Essential tools for testing homemade soap include accurate digital scales, reliable thermometers, pH testing strips or digital pH meters, phenolphthalein drops for alkalinity detection, lather testing equipment, hardness testing tools like fruit sclerometers, and essential oil compatibility testers. You'll need these to guarantee your soap has the right pH balance, texture, and lathering capabilities. Proper testing transforms your soap making from guesswork to precision crafting, assuring consistently high-quality products your customers will love.

7 Quality Testing Tools For Homemade Soap

While creating beautiful handmade soap is an art, guaranteeing its quality requires scientific precision and the right testing tools.

You'll need basic equipment like accurate scales for proper ingredient proportions and thermometers to monitor temperatures during saponification.

For performance assessment, consider pH meters instead of strips for precise alkalinity measurements. Remember that handmade soap typically has a pH between 8-10, which is normal despite being alkaline. Test fragrance retention and moisturizing properties to guarantee customer satisfaction.

Don't skip safety tests—the "zap test" helps detect free alkali, while patch tests identify potential allergens.

Advanced soapmakers might invest in viscometers for liquid soap consistency or spectroscopy equipment for detailed composition analysis.

Durability tests will reveal how well your soap maintains shape over time, while lather production tests evaluate a key performance indicator that customers value.

Proper stress testing guarantees your product remains stable under various environmental conditions.

Ph Testing Strips and Their Proper Application

How do you guarantee your handmade soap won't irritate your customers' skin? pH testing strips provide a simple yet effective way to measure your soap's alkalinity, making them essential tools in any soapmaker's toolkit.

For accurate readings, wet a small area of your soap and press the strip against it. The color change occurs instantly—aim for olive green, indicating a pH around 9. Always compare results with the provided color chart immediately after testing.

Avoid common mistakes like testing dry soap or using tap water, which can skew results. Instead, create a standardized solution using distilled water and soap for more reliable readings. With our eco-friendly PET packaging, these strips are both functional and environmentally conscious.

If you need more precision, consider alternatives like phenolphthalein drops or digital pH meters, which can provide more accurate measurements for your finished products.

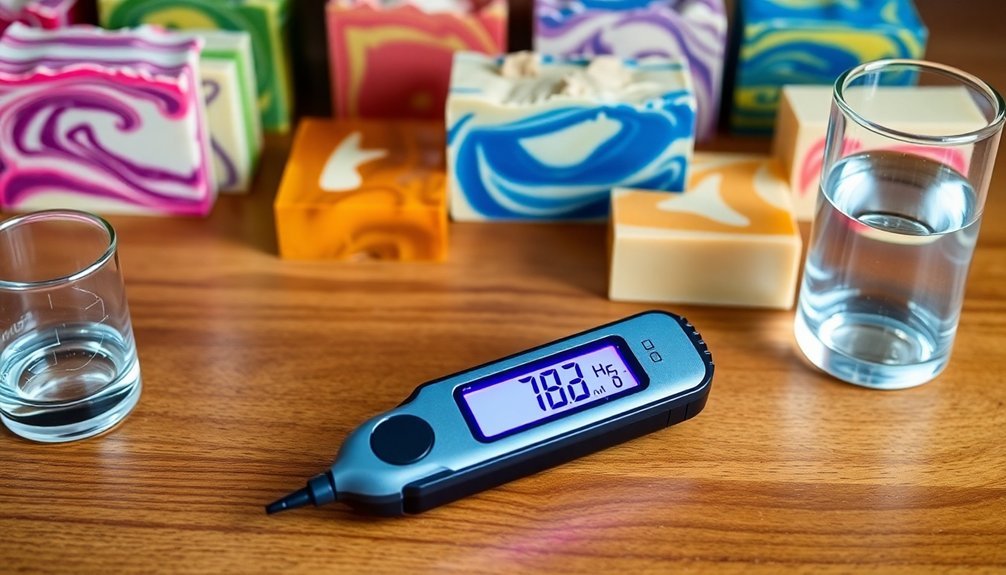

Digital Ph Meters for Precise Measurements

Precision defines the difference between acceptable soap and exceptional products. When you're ready to elevate your soap making, digital pH meters offer accuracy to 0.01 pH units, far superior to testing strips. These devices provide instant readings across a thorough range (-2 to 16 pH), making them ideal for tracking your soap's pH throughout the curing process. For the most accurate readings, consider creating a 10% dilution solution of your soap before measuring.

The leap from basic to extraordinary soapmaking begins with precision that only digital measurement can provide.

- Requires proper calibration with buffer solutions before each use—follow your model's specific three-point calibration instructions

- Choose between enclosed probes (more sensitive) or exposed probes (more durable and easier to clean)

- Essential for commercial production and specialty formulations where exact pH measurements guarantee product safety

While the investment is higher than strips, a quality digital pH meter becomes invaluable when consistency and precision matter in your soap making journey.

