You’re scaling up your soap production in 2026, and you need molds that won’t slow you down. Standard six-cavity configurations, heat-resistant silicone, and stackable designs aren’t luxuries—they’re essentials. But which sets actually deliver the throughput and versatility your operation demands? The answer lies in understanding what separates high-performing molds from the rest.

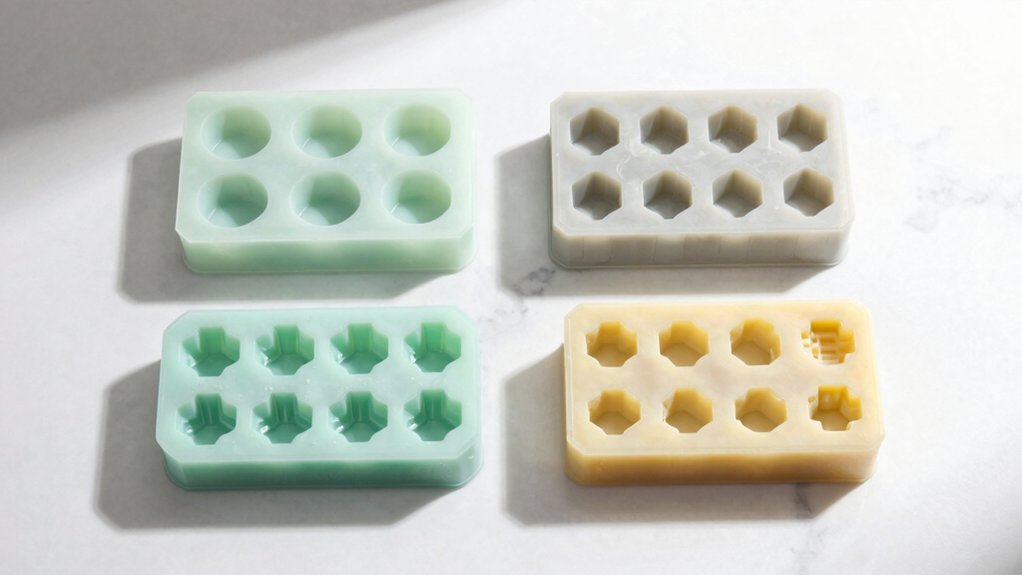

| SJ Silicone Soap Molds 3 Pack Set |  | Most Versatile | Cavity Configuration: 6 cavities per mold (3 molds in set) | Material Type: Premium food-safe silicone | Temperature Range: -104°F to 446°F | CHECK ON AMAZON | Read Our Analysis |

| Silicone Mold for Handmade Soap & Bath Bombs (2-Pack) |  | Best for Bath Bombs | Cavity Configuration: 6 cavities per mold (2-pack) | Material Type: 100% silicone | Temperature Range: -40°F to 445°F | CHECK ON AMAZON | Read Our Analysis |

| Soap Making Kit with Molds and Supplies |  | Complete Starter Kit | Cavity Configuration: Mixed—6 cavities (tropical leaf), 6 cavities (ornate rectangle), 3 cavities (plain rectangle) | Material Type: High-quality silicone | Temperature Range: Not specified | CHECK ON AMAZON | Read Our Analysis |

| Silicone Soap Mold 6 Cavities Rectangle Flower Design |  | Best Design Detail | Cavity Configuration: 6 cavities per mold | Material Type: Food-grade silicone | Temperature Range: Not specified | CHECK ON AMAZON | Read Our Analysis |

More Details on Our Top Picks

SJ Silicone Soap Molds 3 Pack Set

If you’re serious about scaling your soap production without breaking the bank, the SJ Silicone Soap Molds 3 Pack Set delivers exceptional value. You’ll get three molds with six cavities each, yielding 18 individual soaps per batch. Each cavity holds 2.8 fl oz, perfect for standard soap bars. The premium, food-safe silicone is BPA-free and withstands temperatures from -104°F to 446°F, so you’ll use these molds for years. The non-stick surface ensures effortless release—simply push gently from the bottom. Beyond soap, you can craft chocolates, candles, and resin art. With trusted quality and dedicated customer support, you’re investing in reliable batch production equipment.

