The 7 best ways to scale lye-water ratios include: using the Master Formula method, maintaining a consistent 2:1 ratio for beginners, adjusting for oil types (1.5:1 for high olive oil, 1.1:1 for castile), compensating for environmental factors like humidity and elevation, calculating specialty additives as part of total liquid weight, starting with small batches before scaling up, and using precise digital measurements. These techniques will help you avoid common measurement errors and transform your homemade soaps from basic to professional-grade creations.

Understanding the Mathematics Behind Lye-Water Ratios

Three fundamental principles govern lye-water calculations in soapmaking.

First, the amount of lye remains constant regardless of water adjustments—your recipe's lye weight is determined by the oils used, not your water:lye ratio.

Second, expressing ratios properly matters; a 2:1 water:lye ratio means twice as much water as lye by weight.

Third, water discounts are calculated as percentages of lye weight, not total solution.

To calculate the amount of water needed, multiply your lye weight by your desired ratio. For example, with 100g lye at a 2:1 ratio, you'll need 200g water.

When applying a water discount, subtract the percentage from your standard water amount. A 10% discount means using 90% of your calculated water.

This creates a more concentrated lye solution that's still safe to use but accelerates the curing process.

Batch Size Adjustments for Beginners: Starting Small

Starting with small 1-pound batches allows you to master precise lye-water calculations while minimizing the risk of wasting ingredients through errors.

You'll need only 2.2 oz of lye and 4.4 oz of water at a 2:1 ratio, making measurements manageable with a digital scale.

These smaller amounts let you experiment confidently with different water-to-lye ratios before committing to larger soap-making projects.

Small Batch Benefits

When you're new to soapmaking, beginning with smaller batches offers numerous advantages that can greatly improve your learning experience. Working with just 16 oz of oils lets you practice lye-water ratios with minimal risk and waste. You'll quickly master the common 2:1 water-to-lye proportion while gaining confidence.

| Benefit | Small Batch Advantage |

|---|---|

| Cost | Less investment in ingredients |

| Safety | Reduced exposure to lye |

| Experimentation | Easy to try different soaping oils |

| Learning | Faster feedback on superfat percentage |

Using lye calculators becomes more intuitive with smaller quantities, helping you understand how water amount affects trace time. You're free to experiment without the pressure of potentially wasting large batches, making adjustments to your formula until you achieve the perfect bar.

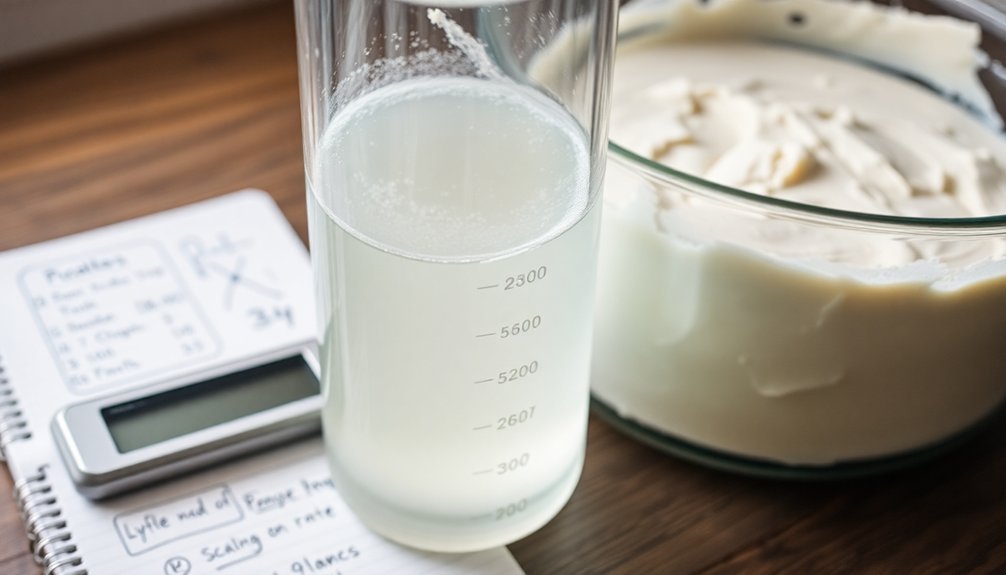

Precise Measurement Techniques

Accuracy forms the foundation of successful soapmaking, especially when adjusting batch sizes for beginners. When scaling recipes, you'll need to maintain a consistent water to lye ratio, with 2:1 being ideal for newcomers. This proportion guarantees you have enough water for lye to saponify properly.

