You’re looking for copper molds that’ll elevate your soap-making game without compromising quality. The right mold doesn’t just shape your bars—it affects heat distribution, release clarity, and your brand’s final appearance. Whether you’re crafting sharp-edged soaps or experimenting with unique designs, you’ll want to know which options deliver consistent results. Let’s explore what makes certain copper molds stand out this year.

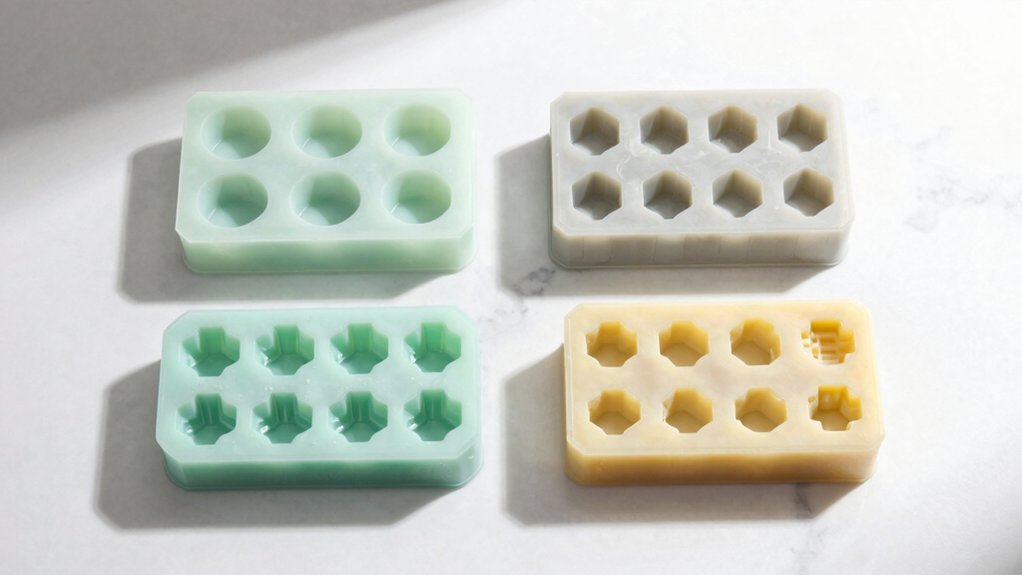

| Silicone Mold for Handmade Soap Bath Bombs (Set of 2) |  | Best for Beginners | Material Composition: 100% silicone | Temperature Resistance Range: -40°F to 445°F | Mold Shape Options: Oval (6 cavities) | CHECK ON AMAZON | Read Our Analysis |

| Sakolla 2 Pack Silicone Soap Molds with Cavities |  | Most Versatile | Material Composition: Silicone | Temperature Resistance Range: -104°F to +446°F | Mold Shape Options: Round flower and rectangle wave (4 cavities) | CHECK ON AMAZON | Read Our Analysis |

| ZOENHOU 7PC Soap Molds Kit with Slicers |  | Complete Starter Kit | Material Composition: Premium silicone and wood | Temperature Resistance Range: -40°F to 446°F | Mold Shape Options: Rectangular loaf bar (10 slots) | CHECK ON AMAZON | Read Our Analysis |

More Details on Our Top Picks

Silicone Mold for Handmade Soap Bath Bombs (Set of 2)

If you’re seeking a versatile silicone mold that handles multiple crafting projects beyond soap-making, this set of two delivers exceptional flexibility. You’ll work with 100% silicone featuring six oval-shaped cavities, each measuring 9 x 6.5 x 2.8 cm. The molds withstand temperatures from -40 to 445°F, so you can craft bath bombs, mousse, jelly, cakes, bread, chocolate, and prepared foods. You’ll appreciate the intentionally soft design for effortless unmolding. For added stability during transfers, you can place each mold on a tray or nest them together. At 22 x 20.5 x 2.8 cm overall, this practical set offers reliable performance for serious crafters.

- Material Composition:100% silicone

- Temperature Resistance Range:-40°F to 445°F

- Mold Shape Options:Oval (6 cavities)

- Non-Stick Design:Designed soft for easy unmolding

- Set Contents:2 molds

- Versatile Applications:Soap, mousse, jelly, cake, bread, chocolate

- Additional Feature:Soft design for easy unmolding

- Additional Feature:6 cavity oval shape

- Additional Feature:Requires tray support for stability

Sakolla 2 Pack Silicone Soap Molds with Cavities

The Sakolla 2 Pack Silicone Soap Molds stands out as the best choice for crafters who want versatility beyond soap making. You’ll appreciate the two distinct designs—ocean wave and flower shapes—offering creative options for your projects. Each mold cavity holds substantial amounts: rectangle cavities accommodate 4 oz while round cavities hold 3.3 oz, giving you flexibility for different batch sizes. The silicone construction withstands temperatures from -40 to +230°C, making it compatible with freezers, microwaves, and ovens. You’ll easily release finished products thanks to the non-stick surface. Beyond soaps, you’ll use these molds for candles, chocolate, resin, and polymer clay. The lightweight design ensures convenient storage, and dishwasher cleaning keeps maintenance effortless.

