Always wear safety goggles and nitrile gloves when handling caustic soda for soapmaking. Work in a well-ventilated area and always add lye to water—never the reverse. Use heat-resistant containers made of HDPE or polypropylene, and stir gently to prevent splashing. Store in sealed, labeled containers away from children, and have vinegar nearby for neutralizing spills. These essential precautions will help protect you from potentially serious chemical burns.

Understanding the Properties of Caustic Soda in Soapmaking

When working with caustic soda in your soapmaking journey, you're handling a powerful chemical that's fundamental to the craft. This potent base, also known as sodium hydroxide, drives the saponification process that transforms oils and fats into soap. To succeed, you'll need caustic soda with at least 98% purity from trusted suppliers like SOAPMAID or Bramble Berry.

Remember that creating a lye solution generates significant heat through an exothermic reaction. Always add caustic soda to water—never the reverse—to prevent dangerous splashing.

The solution's ability to break down various oils makes it effective, but also potentially harmful. That's why proper ventilation and protective gear aren't optional when working with this essential but corrosive ingredient.

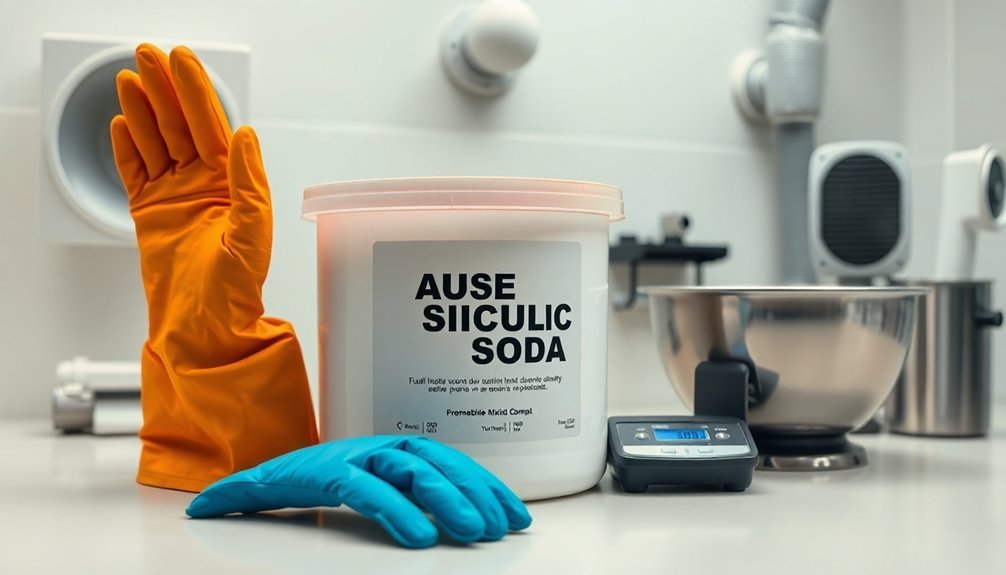

Essential Protective Gear for Handling Lye

When working with lye, you'll need proper eye protection such as safety goggles or a face shield to prevent potential splash damage to your eyes.

Choose heavy-duty rubber or nitrile gloves that cover your wrists, as thin latex gloves won't provide adequate protection against caustic burns.

Always wear long-sleeved shirts, pants, and closed-toe shoes to minimize skin exposure during the soap-making process.

Eye Protection Always

Because caustic soda can cause permanent blindness upon contact with your eyes, proper eye protection isn't optional—it's absolutely essential. Always wear safety goggles specifically designed for chemical splash protection when handling lye. Standard reading glasses or sunglasses won't provide adequate protection.

Choose goggles that meet ANSI Z87.1 standards, ensuring they fit snugly against your face and resist fogging to maintain visibility throughout your soap-making process. Regularly inspect your goggles for cracks, scratches, or deterioration that might compromise their effectiveness.

For maximum protection, consider pairing your safety goggles with a full-face shield, especially when mixing caustic soda with water—the most dangerous step when splashes are likely to occur.

Never compromise on eye safety when working with lye.

Heavy-Duty Glove Selection

Anyone working with caustic soda must protect their hands with appropriate chemical-resistant gloves. When selecting heavy-duty gloves for soapmaking, prioritize materials specifically rated for chemical resistance. Your gloves should feature long cuffs that shield your wrists and forearms from accidental splashes.

| Glove Type | Chemical Resistance | Best Features |

|---|---|---|

| Nitrile | Excellent | Puncture-resistant, form-fitting |

| Natural Rubber | Very Good | Flexibility, affordability |

| Neoprene | Excellent | Heat resistance, durability |

| PVC | Good | Good grip, waterproof |

| Butyl | Superior | Long-lasting protection |

Always inspect your gloves for tears or worn spots before each use. It's wise to dedicate a specific pair exclusively for lye handling to prevent cross-contamination. Remember, compromised gloves won't provide adequate protection, so replace them immediately if you notice any damage.

