For cold process soap making, aim for a humidity range of 45-55% during curing. While humidity isn't critical during mixing, it greatly impacts curing time. High humidity (above 60%) extends curing from 4-6 weeks to 8+ weeks and may cause glycerin dew, while low humidity can dry soap too quickly. You'll need to adjust your water discount—typically 10-15% in humid conditions—and create proper air circulation in your curing space. Proper humidity management transforms your soap's quality and performance.

The Ideal Humidity Range for Cold Process Soap Making

While temperature plays a critical role in cold process soap making, humidity typically doesn't greatly impact the mixing phase of your soap creation.

Unlike temperature, which needs careful monitoring between 120-130°F for both lye solution and oils, specific humidity levels aren't critical during the initial saponification process.

You'll want to focus more on maintaining stable room conditions rather than worrying about exact humidity percentages.

However, extremely high humidity might cause unwanted condensation on your equipment, while very low humidity won't notably affect your soap batch.

If you're working with temperature-sensitive ingredients like coconut oil, palm oil, or butters, remember that their melting points respond to temperature changes, not humidity fluctuations.

For ideal results, keep your ingredients within 10 degrees of each other and maintain a comfortable, moderate humidity in your workspace.

Proper temperature control helps prevent false trace, which occurs when the soap batter appears thick but hasn't actually undergone saponification.

How Humidity Affects Soap Curing Time

Humidity directly impacts how quickly your soap cures by controlling the rate of water evaporation from your bars.

You'll notice remarkably longer curing times in high-humidity regions like Florida, where moisture-heavy air can extend the process from the standard 4-6 weeks to 8 weeks or more.

When making soap in these challenging environments, you'll need to implement strategies like dehumidifiers or increased air circulation to combat the natural tendency of glycerin in your soap to attract ambient moisture. Proper airflow is essential as soaps should never be stored in air-tight containers which can trap moisture and interfere with the curing process.

Moisture Evaporation Patterns

Have you ever noticed your handmade soap taking longer to harden in summer months? This happens because moisture evaporation follows predictable patterns based on environmental conditions.

In high humidity, water evaporates slowly from your soap, extending curing time. The glycerin in cold process soap may even attract additional moisture, causing that dreaded "sweaty" appearance.

Conversely, low humidity accelerates evaporation, potentially creating harder but drier bars.

Your soap's recipe also impacts evaporation patterns. Lower water content and additives like sodium lactate promote faster drying. Cold process soaps typically require a full four to six weeks of curing time regardless of humidity conditions.

For best results, place your soap on drying racks in a well-ventilated area with moderate humidity (40-60%). Increasing air circulation while avoiding direct sunlight creates ideal conditions for consistent moisture evaporation.

Monitor your soap's weight during curing to track evaporation progress and guarantee complete curing.

Regional Humidity Challenges

Across the United States, soap makers face dramatically different curing challenges based on their regional climate. If you're in Florida or other high-humidity areas, your soap may take considerably longer to cure than in drier regions, as moisture-laden air prevents efficient water evaporation from your bars.

You'll notice glycerin in your soap attracting ambient moisture, causing "sweating" that appears as beads of liquid on the surface. This can affect both durability and lather quality.

To overcome these challenges, consider using a dehumidifier in your curing space and reducing water content in your recipes. The curing process typically requires 4 to 6 weeks depending on your specific recipe and environmental conditions. Hot process soap making offers an advantage in humid climates by accelerating the curing process.

Verify good air circulation in your curing area to maintain ideal drying conditions despite regional humidity variations.

Seasonal Variations in Humidity and Adapting Your Process

As the seasons change throughout the year, you'll need to adjust your soap making techniques to accommodate fluctuating humidity levels. Your recipes and storage methods should evolve with the weather to maintain quality and guarantee proper curing. Using Damp Rid buckets and running multiple fans over your soap can effectively combat excessive humidity during summer months.

| Season | Humidity Challenge | Recommended Adaptation |

|---|---|---|

| Winter | Low humidity dries soap too quickly | Increase water ratio slightly; use humidifier in curing area |

| Spring | Fluctuating humidity levels | Monitor closely; adjust packaging to compensate |

| Summer | High humidity slows curing | Reduce water content; add sodium lactate; use dehumidifier |

| Fall | Gradual humidity decrease | Rotate inventory; adjust to shifting recipes |

Consider developing season-specific recipes that account for your regional climate patterns. Using appropriate packaging materials like shrink wrap or biolefin creates effective moisture barriers during humid periods, while proper ventilation systems help maintain consistent curing conditions year-round.

