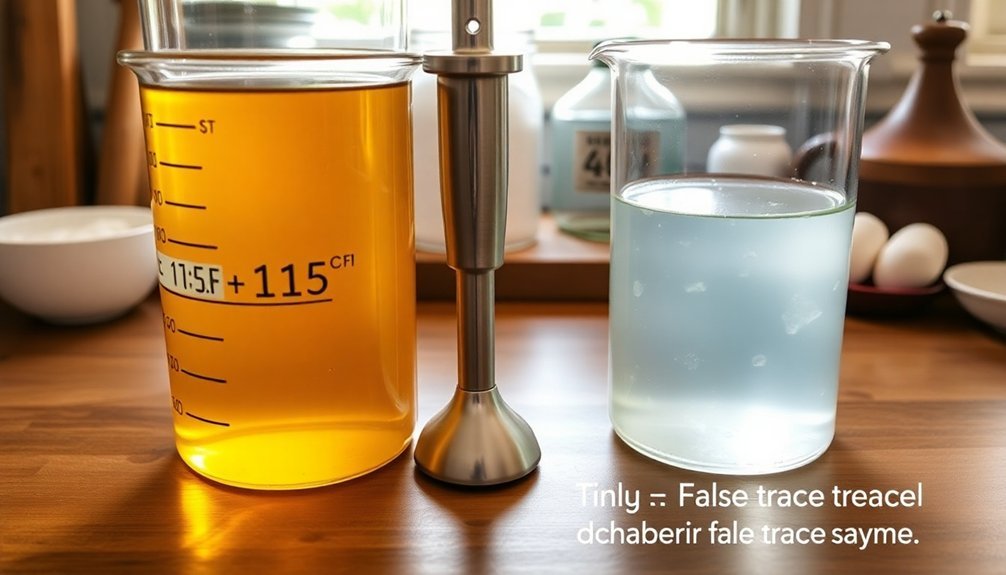

Mixing oils at 110-120°F guarantees all hard oils fully melt, creating a homogeneous mixture that prevents false trace during saponification. This temperature range keeps oils fluid enough for even lye distribution while maintaining proper viscosity for control during trace development. You'll avoid stearic spots and achieve better color vibrancy in your final soap. The ideal temperature also promotes appropriate gel phase and reduces soda ash formation. Mastering this temperature sweet spot will transform your soap-making results.

Why Mix Oils at 110-120°F for Lye Blending?

Why does temperature matter so much when preparing oils for soap making?

When you maintain your oil blend between 110-120°F, you guarantee all hard oils fully melt, preventing unmelted fatty acids that can cause false trace during saponification. This temperature range creates a homogeneous mixture where your lye solution can distribute evenly throughout the oils.

Proper temperature control helps facilitate effective saponification by keeping oils fluid enough to blend seamlessly with your lye solution.

For best results, keep the temperature of soaping lye within 10°F of your oil temperature. The 110-120°F range also promotes a suitable gel phase, enhancing color vibrancy and reducing soda ash formation.

Following these temperature guidelines leads to consistent, high-quality soap with predictable properties.

The Science Behind Ideal Oil Temperatures

You'll notice that heat directly influences how quickly your oils saponify when combined with lye, creating a chemical reaction that accelerates at higher temperatures.

The viscosity of your oil mixture changes dramatically within the 110-120°F range, transforming from potentially grainy or overly thick to smooth and workable.

This ideal temperature window gives you better control over trace development, allowing time for additives and design techniques before the soap begins to set.

Heat Affects Saponification Speed

Because temperature greatly influences chemical reactions, maintaining your oil mixture at 110-120°F creates the perfect environment for controlled saponification.

When you blend oils within this range, you're setting up favorable conditions for the reaction with your lye solution.

Too much heat accelerates saponification dramatically, potentially causing soap volcanoes or glycerin rivers in your final product.

Conversely, temperatures that are too low will slow the process, potentially leaving unmelted fatty acids that lead to false trace or incomplete saponification.

Effective temperature management guarantees that when your lye solution (which can reach 200°F initially) meets your oils, the reaction proceeds at an ideal pace.

This balance gives you better control over the process, allowing proper mixing and emulsification for a smooth, high-quality soap with minimal defects.