Long-Sleeve Clothing Requirements

Proper skin coverage serves as your second line of defense against caustic soda accidents. When working with lye, long-sleeve clothing prevents chemical burns by creating a protective barrier between your skin and potential splashes.

Choose your protective garments carefully:

- Select tightly woven fabrics that resist penetration from caustic soda solution better than thin, loose materials.

- Make certain sleeves fit snugly at the wrists to eliminate skin exposure during mixing and pouring.

- Pair long sleeves with long pants and closed-toe shoes for thorough protection.

- Opt for natural fiber clothing instead of synthetics, which can melt against skin if contacted by lye.

Don't underestimate the importance of proper clothing—while gloves protect your hands, appropriate long-sleeve attire safeguards the rest of your body from painful chemical burns.

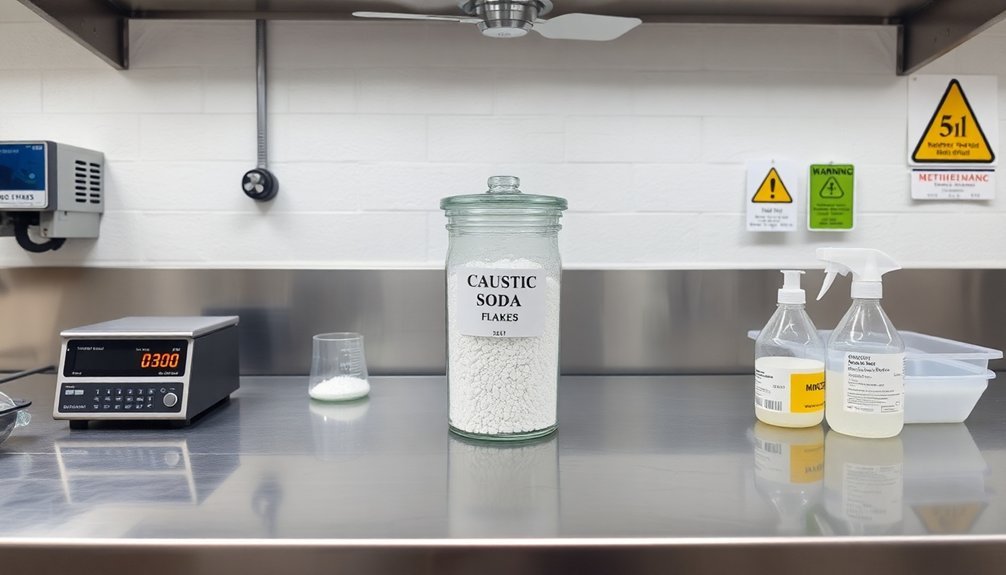

Setting Up a Safe Workspace for Mixing Chemicals

When working with caustic soda, your workspace setup can mean the difference between a safe, enjoyable soap-making experience and a dangerous situation.

Always mix caustic soda in a well-ventilated area, positioning yourself near an open window or using a fan to direct fumes away from your breathing zone.

Designate a specific soap-making area that's free from distractions, children, and pets. Work on a sturdy, stable surface that won't tip or wobble, and avoid using glass containers that could break during the mixing process.

Keep your protective gear—gloves, goggles, and long-sleeved clothing—within easy reach and always wear them when handling chemicals.

Finally, organize emergency supplies like vinegar for neutralizing spills and guarantee you have quick access to water for immediate rinsing.

The Golden Rule: Adding Caustic Soda to Water

Perhaps the most critical rule in soap making involves the order of mixing your ingredients: always add caustic soda to water, never water to caustic soda.

This seemingly simple direction can prevent dangerous splashes and eruptions caused by the intense exothermic reaction.

When mixing:

- Pour caustic soda slowly into a heat-resistant container (HDPE or polypropylene) filled with water.

- Stir gently but consistently, allowing each portion to dissolve before adding more.

- Work in a well-ventilated area to avoid inhaling the fumes released during dissolution.

- Wait for the solution to cool before proceeding with your soap recipe.

Proper Storage Solutions to Prevent Accidents

Nearly all accidents with caustic soda occur due to improper storage. To protect yourself and others, store caustic soda in tightly sealed, clearly labeled heavy plastic containers or gamma-seal buckets that prevent moisture ingress and accidental exposure.

Always use child-proof caps and keep caustic soda in locked cabinets, well out of reach of children and pets. Choose brightly colored containers like orange or green camo to distinguish them from food items and enhance visibility.

For extra protection, double-bag your caustic soda in plastic bags and heat seal them. This additional barrier keeps the lye dry and effective.

Don't forget to regularly inspect your storage containers for wear or damage—maintaining container integrity is essential for long-term safety when storing this powerful soap-making ingredient.

Emergency Response Plan for Caustic Soda Incidents

While proper storage prevents most accidents, you'll still need to prepare for potential caustic soda incidents. Developing a thorough emergency response plan is essential to stay safe when handling this potent chemical.

- Post emergency contact information prominently in your workspace, including poison control (1-800-222-1222) and the address of your nearest emergency room.

