To make pure goat tallow soap, you'll need to render and strain goat fat until it's clean and solidified. Melt your prepared tallow to 90-100°F while mixing lye with distilled water to the same temperature. Combine both mixtures until reaching a light trace consistency, then pour into lined molds. Let the soap set for 24 hours before unmolding, and cure for 4-6 weeks. Following proper safety protocols and temperature control will guarantee your handcrafted soap turns out perfectly.

Essential Equipment and Safety Protocols

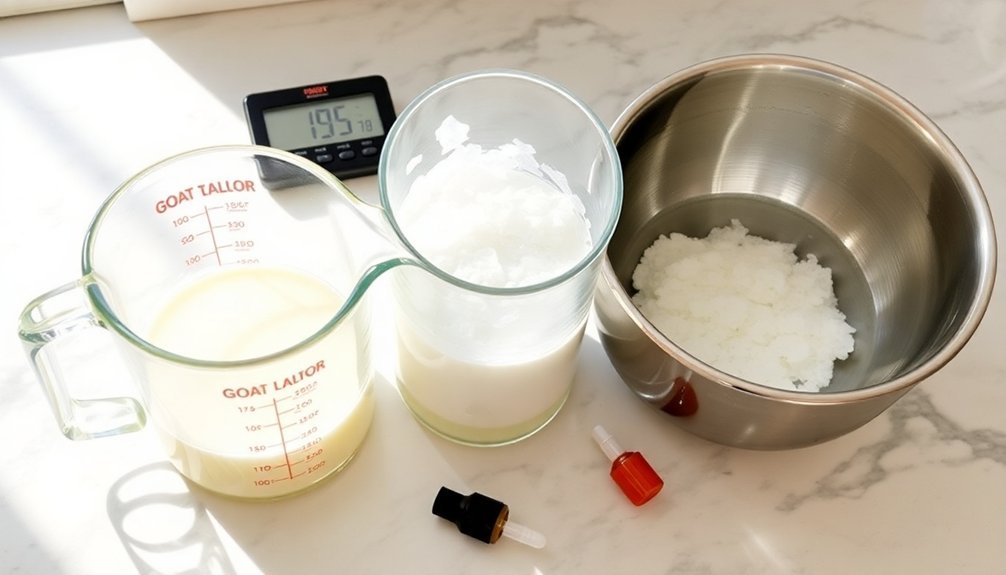

Before beginning your goat tallow soap-making journey, you'll need to gather essential equipment and understand crucial safety measures. Start by collecting a large pot, scale, thermometer, and soap mold for precise ingredient handling and shaping.

To protect yourself from dangerous lye burns, you'll need rubber gloves, safety goggles, and long-sleeved clothing. Set up your workspace in a well-ventilated area away from distractions, and keep white distilled vinegar nearby to neutralize any accidental lye contact.

Safety first: Always wear protective gear and keep vinegar handy when working with lye during soap making.

Remember to handle lye mixing outdoors, as the fumes can be harmful. Organize all your tools and materials before you start, ensuring everything's within reach but safely arranged.

This preparation will help you maintain focus on the task while following proper safety protocols throughout the soap-making process.

Rendering and Preparing Goat Tallow

With your safety equipment ready, it's time to focus on preparing the key ingredient for your soap: goat tallow.

Begin by cutting your rendered animal fat into small pieces, placing them in a large pot over low heat. You'll want to use the wet method by adding water, which prevents burning during the chemical reaction process.

As the fat melts, you'll notice it separating from connective tissue. Strain the liquid through a fine mesh sieve to remove solid particles, ensuring your future lye solution will mix properly during saponification.

Let the strained tallow cool until it solidifies, checking that it has a clean scent and creamy white or pale yellow color.

Store your rendered goat tallow in an airtight container in the refrigerator until you're ready to begin soap making.

Mixing Ingredients and Temperature Control

Since precise temperature control is critical for successful saponification, you'll need to carefully monitor both your tallow mixture and lye solution throughout the mixing process.

Begin by melting your goat tallow with other oils at low heat, then let them cool to 90-100°F.

For the lye solution, slowly combine lye with either distilled water or partially frozen goat milk, allowing it to cool to the same temperature range.

When both mixtures reach the ideal temperature, blend them together until you achieve a light trace, indicating they've properly emulsified.

If your soap recipes call for additives like citric acid or colorants, add them after reaching trace.

Remember that maintaining proper temperature control during the entire process prevents overheating and guarantees proper saponification of your melted oils into smooth, well-formed soap.

Pouring and Molding Techniques

The proper pouring and molding techniques will make or break your goat tallow soap's final appearance.

Before pouring, wait until your soap mixture reaches a light trace consistency, which guarantees proper emulsification. You'll need to prepare your mold by lining it with parchment paper, making it easier to remove the soap later.

Pour the mixture slowly into your prepared mold to prevent air bubbles from forming. If you notice any trapped air, gently tap the mold against a flat surface.

Once you've filled the mold, cover it with a towel to maintain warmth and promote proper saponification. Don't rush to remove your soap – wait at least 24 hours, then check its firmness. If it's still soft, give it more time to set before unmolding.

Curing and Storage Methods

Once your soap has been unmolded, the curing process begins – a vital step that transforms your bars from soft and mild to hard and long-lasting.

Place your soap bars on cooling racks in a cool, dry area away from direct sunlight for 4-6 weeks. Turn them weekly to guarantee even drying and best results.

To prevent Dreaded Orange Spots, add 2% citric acid to your recipe and maintain proper curing conditions.

During the curing period, assure good airflow by storing your bars in a well-ventilated space, such as a cardboard box or cloth bag. This helps minimize the risk of mold and rancidity.

For extended shelf life up to two years, wrap your fully cured soap bars in wax paper or place them in airtight containers. This method protects them from humidity and environmental contaminants.

Frequently Asked Questions

Can You Make 100% Tallow Soap?

Yes, you can make 100% tallow soap! You'll get a hard bar with rich, creamy lather. Just make certain you're using the correct lye ratio and consider adding 5-10% superfat for peak moisturizing properties.

Is Goat Tallow Good for Soap Making?

Yes, you'll love using goat tallow in your soap making. It creates a creamy, foamy lather while producing hard, moisturizing bars. Its natural fatty acids give you excellent cleansing properties and silky-smooth results.

What Are the Disadvantages of Tallow Soap?

You'll notice tallow soap can feel greasy and have a strong odor. It won't lather as much as other soaps, may develop orange spots in humidity, and won't appeal to vegan consumers seeking plant-based alternatives.

How to Make Goat Tallow?

Cut goat fat into small pieces and heat slowly at 200°F. You'll need to strain the melted fat through cheesecloth to remove impurities. Let it cool until it's solid and store in an airtight container.

In Summary

You've now learned the complete process of making pure goat tallow soap from start to finish. With the right equipment, proper safety measures, and careful attention to temperatures and measurements, you'll create beautiful, nourishing bars of soap. Remember to let your soaps cure fully for 4-6 weeks before using them. Once mastered, this traditional soap-making method will provide you with quality handmade soaps for years to come.

Leave a Reply