To safely drain traditional wood ash lye, you'll need proper protective gear including thick rubber gloves and goggles. Set up your drainage station outdoors using a sturdy barrel filled with layers of pebbles and straw. Use only hardwood ashes like hickory or maple, and collect clean rainwater for the process. Monitor the lye strength using the floating egg method and store the solution in non-reactive containers. Understanding the complete process guarantees your safety during this potent alkali production.

Essential Safety Equipment and Precautions

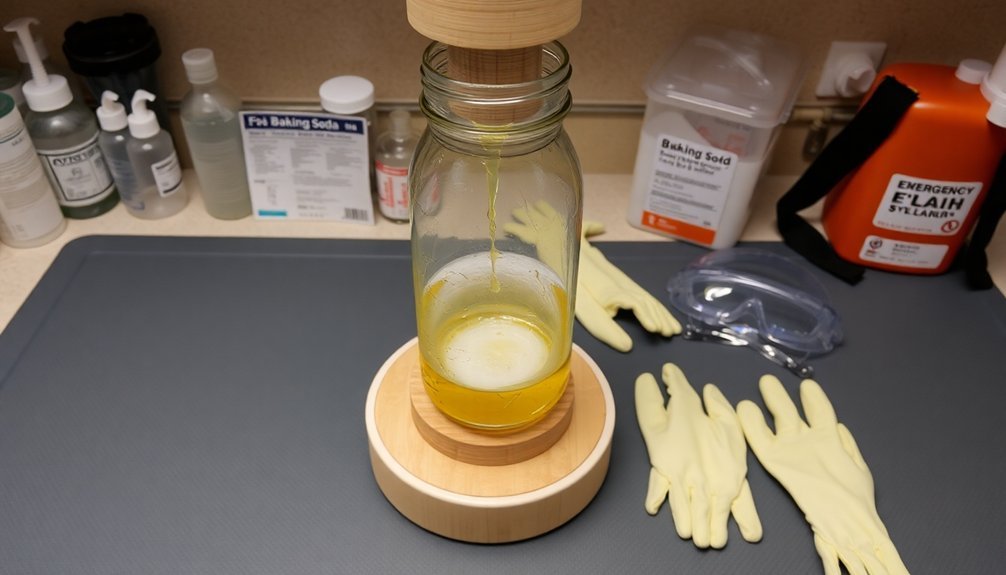

Because wood ash lye can cause severe chemical burns, you'll need proper safety equipment before starting the draining process. Always put on thick rubber gloves and protective goggles to shield your skin and eyes from the highly alkaline solution.

Exercise extreme caution when handling wood ash lye. Protect yourself with heavy-duty rubber gloves and safety goggles to prevent chemical burns.

Keep a bottle of vinegar within arm's reach to quickly neutralize any lye that might accidentally contact your skin.

Set up your workspace in a well-ventilated area to prevent inhaling harmful fumes during the process. Before beginning, remove all aluminum items from your work area, as they can react dangerously with lye.

Select a bucket made from non-reactive materials like plastic or wood for mixing and storing your lye solution. Metal containers aren't suitable, as they'll corrode when exposed to the caustic solution.

Setting Up Your Lye Drainage Station

When working with lye, you'll need a well-ventilated outdoor area away from children, pets, and high-traffic zones to set up your drainage station.

You'll want to gather essential equipment including a sturdy wooden or steel barrel, pebbles, straw, and a collection basin before beginning the process.

Make sure you've chosen a stable, elevated location for your setup where the container won't tip over and where you can safely monitor the lye drainage without risk of exposure.

Choose Safe Work Area

Safety begins with a proper workspace when draining wood ash lye. You'll need to carefully select your work area to guarantee both safety and efficiency. When handling lye, it's essential to choose a well-ventilated space that's inaccessible to children and pets.

- Select a stable wooden or plastic table for your work area, avoiding aluminum surfaces that could react with the lye.

- Position your station in a well-ventilated space to prevent fume accumulation.

- Keep vinegar nearby as a neutralizing agent for immediate spill response.

- Store your protective gear within easy reach of your workspace.

Before beginning any lye drainage work, put on your full protective gear, including rubber gloves, goggles, and long-sleeved clothing.

Remember to keep your mason jar or collection container with a secure lid readily available at your workstation.

Essential Drainage Equipment

Proper equipment selection forms the foundation of a reliable lye drainage station.

You'll need a sturdy container for your lye production – either a wooden hopper or plastic dustbin that's equipped with drainage holes or a spigot at the bottom. This setup allows you to tap and collect the lye solution efficiently without disturbing the ash layer above.

Create a filtration layer at the container's base using twigs or straw. This prevents ash particles from clogging your drainage holes while allowing the liquid lye to flow through freely.

Stock up on rainwater or distilled water for mixing with your wood ash, as these pure water sources won't introduce unwanted chemicals into your lye solution.