- Create a dedicated first aid station with a minimum 15-minute water supply for flushing exposed skin or eyes.

- Keep neutralizing agents like vinegar or citric acid labeled and accessible for small spills.

- Map out clear evacuation routes and meeting points in case of major spills.

Don't wait until an emergency occurs to figure out your response—quick action during caustic soda incidents can prevent serious injuries.

Measuring and Working With Lye Accurately

The foundation of successful soap making lies in precise lye measurements and proper handling techniques. Always measure caustic soda by weight using a digital scale for accuracy—typically 50g per liter of water for soap making. This precision guarantees your final product will be neither too harsh nor ineffective.

When working with caustic soda, always add it to cold water, never the reverse. This controls the exothermic reaction and prevents dangerous splashing. Use only HDPE or polypropylene containers for mixing, as these materials resist caustic damage.

Ascertain you're working in a well-ventilated area to avoid inhaling harmful fumes. Monitor the solution's temperature carefully during mixing, as the reaction generates significant heat that must be managed for safe handling.

Ventilation Requirements When Working With Caustics

Working with caustic soda demands proper ventilation to protect you from potentially harmful fumes released during soap making.

You'll need an effective airflow safety system, which can be as simple as a powerful fan near an open window or as thorough as an outdoor workspace.

Always guarantee fresh air circulation to prevent hydrogen gas buildup, and don't hesitate to move your operation outdoors if you notice any respiratory discomfort or irritation.

VENTILATION ESSENTIALS

Proper ventilation stands as a critical safety requirement when handling caustic soda in your soap-making process.

When working with this powerful caustic, adequate airflow prevents harmful fume accumulation that can irritate your respiratory system or cause more serious health issues.

To guarantee ventilation essentials are met when handling caustic soda:

- Work outdoors when possible, or position yourself near open windows to maximize natural airflow.

- Install exhaust fans or use HEPA air purifiers in your workspace to filter airborne contaminants.

- Maintain at least 10 feet of distance between yourself and others during the mixing process.

- Monitor air quality regularly with a meter to verify safe conditions in your soap-making environment.

These ventilation practices greatly reduce your exposure risk while working with caustic materials.

AIRFLOW SAFETY SYSTEMS

While ventilation basics form the foundation of safety protocols, thorough airflow systems provide critical protection against caustic fumes during soap making.

You'll need more than just an open window when working with caustic soda. Aim to establish at least 5 air changes per hour in your workspace to minimize chemical exposure risks.

For ideal protection, set up your soap making station outdoors or in a room with cross-ventilation.

Installing an exhaust fan or working under a fume hood considerably enhances safety by directing vapors away from your breathing zone. These systems become particularly important when mixing caustic soda with water, as this reaction generates heat and potentially harmful fumes.

Consider supplementing your ventilation with an air purifier designed specifically for chemical fumes to create a thorough airflow safety system.

Safe Disposal Methods for Lye Solutions and Containers

Once you've completed your soapmaking project, you'll need to safely dispose of any leftover lye solutions and containers to protect both people and the environment.

Never discard caustic soda in regular household trash, as this endangers sanitation workers and can harm ecosystems.

For proper disposal:

- Dilute leftover lye solutions thoroughly with water to reduce their corrosive potential.

- Neutralize the solution using vinegar or citric acid until it reaches a safer pH level.

- Follow your local regulations for disposal—either down the drain if permitted or at a hazardous waste facility.

- Rinse empty containers multiple times with water before disposal, and clearly label them to indicate they previously contained caustic soda.

Frequently Asked Questions

What Are the Safe Handling Requirements for Caustic Soda?

You'll need protective gear (gloves, goggles, sleeves), ventilation, and careful mixing by adding caustic soda to water slowly. Store in labeled containers and keep neutralizing agents like vinegar nearby for emergencies.

Is It Safe to Use Caustic Soda for Soap Making?

Yes, you can safely use caustic soda for soap making if you follow proper safety protocols: wear protective gear, mix correctly (soda into water), guarantee ventilation, have neutralizers ready, and store it properly.

How to Handle Lye When Making Soap?

Always add lye to water, not water to lye. You'll need gloves, goggles, and long sleeves. Work in ventilated areas, use proper containers, and have vinegar nearby for spills. Measure by weight for accuracy.

What Are the Precautions to Be Taken for the Storage of Caustic Soda?

You'll need to store caustic soda in sealed plastic containers with clear labels. Keep it in cool, dry places, use brightly colored containers, and always place it out of children's reach, preferably in locked cabinets.

In Summary

When you're making soap, remember that caustic soda demands respect, not fear. By wearing proper protective gear, setting up a dedicated workspace, always adding lye to water, storing chemicals properly, and knowing emergency protocols, you'll create beautiful soaps safely. Don't cut corners with measurements, guarantee good ventilation, and dispose of materials responsibly. With these precautions, you'll enjoy your soapmaking journey with confidence and peace of mind.

Leave a Reply