- Cavity Configuration:6 cavities per mold (3 molds in set)

- Material Type:Premium food-safe silicone

- Temperature Range:-104°F to 446°F

- Cavity Size per Unit:~2.8 fl oz (3.15 L x 2.15 W x 0.75 H inches)

- Additional Applications:Rice Krispies treats, chocolates, candles, resin art, clay crafts

- Included Accessories:None (molds only)

- Additional Feature:Non-stick, easy-release surface

- Additional Feature:Freezer to oven-safe

- Additional Feature:Baking sheet placement pro tip

Silicone Mold for Handmade Soap & Bath Bombs (2-Pack)

For crafters seeking efficient batch production, this 2-pack silicone mold delivers six cavities per set, doubling your output capacity without cluttering your workspace. Each mold measures 22 x 20.5 x 2.8 cm with individual cavity dimensions of 9 x 6.5 x 2.8 cm, providing consistent, professional-sized products. The 100% silicone construction withstands temperatures from -40 to 445°F, accommodating everything from cold-processed soaps to heat-set bath bombs. You’ll appreciate the intentionally soft material design, which simplifies unmolding while preventing damage to finished products. For added stability during handling and transfer, place your mold on a supporting tray. Beyond soap and bath bombs, you can use these cavities for mousse, jelly, chocolate, and baked goods, maximizing your investment’s versatility.

- Cavity Configuration:6 cavities per mold (2-pack)

- Material Type:100% silicone

- Temperature Range:-40°F to 445°F

- Cavity Size per Unit:9 x 6.5 x 2.8 cm (3.5 x 2.5 x 1.5 inches)

- Additional Applications:Mousse, jelly, cake, bread, chocolate

- Included Accessories:None (molds only)

- Additional Feature:Soft design for easy unmolding

- Additional Feature:Oval-shaped fat bath bombs

- Additional Feature:Tray support for sturdy transfer

Soap Making Kit with Molds and Supplies

Looking to launch batch production without breaking the bank? The ZRLABL Soap Making Kit delivers everything you need in one package. You’ll get three silicone molds with varying cavity sizes—a 6-cavity tropical leaf, 6-cavity ornate rectangle, and 3-cavity plain rectangle—each producing standard 2.5-inch soap bars. The kit includes 48 packaging bags, matching kraft paper tags, and 65 feet of jute twine for professional presentation. High-quality silicone construction ensures durability through countless batches. Whether you’re starting out or scaling production, this comprehensive set streamlines your workflow while maintaining quality standards.

- Cavity Configuration:Mixed—6 cavities (tropical leaf), 6 cavities (ornate rectangle), 3 cavities (plain rectangle)

- Material Type:High-quality silicone

- Temperature Range:Not specified

- Cavity Size per Unit:~2.5 x 2.5 inches

- Additional Applications:Decorative patterns for presentation; includes packaging supplies

- Included Accessories:48 soap bags, 48 gift tags, 65 feet jute twine

- Additional Feature:Decorative tropical leaf patterns

- Additional Feature:Complete packaging bundle included

- Additional Feature:Professional presentation ready-to-gift

Silicone Soap Mold 6 Cavities Rectangle Flower Design

You’ll appreciate this mold when you’re serious about scaling up production without sacrificing design quality. This food-grade silicone mold features six rectangular cavities, each measuring 3.15 x 2.17 inches, adorned with elegant flower designs. You can produce six soaps simultaneously, maximizing efficiency. The flexible silicone construction lets you pop finished products out effortlessly. You’ll benefit from its versatility—it works equally well for lotion bars, cake, and ice cubes. Oven, freezer, microwave, and dishwasher safe, this mold simplifies your workflow. At 8.66 x 7.87 x 1.02 inches overall, it fits standard workspace dimensions. You’ll appreciate the durable, reusable design that handles countless batches while maintaining crisp flower details.

