You'll achieve vibrant blue soap colors using natural indigo powder through either oil infusion or lye solution methods. For oil infusion, mix 1/2 teaspoon indigo with 17.6 oz light carrier oil and let it sit for a month. For immediate results, blend indigo directly into your lye solution. Keep temperatures between 110-120°F for best results, and don't forget proper safety gear. Mastering these techniques will open up endless possibilities for creating stunning blue soap variations.

Understanding Natural Indigo Properties and Sources

When exploring true indigo dye for soap making, you'll encounter a natural colorant derived from Indigofera tinctoria leaves that produces deep, rich blue hues through fermentation and drying.

As you source natural indigo for your color soap projects, you'll find it available in two main forms: powdered indigo from soap supply vendors and pre-reduced crystals from specialized suppliers like Dharma Trading.

For the best results in your natural dye endeavors, consider using organic indigo powder from Botanical Colors, which typically yields more vibrant blues than standard options.

You'll need to understand indigo's unique solubility characteristics, as it won't dissolve directly in water or oils.

Watch for color shifts during the soap making process – your initial green or grayish blue will develop into true blue shades after curing.

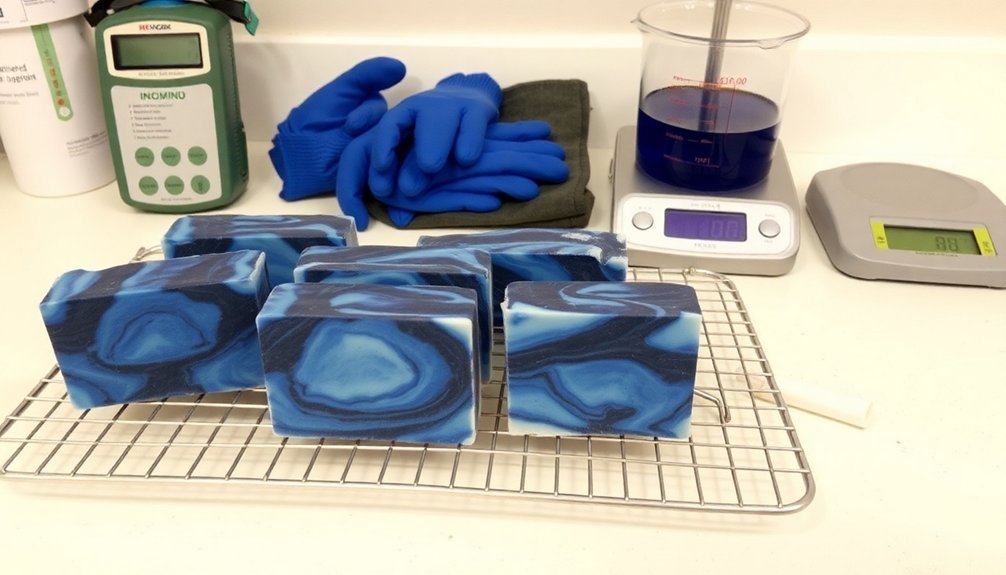

Essential Equipment and Safety Measures

Three essential safety items stand between you and a successful indigo soap-making session: chemical-resistant gloves, protective eyewear, and a proper respirator mask. You'll need these to protect yourself from sodium hydroxide's caustic nature and harmful fumes.

Safety first: Always use chemical-resistant gloves, protective eyewear, and a respirator mask when handling sodium hydroxide for soap making.

Your essential safety equipment also includes a digital scale for precise measurements of oils, lye solution, and indigo powder. You'll want a reliable stick blender to achieve trace efficiently, and a thermometer to maintain temperatures between 110-120°F for ideal color results.

Don't forget durable soap molds made of silicone or sturdy plastic for shaping your creations.

Always work in a space with proper ventilation to safely disperse any fumes that occur during the mixing process. Keep a spatula handy to guarantee you're incorporating all ingredients thoroughly as you work.

Oil Infusion Methods for Indigo Coloring

Creating vibrant blue soap starts with a proper oil infusion, which requires combining 1/2 teaspoon of indigo powder with 17.6 oz of light-colored carrier oil.

For the best results in your natural soap, choose oils like pomace olive or sweet almond oil that won't cause yellowing in your final product.

After mixing your indigo powder with the light-colored oil, you'll need to strain the mixture to remove any clumps. This guarantees smooth incorporation into your soap recipes later.

Let the oil infusion sit for approximately one month to achieve an even blue color throughout.

When you're ready for cold process soap making, add the infused oil at trace. You'll notice this method produces a lighter blue color than direct powder addition, making it perfect for detailed designs similar to working with mica.