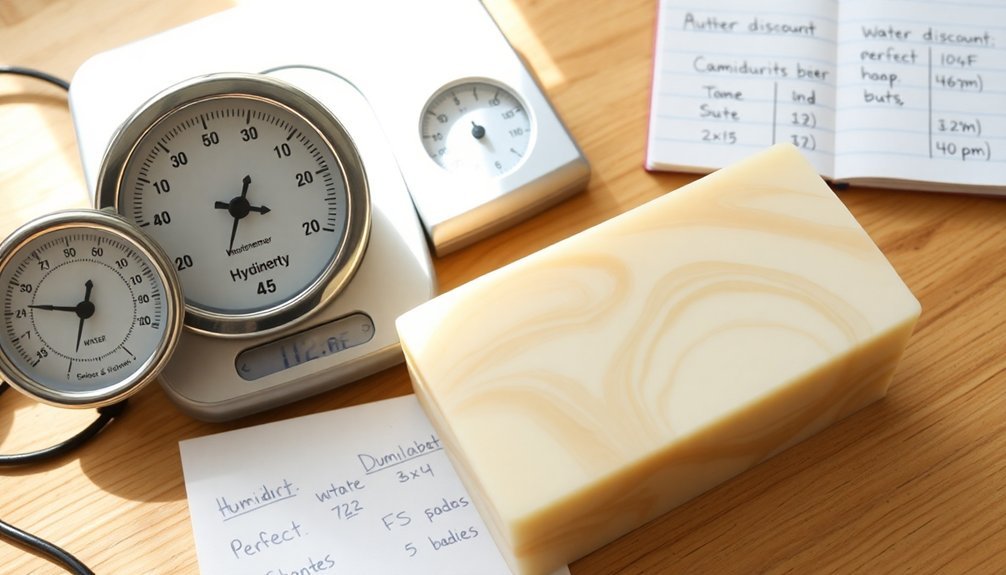

Equipment for Monitoring and Controlling Workshop Humidity

Precision equipment for humidity monitoring forms the backbone of successful soap making operations.

You'll need humidity sensors with accuracy of ±2.5% RH or better to guarantee quality production. Web-based sensors with Ethernet interfaces provide real-time data monitoring, while PoE options simplify installation and reduce wiring clutter.

Consider devices with IP30 protection class that can withstand typical workshop conditions (-20 to +60°C). Look for sensors offering high resolution (0.1% RH) and temperature compensation for consistent readings. Regular calibration maintains accuracy over time.

Software integration capabilities enhance your control—COMET Database can analyze humidity data while alarm systems alert you when conditions deviate from ideal ranges. Advanced sensors include remote alarm capability for immediate notification when humidity levels fall outside optimal soap-making parameters.

For thorough monitoring, choose systems that calculate dew point, absolute humidity, and specific enthalpy.

Temperature-Humidity Relationship in Soap Making

The intricate relationship between temperature and humidity creates a complex environment that can make or break your soap.

When your workshop is warmer, you'll need to maintain lower humidity levels to prevent excessive moisture absorption that can interfere with proper saponification. Soap makers should aim for 90°F to 110°F when balancing temperature with humidity conditions.

Conversely, in cooler conditions, slightly higher humidity can help prevent your soap from drying too quickly, allowing for ideal curing and preventing issues like ash formation or cracking.

Temperature-Humidity Relationship in Soap Making

Understanding the delicate interplay between temperature and humidity provides soap makers with essential knowledge for consistent results.

When temperatures rise, soap-making environments typically experience changes in humidity levels that can affect your final product. Your lye solution should stay between 120-130°F, while warmer room conditions accelerate saponification but may cause overheating. Conversely, cooler, drier environments slow the process.

In high humidity, soaps absorb moisture, potentially affecting their weight and texture over time. For ideal results, aim for moderate humidity during both production and curing phases.

If you're working with temperature-sensitive ingredients like milk or beeswax, you'll need to adjust accordingly. Remember that recipes with primarily liquid oils handle temperature fluctuations better than those heavy in butters. Maintaining both components at approximately body temperature (37°C) helps prevent issues like false trace during the mixing process.

During curing, maintain stable, moderate conditions to prevent mold growth and guarantee proper hardening.

Dew Point Effects

When moisture-laden air reaches its saturation point, dew point conditions create unique challenges for soap makers. High humidity slows water evaporation, extending curing times and keeping soaps softer longer.

You'll notice your soaps retaining more water weight compared to those cured in dry environments.

The most visible impact is glycerin dew—that "sweaty" appearance on soap surfaces, particularly noticeable in melt and pour varieties. You can combat this by wrapping soap after cooling or using water discounting techniques. This is why proper cure time periods vary depending on environmental humidity levels, with standard cold process soaps needing 4-8 weeks.

