Author: Soap Legacy

-

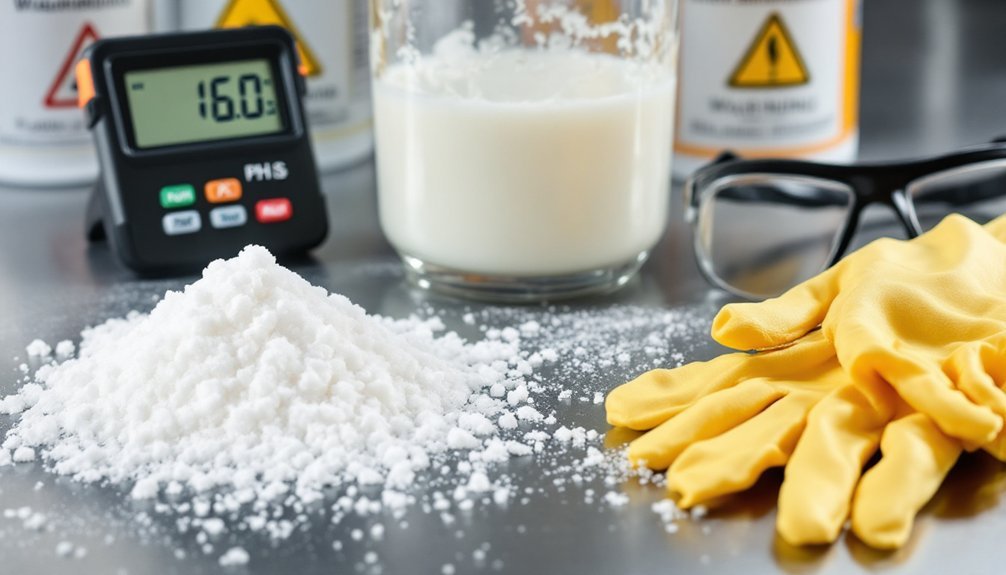

Why Do Soap Makers Get Chemical Burns?

Burns plague soap makers who handle lye carelessly, but simple precautions could save your skin.

-

What Eye Protection Should Soap Makers Wear?

When making soap, proper eye protection prevents devastating chemical burns, but which option actually keeps you safe?

-

Traditional Plant-Based Soap Scenting: Time-Tested Methods

When creating authentically scented plant-based soaps, artisans discover ancient techniques that transform ordinary bars into aromatic treasures.

-

10 Time-Tested Herbs for Scenting Handmade Soap

Herbs like lavender and rosemary transform homemade soaps, but which botanical treasure creates the most luxurious bathing experience?

-

Classic Soap Fragrancing: Master Historical Blending Techniques

Skilled artisans once crafted sublime soap scents using three-tiered notes—discover their forgotten techniques before these aromatic treasures vanish forever.

-

5 Essential Herb Extracts For Handcrafted Soaps

Gorgeous botanical extracts transform ordinary soap into healing skin remedies—discover which five herbs belong in your soap-making arsenal.

-

Artisanal Soap Making: Heritage Botanicals & Aromatics

Witness the ancient wisdom of soap-making transform into aromatic treasures that connect your daily ritual to centuries of healing tradition.

-

Natural Herb Combinations For Heritage Soapmaking Success

Blending medicinal herbs creates authentic heritage soaps that transform skincare, but which combinations yield the most beneficial results?

-

Ancient Soapmaking: Crafting Fragrances Like Our Ancestors

Craftsmen of antiquity transformed oils and botanicals into aromatic soaps that cleansed both body and spirit—what secrets await?

-

5 Best Botanical Soap Recipes Using Natural Herbs

Just when you thought soap-making couldn’t get more natural, these 5 herbal recipes will transform your skincare routine forever.