Lye Solution Incorporation Techniques

Your success with indigo soap coloring depends heavily on proper lye incorporation, starting with thorough pre-mixing of indigo powder and dry lye crystals before adding water.

You'll achieve the most vibrant results by maintaining temperatures between 120-140°F during the mixing process, as heat activation helps promote the essential gel phase.

Testing various powder-to-lye ratios, starting with smaller amounts of indigo (around 1 teaspoon per pound of oils), will help you discover the perfect balance for your desired shade intensity.

Pre-Mixed Lye Color Methods

While many soap makers struggle with color consistency, incorporating indigo powder directly into your lye solution offers a foolproof method for achieving deep, uniform blues throughout your soap.

You'll want to start by mixing the indigo powder with dry lye crystals before adding water, which helps prevent clumping and guarantees even distribution of this natural coloring.

For the best results, use less than 1/2 teaspoon of indigo powder per pound of oils when pre-mixing with your lye solution.

The type of indigo you choose matters – powdered organic indigo creates darker blue shades, while pre-reduced crystals might give you greenish undertones.

Don't forget to monitor the gel phase during soap making, as proper heating will enhance your final color's vibrancy.

This pre-mixing technique eliminates speckling and delivers consistent results every time.

Temperature Impact Testing

To achieve the richest indigo hues in your soap, maintaining precise temperature control during lye incorporation proves vital. You'll want to keep your lye solution between 110-120°F (43-49°C) for ideal color development.

Start by dissolving pre-reduced indigo powder directly into your hot lye solution, rather than adding it later. This method guarantees even distribution and deeper soap colors throughout.

During saponification, you'll notice the gel phase plays a significant role in enhancing color intensity. The heat generated during this phase helps fully develop the indigo's vibrancy.

Through temperature impact testing, you'll find that cooler conditions result in weaker color saturation. For best results, maintain higher temperatures within the recommended range, and don't skip the gel phase – it's key to achieving those deep, consistent indigo shades you're aiming for.

Powder-to-Lye Ratio Guidelines

Precise measurement and mixing techniques make all the difference when incorporating indigo powder into your lye solution.

You'll achieve the best results by using less than 1/2 teaspoon of indigo powder per pound of oils, which prevents clumping and guarantees even distribution throughout your soap batter.

To maximize your colorant's effectiveness, you've got two reliable methods.

First, you can stir the indigo powder directly into dry lye crystals before adding water, which helps prevent speckling in your final soap color.

Alternatively, if you're working with pre-reduced indigo crystals, dissolve them in hot water before combining with your lye solution.

This careful preparation enhances the blue shade you're aiming for.

Color Intensity Control and Troubleshooting

Mastering color intensity with true indigo dye requires understanding several key variables in the soap-making process.

You'll find that using less indigo powder actually produces stronger shades in your cold-process soap, while achieving ideal color outcomes depends heavily on your mixing technique.

For the deepest, most uniform results, mix your indigo directly into the lye solution.

Mixing indigo powder directly into your lye solution creates deeper, more consistent color saturation throughout your handcrafted soap.

You'll want to monitor the gel phase carefully, as it's essential for enhancing color vibrancy – gelled portions will show more intense hues.

When troubleshooting color issues, watch for clumping during mixing and maintain proper temperature control.

Consider using organic indigo for more saturated results than standard soap supply options.

If you're experiencing unexpected results, check both your powder quality and incorporation method, as these factors greatly impact your final color.