Viscosity Changes Matter

When oils reach the 110-120°F sweet spot, they transform from stubborn solids or sluggish liquids into a perfectly flowing medium for lye interaction. This temperature-induced viscosity change is essential for successful soapmaking as it directly impacts how oils combine with your lye solution.

The science behind these viscosity changes reveals why proper temperature control matters:

- Lower viscosity oils blend more uniformly with lye, creating consistent saponification throughout your batch.

- Proper flow prevents false trace, ensuring you're seeing actual chemical reactions rather than temperature-related thickening.

- The ideal viscosity window gives you better control over the saponification process timing.

You'll notice when mixing oils at the correct temperature that they'll accept the lye solution enthusiastically, rather than resisting it or reacting too quickly, leading to more predictable results.

How Temperature Affects Trace Development

The temperature of your oils plays a crucial role in how quickly or slowly your soap batter reaches trace. When you keep oils and lye solution within 10 degrees of each other (ideally between 110-120°F), you're setting yourself up for a smooth, predictable saponification process.

Cooler temperatures around 100-110°F give you more control and working time—perfect when you're creating intricate designs that require a slow trace development.

Conversely, if your oils exceed 130°F, you'll notice trace accelerating rapidly, potentially pushing your soap into gel phase too quickly and causing glycerin rivers.

Temperature balance isn't just about preventing problems; it guarantees all oils fully melt and integrate, eliminating stearic spots and false trace that can compromise your final product's quality and appearance.

Preventing False Trace During Saponification

To prevent false trace during saponification, you'll need to maintain your oil mixture at 110-120°F so all fats remain fully melted.

When your oils cool too quickly, solid fatty acids can form, creating a deceptive thickness that mimics true trace but doesn't represent actual saponification.

You can recognize true trace by its pudding-like consistency that holds its shape momentarily when drizzled across the surface, rather than the grainy, stiff texture of false trace caused by solidified fats.

Temperature Affects Emulsion Stages

Maintaining proper temperature control during oil mixing greatly impacts your soap's emulsion stages and prevents frustrating false trace issues.

When you keep your oils within the 110-120°F range, you're ensuring complete melting and ideal conditions for saponification to begin correctly.

The temperature relationship between your oils and lye solution is critical for proper emulsification:

- Keeping both components within 10°F of each other facilitates smooth blending and prevents premature thickening

- Consistent temperatures help distribute ingredients evenly, supporting the chemical reaction needed for complete saponification

- The recommended range minimizes the risk of stearic spots or cloudiness that can interfere with detecting true trace

Fats Solidify Too Fast

When fats begin to solidify prematurely during the mixing process, you'll quickly find yourself battling the frustrating phenomenon of "false trace."

This deceptive thickening occurs as harder oils and butters return to their solid state rather than properly emulsifying with the lye solution.

Maintaining oils at 110-120°F is essential for proper temperature management. If your mixture drops below this range, solid oils will begin to re-harden, creating a cloudy appearance that mimics trace but hasn't actually saponified.

This compromises saponification consistency and can lead to uneven curing and spots of unmixed fats in your final soap.

You'll know you're experiencing false trace when your batter thickens suddenly rather than gradually.

To avoid this pitfall, keep your oils warm enough to remain fully liquid throughout the mixing process.

Identifying True Trace

The difference between true trace and false trace can make or break your soap batch. Maintaining proper oil and lye temperatures between 110-120°F is essential for achieving true trace—that moment when saponification begins and your mixture leaves lasting trails on the surface.

Watch for these key indicators of true trace:

- Your soap batter maintains its thickness and doesn't revert to a liquid state

- Surface trails remain visible for several seconds after stirring

- The mixture appears uniform with no cloudy patches or solidified bits

Remember that if your lye solution is too cold, it can cause oils to solidify prematurely, creating false trace. This imposter looks thick initially but hasn't actually begun saponification.

The Relationship Between Oil Types and Temperature Needs

Different oils in your soap recipe demand specific temperature considerations for successful blending with lye. Hard oils and butters like coconut oil and lard require careful monitoring – they need to be fully melted at 110-120°F to prevent stearic spots in your final product.

