For safe hot process soap making, always wear protective gear including safety goggles, nitrile gloves, long sleeves, and a respirator when handling lye. Add lye to water (never reverse) and guarantee proper ventilation with exhaust fans or open windows. Set up a dedicated workspace with clear emergency routes and spill control systems. Store materials in labeled containers away from children and pets. Following these protection rules will keep your soapmaking journey both creative and hazard-free.

Essential Protective Gear for Hot Process Soapmaking

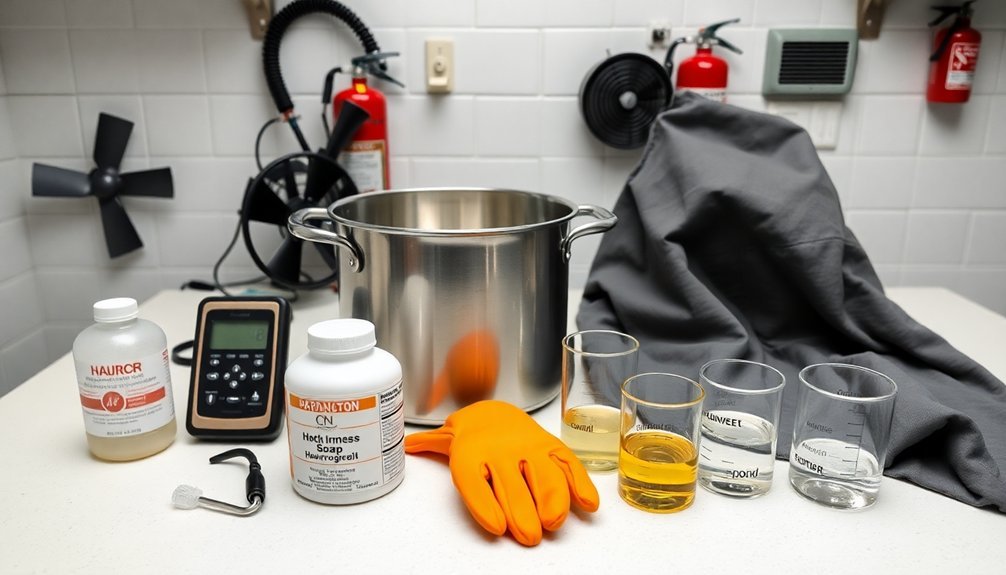

When working with lye and high temperatures during hot process soap making, you'll need proper safety equipment to protect yourself from potential hazards.

Safety goggles or a full face shield are non-negotiable to guard your eyes against caustic splashes and harmful fumes that can cause serious damage.

Always wear properly fitting nitrile gloves specifically designed for lye handling. Check them regularly for wear and replace as needed.

Protective clothing is essential too—opt for long sleeves and a non-porous apron to prevent skin contact with dangerous substances.

Don't forget respiratory protection; a respirator with replaceable cartridges will filter out particulates and VOCs released during the process.

Ascertain your workspace has adequate ventilation through fans or air purifiers to maintain safe air quality.

Understanding Lye Safety and Handling Protocols

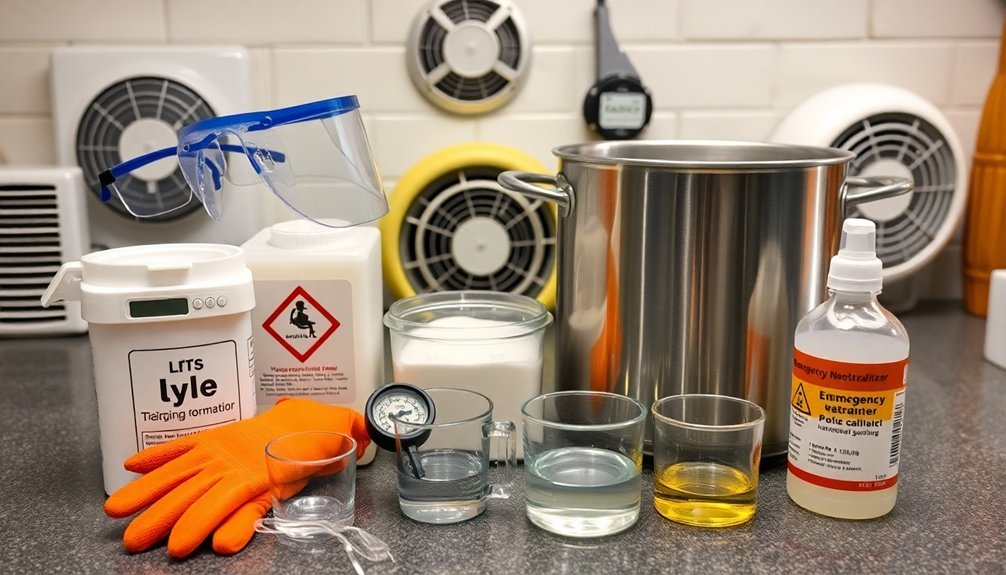

Now that you're equipped with proper protective gear, mastering lye safety becomes your next priority. Sodium hydroxide (lye) demands respect due to its caustic nature. Always work in well-ventilated areas to avoid inhaling fumes during preparation.

