When you're crafting handmade soaps, the right cutting tool can make the difference between professional-looking bars and uneven chunks. A quality wire cutter system isn't just about straight cuts—it's about precision, consistency, and efficiency in your soap-making process. Whether you're a hobbyist or running a small business, you'll need a reliable system that matches your production needs. Let's explore the top wire cutters that'll help you achieve those perfect, uniform slices every artisan dreams of.

Kelodo Wooden Soap Cutter with Adjustable Wire

Soap artisans seeking professional-grade cutting precision will find their match in the Kelodo Wooden Soap Cutter. You'll appreciate its adjustable wire tension system and scale-lined guide for achieving consistent, uniform cuts. At 13.4 x 9.8 x 7.1 inches, it's substantial enough for most artisanal needs.

This versatile tool isn't limited to soap – it handles bread, cheese, chocolate, and butter with equal efficiency. While it comes pre-assembled, you'll get replacement wires and maintenance tools for long-term use. Users consistently praise its smooth operation and stability, though adding a washer might enhance its performance. A quick wipe-down with a towel is all it needs for cleaning.

Best For: Soap makers, artisanal crafters, and small-batch producers looking for precise, uniform cuts in soap, cheese, chocolate, and other soft materials.

Pros:

- Adjustable wire tension and measurement scale allow for consistent, precise cuts

- Versatile use across multiple materials including soap, cheese, bread, and chocolate

- Easy maintenance with simple wipe-down cleaning and included replacement wires

Cons:

- May require additional stabilization (washer) for optimal performance

- Lacks instruction manual for assembly and operation

- Higher price point compared to basic manual soap cutters

Adjustable Wire Soap Cutter with Replaceable Steel Wires

Craftspeople seeking precision in their soap-making journey will appreciate the Adjustable Wire Soap Cutter's versatile design. You'll find premium pine wood construction paired with stainless steel components that guarantee durability and easy maintenance.

The built-in ruler and adjustable block let you customize your soap bar thickness with precision. You won't need to worry about replacement parts, as the kit includes 10 extra cutting wires. Assembly is straightforward with just a few screws and butterfly nuts.

Beyond soap making, you can use this tool for cutting candles, cheese, chocolates, and butter. The package includes all necessary tools: wrenches, screwdriver, and an illustrated manual.

Best For: Soap makers, candle crafters, and DIY enthusiasts who need precise, consistent cutting capabilities for their handmade products.

Pros:

- Versatile tool that works for multiple materials including soap, cheese, candles, and chocolates

- Highly adjustable with built-in ruler and customizable thickness settings

- Comes with comprehensive kit including 10 replacement wires and all necessary assembly tools

Cons:

- Requires initial assembly before use

- Limited to straight-line cutting only

- Pine wood construction may be less durable than metal alternatives in high-moisture environments

Wooden Adjustable Soap Cutter with Wire Slicer

Professional soapmakers seeking precision and consistency will appreciate the Hepgodin Wooden Adjustable Soap Cutter's versatile design. This premium wood cutter, measuring 13.4 x 10 x 7.7 inches, features an adjustable wire slicer and built-in rulers for accurate measurements.

You'll find everything needed in the package: the main cutter, 10 replacement stainless steel wires, an Allen wrench, and instructions. The sliding block lets you customize bar thickness, while the wire tension is easily modified. With a 4.8-star rating from 167 users, it's proven reliable for regular use. For best results, cut your soap 1-3 days after demolding to prevent wire breakage.

Best For: Professional and hobbyist soap makers who need precise, consistent cuts and value a durable, adjustable tool for regular soap production.