At these temperatures, your oil mixture remains clear and free from cloudiness, eliminating the risk of false trace.

Maintaining oil temperatures within 10 degrees of your lye solution creates an ideal environment for the saponification process. This temperature harmony helps prevent separation and texture issues later.

For recipes containing oils prone to acceleration, such as when working with certain fragrances, aim for the lower end of the range (around 110°F). This gives you more working time to achieve intricate designs before trace occurs.

Managing Hard Oils vs. Soft Oils in Your Recipe

Successfully balancing hard and soft oils in your soap recipe requires understanding their distinct melting behaviors. Hard oils like coconut and palm need temperatures above 76-120°F to fully liquefy, while soft oils such as olive and sweet almond remain fluid at lower temperatures.

Effective temperature management means:

- Heating your hard oils completely before adding soft oils to prevent stearic spots

- Maintaining the total oil blend at 110-120°F for ideal integration and saponification

- Using a thermometer to monitor both oil types to avoid false trace issues

When combining these different oil types, aim for the 110-120°F range to guarantee all hard oils are fully melted while not overheating your soft oils.

This temperature balance creates a homogenous mixture and promotes a smoother, more uniform final soap product.

Temperature's Impact on Color Development and Additives

When mixing oils at 110-120°F, you'll notice considerably more vibrant pigment development in your soap compared to working at improper temperatures.

Your additives like clays and natural colorants need this ideal temperature range to blend effectively and maintain their true hues throughout the saponification process.

If you let your oils get too cool or overheat them, you'll risk color inconsistencies, poor additive incorporation, and potential texture issues like glycerin rivers or unmelted fatty acids.

Heat Affects Pigment Vibrancy

The vibrancy of your soap's pigmentation largely depends on the temperature at which you mix your oils. When you maintain proper temperature control between 110-120°F, you'll achieve more brilliant colors in your final soap. This ideal range guarantees all hard oils and butters fully melt, creating the perfect environment for pigments to disperse evenly.

Higher temperatures while mixing oils offer several benefits for color development:

- Enhanced dissolution of colorants throughout your soap batter

- Prevention of false trace that can lead to uneven coloring

- Improved integration of specialty colorants like LabColors for more saturated hues

You'll notice a significant difference in your soap's visual appeal when working in this temperature range, as cooler temperatures often result in cloudiness and muted colors due to incomplete saponification.

Additives Need Specific Temperatures

Different additives in your soap making process demand specific temperature ranges to perform at their best and maintain their beneficial properties. When mixing oils at temperatures between 110-120°F, you create the ideal environment for most additives to blend harmoniously with your soap batter.

| Additive | Ideal Temp | Reason |

|---|---|---|

| Milk | 100-110°F | Prevents curdling |

| Fruit Juices | 100-110°F | Maintains stability |

| Fragrance Oils | 110-120°F | Guarantees even distribution |

| Clays | 110-115°F | Prevents clumping |

| Botanicals | 105-115°F | Preserves properties |

Maintaining these temperature guidelines helps you avoid issues like false trace that can occur below 110°F, where saponification appears complete but isn't. For temperature-sensitive additives, you'll want to adjust your oil temperatures slightly lower, while still guaranteeing complete melting of hard oils and butters.

Seasonal Adjustments for Soap Making Temperatures

As seasons change throughout the year, you'll need to adjust your soap making temperatures to accommodate shifting ambient conditions.

During summer months, when ambient temperature rises, lower your oil temperatures to 100-110°F to prevent your cold process soap making from reaching trace too quickly.

Conversely, winter calls for slightly higher temperatures (110-120°F) to guarantee complete melting of solid oils when combined with your Sodium Hydroxide Pure solution.

Weather affects your soap in several critical ways:

- Summer heat accelerates saponification, requiring cooler oil temperatures to maintain control

- Winter's chill demands warmer oil temperatures to properly dissolve hard butters and oils

- Ambient temperature impacts gel phase, potentially causing issues like glycerin rivers if not managed

Safety Considerations When Blending Lye and Oils

Beyond the seasonal adjustments you'll make for proper temperatures, safety remains at the heart of successful soap making.

When handling lye water and oils, always maintain their temperatures within 10 degrees of each other to prevent violent reactions like lye volcanoes, which can occur when temperature differentials are extreme.