| Lye Safety Protocol | Required Action | Why It Matters |

|---|---|---|

| Storage | Original labeled container, locked away | Prevents accidental exposure |

| Mixing | Add lye to water, never reverse | Prevents dangerous splashing |

| Personal protective gear | Gloves, goggles, long sleeves | Protects skin and eyes |

| Lye solution spills | Rinse with plenty of water immediately | Water neutralizes effectively |

| Emergency response | Rinse affected area 15+ minutes, seek medical help | Prevents serious chemical burns |

Remember to keep vinegar away from lye solution spills—this combination creates harmful reactions. Instead, use water generously to dilute and rinse any accidental contact.

Setting Up a Hazard-Free Workspace

Setting up a hazard-free workspace requires proper ventilation to disperse chemical fumes, especially when working with lye and hot oils.

You'll need to map out clear emergency exit routes that remain unobstructed during your soap making process, ensuring you can quickly leave the area if a dangerous situation develops.

Implement spill control systems by keeping absorbent materials like baking soda, vinegar, and paper towels readily available to neutralize and contain any accidental spills of lye or oils.

Ventilation Requirements

Proper ventilation stands as the cornerstone of a safe soap making environment.

You'll need to make certain your workspace has adequate airflow by installing exhaust fans or simply opening windows during the lye mixing and saponification stages. These processes release harmful fumes that require immediate dispersal.

For peak safety, consider taking your soap making outdoors or setting up in a dedicated room equipped with an exhaust hood.

Install air purifiers with HEPA filters to capture airborne contaminants and maintain superior air quality.

Don't overlook the importance of regular monitoring—an indoor air quality monitor will help you detect potential problems before they become dangerous.

Always establish your soap making station away from living areas to protect family members and pets, while making certain it remains close to running water for emergency situations.

Emergency Exit Planning

Three essential elements define effective emergency exit planning for hot process soap making: designated pathways, organized workspaces, and practiced protocols. You'll need to establish a clutter-free soap making area with an unobstructed emergency exit that everyone can quickly access.

| Safety Element | Location | Purpose |

|---|---|---|

| Emergency Exit | Clearly marked, unobstructed | Quick escape during accidents |

| First Aid Kit | Within arm's reach | Immediate treatment for burns/exposure |

| Emergency Procedures | Posted visibly | Quick reference during incidents |

| Practice Drills | Scheduled regularly | Build muscle memory for evacuation |

Don't skip communicating these safety measures with anyone sharing your workspace. Regular practice guarantees everyone knows exactly what to do when seconds count. Your emergency procedures should include contact numbers and specific steps for handling lye spills or burns.

Spill Control Systems

While emergency exits help you escape danger, effective spill control systems prevent hazards from occurring in the first place. Organize your soap making station with designated areas for lye mixing near a sink for immediate cleanup access.

Keep your workspace decluttered and maintain clear protocols for handling accidents. Assemble a thorough spill kit containing absorbent materials, protective gloves, and safety goggles within arm's reach.

Store all ingredients in labeled, tightly sealed containers to prevent accidental spills and guarantee easy identification. For added protection, have a spill plan posted visibly in your workspace that outlines step-by-step response procedures.

These safety measures will help you respond quickly and effectively to accidents, minimizing risks while allowing you to enjoy the creative process of soap making.

Proper Ventilation to Prevent Respiratory Issues

You'll need proper ventilation to protect your lungs during hot process soap making, where lye fumes and essential oil vapors can cause serious respiratory issues.

An exhaust hood captures harmful particles while portable ventilation systems offer flexibility for those without permanent setups.

Choosing the right respirator with appropriate cartridges provides an additional layer of protection when working with caustic ingredients and fragrance compounds.

Exhaust Hood Essentials

Proper ventilation stands as a cornerstone of safe hot process soap making. An exhaust hood is your first line of defense against harmful fumes and lye particles that can compromise respiratory health.

When selecting one, focus on adequate airflow capacity with a suitable CFM rating for your workspace size.

You'll want to pair your exhaust hood with a fan exhaust system to enhance air circulation and minimize your exposure to airborne irritants. This combination greatly reduces the concentration of VOCs that spike during soap production, creating a safer breathing environment.

