To set up for batch cutting, you'll need a reliable table saw as your primary tool, along with essential safety gear like goggles, hearing protection, and dust masks. Stock your workspace with precise measuring instruments, marking tools, and proper lighting for accuracy. Don't forget material handling equipment for heavy items and storage systems to keep everything organized. A well-maintained setup with regular tool care will guarantee your batch cutting operations run smoothly and efficiently.

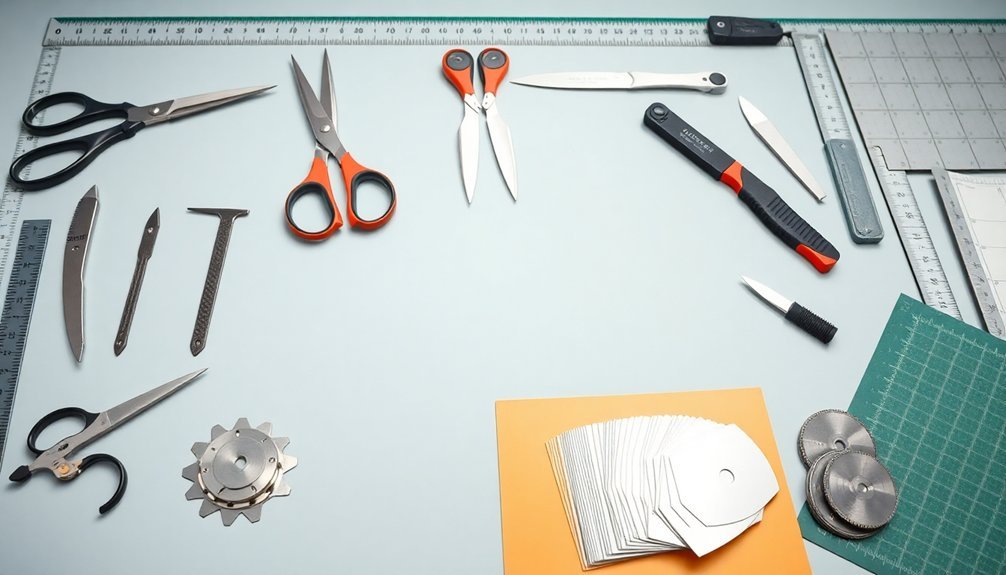

Essential Cutting Tools and Surfaces

When setting up for batch cutting operations, a high-quality table saw serves as your primary workhorse, alongside essential tools like adjustable stops and sturdy work surfaces.

You'll need a dedicated cutting table that prevents movement and maintains stability throughout your production process.

To maximize efficiency, you'll want to invest in adjustable stops, similar to those found in professional systems like the Festool MFT/3-AR. These stops help you maintain consistent measurements without constantly repositioning your cutting tool.

Adjustable stops are essential for consistent batch cutting, eliminating the need to remeasure and reposition for each workpiece.

Don't forget to include essential accessories like clamps and speed squares to guarantee accuracy in your cuts.

For specialized projects that require more intricate work, consider supplementing your setup with additional cutting tools such as jigsaws or band saws. These will expand your capabilities beyond straight cuts and enhance your batch production potential.

Safety Equipment and Protective Gear

Before starting your batch cutting work, you'll need essential safety equipment including goggles, hearing protection, a dust mask, steel-toed boots, and cut-resistant gloves.

Proper safety gear prevents serious injuries like eye damage, hearing loss, respiratory issues, and hand cuts that can occur during cutting operations.

Your safety equipment must be in good condition and worn consistently throughout the cutting process to effectively protect you from workplace hazards.

Essential Safety Gear Checklist

Five essential pieces of safety gear form the foundation of any batch cutting operation.

You'll need proper eye protection with safety glasses to shield against flying debris and dust.

Don't forget to protect your hearing with earmuffs or earplugs when operating loud power tools.

A dust mask or respirator is vital to prevent inhaling harmful particles generated during cutting.

Your hands need protection too – always wear cut-resistant gloves while handling materials and using safety tools.

Complete your protective gear with steel-toed boots to guard against heavy equipment and falling objects in your work area.