- Material Composition:Silicone

- Temperature Resistance Range:-104°F to +446°F

- Mold Shape Options:Round flower and rectangle wave (4 cavities)

- Non-Stick Design:Non-stick surface with easy release

- Set Contents:2 molds (4 cavities total)

- Versatile Applications:Soap, candle, mousse cake, baking, chocolate, resin, polymer clay

- Additional Feature:Multiple shape options included

- Additional Feature:Dishwasher and microwave safe

- Additional Feature:Holds up to 4 oz per cavity

ZOENHOU 7PC Soap Molds Kit with Slicers

Want a complete soap-making setup that doesn’t require hunting down separate tools? The ZOENHOU 7PC kit offers everything you need in one package. You’ll get two silicone molds, a ten-slot loaf bar mold, and both wavy and straight stainless steel slicers. The premium silicone withstands temperatures from -40°F to 446°F, ensuring durability through countless batches. Its non-stick design lets you pop finished soaps out effortlessly with a finger press. The wood storage box keeps all components organized and protected. Dishwasher-safe construction makes cleanup simple, and the rectangular design creates professional-looking bars perfect for gifting during holidays.

- Material Composition:Premium silicone and wood

- Temperature Resistance Range:-40°F to 446°F

- Mold Shape Options:Rectangular loaf bar (10 slots)

- Non-Stick Design:Non-stick coating with finger press release

- Set Contents:2 silicone molds, 1 loaf mold, 2 stainless steel slicers, wood box

- Versatile Applications:Handmade soap, DIY crafts, gift-making

- Additional Feature:Includes stainless steel slicers

- Additional Feature:Wood storage box included

- Additional Feature:10-slot loaf bar mold

Factors to Consider When Choosing Soap Making Copper Molds for Vintage and Traditional Bar Shapes

When you’re selecting copper molds for vintage and traditional bar shapes, you’ll want to prioritize material quality and durability to ensure your investment withstands repeated use. You should also evaluate the heat resistance and temperature range, mold capacity, size options, and design features that’ll let you release your soaps cleanly and easily. Beyond these core considerations, you might discover that versatile molds designed for soap making can serve double duty for candles, chocolates, or other craft projects.

Material Quality And Durability

Every copper mold you choose will directly impact your soap’s final appearance and your molding experience, making material quality non-negotiable. You’ll want thick, sturdy walls that resist denting and maintain consistent heat distribution throughout long pour and cure times. Smooth, well-finished surfaces prevent soap from sticking while ensuring sharp edge details on traditional designs remain crisp and defined.

Durability extends beyond initial construction. You should prioritize corrosion resistance by selecting copper with protective linings or plating that prevent patina development and unwanted reactions with soap ingredients. Sturdy handles or reinforced rims protect your investment by enabling safe unmolding of heavier bar shapes without compromising the mold’s structural integrity. Quality materials ensure your molds perform reliably across multiple batches.

Heat Resistance And Temperature Range

Because copper conducts heat rapidly, you’ll need molds with a temperature tolerance matching your soap base—typically up to 230°C (446°F) for safe hot-pour work. This heat resistance prevents warping, off-gassing, and distortion of your vintage bar shapes during pouring.

A wider temperature range proves essential for maintaining thermal stability throughout both heating and cooling phases. This prevents cracking, sweating, and ensures your embossed details and layered designs stay sharp and precisely defined. Consistent temperature control matters too—copper’s excellent heat conductivity can create hotspots that compromise bar integrity if not managed carefully.

Choose molds engineered for thermal consistency, protecting your investment while delivering professional-quality finished bars every time.

Mold Capacity And Size Options

How you’ll scale your soap production hinges on selecting the right mold capacity and dimensions. Larger molds let you produce more bars per batch, but they’ll require longer cure times and sturdier support during unmolding. You’ll need to consider cavity shape and uniformity to ensure consistent weights and achieve traditional bar silhouettes with decorative embossing. Precise measurements—length, width, and height—directly affect cooling airflow and shrinkage, which are critical for maintaining authentic vintage bar proportions. Multi-cavity configurations give you flexibility; single large loaves work well for bulk production, while individual bar cavities suit smaller batches and varied presentation styles. Match your mold choice to your production goals and aesthetic vision.

Design Features For Easy Release

What separates a frustrating unmolding experience from a seamless one? The mold’s design features. You’ll want smooth, polished interiors that minimize sticking and allow your finished bars to release effortlessly. Look for slightly flexible, well-tempered metal construction that won’t bend or warp during unmolding—this durability matters.

