For perfect cold process soap, you'll want to blend essential oils at 1-3% concentration of your total base oils. Popular combinations include "Love Struck" (clary sage, bergamot, ylang ylang) and floral-woody pairings like rose with sandalwood. Work at temperatures between 90-110°F for ideal emulsification, and measure oils by weight rather than volume. Let your soap cure 4-6 weeks for best results. These fundamental techniques reveal endless possibilities for creating unique, aromatic soaps.

Understanding Essential Oil Properties in Cold Process Soap

When crafting cold process soap, understanding essential oil properties is crucial for creating effective and therapeutic products.

You'll find that essential oils aren't just for fragrance – they're packed with antioxidants and beneficial compounds that enhance your soap's skincare benefits.

Each oil brings unique properties to your soap. Lavender calms and relaxes, while tea tree and peppermint fight bacteria and help with acne.

These natural properties are preserved through the cold process method, ensuring your soap delivers maximum therapeutic benefits.

When selecting oils, you'll need to reflect on their specific traits and how they'll behave in your recipe.

Remember to start with a conservative 1% solution for facial soaps or if you're new to soap making.

You can increase to 3% for body soaps once you're more experienced with blending.

The beauty of cold process soap making lies in its ability to create long-lasting bar soap that maintains quality over time.

Popular Valentine's Day Essential Oil Combinations

When crafting Valentine's Day soaps, you'll find that certain essential oil combinations naturally evoke feelings of romance and warmth.

You can create enchanting blends by pairing floral oils like ylang ylang and rose with woody notes of sandalwood, or by mixing sweet orange with spicy cinnamon for an alluring aroma.

Popular romantic combinations include the "Love Struck" blend of clary sage, bergamot, and ylang ylang, as well as the "Endless Love" mixture of sandalwood, lavender, and ylang ylang. These natural blends provide health benefits beyond fragrance while creating an inviting atmosphere.

Romantic Scent Pairings

Creating romantic essential oil blends for your Valentine's Day soaps starts with understanding classic scent combinations that evoke feelings of love and sensuality.

The key is to balance floral notes with woody or citrus elements for a well-rounded fragrance that's not overpowering. Essential oils should be carefully selected as they can stimulate excitement and desire through their aromatic properties.

- Rose and Sandalwood: Combine 3 parts rose with 2 parts sandalwood, adding a touch of bergamot for brightness and depth.

- Ylang Ylang and Jasmine: Mix equal parts of these florals with a hint of sweet orange and patchouli for a sensual, exotic blend.

- Lavender and Geranium: Blend 2 parts lavender with 1 part geranium, complemented by cedarwood for a soothing, romantic aroma.

These combinations work particularly well in cold process soap making, as they maintain their scent profile throughout the curing process.

Natural Love Blends

To achieve the perfect Valentine's Day soap, natural essential oil blends offer the most authentic and enchanting aromas for your romantic creations.

You'll find that combining lavender with other oils creates versatile bases – try pairing it with litsea for a 60/40 blend or mixing it equally with geranium for a balanced floral scent.

For a more complex fragrance, combine ylang-ylang, bergamot, and lavender in a 30/20/50 ratio. This blend delivers depth while maintaining the romantic theme. Temperatures during the soap making process can reach up to 60 degrees Celsius during saponification.

If you're seeking an earthier profile, mix patchouli and lavender in a 40/60 split, optionally adding cedarwood for extra warmth.

Remember to add these blends at trace and stay within safe dermal limits. You'll need to account for the volatile nature of essential oils during the saponification process.