Phenolphthalein Drops for Alkalinity Detection

Chemical simplicity makes phenolphthalein drops one of the most trusted tools in a soapmaker's quality control arsenal. This 1% solution in ethanol changes from colorless to pink between pH 8.2-9.8, instantly revealing excessive alkalinity in your soap.

When you apply these drops directly to your soap sample, a pink color indicates potentially unsafe levels of leftover lye. No color change suggests your soap is safe for use, though this isn't a definitive safety measurement. Many soapmakers prefer phenolphthalein drops because they are more economical than pH strips.

While commonly used for liquid or hot process soap, phenolphthalein requires careful handling as it's potentially carcinogenic. Always wear gloves and properly dispose of tested samples.

For most accurate results, test soap in slurry form and consider combining with other methods like pH strips during your several-week curing process.

Lather Quality Testing Equipment

While alkalinity testing focuses on soap safety, evaluating lather quality addresses the performance aspect that customers notice immediately.

You don't need expensive industrial equipment to assess your homemade soap's lathering capabilities. The hand rubbing technique offers reliable feedback when performed systematically under controlled water conditions.

For more consistent results, consider:

- Maintaining identical water temperature and hardness for all tests by using distilled water heated to a specific temperature

- Creating a simple foam chamber using a clear container to visually compare lather height and stability between batches

- Keeping detailed records of lather characteristics, including formation speed, bubble size, and how long it persists

Temperature and soap moisture levels greatly impact results, so standardize your testing environment for meaningful comparisons. Professional manufacturers use specialized Soap Foaming Test Equipment to analyze these exact same qualities at industrial scale.

Hardness Testing Tools for Soap Bars

Testing your soap's hardness reveals essential insights about its durability and shelf life that directly impact customer satisfaction.

You'll need specific tools to measure this important attribute accurately.

Fruit sclerometers like the GY-3 model are popular options, capable of measuring hardness up to 24 kg/cm² with different probe fixtures (11mm and 8mm).

These devices work by pushing a probe into your soap until reaching a set depth.

For more advanced testing, consider texture analyzers like the TA.XT Plus or specialized soap hardness testers. Professional testing often employs a 2 mm diameter probe to accurately measure hardness, brittleness, and internal consistency of soap bars.

Some artisans even use soil penetrometers as affordable alternatives.

Remember that soap age, ingredients, production methods, and environmental conditions all affect your results.

Use this data to adjust formulations, guarantee quality control, and tailor your products to meet customer preferences.

Fragrance and Essential Oil Compatibility Testers

Selecting the right fragrance and essential oil testers represents a critical step in creating high-quality homemade soaps that maintain their scent profiles throughout their lifecycle.

When evaluating fragrances, you'll need cotton swabs, disposal cups, and small soap mold segments to test multiple options simultaneously without wasting materials.

To guarantee compatibility with your cold process soap, never exceed 5% fragrance concentration and always purchase from reputable suppliers who provide detailed safety information.

For essential oil blends, allow them to mingle for at least 5 minutes before evaluation, and wait 4-6 weeks post-curing for accurate performance assessments.

Consider testing your essential oils with complementary natural ingredients like cocoa butter and bananas for unique aromatic combinations in your soap formulations.

- Use cotton swabs in jars to test essential oil blend combinations before committing to a full batch

- Monitor temperature with a thermometer to prevent acceleration when testing fragrance reactions

- Add stabilizing ingredients like clay to help maintain essential oil scent longevity

Frequently Asked Questions

Can Homemade Soap Be Tested for Shelf Life?

Yes, you can test homemade soap's shelf life by monitoring for rancid odors, mold growth, texture changes, and discoloration over time. Store samples in different conditions to evaluate durability and longevity.

How Do You Test Soap for Skin Sensitivity?

You can test soap for skin sensitivity by conducting a patch test on your inner wrist or elbow for 24-48 hours. Watch for redness, itching, or irritation. Always avoid known irritants like SLS or fragrances.

Are There Tools to Measure Soap's Moisturizing Properties?

Yes, you can measure soap's moisturizing properties using glycerin content analyzers, moisture analyzers like IR-3000, pH meters, and Total Fatty Matter (TFM) tests. These tools help quantify components that affect how moisturizing your soap is.

Can Soap Quality Be Affected by Water Mineral Content?

Yes, water mineral content greatly affects your soap quality. Hard water's calcium and magnesium can create soap scum, reduce lather, and cause white film. You'll get better results using purified or filtered water.

What Equipment Tests Soap's Environmental Impact and Biodegradability?

You'll need biodegradability testing equipment like simulation chambers, pH meters, and respirometry tests. Don't forget automated systems that monitor decomposition rates and environmental impact analysis tools that assess aquatic ecosystem effects.

In Summary

You'll find these seven testing tools essential for your soapmaking journey. From pH strips to hardness testers, they'll help you create safe, effective products every time. Don't underestimate the importance of proper testing—it's what separates amateur efforts from professional-quality soaps. Invest in these tools, follow the testing protocols, and you'll consistently create soaps that you're proud to use and share.

Leave a Reply