Always use a digital scale for precise measurements—volume simply won't cut it. For example, a small test batch might use just 1 oz of lye with 2 oz of water. Before mixing anything, run your ingredients through a lye calculator to verify exact amounts needed for your specific oils.

As you work, document measurements and observations in each batch. Note how water adjustments affect trace time and texture. This record-keeping becomes invaluable as you gain confidence in scaling recipes and developing your signature formulations.

Minimize Waste Risk

While experienced soapmakers confidently produce 5-pound batches, beginners should embrace the wisdom of starting small. Beginning with just 1 pound of oils helps you minimize waste and reduce risk while mastering the craft. Maintain a lye-to-water ratio of 2:1 or 1.5:1, ensuring water amounts never fall below your lye quantity.

| Batch Size | Benefits | Lye-Water Considerations | Documentation |

|---|---|---|---|

| 1 lb oils | Minimal waste | Use lye calculator for precision | Record all measurements |

| Small test batches | Low cost of failure | Maintain 2:1 or 1.5:1 ratio | Note trace time |

| 16 oz total | Easy to handle | Water never less than lye amount | Track texture results |

| Beginner-friendly | Room to experiment | Adjust ratios gradually | Build scaling confidence |

Using small batch sizes allows you to experiment with different water ratios while developing your soapmaking skills before scaling up.

Master Formula Method for Consistent Results

To achieve predictable results every time you make soap, the Master Formula method offers a systematic approach to scaling lye-water ratios. This technique starts with a base 2:1 water-to-lye ratio, giving you precise control over trace development and design flexibility.

When calculating the correct amount of lye, consider your desired lye discount (superfat percentage), then determine the amount of water needed. For recipes with high olive oil content, a recommended water ratio of 1.5 times the lye works well, while reducing to 1.1 times for castile soaps containing 90-100% olive oil.

Using a reliable lye calculator guarantees accurate measurements of lye crystals and water, preventing common issues like lye-heavy batches.

Advanced Water Discount Techniques for Different Oil Blends

Different oil blends require specific water adjustments to maximize your soap's quality and workability.

For high-oleic recipes like those with 50%+ olive oil, you'll want a water ratio of 1.5:1 (water:lye) to speed up trace time, while coconut-rich formulas benefit from a 10-15% water discount to prevent excessive hardness.

When working with butter-heavy recipes, consider a moderate 10% water discount to balance the naturally firm properties of butters while maintaining adequate working time for your design elements.

High-Oleic Blends Adjustments

Since high-oleic formulations present unique challenges in soap making, adjusting your water-to-lye ratios becomes critical for success.

When working with these blends, start with a 1.5:1 water-to-lye ratio to guarantee a harder bar and accelerate curing, especially when using moisture-retaining oils like olive.

If you're experienced, you can implement water discounts up to 20% to enhance soap hardness while maintaining adequate trace time for design work.

However, for 90-100% castile or bastile formulations, opt for a 1.1:1 ratio to prevent your soap batter from thickening too quickly.

Always calculate the saponification value of each oil to determine precise lye amounts.

When applying advanced water discount techniques, carefully monitor the heat generated by concentrated lye solution, as it can accelerate trace and impact your design capabilities.

Coconut-Rich Formula Considerations

Coconut-rich soap formulations require special attention to water-lye ratios because they naturally accelerate trace and generate significant heat during saponification.

When working with high coconut oil percentages (80%+), begin with a water-to-lye ratio of 1.5:1 to manage the rapid reaction and guarantee proper saponification.

For advanced soapers pursuing intricate designs, a 20-30% water discount improves pouring consistency while maintaining workability. Aim for a lye concentration between 33-38% to balance the accelerated trace.

When incorporating coconut milk, add it as a supplemental ingredient rather than a complete water replacement, adjusting your water content accordingly—reduce water by one ounce for each ounce of coconut milk added.

Remember that higher lye concentrations with coconut-rich formulas can create excessive heat, potentially causing burns during mixing, so monitor temperatures carefully.

Butter-Heavy Water Ratios

While coconut-rich formulas demand higher water content to manage their rapid trace, butter-heavy recipes benefit from a more conservative approach.

