Different soapmaking oils require specific heating temperatures for ideal results. Hard oils like cocoa butter (93°F) and palm oil (96°F) need higher temperatures (120-130°F) for complete melting, while liquid oils work at 90-110°F. Butters such as shea (84°F) and mango (86°F) offer balance between hardness and moisture. Keep oils within 10°F of your lye solution and maintain workspace temperatures between 70-75°F for consistent saponification. These temperature nuances can make the difference between grainy soap and silky perfection.

Numeric List of Second-Level Headings

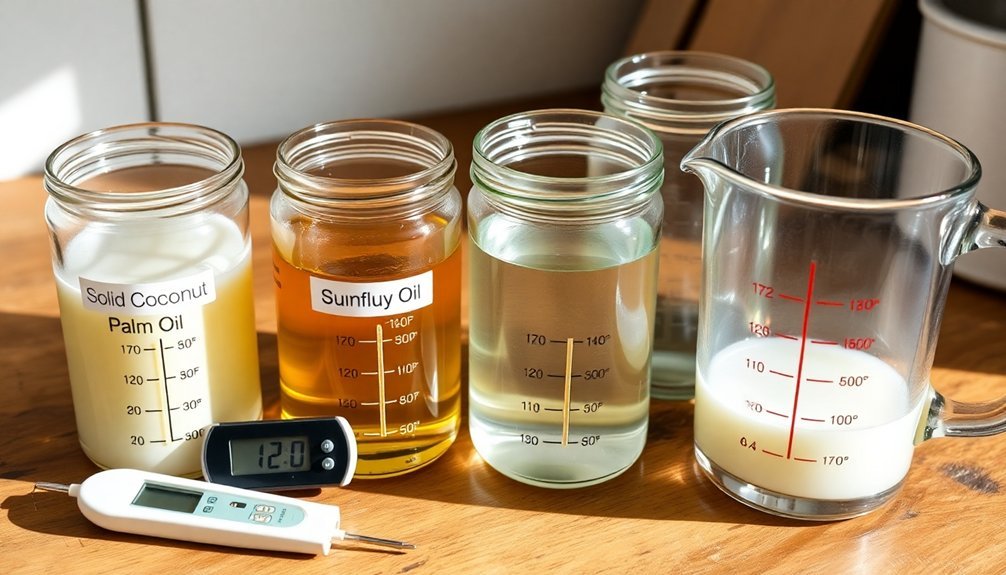

Five essential oils require specific heating temperatures for successful soapmaking.

When crafting your soap recipes, you'll need to pay close attention to these melting points to guarantee proper incorporation:

- Cocoa Butter: Heat to 93°F (34°C)

- Coconut Oil: Melt at 76°F (24°C)

- Mango Butter: Warm to 86°F (30°C)

- Palm Oil: Heat to 96°F (36°C)

- Shea Butter: Melt at 84°F (29°C)

Understanding these heating temperatures will greatly improve your soap quality and consistency.

Liquid oils like coconut oil require less heat than solid butters such as cocoa and palm. Each oil's unique melting point affects how it behaves in your soap formula.

Overheating can damage beneficial properties, while insufficient heating causes improper blending, resulting in grainy textures.

Understanding Melting Points of Common Soapmaking Oils

While mastering the art of soapmaking, you'll discover that understanding melting points is essential for achieving consistent results. Each oil contributes differently to your final product based on its unique temperature threshold.

Hard oils like cocoa butter (93°F) and palm oil (96°F) provide structure and firmness to your soap bars. They'll remain solid at room temperature, creating stability in your formulations.

Meanwhile, shea butter (84°F) and mango butter (86°F) fall in the middle temperature range, offering a balance between hardness and moisturizing properties.

Coconut oil, with its lower melting point of 76°F, often requires less heating during the soapmaking process. By respecting these temperature differences, you'll avoid overheating your soapmaking oils while still ensuring they're properly melted for uniform blending.

Temperature Requirements for Hard Oils vs. Liquid Oils

Now that you're familiar with melting points, let's focus on the specific temperature needs for different oil types.

Hard oils like cocoa butter and palm oil require higher temperatures—ideally 120-130°F (49-54°C)—to melt completely and participate properly in the saponification reaction. Without sufficient heat, these oils won't incorporate fully into your soap mixture.

In contrast, liquid oils such as olive, coconut, and sunflower remain fluid at room temperature and work well at 90-110°F (32-43°C).

When combining both types in your recipe, you'll need to find a middle ground that melts the hard oils without overheating the liquid ones.

Always keep your oils within 10°F of your lye solution temperature to prevent premature solidification of fats, which can ruin your batch.