Mastering Temperature Control for Oil Stability

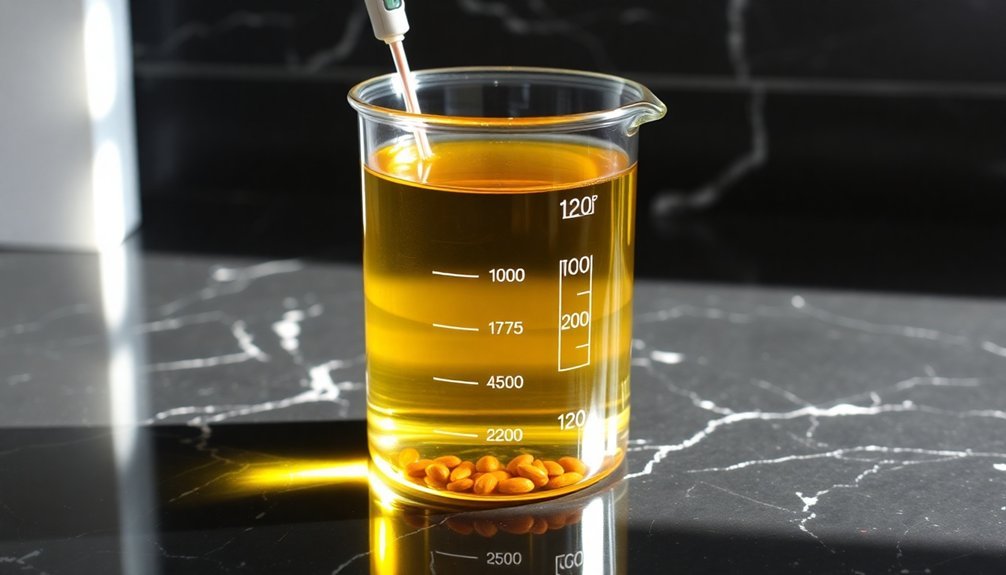

Successful cold process soap making hinges on precise temperature control of your oils and lye solution.

You'll need to maintain temperatures between 90-110°F for ideal emulsification, though many soapers prefer working at 120-130°F. Using a digital laser thermometer, you can confirm your lye and oils stay within 10 degrees of each other. Higher temperatures often lead to cracking in soap.

- For basic recipes, aim for temperatures around 120°F to prevent trace acceleration while still achieving proper saponification.

- When working with milk-based soaps, keep temperatures lower (100-110°F) to prevent scorching your alternative liquids.

- For recipes featuring shea butter or other temperature-sensitive ingredients, carefully monitor temperatures above 84°F to prevent premature solidification.

Remember that your soaping environment's temperature affects your final product, so consider using heat transfer methods to maintain stability throughout the process.

Base Oil Selection and Their Impact on Fragrance

When working with natural butters in your soap recipes, you'll notice they can impart their own subtle scents that might compete with or complement your chosen fragrance oils.

Neem oil presents a unique challenge due to its strong, distinct aroma that can overpower other scents and requires careful consideration in your fragrance selection.

You'll need to adjust your fragrance oil percentages higher when using neem oil, or consider restricting its use to unscented formulations where its medicinal benefits take priority over aesthetic concerns.

Natural Butter Scent Effects

Understanding the natural scent profiles of base oils and butters plays an essential role in crafting well-balanced cold process soaps.

When you're working with natural butters, you'll notice that cocoa butter contributes a distinct chocolate aroma that can either complement or compete with your chosen fragrance oils. Shea butter adds a subtle nutty scent, while mango and kokum butters offer milder scent profiles that won't interfere with your fragrance choices.

- Natural butters can be deodorized to minimize their impact on your soap's final scent, giving you more control over the fragrance profile.

- You'll need to take into account how coconut oil's strong natural scent might overpower delicate fragrances when used in higher percentages.

- The combination of different butters can create unique base notes that enhance your chosen fragrance oils.

Neem Oil Fragrance Challenges

Despite its numerous skin benefits, neem oil presents one of the biggest fragrance challenges in cold process soapmaking. You'll need to carefully consider your approach when incorporating this potent ingredient, as its strong garlic-like aroma can overwhelm your soap's intended scent.

To effectively manage neem oil's distinct smell, you'll want to start with a lower concentration, typically around 2.5%, and pair it with robust essential oil blends. Earthy scents like patchouli, lavender, and lemongrass work particularly well at masking neem's aroma.