Don't forget to keep pH testing supplies handy to monitor your lye's alkalinity levels during the drainage process.

Proper Wood Ash Selection and Preparation

Your first step in making wood ash lye is choosing high-quality hardwoods like hickory, sugar maple, ash, beech, or buckeye, as these varieties produce superior lye compared to softwoods.

You'll need to let your ashes cool completely, then sift them through a flour sifter to remove any unburnt chunks and create a fine, uniform powder.

Once sifted, inspect the ash to verify it's pure white and free of carbon specks, then store it in a clean, dry container where it can age slightly to improve its leaching potential.

Best Hardwoods to Use

When selecting wood for lye production, hardwoods like hickory, sugar maple, ash, beech, and buckeye stand out as top choices due to their high potassium content.

These best hardwoods yield more ash and create stronger lye solutions than softwoods, making them ideal for traditional soap-making and other applications where lye is used.

For best results when working with hardwoods:

- Burn the wood completely until you've got fine white ash

- Sift thoroughly to remove any unburnt pieces and carbon remnants

- Store your sifted ashes in an airtight, dry container

- Avoid mixing with softwood ashes to maintain potency

You'll get the most efficient leaching process and highest quality lye by focusing on these premium hardwood varieties, ensuring proper burning, and maintaining dry storage conditions for your collected ashes.

Sifting for Clean Ash

The careful sifting of wood ash marks the next vital step after selecting quality hardwoods.

You'll want to guarantee you're working with completely burned, white ash that's free from any unburnt wood pieces or carbon chunks.

To achieve clean wood ashes, you'll need to use a flour sifter or fine mesh screen. This process separates the fine ash particles you want from larger debris that could interfere with lye production.

Take time to inspect your sifted material, looking for any remaining black specks or carbon particles that might've slipped through.

Once you've completed the sifting process, store your refined ash in a clean, dry five-gallon bucket.

Keeping moisture away from your sifted ash is vital, as it'll help maintain its quality for effective lye extraction later.

Building a Secure Lye Hopper System

Building a secure lye hopper system starts with selecting a durable container that can withstand repeated exposure to water and alkaline solutions.

When producing lye, you'll need to create proper drainage by adding holes at the container's bottom and elevating it off the ground for easy collection.

Essential steps for a functional lye hopper:

- Layer the bottom with small pebbles or twigs to create a natural filtration barrier.

- Form a depression at the top of your ash pile to collect rainwater effectively.

- Position a collection trough underneath to catch the leached lye.

- Test lye strength regularly using an egg float test or pH indicators.

This setup guarantees your lye drains properly while maintaining safety and efficiency.

Remember to monitor the filtration process regularly to prevent ash particles from clogging the system.

Water Quality Requirements and Testing

Selecting high-quality water serves as the foundation for successful lye production. Rainwater is your best choice for making lye since it's naturally free from chemicals and minerals that could compromise your final product.

You'll want to collect it in clean containers to prevent any contamination.

If you can't access rainwater, distilled water is your next best option. Don't use tap water, as its chlorine and chemical treatments can interfere with the lye-making process and affect your soap's quality.

Before you begin, it's important to test your water's pH level – you're looking for a neutral reading around 7. This simple test will confirm your water meets the quality requirements for lye production and help guarantee your success in creating effective wood ash lye.

The Leaching Process Step-by-Step

Setting up a proper leaching system marks the first critical phase of wood ash lye production. When you're ready to make lye from wood ashes, you'll need a leaching barrel with drainage holes elevated off the ground.

This traditional method of creating lye soap begins with layering pebbles and straw at the barrel's bottom.

Follow these essential steps for successful leaching:

- Create a depression in your ash layer to hold water effectively.

- Pour distilled water slowly over the ashes.

- Allow mixture to rest for several hours or overnight.

- Test the leachate's strength using an egg float test.

The clear liquid draining from your barrel should be free from ash particles.

Proper filtration ensures your leachate runs crystal clear – a crucial sign you're ready for the next soapmaking step.

Once you've collected enough leachate, test its alkalinity to verify it's suitable for your lye soap making needs.

Monitoring Lye Strength During Drainage

Once you've begun the drainage process, monitoring your lye solution's strength becomes essential for successful soap making. Use the floating egg method by checking if an egg floats with a quarter-sized circle exposed – this indicates ideal lye strength. Test pH levels with universal indicator paper; you'll want readings above 13.

| Time | Test Method | Desired Result |

|---|---|---|

| Hourly | Egg Float | Quarter-sized circle |

| Every 2 hrs | pH Paper | Above 13 |

| Continuous | Visual Check | Clear liquid |

| As needed | Sample Collection | Consistent flow |

| Daily | Record Keeping | Complete log |

Collect and examine samples regularly to check clarity and consistency. If you find the solution's too weak, continue leaching the ashes. Keep detailed records of drainage volume and test results to improve your future batches.