The Science Behind Heat Transfer Method in Cold Process

You'll find that thermal conductivity principles drive the heat transfer method, where hot lye solution efficiently melts solid oils through direct contact.

By understanding these dynamics, you can control whether your soap reaches gel phase, which notably affects clarity and color vibrancy.

Your temperature monitoring techniques, including infrared thermometers or temperature guns, provide essential feedback throughout this process to guarantee ideal saponification conditions.

Thermal Conductivity Basics

Understanding thermal conductivity forms the foundation of successful cold process soapmaking, especially when using the heat transfer method.

When you combine hot lye (120-130°F) with room temperature oils, you're relying on the thermal conductivity of each oil to efficiently distribute heat throughout your mixture.

Oils with higher thermal conductivity, like coconut oil, melt faster when they meet hot lye, accelerating saponification and helping you reach trace more quickly.

The specific heat capacity of each oil also matters—liquid oils require less energy to heat compared to hard butters like cocoa or shea.

Gel Phase Control

The heat transfer method represents a practical application of thermal conductivity principles in cold process soapmaking.

By strategically managing the exothermic reaction between your lye solution and oils, you'll gain precise control over the gel phase.

When you maintain oil temperatures between 120°F to 130°F (49°C to 54°C), you're creating ideal conditions for complete saponification.

The hot lye solution naturally transfers heat to your oils, promoting full gel phase development which enhances your soap's color saturation and overall texture.

This approach works exceptionally well with soft or liquid oils that don't require excessive heating.

By carefully timing when you combine your heated ingredients, you'll minimize risks like glycerin rivers or soap volcanoes that can occur with temperature mismanagement.

The heat transfer method ultimately gives you greater control over your soap's appearance and quality.

Temperature Monitoring Techniques

While mastering the heat transfer method requires practice, proper temperature monitoring serves as its foundation. You'll want to track both your lye solution and oil mixture temperatures consistently throughout the process.

For ideal results, aim to maintain your lye solution between 120-130°F (49-54°C) when introducing it to your pre-measured solid oils. This temperature range effectively melts oils while initiating proper saponification without excessive heating.

A digital laser thermometer provides the most accurate readings without contaminating your ingredients. Simply point and click to verify temperatures at critical stages.

After combining your lye solution with oils, stir gently until all solids have completely melted before proceeding to blend. This temperature control prevents common issues like false trace and soda ash while ensuring your soap cures properly with consistent texture throughout.

Preventing False Trace Through Proper Oil Heating

Because false trace can derail even the most carefully planned soap recipe, maintaining proper oil temperatures is essential for successful soapmaking. You'll need to heat your oils to at least 90°F (32°C), but not exceeding 110°F (43°C) to guarantee solid oils fully melt and blend properly in cold process soap making.

| Oil Type | Melting Point | Ideal Temp | Risk Level |

|---|---|---|---|

| Coconut | 76°F (24°C) | 90°F (32°C) | Medium |

| Palm | 96°F (36°C) | 100°F (38°C) | High |

| Cocoa Butter | 93°F (34°C) | 100°F (38°C) | High |

| Shea Butter | 89°F (32°C) | 95°F (35°C) | Medium |

For preventing false trace, always verify your oils appear clear, not cloudy. Using a digital laser thermometer will help you accurately monitor heating temperatures, especially when working with recipes containing high percentages of solid oils.

Optimal Temperature Ranges for Olive Oil-Based Recipes

When making olive oil-based soaps, you'll want to heat your oils to 90-110°F (32-43°C) for cold-process methods, which balances smooth mixing with adequate working time.

For hot-process recipes, maintain slightly higher temperatures between 110-120°F (43-49°C) to facilitate proper saponification while still preventing overheating issues.

Matching your oil temperature closely with your lye solution (ideally both around 100°F or 38°C) creates the best combination for achieving consistent trace and preventing separation in your finished olive oil soap.

Cold-Process Temperature Guidelines

The success of olive oil-based cold-process soap largely depends on maintaining proper temperature ranges throughout the saponification process.

When working with olive oil, you'll want to keep temperatures between 90°F to 110°F (32°C to 43°C) to guarantee proper chemical reactions while avoiding false trace issues.

Since olive oil tends to trace more slowly than other oils, maintaining temperatures around 100°F (38°C) will help speed up the process without compromising quality.

Always keep your lye solution and olive oil within 10 degrees of each other to promote smooth emulsification.

The heat transfer method works well with olive oil soaps—simply add hot lye solution to room temperature olive oil.

Remember to stay below 120°F (49°C) throughout the entire process to prevent rapid trace and soda ash formation on your finished soap.