You can also use fragrance oils with earthy notes, such as cannabis and cocoa. Remember that proper temperature control (100°F to 110°F) and thorough mixing are vital for achieving an even fragrance distribution.

During the curing process, you'll notice the neem scent gradually mellowing, though it may still remain detectable.

Safety Protocols for Essential Oil Handling

Since essential oils are highly concentrated plant compounds, proper safety protocols are crucial for their handling in soap making.

You'll need to protect yourself and your workspace while ensuring safe incorporation of these potent ingredients into your soap formulations. Always work in a well-ventilated area and keep oils away from flames or heat sources.

- Never handle essential oils without proper dilution guidelines – stick to concentrations between 1-5% in your soap recipes and always perform a patch test if you're working with new oils.

- Keep your oils stored safely away from children and pets, and wash your hands thoroughly after handling to prevent accidental eye contact.

- Don't diffuse oils while soaping, and if skin irritation occurs, apply vegetable oil to the affected area and discontinue use of the problematic oil.

Measuring and Blending Oil Combinations

Creating consistent oil blends requires precise measurements and systematic documentation for successful cold process soaping.

You'll need to calculate your essential oils at about 3% of your total base oil weight, though you can adjust between 2-4% depending on your desired scent strength.

Always measure your oils by weight rather than volume for accuracy. For example, if you're working with 800 grams of base oils, you'll need 24 grams of essential oils at a 3% usage rate.

When creating custom blends, convert your drop ratios to percentages to determine exact amounts needed for each oil. If one oil represents 37.5% of your blend, you'd use 9 grams of that specific oil.

Keep detailed records of your measurements and combinations to guarantee you can reproduce successful batches consistently.

Curing Process and Scent Development

While curing soap may seem like a test of patience, this critical 4-6 week period allows your soap to fully develop its qualities.

During this time, excess water evaporates, making your bars harder and longer-lasting. Even though saponification is mostly complete within 48 hours, you'll need to wait for the remaining lye to fully bond and for proper water content reduction.

For ideal scent development in your cold process soap:

- Choose fragrance oils with higher flash points to prevent scent fading during the gel phase

- Add approximately .8 ounces of fragrance per pound of soap base

- Consider blending different essential oils to create unique scents and improve retention

Remember that your soap's environment matters – a drier room can speed up the curing process, and smaller bars may cure faster due to their larger surface-area-to-mass ratio.

Frequently Asked Questions

Can I Use Synthetic Fragrance Oils Instead of Essential Oils?

Yes, you can use synthetic fragrance oils instead of essential oils. They're often more affordable, provide consistent scents, and last longer. You'll find they're specifically formulated for soap making and offer more fragrance options.

How Long Do Essential Oil Scents Typically Last in Cold Process Soap?

You'll find essential oil scents typically last 3-6 months in cold process soap, though base notes like patchouli can extend longer. Citrus oils fade fastest, while anchoring with fixatives helps preserve fragrances.

What Causes Essential Oils to Fade or Change During Saponification?

Your essential oils fade during saponification due to heat's evaporation effects, chemical reactions with base oils, and ongoing curing processes. You'll notice changes from both the initial reaction and continued exposure to air.

Which Essential Oils Are Most Cost-Effective for Large Soap Batches?

You'll find sweet orange essential oil most cost-effective at $10-30 per pound, followed by rosemary at $40-50. Lemon, peppermint, and lavender are moderately priced options that'll work well for bulk production.

Will Adding More Essential Oil Make the Scent Stronger and Last Longer?

No, adding more essential oil won't guarantee a stronger or longer-lasting scent. You'll risk skin irritation and waste money. Instead, stick to recommended amounts and focus on using oils known for better retention.

In Summary

You're now equipped to create beautifully scented cold process soaps using carefully selected oil blends. Remember to measure your essential oils precisely, maintain proper temperatures, and allow adequate curing time for the best fragrance development. Don't forget to document your successful combinations and always follow safety protocols. With these techniques mastered, you'll consistently produce aromatic, professional-quality soaps that your customers will love.

Leave a Reply