Safe Collection and Storage Methods

With your lye strength properly monitored, the next step involves collecting and storing your wood ash lye safely. During collection, you'll need to wear protective gear, including rubber gloves and goggles, to shield yourself from caustic splashes.

For successful collection and long-term storage, follow these essential steps:

- Filter the lye solution through a fine mesh strainer or cheesecloth to remove ash particles.

- Pour the filtered solution into a non-reactive container made of glass or food-grade plastic.

- Label your storage container clearly and keep it in a cool, dry place, away from children and pets.

- Check your storage containers regularly for any signs of leakage or deterioration.

Always maintain an airtight seal on your containers to prevent moisture absorption, which can weaken your lye solution over time.

Emergency Response and First Aid Measures

Because working with wood ash lye poses serious safety risks, you'll need to prepare for potential emergencies before handling this caustic substance.

Keep a first aid kit nearby and post emergency medical assistance numbers in a visible location.

If lye contacts your skin, immediately rinse the affected area with plenty of water for at least 15 minutes.

You can apply vinegar or diluted acetic acid to neutralize minor burns. For eye exposure, flush with clean water or saline solution for 15 minutes and seek immediate medical help.

If you inhale lye dust or fumes, move to fresh air right away.

Remember: Quick action is essential when dealing with lye accidents.

When dealing with lye accidents, rapid response can make the difference between minor injury and severe damage.

Don't wait to see if symptoms develop – contact emergency services immediately if you experience burns, eye exposure, or breathing difficulties.

Environmental Considerations and Disposal

After taking precautions for safe handling and emergency response, proper disposal of wood ash lye demands equal attention to protect our environment.

To prevent environmental contamination, you'll need to follow specific guidelines that guarantee safe disposal while maintaining ecosystem health.

Here's what you need to know about responsible disposal:

- Never pour lye directly down drains – it'll damage plumbing systems and harm water treatment facilities.

- Neutralize the lye with vinegar before disposal to reduce its alkaline properties.

- Dilute with large quantities of water if using as a natural soil fertilizer.

- Check your local hazardous waste regulations to guarantee compliance.

When disposing of wood ash lye, you must prevent runoff into waterways to protect aquatic life.

Maintaining Your Drainage Equipment

Since proper maintenance of your drainage equipment directly impacts the safety and effectiveness of wood ash lye production, you'll need to establish a regular inspection routine.

Check for cracks, holes, or signs of wear that could compromise your lye solution or cause dangerous leaks during the draining process.

After each use, thoroughly clean your drainage equipment to prevent ash and lye buildup that could affect future extractions.

Use only non-reactive materials like stainless steel or food-grade plastic filters to avoid unwanted chemical reactions.

Store your equipment in a dry area away from sunlight and moisture to prevent deterioration.

Don't forget to label each piece of drainage equipment clearly – this simple step helps prevent dangerous mix-ups and guarantees safe handling of your lye-making materials.

Troubleshooting Common Drainage Issues

Even with well-maintained equipment, you'll likely encounter drainage problems when making wood ash lye. When your drainage system isn't performing properly, there are several effective solutions you can implement to restore proper flow.

Here are key steps to resolve common drainage issues:

- Check your filter layer for twigs or wood shavings that might be blocking the lye's path.

- Position your drainage container at a slight incline to help gravity do its work.

- Add more water if your lye solution is too thick to flow properly.

- Test the pH regularly to guarantee proper alkalinity.

If you're still experiencing slow drainage, consider the quality of your ashes. Fresh hardwood ashes typically provide better results than older, compacted ones.

Remember that proper lye extraction requires patience and careful monitoring of the process.

Frequently Asked Questions

How to Extract Lye From Wood Ash?

You'll need to sift wood ash first, mix it with distilled water, let it settle, then drain the liquid. Boil the solution until it's concentrated enough to float an egg, and store safely.

How Do You Leach Wood Ashes?

You'll need to fill a container with hardwood ashes, create a depression on top, and slowly pour clean rainwater through them. Let it sit overnight, then collect the filtered lye solution from the bottom drainage holes.

Does Wood Ash Turn to Lye When Wet?

Yes, when you add water to wood ash, it'll create lye through a chemical reaction. The water dissolves potassium and sodium hydroxides from the ash, producing an alkaline solution you can use for various purposes.

Does Lye React With Wood?

Yes, lye will react strongly with wood. You'll notice it breaks down cellulose fibers, weakens the wood's structure, and can cause serious damage. That's why you shouldn't store lye in wooden containers.

In Summary

Wood ash lye draining requires your constant attention to safety and proper technique. You'll need to maintain your equipment, follow strict safety protocols, and guarantee proper disposal methods. By carefully selecting quality wood ash, using appropriate testing methods, and having emergency measures ready, you can successfully drain lye while protecting yourself and the environment. Remember, it's a caustic substance that demands respect and careful handling.

Leave a Reply