Pros:

- Highly adjustable design with customizable bar thickness and wire tension

- Complete kit includes 10 replacement wires and necessary tools

- High user satisfaction with 4.8/5 rating and positive feedback on cut quality

Cons:

- Relatively high price point compared to basic soap cutters

- Limited to cutting within specific time window (1-3 days post-demolding)

- Assembly required and may need periodic wire replacement

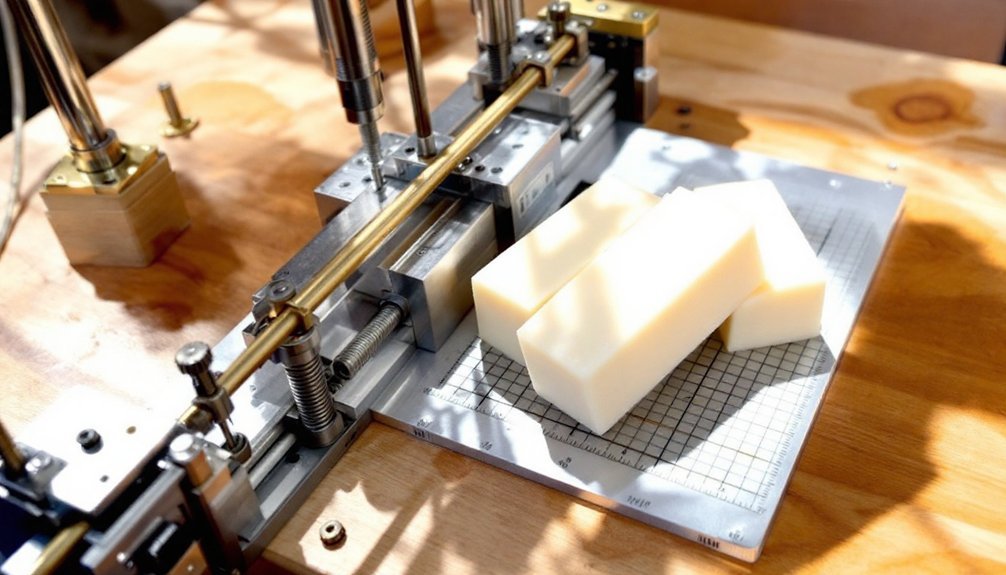

12 Wire Wooden Soap Cutter (2.5cm)

Artisans seeking precision and efficiency will appreciate the 12 Wire Wooden Soap Cutter's robust construction and consistent 2.5cm cutting capability. Made from durable birch plywood and food-grade HDPE, this cutter accommodates both cold and hot process soaps.

You'll find its generous dimensions of 40cm x 26.5cm x 19cm perfect for handling various soap logs. The five galvanized stainless steel wires guarantee clean cuts, though you'll need to keep them free of soap residue to prevent draglines. While not suitable for M&P soaps, this tool's customizable options and proven track record make it a valuable investment for your soap-making business.

Best For: Professional soap makers and artisans who need to efficiently produce uniform 2.5cm soap cuts in large batches with consistent results.

Pros:

- Durable construction using high-quality birch plywood and food-grade HDPE materials

- Versatile design accommodates both cold and hot process soaps with customizable sizing options

- Time-saving tool that produces consistent, uniform cuts with its 12-wire system

Cons:

- Not suitable for melt and pour (M&P) soaps

- Requires regular maintenance to keep wires clean and prevent draglines

- May face customs issues during shipping due to wooden components

Stainless Steel Soap Cutter Replacement Wires (10 Pack)

Soap makers seeking reliable cutting precision will find exceptional value in this 10-pack of stainless steel replacement wires. At 19.7 inches long and 0.4mm wide, these high-grade wires fit most standard soap cutters and include convenient installation rings.

You'll appreciate their versatility beyond soap making, as they're perfect for slicing cheese, chocolate, cake, and butter. The corrosion-resistant steel guarantees longevity, while simple maintenance keeps them cutting efficiently – just wash in warm, soapy water after use. With a strong 4.6-star rating, these EVINIS wires prove their worth through consistent performance and durability.

Best For: Professional and hobbyist soap makers, bakers, and food artisans who need precise, reliable cutting tools for their crafts.

Pros:

- High-grade stainless steel construction ensures durability and rust resistance

- Versatile application for multiple cutting tasks beyond soap making

- Excellent value with 10 wires per pack and strong customer satisfaction rating

Cons:

- Limited to 19.7 inch length which may not fit all cutter sizes

- Thin 0.4mm width may require careful handling to prevent damage

- May need regular tension adjustments for optimal cutting performance

15 Pieces Stainless Steel Soap Cutter Replacement Wires

Crafters seeking reliable replacement wires will find exceptional value in this 15-piece stainless steel set from AOFOX. At 18 inches long and 0.4mm wide, these premium wires deliver precise cuts for soap, cheese, and other materials. You'll appreciate the rust-free, corrosion-resistant construction that guarantees longevity.