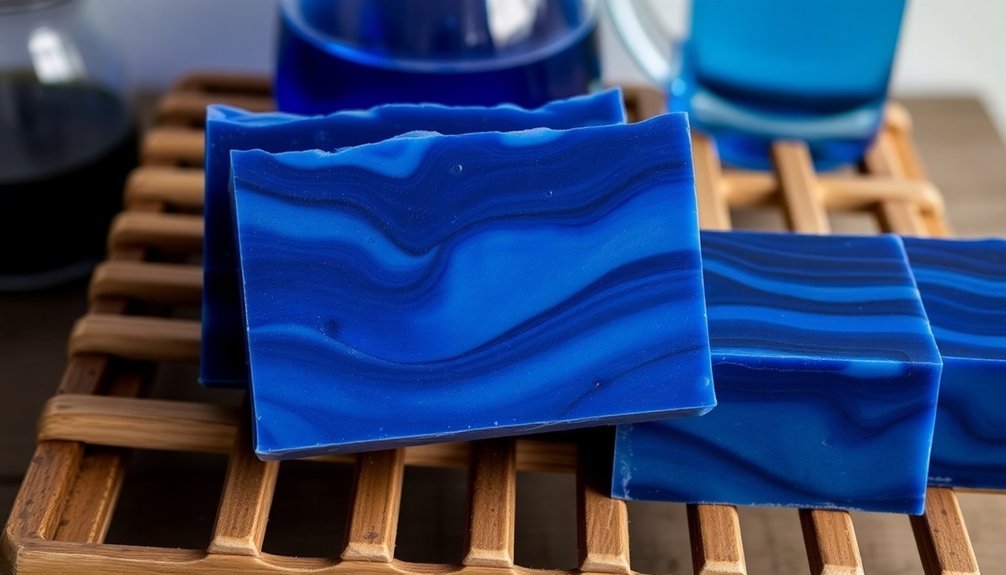

Design Techniques With Indigo Colorant

To create stunning swirl patterns with indigo, you'll want to mix separate portions of soap batter with varying indigo-to-oil ratios, typically starting at 1/4 teaspoon per pound of oils for lighter shades and up to 1/2 teaspoon for darker tones.

Your swirls will achieve better definition when you blend the indigo with liquid oils first, allowing for smoother incorporation and more controlled color changes.

For complex designs, try layering different concentrations of indigo-infused batters while maintaining a medium trace consistency, which gives you enough working time to perfect your swirl techniques.

Complex Swirl Pattern Tips

While creating intricate swirl patterns with indigo dye might seem intimidating, you'll achieve stunning results by following key preparation steps.

Start by mixing your indigo powder with a light-colored oil to maintain vibrancy and prevent yellowing during the gel phase. You'll find that less soap colorant often produces stronger colors, creating more dramatic swirls.

For ideal color distribution, add your indigo to the lye solution rather than directly into oils.

Maintain a slow-moving trace when blending your soap batter, giving yourself ample time to craft defined swirls before the mixture thickens.

Try layering techniques by pouring different colored batches in succession – this creates striking contrast in your final design.

Oil-Blending Color Ratios

Precise oil-blending ratios form the foundation of successful indigo soap coloring.

You'll want to use less than 1/2 teaspoon of indigo powder per pound of oils in your cold-process soap to achieve balanced results. Start by mixing your blue pigment with liquid oils before incorporating it into your main formula to prevent clumping.

For deeper shades, you've got two effective options.

You can blend the indigo powder directly with sodium hydroxide in your lye solution, which creates intense, uniform colors. Alternatively, pair your indigo with light-colored oils to prevent yellowing and maintain vibrancy.

Don't be afraid to experiment with oil blending and color ratios – you can achieve unique color outcomes like sage blue by combining different indigo powder varieties in your soap designs.

Testing and Quality Assessment Methods

Since quality indigo dye can vary considerably between suppliers, you'll need reliable testing methods to guarantee consistent soap coloring results.

Start by measuring indigo powder from different suppliers, documenting the color intensity of each in your soap formulation. You'll want to conduct color bleed tests to evaluate how well the indigo stays within your bars during use.

Compare indigo powders from multiple suppliers and test for color bleeding to ensure consistent, stable dye performance in your soaps.

Test various saturation levels by incorporating the indigo powder through different methods – whether in your lye solution or oil infusions.

Record how each technique affects the final color outcome, from light grayish blues to deeper shades. Keep detailed notes on temperature impacts, mixing methods, and any clumping issues you encounter.

This systematic testing approach will help you identify the most reliable suppliers and best incorporation methods for your specific soap-making needs.

Frequently Asked Questions

Is Indigo Powder Blue or Green?

You'll notice indigo powder can appear green in its raw form or when mixed, but it'll typically give you a deep blue color in finished products once it's properly processed and incorporated.

How to Use Indigo in Soap Making?

You'll need to mix indigo powder with liquid oils (under 1/2 tsp per pound) or add it to lye solution. First dissolve it in hot water to prevent clumping and guarantee even distribution.

What Is the Benefit of Indigo Soap?

You'll benefit from indigo soap's natural blue color and calming properties. It's gentle on your skin, offers antioxidant protection, and provides an eco-friendly alternative to synthetic products during your bathing routine.

Which Color Is Best for Soap Making?

You'll find natural earthy tones like blue, green, and brown work best for soap making. They're stable, appealing, and easily achieved with natural colorants. White's also popular as it's clean and versatile.

In Summary

You've now mastered the art of using true indigo dye in cold-process soap making. Don't hesitate to experiment with different oil infusion ratios and incorporation methods to achieve your desired blue hues. Remember to always document your results and maintain proper safety protocols. Whether you're creating marbled effects or solid colors, you'll find that natural indigo offers endless possibilities for unique, artisanal soaps.

Leave a Reply