bars with enough space between them on greaseproof paper to guarantee optimal airflow and prevent moisture buildup.

Optimal Curing Conditions Required

Once you've cut your bars, proper curing conditions become essential for achieving high-quality soap. You'll need to store your bars in a cool, dry space with excellent air circulation for about four weeks. Using a drying rack will help air flow around each bar, improving the curing process and final texture.

| Condition | Why It Matters | What to Do |

|---|---|---|

| Temperature | Affects drying time | Keep cool |

| Humidity | Impacts moisture content | Use dry space |

| Air Flow | Guarantees even curing | Place on rack |

Don't expose your bars to direct sunlight or high humidity during the curing period, as these can compromise your soap's quality. For best results, place greaseproof paper under your bars to absorb excess moisture and prevent sticking. This careful attention to curing conditions will guarantee your hand-cut soap reaches ideal hardness and mildness.

Organizing Your Drying Space

Proper organization of your drying space plays an essential role in achieving perfectly cured soap bars.

You'll need to set up a drying rack that provides adequate spacing between each bar, ensuring ideal air circulation throughout the curing process.

Line your drying trays with greaseproof paper to absorb excess moisture and prevent your soaps from sticking.

Place the freshly cut bars in a cool, dry area away from direct sunlight, where they'll need to cure for approximately four weeks.

Don't forget to label each batch with the cutting date and soap type – this simple step helps you track curing progress and maintain proper rotation of your inventory.

Sustainable Practices in Artisanal Cutting

While mass production dominates today's soap industry, artisanal hand-cutting offers a more sustainable alternative that considerably reduces environmental impact. When you choose hand-cut soap, you're supporting a practice that minimizes waste and carbon emissions associated with industrial manufacturing.

You'll find that artisanal cutting relies on locally sourced materials and tools, which strengthens community economies while reducing transportation-related pollution.

This hands-on approach guarantees superior quality control without harsh chemicals or synthetic additives common in factory-made soaps. Through small-batch production, you're enabling artisans to innovate with eco-friendly ingredients and techniques.

Frequently Asked Questions

How Long Does It Take to Master Hand-Cutting Soap Bars?

You'll need 6-12 months of consistent practice to master hand-cutting soap bars. It's all about developing steady hand movements, learning proper techniques, and understanding how different soap textures behave under the blade.

Can Left-Handed Artisans Use Regular Soap-Cutting Tools Effectively?

You'll find most soap-cutting tools work well for left-handed artisans. While some tools are right-hand oriented, you can adapt your technique or find left-handed versions to cut soap bars just as effectively.

Do Certain Soap Ingredients Affect the Difficulty of Hand-Cutting?

You'll find that softer ingredients like milk and honey make cutting trickier, while harder additives like clay create cleaner cuts. Temperature also affects difficulty – cold soap's easier to slice than warm soap.

What's the Average Waste Percentage When Cutting Soap Bars by Hand?

When you're hand-cutting soap bars, you'll typically experience 2-5% waste from uneven edges and trimming. You can minimize this by using proper cutting techniques and sharp tools, but some loss is inevitable.

How Often Should Cutting Tools Be Sharpened for Optimal Soap-Cutting Results?

You'll need to sharpen your cutting tools after every 50-75 soap bars to maintain clean cuts. If you notice rough edges or resistance while cutting, it's time to sharpen, regardless of the count.

In Summary

Hand-cutting your soap bars isn't just about tradition – it's about crafting a product that's uniquely yours. You'll maintain better control over your soap's properties, create custom designs, and connect with age-old artisanal methods. Whether you're making soap for personal use or building a business, manual cutting techniques let you express creativity while preserving the natural qualities of your handmade bars.

Leave a Reply