You'll need essential safety gear including chemical-resistant goggles, nitrile gloves, and a respirator before starting your soap making journey. Stock up on base ingredients like lye, distilled water, and quality oils such as avocado and jojoba. Don't forget tools like a digital scale, thermometer, and immersion blender. Grab silicone molds, curing racks, and storage bins for the final steps. The world of optional additives opens up endless creative possibilities.

Essential Safety Equipment and Protective Gear

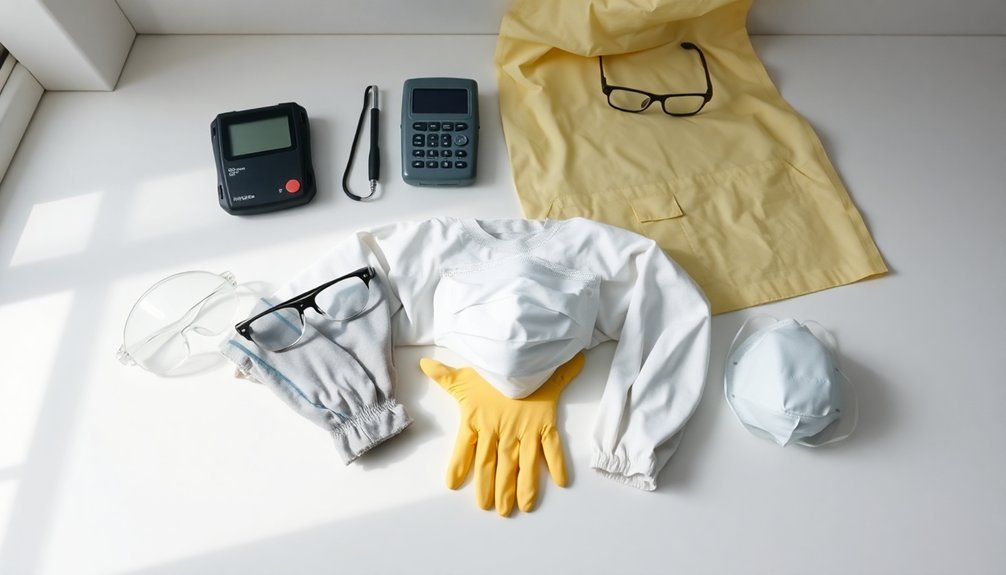

When making cold process soap, proper safety equipment is non-negotiable due to the caustic nature of lye and other potentially harmful ingredients.

You'll need chemical-resistant safety goggles or a full face shield respirator to protect your eyes from splashes and particles.

For your hands and arms, select nitrile gloves that extend to your elbows, as they're available in various sizes and won't trigger latex allergies.

Your respiratory system needs protection too – invest in a respirator with appropriate cartridges for filtering particulates and volatile compounds.

Don't forget to protect your body with a waterproof apron or lab coat, and wear long sleeves that you can quickly remove if needed. Always inspect for damage to your protective gear before starting each soapmaking session.

Complete your safety gear with closed-toe shoes, protective trousers, and a hair net to keep your workspace contamination-free.

Base Ingredients and Raw Materials

For the chemical reaction, you'll require sodium hydroxide (lye) and distilled water at room temperature.

Always ensure your area has proper ventilation when mixing lye solution.

If you're looking to enhance your soap's properties, consider adding luxury ingredients like mango butter, cocoa butter, or shea butter for extra conditioning.

Avocado oil and jojoba oil can provide additional skin benefits.

For customization, you can incorporate essential oils for fragrance, clays for color, or exfoliants like coffee grounds and salt.

Tools and Equipment for Soap Production

Successful soap making requires a specific set of tools and equipment for safe, precise production. You'll need measuring tools like a kitchen scale and digital thermometer to guarantee accurate ingredient ratios and temperatures. An immersion blender and heat-proof containers are essential for mixing and handling your soap batter. For safe handling of caustic materials, always use proper protective gear while working.

| Safety Gear | Mixing Tools | Design Tools |

|---|---|---|

| Safety Goggles | Immersion Blender | Multi-Pour Tool |

| Rubber Gloves | Silicone Spatulas | Comb Swirl Tool |

| Protective Apron | Steel Bowls | Pour Containers |

| Face Mask | Double Boiler | Soap Cutter |

Don't forget to stock up on mixing tools like heat-resistant spatulas and whisks for efficient blending. For the curing process, you'll need cardboard boxes and old blankets to properly insulate your soap during saponification.

Molds, Storage, and Curing Supplies

Three essential components of cold process soap making involve the right molds, proper storage solutions, and reliable curing supplies.

You'll need silicone molds, which are non-toxic and don't require lining, or wooden molds that provide excellent insulation for the gel phase. If using wooden molds, always use freezer paper lining to prevent sticking.

For storage, invest in well-ventilated bins with unsecured lids to prevent moisture buildup and dreaded orange spots (DOS). Keep your soaps in a cool, dry place away from direct sunlight and heat.

For curing, you'll need coated wire racks that allow proper air circulation around your soap bars.

Set up your curing area in a space with consistent temperature and good ventilation.

Remember to cure your cold process soaps for 6-8 weeks, ensuring all surfaces are exposed to air for best results.

Optional Additives and Design Elements

While basic cold process soap can be beautiful on its own, adding natural colorants, exfoliants, and lather boosters can transform your bars into unique creations. Essential oils can be incorporated at 3% by weight for natural fragrances.

You'll want to contemplate incorporating natural elements like cocoa powder, activated charcoal, or clay for coloring, while oatmeal and poppy seeds can add texture and exfoliation benefits.

- Natural colorants: Start with 1 tablespoon cocoa powder or 1 teaspoon clay per pound of oils to create earthy tones

- Exfoliants: Mix in 1 tablespoon oatmeal or 1 teaspoon cornmeal per pound of oils for gentle scrubbing

- Lather enhancers: Add 1 tablespoon honey or milk powder per pound of oils to boost bubbles and creaminess

For harder bars, contemplate incorporating sodium lactate or salt, but remember that some additives like honey can accelerate trace or cause overheating during saponification.

Frequently Asked Questions

What Alternative Ingredients Can Replace Lye in Homemade Soap Making?

You can't replace lye in true soap making – it's chemically impossible. If you're concerned about handling lye, use melt and pour soap bases instead. They've already gone through the lye process safely.

How Long Can Soap Making Ingredients Be Stored Before Expiring?

You'll find most oils last 6-12 months when stored properly. Lye stays good for years if kept dry. Essential oils typically last 1-2 years, but you should check each ingredient's specific expiration date.

Which Local Stores Typically Carry Soap Making Supplies?

You'll find soap making supplies at craft stores like Michaels, Hobby Lobby, and Jo-Ann's. Health food stores carry natural ingredients, while specialty soap making shops and local artisan stores offer extensive selections.

Can Regular Kitchen Equipment Be Used for Both Cooking and Soapmaking?

You can safely use stainless steel and glass items for both cooking and soapmaking with thorough cleaning, but keep silicone and plastic tools separate. Never reuse equipment that's absorbed fragrances or contacted lye.

What's the Minimum Investment Needed to Start Making Cold Process Soap?

You'll need about $100-150 to start making cold process soap. This covers essential safety gear, basic equipment like a scale and thermometer, and ingredients including lye, oils, and basic molds.

In Summary

You're now equipped with a detailed shopping list to begin your cold process soap making journey. Start with the essential safety equipment, gather your base ingredients, and make sure you've got the right tools and molds before diving in. Once you've collected these supplies, you'll be ready to craft beautiful, custom soaps. Don't forget those optional additives to make your creations truly unique.

Leave a Reply