For soap containing substantial amounts of shea or cocoa butter, aim for a water-to-lye ratio between 1.5 and 2 times the lye weight.

Consider implementing a 10-20% water discount when working with butter-heavy oils to promote firmer bars and shorter curing times.

Always use a lye calculator to determine precise amounts since saponification values vary greatly among butters.

Advanced soapmakers can experiment with ratios as low as 1.1:1 for high-butter recipes to achieve a harder bar.

Be warned – this accelerated saponification requires vigilant temperature monitoring and quick work.

The concentrated lye solution will speed trace, so prepare to execute your design efficiently.

Environmental Factors Affecting Lye Concentration

Although many soapmakers focus primarily on ingredient measurements, environmental conditions play an essential role in achieving consistent lye concentrations.

Humidity levels directly impact your ingredients' moisture content, requiring adjustments to water ratios to maintain proper saponification. Ambient temperatures can accelerate or slow chemical reactions, affecting how lye dissolves and interacts with oils.

Consider these environmental factors when adjusting your recipe:

- Humidity – In high humidity, reduce water by 5-10% to compensate for moisture absorption in dry ingredients.

- Altitude – Higher elevations require water ratio adjustments as evaporation rates increase.

- Seasonal changes – Summer batches may need less water than winter batches due to natural humidity differences.

Understanding these variables allows you to make informed recipe adjustments throughout the year, ensuring consistent soapmaking results regardless of environmental conditions.

Adapting Ratios for Specialty Additives and Fragrances

Just as environmental conditions require adjustments to your lye-water ratios, specialty additives and fragrances demand their own specific modifications.

Customizing your soap formula isn't just chemistry—it's adapting to ingredients that each bring their own personality to the process.

When incorporating milk or coconut milk, count them as part of your total liquid weight, adjusting your lye water accordingly to maintain proper concentrations.

For fragrance oils, start with the standard 3% of total oils, but don't hesitate to experiment since scent strength varies between products.

Remember that certain additives accelerate trace, requiring you to modify your water ratio to maintain workability with fast-moving fragrances.

When working with hard oils, you can use higher lye concentrations, but keep the water-to-lye ratio between 1:1 and 2:1 for ideal saponification.

Strategic water discounts can give you better control over gel phase and improve your final soap quality.

Troubleshooting Common Scaling Errors in Large Batches

Many soapmakers encounter significant challenges when scaling up their recipes from small test batches to larger production runs.

When troubleshooting errors in larger batches, always verify your lye-water ratios maintain proper proportions, as insufficient water can lead to unsaponified lye pockets in your final product.

Common scaling issues to address:

- Calculation discrepancies – Cross-reference your measurements using multiple lye calculators to verify amounts before committing to large batches.

- Equipment failures – Check your scale's battery regularly, as even minor measurement errors multiply dramatically when scaling up.

- Unexpected trace acceleration – If implementing a water discount, remember that concentrated lye solutions speed up saponification, requiring faster work.

Start with conservative water discounts when refining your scaling techniques, gradually adjusting as you build confidence with larger batches.

Frequently Asked Questions

How to Calculate Lye to Water Ratio?

Calculate lye-to-water ratio by dividing your lye weight by your water weight. You'll typically want a 1:2 ratio (one part lye to two parts water) as your starting point for soap recipes.

How to Calculate the Amount of Water in Soap Making?

To calculate water in soapmaking, multiply your lye weight by the desired ratio (typically 1.5-2). For example, if you're using 100g lye, you'll need 150-200g water. Adjust ratios for specific soap types like Castile.

What Happens if You Use Too Much Lye in Soap Making?

Using too much lye creates unsafe soap that can burn your skin. You'll experience harsh, drying effects as excess lye strips natural oils from skin. The soap becomes overly alkaline with poor lather, making it unusable and potentially dangerous for contact with skin.

What Are the Proportions for Soapy Water?

For soapy water, you'll want to use 1-2 tablespoons of liquid soap per gallon of water. You can adjust this ratio depending on how dirty the surface is or how much suds you're looking for.

In Summary

You've now mastered the art of scaling lye-water ratios for your soap making projects. Remember, precise measurements are non-negotiable for safety and quality. Don't hesitate to adjust your calculations based on oil types, environmental conditions, and batch sizes. When in doubt, start small and test your formula before scaling up. With practice, you'll develop an intuition that complements your mathematical precision.

Leave a Reply