Be cautious with insulation during humid conditions, as overheating risks increase, potentially causing "alien brain" effects that compromise design integrity.

Consider using fans to improve air circulation and dehumidifiers to control your workspace environment. Monitoring humidity levels with a hygrometer will help you make appropriate adjustments to your recipes and processes.

Preventing Glycerin Dew in High Humidity Environments

Despite your best soap-making efforts, glycerin dew can appear on your beautifully crafted bars when humidity levels rise too high. To combat this issue, implement strategic humidity control and proper packaging solutions. High glycerin content in natural soaps makes them particularly susceptible to drawing moisture from the air.

| Strategy | Implementation |

|---|---|

| Humidity Control | Use dehumidifiers or air conditioning to maintain consistent moisture levels |

| Packaging | Wrap bars tightly in plastic, biodegradable wraps, or store in airtight containers |

| Storage | Keep soap in dry areas with silica packets to absorb excess moisture |

Consider reducing glycerin content in your soap base, especially for melt and pour varieties. For cold process soaps, manage curing conditions carefully. Remember to adapt your approach seasonally, taking extra precautions during humid months. Proper wrapping not only prevents dew formation but also preserves your soap's appearance and quality until it reaches your customers.

Adjusting Water Discounts Based on Ambient Humidity

While glycerin dew represents one humidity challenge, the water content in your soap recipe itself offers another powerful way to adapt to changing moisture levels.

In high humidity environments, you'll benefit from increasing your water discount to compensate for slower evaporation rates.

Start with a 10% water discount when humidity levels exceed 60%, which can reduce your overall curing time from 6 weeks to about 4 weeks. This adjustment also helps your soap release from molds faster, a significant advantage in humid conditions.

Remember that increased water discounts accelerate trace, so you'll need to simplify your design work accordingly. The faster trace makes creating intricate designs more difficult as soap batter thickens quickly.

Don't exceed a 15% discount, as this risks lye pockets and potential skin irritation. Balance your discount rate with your environment's specific humidity levels for best results.

Creating Microclimates for Optimal Soap Curing

Creating a controlled microclimate for soap curing can dramatically improve your final product quality, especially if you live in an area with challenging humidity conditions.

Set up your curing space with stainless steel racks that allow air circulation around your bars, positioning them away from direct sunlight and heat sources.

Consider investing in a dehumidifier to maintain the ideal 45-55% humidity range, particularly during monsoon seasons or in naturally humid climates. Florida's unique climate demonstrates how environmental factors can significantly alter curing times and final soap characteristics.

Supplement this with desiccants like Damp Rid or silica gel in enclosed spaces. Monitor conditions regularly with a hygrometer and thermometer to guarantee consistency.

Don't store curing soap in airtight containers—ventilation is essential.

Rotate your bars periodically for even drying and clean your racks regularly to prevent contamination that might interfere with the curing process.

Frequently Asked Questions

Can I Make Soap During Rainy Seasons?

Yes, you can make soap during rainy seasons. You'll need to manage humidity with dehumidifiers, fans, and proper ventilation. Consider water discounting and using sodium lactate to help your soap unmold and cure properly.

Will Humidity Affect Fragrance Retention in Soap?

Yes, humidity can indirectly affect your soap's fragrance retention. While it won't directly degrade scents, improper storage in humid conditions accelerates fragrance fading. Keep your soaps in cool, dry places to preserve their scent longer.

How Do Different Oil Combinations Perform in High Humidity?

In high humidity, your olive oil soaps resist sweating due to stable oleic acid, while coconut oil-based formulas remain drier. You'll find castor oil soaps absorb more moisture, and shea butter additions may increase water retention.

Can Humidity Influence Color Stability in Natural Soaps?

Yes, humidity can affect your natural soaps' color stability. High moisture levels accelerate the degradation of natural colorants, causing fading or dulling over time. You'll notice more dramatic effects in plant-based formulations with natural pigments.

Does Humidity Impact the Effectiveness of Soap Preservatives?

Yes, high humidity impacts your preservatives' effectiveness. It introduces more water into your soaps, potentially diluting preservatives and creating an environment where microbes thrive. You'll need stronger preservation systems in humid conditions.

In Summary

You'll find that maintaining humidity between 40-60% is your soap making sweet spot. Don't let environmental conditions dictate your results—take control by monitoring and adjusting your workspace as needed. Remember, you're not just making soap; you're creating an environment where your creations can thrive. With the right humidity balance, you'll consistently produce professional-quality bars that cure properly every time.

Leave a Reply