With a solid 4.3-star rating, these replacement wires have proven their worth in real-world applications. The sturdy design allows for smooth cutting, while the hygienic stainless steel composition makes them food-safe. Though some users note thickness concerns, the overall durability and versatility make these wires a practical choice for your cutting machine needs.

Best For: Soap makers, crafters, and food preparation enthusiasts who need reliable, long-lasting replacement cutting wires for their cutting machines.

Pros:

- High-grade stainless steel construction ensures durability and rust resistance

- Versatile 18-inch length suitable for multiple applications including soap, cheese, and chocolate cutting

- Excellent value with 15 replacement wires in each pack

Cons:

- Some users report concerns about wire thickness consistency

- Limited customer feedback with only 15 ratings

- Relatively new product (launched July 2023) with limited track record

Walfos Stainless Steel Soap Mold Loaf Cutters (2 Pack)

Professional makers seeking reliable soap-cutting tools will find exceptional value in the Walfos Stainless Steel Soap Mold Loaf Cutters. This two-pack set features both wavy and straight blades crafted from food-grade stainless steel, delivering superior rust resistance and durability through heat treatment.

You'll appreciate the reinforced wooden handle's comfortable grip and the one-piece design that prevents dirt buildup. At 7 x 5.5 inches, these cutters excel at slicing through cold press and melt & pour soaps. They're also versatile enough to serve as kitchen scrapers and dough knives. With a 4.6-star rating and ranking #3 in Soap Making Molds, these cutters prove their worth in professional soap making.

Best For: Professional soap makers and DIY crafters seeking durable, versatile cutting tools for precise soap slicing and various kitchen tasks.

Pros:

- High-quality food-grade stainless steel construction with heat treatment for enhanced durability and rust resistance

- Versatile two-pack set includes both wavy and straight blade options for varied cutting needs

- Ergonomic wooden handle design with practical storage option and easy cleaning capabilities

Cons:

- Relatively higher price point compared to plastic alternatives

- Limited size options at 7 x 5.5 inches may not suit all project dimensions

- Requires hand washing for optimal maintenance of wooden handles despite dishwasher-safe claim

Factors to Consider When Choosing a Traditional Soap Cutter Wire System

When you're shopping for a traditional soap cutter wire system, you'll want to examine the material quality and durability of the frame alongside the wire tension adjustment features to guarantee consistent cuts. Your ideal cutter should offer precision cutting features and accommodate your workspace with its size while allowing for easy storage. It's also smart to verify the system's compatibility with replacement wires, as you'll need to change these periodically for peak performance.

Material Quality and Durability

The durability of a soap cutter's wire system directly impacts your success in producing consistently smooth, well-cut bars. When evaluating a system's material quality, you'll want to focus on the wire specifications and construction materials.

Look for high-grade stainless steel wire with a thickness of approximately 0.4 mm, as this provides superior cutting performance while resisting rust and wear. You'll find the best systems feature adjustable tension settings, which help extend the wire's lifespan and maintain cutting precision. The cutter's frame should incorporate quality wood and stainless steel components to guarantee stability during use.

To maximize your investment, choose a system that's built for easy maintenance. You'll need to regularly clean the wires to prevent soap residue buildup, which can affect cutting quality over time.

Wire Tension Adjustment Capability

Ideal wire tension stands as a cornerstone feature in reliable soap cutting systems. You'll want to look for a cutter that offers easy tension adjustment capabilities to guarantee consistent, clean cuts across different soap densities and hardness levels.

The best systems come equipped with rotary buttons or tuner knobs that let you modify wire tightness without needing extra tools. When you're working with various soap formulations, you'll appreciate being able to quickly adjust the tension to prevent wire breakage and minimize drag during cutting.

Make certain your chosen system allows for regular tension checks and adjustments. This feature won't just help you achieve uniform soap bar sizes – it'll also extend your cutting wires' lifespan and maintain your system's efficiency over time.