Never add lye to hot oils exceeding 200°F, as this risks dangerous steam reactions and makes controlling the soap mixture difficult. Always add your lye water to the oils—never the reverse—to minimize hazardous chemical reactions during blending.

Effective temperature management between 110-120°F guarantees your oils are fully melted while preventing false trace issues where your soap appears thick but hasn't properly saponified.

This temperature range optimizes both safety and soap quality during the critical soaping lye and oils phase.

Temperature Control Methods for Consistent Results

While crafting quality soap depends on multiple factors, precise temperature control remains the cornerstone of consistent results.

When blending lye with oils, maintaining both components between 110-120°F guarantees hard oils fully melt and prevents false trace issues. For reliable temperature control methods, you'll need accurate thermometers to monitor both your lye solution and oil mixture.

- Keep lye solutions below 150°F and cool to 110-120°F before blending to prevent dangerous overheating reactions.

- Ascertain oil temperatures stay consistent throughout the process to promote even saponification.

- Maintain both lye and oils within 10 degrees of each other for ideal fluidity and design capabilities.

These temperature control practices not only improve safety but also lead to better soap quality with fewer defects like glycerin rivers or soda ash.

Common Temperature Mistakes and How to Avoid Them

Even experienced soap makers can fall victim to temperature blunders that compromise their final product.

The most dangerous mistake is adding cold lye to hot oils, potentially triggering a "lye volcano" that can cause serious burns.

When mixing oils, remember that temperatures above 200°F can create unmanageable soap blobs and dangerous steam reactions.

Equally problematic is allowing your lye solution to cool too much, which can solidify your oils on contact, leading to false trace and incompletely saponified soap.

Always keep your oil and lye temperatures within 10 degrees of each other—ideally between 110-120°F—to guarantee proper blending.

Use a reliable thermometer to monitor temperatures throughout the process, and you'll avoid the inconsistent textures and poor quality that plague improperly temperature-controlled batches.

Advanced Temperature Techniques for Specialty Soaps

Although standard temperature ranges work well for basic soap formulations, specialty soaps require more nuanced temperature control to achieve their distinctive qualities.

When crafting milk-based or juice-infused recipes, you'll want to work at the lower end of the 110-120°F temperature range (around 100-110°F) to prevent overheating that can cause glycerin rivers or scorching of delicate additives.

For specialty soaps requiring intricate designs, consider these temperature adjustments:

- Maintain lye and oils within 10°F of each other to guarantee controlled saponification and prevent thermal shock

- Reduce temperatures to 110°F for swirls and detailed patterns to extend working time

- Use cooler temperatures for milk soaps, honey additives, or natural colorants that are heat-sensitive

These targeted temperature techniques will help you master even the most challenging specialty soap formulations.

Frequently Asked Questions

What Temperature to Mix Oils and Lye?

Mix your oils and lye between 110-120°F for ideal soap making. You'll want to keep them within 10 degrees of each other to prevent false trace and guarantee proper saponification. Beginners can aim for 100°F.

What Is the Best Temperature for Saponification?

For ideal saponification, you'll want to keep both oils and lye between 120-130°F. They should be within 10°F of each other. This temperature range guarantees smooth reactions and helps you avoid common soap-making problems.

How Hot Does Lye Get When Mixed With Water?

When you mix lye with water, it'll get extremely hot, typically reaching temperatures up to 200°F (93°C). You'll need to let it cool to 120-130°F before combining it with your oils for soapmaking.

What Happens if Cold Process Soap Gets Too Hot?

If your cold process soap gets too hot, you'll face gel phase issues, alien brain formation, glycerin rivers, soap volcanoes, accelerated saponification ruining swirl designs, and potentially dangerous lye volcanoes. Keep temperatures below 160°F for best results.

In Summary

Maintaining your oils at 110-120°F when blending with lye isn't just tradition—it's science. You'll achieve proper saponification, avoid false trace, and guarantee thorough mixing of all ingredients. While experienced soapmakers may experiment with temperature variations, you can't go wrong with this proven range. Remember, temperature control is your key to consistent, high-quality soap every time you craft.

Leave a Reply