Hot-Process Heating Considerations

Unlike cold-process methods, hot-process soap making with olive oil requires higher temperature ranges to accelerate saponification and guarantee complete chemical reactions.

You'll want to heat your olive oil to approximately 120°F (49°C), which is well above its 75°F melting point to prevent any solidification issues.

For ideal results, maintain your oils within the 120-130°F (49-54°C) range throughout the process.

When working with a hot lye solution around 200°F (93°C), make sure the temperature difference between your oils and lye doesn't exceed 10 degrees to avoid false trace problems.

This temperature balance is essential for successful saponification.

The higher temperatures in hot process effectively melt all components, creating a smoother mixture and producing soap that cures faster than cold-process methods.

Optimal Oil-Lye Combinations

Three key temperature ranges form the foundation of successful olive oil-based soap recipes. For ideal oil-lye combinations, you'll want to maintain both components within 10°F of each other, ideally around 100°F (38°C). This balanced approach guarantees proper saponification without false trace issues.

| Temperature Range | Olive Oil Behavior | Best For |

|---|---|---|

| 90-100°F (32-38°C) | Slower trace | Intricate designs/swirls |

| 100-105°F (38-41°C) | Ideal saponification | Most olive oil recipes |

| 105-110°F (41-43°C) | Faster reaction | Quick-trace formulas |

Keep heating temperatures lower (90-110°F) when working with olive oil-dominant formulations. For recipes with solid oils or butters, verify all ingredients are properly melted before combining. A water-to-lye ratio of 2.105:1 works well with olive oil soaps, preventing cooling issues while maintaining workability.

Managing Heat for Butters: Cocoa, Shea, and Mango

Butters require special attention when heating for soapmaking because their unique melting points affect both the quality and texture of your final soap. Each butter has specific temperature needs to achieve proper liquefaction without damaging its beneficial properties.

Cocoa butter needs to reach about 93°F (34°C) to fully melt, while shea butter liquefies at around 84°F (29°C). Mango butter falls between them at approximately 86°F (30°C).

When working with these butters, you'll want to maintain temperatures between 90-110°F (32-43°C) to guarantee they blend smoothly with other oils.

Don't forget to use a digital thermometer for precision—excessive heat can degrade these butters' qualities. Gentle warming is key to preserving their beneficial properties while achieving the smooth consistency you need for perfect soap.

Temperature Considerations When Working With Coconut Oil

When working with coconut oil in soapmaking, you'll need to pay close attention to temperature due to its unique melting properties.

With a melting point of 76°F (24°C), coconut oil shifts from solid to liquid state within a specific range that's essential for ideal soap making.

For successful saponification process, aim to heat your coconut oil between 90°F and 110°F (32°C-43°C). This guarantees proper melting while preventing complications:

- Monitoring temperature with a thermometer prevents overheating that can degrade oil quality

- Keeping coconut oil within the perfect range helps you avoid false trace issues

- Excessive heat accelerates trace, making it difficult to incorporate additives

- Proper temperature control enhances the overall quality and smoothness of your final soap

The Role of Room Temperature in Soap Setting Process

Although often overlooked, room temperature plays an essential role in determining soap setting success. When making soap, maintaining your workspace between 70-75°F (21-24°C) prevents solid oils and butters from solidifying too quickly while ensuring proper saponification.

| Room Temperature | Effect on Process | Troubleshooting |

|---|---|---|

| Too Cold (<65°F) | Slow trace, oils solidify | Preheat workspace |

| Ideal (70-75°F) | Balanced reaction rate | Keep oils within 10°F of lye |

| Too Warm (>80°F) | Accelerated trace | Cool workspace or ingredients |

| Fluctuating | Inconsistent results | Stabilize environment |

| Drafty Areas | Risk of false trace | Shield soap mold from drafts |

Keeping your oils and lye solution within 10°F of each other helps avoid false trace—when your soap batter appears thick but hasn't properly saponified. You'll achieve more predictable, consistent results when you monitor and control your soap making environment.

Using Digital Thermometers for Precise Oil Temperature Control

Digital thermometers serve as your most reliable tool for precise temperature control when heating soapmaking oils.

You'll get the most accurate readings by holding the thermometer in the center of your oil mixture, away from the pot's sides or bottom, and regularly calibrating your device using ice water or boiling water methods.

For ideal results, place your thermometer at consistent depths in the oil, avoid measuring near heat sources, and take multiple readings to guarantee your oils stay within the vital 90°F to 110°F range.

Accurate Reading Techniques

Since accuracy determines success in soapmaking, mastering proper thermometer technique is essential for consistent results. Your digital laser thermometer should be calibrated regularly to guarantee precise temperature monitoring.