Cutting Precision Features

Maintaining precise cuts stands at the heart of professional soap making, and you'll find several key precision features that distinguish quality wire cutting systems. Look for built-in rulers marked in both centimeters and inches, which help you achieve consistent bar sizes across batches. You'll want adjustable thickness settings through sliding blocks or rotary knobs to customize your soap designs.

Pay attention to the cutting wire's sharpness, as it directly affects the smoothness of your cuts and reduces the effort you'll need to apply. To maximize these precision features, wait 1-3 days after demolding before cutting your soap. This timing guarantees ideal firmness and cleaner cuts. When evaluating systems, prioritize those with tension adjustment capabilities, as a taut wire is essential for maintaining cutting accuracy.

Size and Storage Space

Smart storage planning begins with understanding your soap cutter's spatial requirements. You'll want to carefully measure your available workspace and choose a model that fits comfortably without cramping your production area.

Consider lightweight, stainless steel cutters if you need portability and easy storage. These models often feature sleek designs that take up minimal space compared to their wooden counterparts. Look for units with removable wires or foldable components, as these features can greatly reduce the storage footprint when the cutter isn't in use.

If you're eyeing a larger, heavier model, verify you have a sturdy workbench or dedicated storage area. Some professional-grade cutters can be disassembled between uses, making them more manageable despite their size. This flexibility in storage options can be essential for optimizing your workspace.

Replacement Wire Compatibility

While selecting a soap cutter, you'll need to verify its wire compatibility to confirm seamless maintenance and operation. Look for models that use standard stainless steel wires, typically measuring between 18 and 19.7 inches in length and 0.4 mm in width. These specifications confirm you'll have easy access to replacements when needed.

Choose a cutter that comes with extra replacement wires in the package, as this provides immediate backup options and better value for your investment. You'll want to focus on rust-free and corrosion-resistant wires to maintain consistent cutting quality over time. Remember to replace your wires regularly, as worn-out wires can compromise the precision of your soap cuts. Always check your cutter's specific requirements before purchasing replacement wires to confirm proper fit and functionality.

Assembly and Maintenance Needs

Before investing in a traditional soap cutter wire system, you'll need to evaluate its assembly and maintenance requirements. Most systems offer straightforward assembly processes that don't require complex tools, making initial setup hassle-free.

You'll want to look for models that include replacement wires and necessary tools, as these components are vital for long-term maintenance. Regular cleaning of the wires is important to prevent draglines and guarantee smooth cuts. Pay special attention to wire tension mechanisms, such as adjustable knobs or screws, as proper tension helps prevent breakage and delivers cleaner cuts.

While some systems might need minor tweaks like adding washers for stability, these adjustments are typically simple to implement. Choose a system that makes routine maintenance accessible, allowing you to keep your equipment in the best cutting condition.

Frequently Asked Questions

How Do I Prevent My Soap Wire Cutter From Rusting?

You'll prevent wire cutter rust by drying it thoroughly after each use, applying a light coat of mineral oil, storing it in a dry place, and using stainless steel wire when possible for your soap cutting.

Can I Use a Soap Wire Cutter for Cutting Cheese?

You can use a soap wire cutter for cheese, but it's best to keep separate tools for food and soap. If you do use it for cheese, thoroughly clean and sanitize it first to avoid contamination.

What's the Best Wire Tension for Cutting Different Soap Hardnesses?

You'll want medium tension (around 30-40 lbs) for soft soaps and higher tension (50-60 lbs) for harder soaps. Test with a small piece first and adjust until you get clean, smooth cuts.

How Often Should I Replace the Cutting Wires?

You'll need to replace your cutting wires every 3-6 months with regular use. If you notice fraying, rust, or uneven cuts, replace them sooner. Hard soaps and frequent cutting require more frequent replacements.

Will Cutting Hot Process Soap Damage the Wires More Quickly?

Yes, cutting hot process soap can wear your wires faster since it's typically thicker and more dense. You'll likely need to replace them more frequently compared to cutting cold process soap at room temperature.

Leave a Reply