- Cavity Configuration:6 cavities per mold

- Material Type:Food-grade silicone

- Temperature Range:Not specified

- Cavity Size per Unit:3.15 x 2.17 inches

- Additional Applications:Lotion, cake, ice cube, desserts, muffins, brownies

- Included Accessories:None (single mold only)

- Additional Feature:Flower-printed cavity design

- Additional Feature:Dishwasher-safe cleaning

- Additional Feature:Occasion-specific craft versatility

Factors to Consider When Choosing Multi-Cavity Soap Molds for High-Volume Batch Production

When you’re scaling up your soap production, you’ll want to evaluate cavity count and capacity against your actual batch sizes to avoid bottlenecks or wasted mold space. You should also examine material quality, durability, temperature range specifications, and mold release properties—these factors directly impact your production efficiency and product consistency. Your choice hinges on balancing these practical considerations with your specific production volume and workflow requirements.

Cavity Count And Capacity

How do you maximize your soap production without sacrificing quality? You’ll need to balance cavity count with individual capacity. A 6-cavity mold holding 2.8 fl oz per cavity yields approximately 16.8 fl oz per batch—a solid foundation for consistent output.

Higher cavity counts boost production volume, but they can reduce individual cavity size, potentially affecting your total yield. You’re trading larger per-unit capacity for more units per batch.

Consider your production workflow and cooling requirements carefully. You’ll want uniform cavity shapes and sizes that promote consistent curing and easier release. This consistency directly reduces batch variability and minimizes labor demands during demolding.

When selecting your mold, prioritize designs that fit your workspace dimensions while maintaining cavity uniformity for reliable, efficient production runs.

Material Quality And Durability

Longevity becomes your competitive advantage in high-volume soap production. You’ll want food-grade silicone that’s BPA-free and rated for -104°F to 446°F, ensuring your molds withstand freezer-to-oven transitions without degrading or warping. This temperature range protects your investment across countless production cycles.

Durability directly impacts your bottom line. Quality molds maintain their cavity geometry and structural integrity after repeated use, preventing leaks and deformations that compromise product consistency. You’ll notice the difference in cavity dimensions remaining uniform batch after batch.

Flexibility matters too. Choose molds with non-stick surfaces and easy-release designs that resist wear from constant demolding. Dishwasher-safe or easy-to-clean options reduce downtime between cycles. When you invest in superior materials, you’re reducing replacement frequency and maximizing your production efficiency.

Temperature Range Specifications

Why does temperature flexibility matter so much in your soap production workflow? You’ll encounter vastly different curing requirements across product lines—cold-setting soaps need freezer stability, while hot-molded candles demand heat resistance. Quality molds span roughly -104°F to 446°F, eliminating replacement costs when switching between processes.

This wider range directly supports your batch efficiency. You’ll avoid purchasing separate molds for different production stages, streamlining inventory and reducing overhead. Verify that silicone remains stable at maximum temperatures to prevent warping or odor transfer that compromises product quality.

Check minimum temperature tolerance carefully too. Inadequate freezer ratings cause cracking or shape loss, ruining unmolded products. Confirm dishwasher and microwave/oven compatibility aligns with your curing workflow, ensuring consistent temperatures throughout your high-volume production cycle.

Mold Release And Flexibility

Beyond temperature stability, your mold’s release properties and flexibility directly impact production speed and product quality. You’ll want a soft, flexible silicone mold with a non-stick surface that facilitates easy release, reducing damage to delicate batches during high-volume production. This flexibility prevents warping across the temperature range from -104°F to 446°F, enabling quick cycle changes between hot and chilled materials.

For smoother unmolding, choose designs that allow release from the bottom or on a stable tray, minimizing handling time per batch. Placing molds on a baking sheet or rigid tray enhances stability during transfer and release, helping you maintain consistent batch quality. These features streamline your workflow and protect your final products.