Don't neglect maintenance—regular cleaning of filters guarantees your ventilation system operates at peak efficiency. This simple routine significantly decreases respiratory risks and protects your lungs while you craft beautiful soaps.

Portable Ventilation Options

Not all soap makers have the space or budget for permanent exhaust hood installations.

Fortunately, effective portable ventilation options exist to protect your respiratory health during hot process soap making.

Consider investing in a portable fume extractor that captures VOCs released from lye solutions and fragrance oils.

Position it to direct airflow away from your breathing zone while mixing ingredients.

Exhaust fans and HEPA-equipped air purifiers also considerably reduce harmful particles and improve overall air quality in your workspace.

For maximum protection, pair your ventilation system with a respirator that has replaceable cartridges.

This dual approach shields you from both particulates and chemical exposure.

Don't neglect maintenance—regular filter replacement guarantees your equipment continues to function at its best, maintaining a safe environment for your creative soap making endeavors.

Respirator Selection Guide

Selecting the right respirator can mean the difference between a safe soap making session and potential respiratory distress. For hot process soap making, choose models with replaceable cartridges specifically designed to filter particulates and VOCs released during the process.

Full face shield respirators offer maximum protection when handling lye and fragrance oils, safeguarding both your lungs and face from potential splashes. Confirm your respirator creates a proper seal against your face—any gaps will allow dangerous fumes to bypass filtration.

Complement your respirator selection with an exhaust fan or air purifier to further reduce airborne contaminants in your workspace.

Remember to inspect your equipment regularly and replace cartridges according to manufacturer guidelines. Your respirator is only effective when properly maintained and correctly fitted.

Safe Mixing Techniques for Lye Solutions

When handling lye, your safety must come first, as this powerful caustic substance requires careful management to prevent serious burns and injuries.

Always wear complete personal protective equipment, including safety goggles, gloves, and protective clothing before working with sodium hydroxide.

Mix your lye solution in a well-ventilated area or outdoors to avoid inhaling harmful fumes.

Select a heat-resistant polypropylene container (number five plastic) that won't react with the caustic substance.

Remember the critical rule: always add lye to water, never water to lye. This prevents dangerous splattering and violent reactions.

Keep a supply of fresh water nearby while mixing lye solution for immediate rinsing if accidental contact occurs.

Know emergency procedures before you begin your soap making process.

Emergency Response Procedures for Spills and Burns

Even with stringent safety measures in place, accidents can happen during soap making. Knowing how to respond quickly can prevent serious injuries when working with caustic substances like lye.

If a lye spill occurs:

- Immediately rinse the area with plenty of water for at least 15 minutes—never use vinegar as it may worsen chemical burns.

- For ingestion, don't induce vomiting; rinse the mouth with water and seek immediate medical assistance.

- Keep an emergency contact list prominently displayed in your workspace, including poison control numbers for quick access during incidents.

Ensure your first aid kit contains burn treatment supplies and is easily accessible.

Familiarize yourself with these emergency procedures before you begin making soap—preparation is your best defense against potential accidents.

Child and Pet Safety Considerations

Soap making at home requires special attention to protect your most vulnerable family members. Establish a dedicated workspace that's completely off-limits to children and pets, as sodium hydroxide and raw soap batter can cause severe burns or poisoning if touched or ingested.

Store all ingredients and equipment in locked cabinets or high shelves where curious hands and paws can't reach them. Never leave your soap-making station unattended, even briefly—accidents happen in seconds.

Take time to explain child safety rules to everyone in your household, clarifying why certain areas are restricted. When working with caustic materials, make certain you're free from distractions and interruptions that pets or children might cause.

Consider scheduling your soap making during times when supervision of little ones isn't competing for your attention.