Integrated ridges and beveled edges on vintage shapes enable clean, single-handed release while reducing residue around seams. These thoughtful details make a real difference in your workflow.

Pay attention to decorative elements too. Shallow embossing or die-cut details prevent tearing when you unmold your bars. Finally, consider molds with proper coatings or lining options designed for soap-safe release agents. These enhancements significantly improve efficiency, especially with complex or multiple cavity designs.

Versatility Beyond Soap Making

Flexibility extends the value of your copper mold investment far beyond soap crafting. You can use your copper molds for wax, gelatin, and other mediums without worry. The non-reactive surface won’t interact with different materials, while the seasoned finish ensures consistent release across applications.

This versatility means you’re not limited to seasonal soap production. During slower months, you’ll repurpose the same molds for candle-making projects or decorative gelatin work. You’ll maximize your equipment investment by rotating between mediums based on your creative needs.

Maintenance remains straightforward across all uses. Thorough drying prevents tarnish buildup, and occasional polishing keeps your release efficiency sharp. This simple care routine preserves your molds’ performance regardless of what you’re molding, making copper an economical choice for diverse crafting pursuits.

Maintenance And Cleaning Requirements

Why does maintenance matter so much when you’re investing in copper molds? Proper care directly preserves their functionality and appearance. You’ll want to clean your molds promptly after each use with warm water and mild soap, then dry them thoroughly to prevent corrosion and tarnish.

Skip abrasive scrubbers—they damage the surface and eliminate any developing vintage patina. Instead, use soft cloths or sponges. Always air-dry your molds rather than leaving them damp, which invites rust.

If verdigris or corrosion appears, treat it gently with lemon juice and salt, then re-season the surface. Between uses, polish your molds regularly with copper-safe metal polish or a baking soda and water paste. This prevents oxidation and maintains their nonstick qualities for consistent soap production.

Shape Variety And Aesthetic Appeal

Once your copper molds are properly maintained and protected, you’ll want to focus on selecting designs that genuinely reflect your soap-making vision. Shape variety dramatically influences your final product’s appeal—from simple rectangular loaves to intricate cavity designs with scalloped or floral edges. You’re essentially choosing between minimalist elegance and decorative artistry.

Vintage-inspired molds featuring embossed borders or unique profiles add perceived artisanal value that customers notice and appreciate. Consider molds yielding clean, crisp edges with smooth releases, which requires well-tempered copper and proper lining.

Consistency matters too. Select molds that reproduce uniform cavities across batches, maintaining that cohesive, timeless appearance your brand promises. This attention to detail transforms ordinary soap into recognizable, collectible pieces that justify premium pricing and foster customer loyalty.

Long-Term Reusability And Value

Investing in copper molds with superior long-term reusability assures your soap-making equipment pays dividends across countless production cycles. You’ll benefit from durable metal construction that resists warping and corrosion when you properly season and clean molds after each use. Through thorough drying and occasional reseasoning, you extend mold life while preserving distinctive edge contours that define classic bar shapes.

However, you must address copper’s natural tendency toward patina and oxidation. Regular polishing or protective coatings prevent surface texture degradation that compromises appearance and value. Consider molds offering matching lids or supports—these accessories facilitate repeated un-molding without damage, protecting your investment. When evaluating replacement costs, prioritize size variety and historical shape accuracy alongside maintenance requirements to maximize your long-term value.

Frequently Asked Questions

How Long Do Copper Molds Typically Last Before Needing Replacement or Repair?

You’ll find that quality copper molds typically last 10-15 years with proper care. You can extend their lifespan by cleaning them regularly, drying them thoroughly, and storing them in a dry environment. You’ll rarely need replacement if you maintain them well.

Can Copper Molds Be Used for Cold Process Soap Making Safely?

You can safely use copper molds for cold process soap making. You’ll want to line them with plastic or silicone to prevent the lye from directly contacting the copper, which could cause discoloration or chemical reactions.

What Is the Proper Cleaning and Maintenance Routine for Copper Molds?

You’ll wash your copper molds immediately after use with warm soapy water and a soft cloth. You should dry them thoroughly to prevent oxidation. Store them in a dry place, and occasionally polish them with vinegar to maintain their shine.

Are Copper Molds More Expensive Than Silicone or Other Alternative Mold Materials?

You’ll find copper molds cost more upfront than silicone alternatives, but they’ll last longer and provide superior heat conductivity. You’re investing in durability and professional results that justify the higher price.

Do Copper Molds Require Seasoning or Special Preparation Before First Use?

You should clean your copper molds thoroughly with warm soapy water and dry them completely before first use. You don’t need seasoning, but you’ll want to oil them occasionally to prevent oxidation and maintain their appearance.

Leave a Reply