Production Batch Sizing

How you size your production batches directly determines your operational efficiency and profitability. You’ll calculate batch volume by multiplying cavity count by the number of molds per run to estimate total units per cycle. Align your mold’s cavity volume with your target bar weight—this minimizes trimming waste and guarantees consistent yields across batches. Consider your production area’s footprint; calculate total mold dimensions multiplied by quantity to verify they’ll fit your workspace and handling equipment. Don’t overlook cycle time: larger cavities demand extended setting and cooling periods, which impacts your overall throughput. Finally, standardize cavity counts across your mold sets to streamline automated filling and unmolding, reducing labor and operational bottlenecks throughout production.

Multi-Design Versatility Options

When you’re scaling production, you’ll want molds that offer multiple cavity designs—such as 6-cavity rectangles with floral or tropical leaf patterns—so you can diversify your product line within a single batch run. This approach maximizes your output without requiring mold switches between batches.

Look for sets combining both small and large cavities or varying shapes to expand beyond soap into desserts or candles. You’ll appreciate the flexibility this versatility provides for testing new markets.

Choose molds featuring a mix of decorative and plain cavities, allowing you to customize individual batches without equipment changes. This strategic combination lets you differentiate products while maintaining production efficiency, ultimately reducing setup time and increasing your profitability across diverse product categories.

Cleaning And Maintenance Requirements

You’ll find that dishwasher-safe silicone molds dramatically reduce your turnaround time between batches, especially when you’re running high-volume production schedules. However, you’ll need to verify that all molds are fully dishwasher-safe to prevent warping or residue buildup.

The non-stick, flexible surface of quality silicone molds enables easy soap release, eliminating manual scraping that risks product damage during bulk runs. You’ll also benefit from smooth, seamless cavities with consistent geometry—they prevent residue from caking in hard-to-reach corners, making cleanup faster and more thorough.

Consider molds with wide temperature ranges for oven or freezer use. These capabilities let you incorporate heat- or cryo-setting steps that streamline your entire cleaning process through uniform procedures, ultimately saving you significant time and effort.

Stackability And Storage Efficiency

Once your molds are clean and ready for the next batch, how you store them becomes equally important to maintaining production efficiency. You’ll want molds that nest or stack securely, minimizing vertical footprint while maximizing rack space between runs. Look for uniform cavity spacing and flat exteriors that prevent warping or sticking during multi-layer stacking, reducing handling time considerably.

Interlocking features on lids or rims keep molds aligned and prevent shifting during storage, which cuts down on costly diverter waste. Flexible, non-stick silicone releases easily, enabling tighter batch-to-batch turnaround and better space utilization overall. Finally, choose standardized sizes across your mold sets to ensure cross-compatibility with existing racks and shelving, streamlining your entire high-volume operation’s storage system.

Frequently Asked Questions

What Is the Ideal Curing Time for Soap Made in Multi-Cavity Molds?

You’ll typically cure your soap for 4-6 weeks in multi-cavity molds. This timeframe allows you to achieve proper hardness, better lather, and reduced irritation. You can remove bars after 24-48 hours, then let them cure fully on racks.

How Do I Prevent Soap From Sticking to Silicone Molds During Demolding?

You’ll prevent sticking by lightly dusting your silicone molds with cornstarch or mica powder before pouring. You can also refrigerate your soap for 30 minutes, then gently flex the mold’s sides while slowly releasing it.

Can Multi-Cavity Molds Handle Different Soap Recipes Simultaneously Without Cross-Contamination?

You can safely use multi-cavity molds for different recipes if you’ll clean each cavity thoroughly between batches. However, you shouldn’t pour dissimilar recipes simultaneously, as oils and fragrances can migrate between adjacent cavities.

What Temperature Range Is Safe for Silicone Soap Molds During Production?

You’ll want to keep your silicone molds between 140-180°F (60-82°C) during production. They’re heat-resistant up to 500°F, but you’ll prevent warping and ensure proper curing by staying within this safer range for soap making.

How Many Production Cycles Can Quality Silicone Molds Withstand Before Replacement?

You’ll get between 500 to 1,000 production cycles from quality silicone molds before you’ll need replacement. The exact number depends on your handling practices, demolding techniques, and how well you maintain them throughout their lifespan.

Leave a Reply