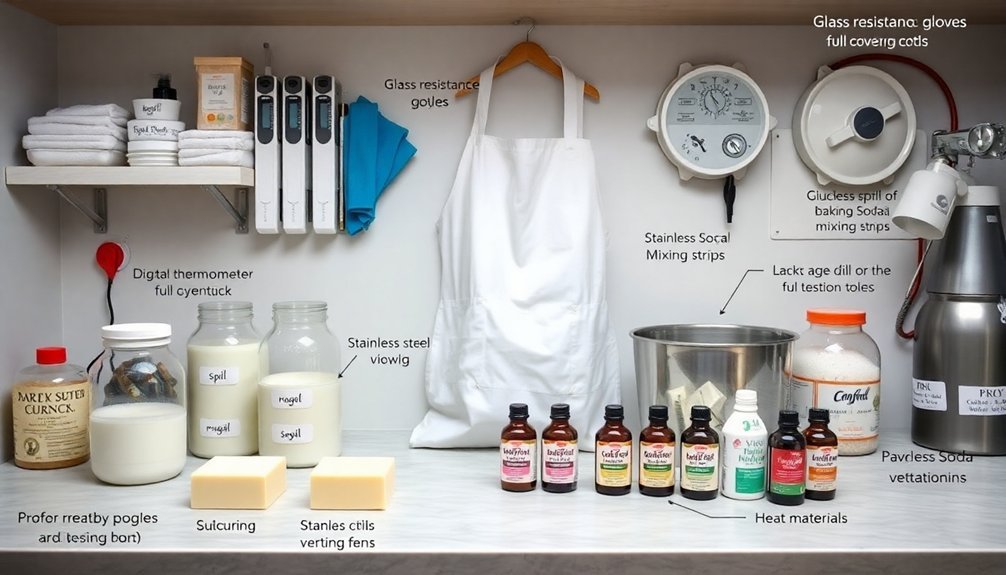

Proper Storage of Raw Materials and Equipment

Securing your workstation doesn't end with keeping family members safe—your materials and equipment also need proper storage protocols.

Proper storage prevents contamination, maintains ingredient quality, and reduces accident risks in your soap-making area.

- Store sodium hydroxide (lye) in its original labeled container with a screw-top lid in a cool, dry place to prevent moisture absorption that can compromise safety and effectiveness.

- Maintain oils, fragrances, and colorants in airtight containers, preferably using polypropylene (number five) plastic containers for lye solutions and soap batters as they resist corrosion.

- After each soap-making session, dedicate time to cleaning and storing equipment properly—wash all utensils thoroughly, dry completely, and store in designated areas away from food preparation spaces.

Regular inspection of your storage area helps identify potential problems before they become hazards.

Managing High Temperatures During Processing

While measuring ingredients creates the foundation for quality soap, controlling temperature remains one of the most critical safety aspects of hot process soap making.

All safety plans which dictate proper handling procedures should emphasize maintaining a safe distance from heat sources to prevent burns.

Always monitor the temperature with a reliable thermometer, keeping mixtures below 200°F to avoid dangerous splattering.

Wear heat-resistant gloves and protective clothing whenever handling hot mixtures or equipment.

Select stainless steel or heat-resistant silicone containers that can withstand high temperatures without compromising your safety.

Position a Class K fire extinguisher within reach when working with hot oils.

Proper ventilation is also essential to disperse potentially harmful fumes that develop during heating.

These precautions will greatly reduce your risk of thermal injuries.

Post-Production Handling and Curing Safety

After completing the hot process, your freshly made soap requires careful handling and proper curing to secure a safe, high-quality final product.

Even after cooking, your soap may contain caustic elements for up to 48 hours, so proper post-production handling is essential.

- Wear protective gear including gloves when handling fresh soap, as it's not fully saponified for 24-48 hours after production.

- Store in a cool, dry, well-ventilated area away from children and pets to prevent accidental exposure while curing for 4-6 weeks.

- Label all soap bars with production dates to track curing progress and regularly inspect for moisture or contamination.

Remember that curing safety isn't just about protection from caustic elements—it also guarantees your soap develops its best texture, longevity, and effectiveness.

Frequently Asked Questions

What Are the Safety Precautions for Soap Making?

You'll need to wear protective goggles and nitrile gloves when making soap. Guarantee proper ventilation, keep a first aid kit nearby, understand ingredient hazards, and maintain a clean, organized workspace away from children.

Do I Need FDA Approval to Sell Soap?

You don't need FDA approval to sell basic soap, but you must comply with proper labeling requirements. If you're making therapeutic claims or medicinal soap, it would then be classified as a drug requiring approval.

What Precautions Should Be Taken When Making Homemade Soap?

Always wear PPE including goggles and gloves. You'll need adequate ventilation when mixing lye. Keep your workspace organized, store caustic materials properly, and have a first aid kit ready for emergencies.

What PPE Is Needed for Soap Making?

You'll need safety goggles or face shields to protect your eyes, long rubber or nitrile gloves for your hands, and protective clothing like long-sleeved shirts and aprons made from caustic-resistant materials.

In Summary

Making hot process soap requires your vigilance at every step. You've learned the essential protective measures, from proper gear to workspace setup. Remember, it's not just about your safety but also protecting others around you. By following these protocols for handling lye, managing temperatures, and ensuring proper ventilation, you'll create beautiful soaps without compromising your well-being. Stay protected, and you'll enjoy this rewarding craft safely.

Leave a Reply