Following this essential checklist helps guarantee you're adequately protected from common workshop hazards and ready to tackle your batch cutting projects safely.

Accident Prevention While Cutting

The highest priority in batch cutting operations remains protecting yourself from preventable injuries through proper safety equipment and protective gear.

For effective accident prevention, you'll need to safeguard your most vulnerable areas. Start by protecting your eyes with safety glasses or goggles to shield against flying debris that causes thousands of workplace injuries annually.

Don't forget to wear ear protection when using loud machinery like table saws, as exposure to high decibels can permanently damage your hearing. You'll also need a dust mask or respirator when cutting materials that produce fine particles.

Keep your hands safe by using push sticks to maintain distance from cutting blades.

Finally, protect your feet with steel-toed boots in case heavy materials fall during the cutting process.

Measuring and Marking Instruments

Your batch cutting success starts with essential layout tools like squares, tape measures, and calipers that guarantee dimensional accuracy across multiple pieces.

You'll find precision marking devices, including chalk lines and marking knives, create clearer cutting guides than traditional pencils alone.

Digital measuring systems and adjustable stops take your accuracy further by enabling consistent, repeatable measurements that speed up your workflow while reducing costly errors.

Essential Layout Tools

Precision and efficiency in batch cutting operations depend heavily on having the right layout tools at your disposal.

You'll find that proper layout tools can greatly reduce errors and improve your workflow when cutting multiple pieces. Digital calipers and adjustable stops on cutting tables guarantee consistently accurate measurements across your batch production.

Essential layout tools for batch cutting include:

- Swanson Speed Square for quick angle measurements and straight cuts

- Chalk lines and marking knives for clear, visible cutting guidelines

- Tape measures and squares for precise dimensional measurements

- Digital calipers for exact specifications

Precision Marking Devices

Measuring and marking instruments serve as the foundation for successful batch cutting operations. You'll need a thorough set of precision marking devices to guarantee consistent results across multiple pieces. Essential tools include measuring tapes, squares, and digital calipers for accurate dimensioning and layout work.

For larger materials, you'll want to use a chalk line to create extended straight reference lines. Marking gauges are invaluable when you're working on repetitive tasks that require uniform depth measurements, such as cutting dados or grooves.

Combining T-squares and bevel gauges helps you achieve precise angles and maintain consistency throughout your batch production process. These tools not only improve your accuracy but also increase efficiency by reducing mistakes and material waste, ultimately leading to higher-quality finished products.

Digital Measuring Systems

Modern digital measuring systems represent a significant advancement in batch cutting technology. They'll streamline your workflow with precise measurements and data storage capabilities, helping you maintain consistency across multiple cuts.

You'll find these tools particularly valuable when working on complex projects that require exact specifications.

Digital measuring systems offer several key advantages for your batch cutting operations:

- Laser distance measurers and digital calipers provide highly accurate measurements, reducing errors in your cutting process

- Built-in memory functions let you store multiple measurements for quick reference during repetitive tasks

- Bluetooth connectivity enables direct transfer of measurements to your CAD software

- Backlit displays guarantee clear readability in any lighting condition

Storage and Organization Systems

Proper storage and organization of batch cutting equipment maximizes workflow efficiency and keeps your tools in top condition.

You'll want to invest in effective storage systems that include shelving units and dedicated bins for your cutting tools and materials.

Clear storage containers make it easy to spot what you need quickly, while proper labeling helps you maintain control of your inventory.

Clear containers and detailed labels create a visual inventory system that streamlines access and maintains precise stock control.

Consider adding a mobile cart to your setup – it'll let you move tools and supplies wherever you're working, whether that's across your shop or to different job sites.

Don't forget to regularly review and declutter your storage areas.

This practice guarantees you're only keeping frequently used items within easy reach, maximizing your workspace's efficiency and helping you maintain a productive cutting operation.

Lighting and Visibility Solutions

Clear vision makes every cut count in batch woodworking operations.

You'll need proper lighting and visibility solutions to guarantee accurate measurements and precise cuts every time. By installing LED strip lights along your work surfaces, you'll achieve consistent, shadow-free illumination that's essential for repetitive cutting tasks.