When taking readings, hold the thermometer approximately 6 inches from the oil surface and aim at the center of the liquid for the most accurate measurement.

- Always measure melted solid oils, not partially melted ones, to get true temperature readings

- Check temperatures frequently during the process, especially when using heat transfer methods

- Keep both oils and lye solution within the 90-110°F (32-43°C) range for ideal mixing

- Take multiple readings from different areas of large batches to guarantee uniform heating

Calibration For Reliability

Regular calibration of your digital thermometer guarantees the accuracy that can make or break your soap recipe.

To verify reliable temperature readings, check your thermometer's calibration at least monthly by measuring ice water (32°F/0°C) and boiling water (212°F/100°C at sea level).

With properly calibrated equipment, you'll maintain precise temperature control throughout the soapmaking process. This precision prevents common issues like false trace and oil separation while verifying your ingredients remain within the ideal 90°F-110°F range.

When monitoring melting points—coconut oil at 76°F or cocoa butter at 93°F—accurate readings confirm complete melting before lye introduction.

Remember that keeping your oil and lye temperatures within 10 degrees of each other optimizes saponification.

Your calibrated digital thermometer helps avoid overheating oils beyond 120°F, which can accelerate trace and create defects.

Placement For Best Results

Proper placement of your digital thermometer guarantees the most accurate readings when monitoring oil temperatures.

When using a laser thermometer, aim at the center of your oil mixture rather than the container edges for true temperature assessment. This precision helps maintain the ideal 90-110°F range essential for perfect soap making conditions.

- Point your thermometer at different locations in your oils to detect any temperature variations that could affect trace.

- Always measure after stirring to verify uniform temperature throughout the entire mixture.

- When working with both solid and liquid oils, check temperatures after combining to confirm they've equilibrated.

- Take readings just before adding lye solution to verify your oils are around 100°F for best blending.

Consistent temperature monitoring prevents accelerated trace, allowing you enough working time for intricate soap designs.

How Temperature Affects Trace Time and Soap Consistency

When mixing oils and lye for soapmaking, temperature plays an essential role in determining how quickly your soap reaches trace and its final consistency.

Working within the ideal range of 90°F to 110°F helps prevent false trace and guarantees proper saponification of your soap batter.

Higher temperatures accelerate the process, creating a thick trace faster—perfect for layered designs but challenging for intricate patterns.

If you're planning detailed swirls, you'll want cooler temperatures around 90°F to extend your working time.

Be cautious of temperatures that are too low, as they can cause your soap batter to appear thick without being properly saponified.

For best results, maintain both oils and lye at consistent temperatures for soap, ideally close to 100°F, promoting smooth blending and excellent trace development.

Seasonal Adjustments for Oil Heating in Soapmaking

The temperature needs for your soapmaking oils change throughout the year, requiring thoughtful adaptations to your heating methods.

During winter months, you'll need to apply higher temperatures to solid oils like cocoa butter (around 120°F) and shea butter to guarantee complete melting and proper blending.

- In summer, reduce heating for all oils to prevent overheating—keep temperatures below 120°F, especially when working with mainly soft oils.

- For coconut oil, aim for about 100°F in cooler months to prevent premature solidification during mixing.

- Liquid oils such as olive oil may not need heating at all during warmer seasons.

- Adjust your approach based on ambient temperature—cooler environments require more careful heating of oils to avoid false trace issues.

Frequently Asked Questions

What Temperature Should Oil Be for Soap Making?

For soap making, you'll need to heat your oils to 90-110°F (32-43°C). You should guarantee cocoa butter (93°F), coconut oil (76°F), palm oil (96°F), and shea butter (84°F) all exceed their melting points.

What Is the Best Temperature for Saponification?

For ideal saponification, you'll want to maintain temperatures between 90-110°F (32-43°C). Keep your oils and lye solution within 10 degrees of each other, ideally around 100°F (38°C) for a successful chemical reaction.

What Is the Best Temperature for Curing Soap?

You'll want to cure your soap at room temperature, between 70-80°F (21-27°C). Keep it in a well-ventilated space away from direct sunlight for 4-6 weeks to achieve properly hardened, high-quality bars.

What Temperature Do You Add Essential Oils to Soap?

You should add essential oils to your soap when it's cooled to 100-110°F (38-43°C). Don't add them when it's too hot, or you'll lose their fragrance. Wait until you've reached a light trace.

In Summary

You'll find mastering oil temperatures is essential for successful soapmaking. Remember to heat hard oils to just above their melting points while keeping liquid oils cooler. Don't underestimate the impact of your workspace temperature on the final product. With practice and precise temperature monitoring, you'll develop intuition for seasonal adjustments and create consistently perfect soap batches every time.

Leave a Reply