- Position your workstation near windows to take advantage of natural light while supplementing with task lighting for consistent visibility

- Mount adjustable task lights with magnifying features to enhance visibility of intricate details

- Install LED strip lighting systems to eliminate shadows and provide even illumination across your entire work surface

- Use light-colored cutting surfaces to improve contrast and make measurement marks more visible

These lighting solutions will help you maintain accuracy and reduce errors throughout your batch cutting projects.

Material Handling Equipment

With your workspace well-lit, you'll need the right equipment to move materials efficiently through your batch cutting process. Material handling equipment like pallet jacks and forklifts can streamline the movement of heavy sheets and panels between cutting stations.

You'll benefit from properly designed carts and work tables that keep materials organized and easily accessible, reducing time wasted searching for stock.

Consider installing conveyor systems to automate material transfer between cutting and assembly areas. For heavy lifting tasks, ergonomic hoists and lifts help position materials safely while preventing workplace injuries.

Don't overlook the importance of storage solutions – racking systems optimize your space and protect materials from damage.

These handling solutions work together to create a smooth, efficient workflow that maximizes your batch cutting productivity.

Maintenance Tools and Supplies

Maintaining your batch cutting equipment requires a carefully selected arsenal of tools and supplies.

You'll need to invest in quality maintenance tools and cleaning materials to keep your cutting equipment operating at peak performance. Regular servicing and prompt repairs will extend the life of your tools while ensuring consistent batch cutting results.

- High-grade lubricants and cleaning solutions to prevent rust and maintain smooth operation

- Premium sharpening stones and honing equipment for keeping blades in ideal condition

- Storage solutions including protective cases and organized racks for proper tool preservation

- Essential replacement parts like spare blades and belts to minimize production downtime

Following a structured maintenance schedule with these supplies will help you maintain equipment reliability and maximize efficiency in your batch cutting operations.

Keep your maintenance tools readily accessible and well-organized for quick response to service needs.

Batch Processing Workstations

Proper maintenance tools serve your equipment well, but a well-designed batch processing workstation forms the backbone of efficient cutting operations. You'll need a robust setup that allows for simultaneous cutting of multiple pieces while maintaining precision and safety.

| Component | Purpose | Key Feature |

|---|---|---|

| Work Surface | Stability | Sturdy construction |

| Adjustable Stops | Precision | Repeatable cuts |

| Flag Stops | Efficiency | Waste reduction |

| Power Tools | Versatility | Quick setup |

Your batch processing workstation should include adjustable stops, like those in the Festool MFT/3-AR system, to guarantee consistent cuts across various materials. Integrate tools such as sliding miter saws or table saws for maximum workflow efficiency. Remember that a solid work surface isn't just about durability – it's essential for maintaining accuracy during operation and protecting both you and your materials.

Frequently Asked Questions

What Equipment Is Used for Cutting Preparation?

You'll need measuring tools like tape measures and squares, sturdy clamps to secure materials, a reliable cutting mat, various cutting tools including utility knives, and proper lighting for accurate preparation work.

What Equipment Is Used for Cutting?

You'll need miter saws and table saws for precision cuts, along with Festool MFT/3-AR adjustable stops and flag stops. Don't forget circular saws and jigsaws for versatility, plus quality blades and clamps.

What Equipment Should Be Used When Cutting Metal?

You'll need a high-speed band saw for straight cuts, plasma cutter for thick metals, angle grinder with cutting discs for versatility, and metal shears for sheet metal. Don't forget safety gear like gloves and goggles.

What Is the Best Tool to Cross Cut Wood?

You'll get the best results with a compound sliding miter saw for cross-cutting wood. It's precise and handles wide lumber up to 16 inches. For smaller projects, you can use a circular saw with a guide.

In Summary

You'll need reliable batch cutting equipment to maintain efficiency and safety in your operations. From the essential cutting tools and proper safety gear to measuring instruments and organized storage systems, each component plays a crucial role. Don't forget adequate lighting, material handling equipment, and maintenance supplies. Set up a dedicated workstation that maximizes productivity while keeping all your tools within easy reach.

Leave a Reply