Weather greatly affects your cold process soap making. Temperature influences saponification rates—ideal range is 120-130°F for oils and lye, while ambient temperatures between 70-90°F work best. High humidity extends curing times and may cause glycerin sweat, while low humidity speeds water evaporation. Seasonal changes require adjustments to your process, from cooling solutions in summer to increased insulation in winter. The right techniques guarantee successful batches throughout the year, no matter what Mother Nature throws your way.

Temperature Thresholds: How Hot and Cold Affect Saponification

When you understand how temperature affects the saponification process, you'll gain greater control over your cold process soap making.

The ideal range for combining oils and lye typically falls between 120-130°F (49-54°C), ensuring proper melting and uniform mixture.

Higher temperatures accelerate saponification, reducing curing time and preventing soda ash formation.

However, you'll notice faster tracing and quicker hardening, which might limit design flexibility and risk soap volcanoes if the mixture overheats.

Conversely, cooler temperatures slow saponification and can prevent gel phase—desirable for certain recipes.

You'll find lower temperatures essential when working with heat-sensitive ingredients like milk or fragile fragrance oils.

This slower process preserves intricate designs by giving you more working time before the soap sets.

Maintaining temperatures of both the lye and oils within 10 degrees of each other helps achieve optimal saponification and prevents potential issues like false trace.

The Gel Phase: Weather's Role in Achieving Perfect Texture

When making cold process soap during hot weather, you'll need strategies to control environmental heat that can trigger an unwanted gel phase or excessive overheating.

You can manage temperature by placing molds in refrigerators, using cooling racks, or working in air-conditioned spaces when outdoor temperatures soar. Gel phase can cause temperatures to reach up to 180°F internally, potentially affecting delicate additives in your soap formulation.

Humidity levels, while not directly affecting gel phase, will influence your soap's drying time and final texture, requiring adjustments to your curing environment and timeline.

Controlling Environmental Heat

The gel phase represents a critical juncture in cold process soap making, heavily influenced by environmental temperature conditions. You'll need to carefully manage heat to achieve your desired soap appearance and texture.

| Temperature Condition | Effect on Soap | Recommended Action |

|---|---|---|

| Hot weather (85°F+) | Natural gel phase induction | Minimal insulation needed |

| Moderate weather (65-85°F) | Partial gel possible | Use towel insulation if gel desired |

| Cold weather (below 65°F) | Gel phase difficult | Use additional insulation or heat source |

For vibrant colors, you'll want to encourage gel phase through insulation or warm placement. If overheating occurs, remove insulation immediately or use cooling methods like refrigeration. Remember that weather conditions directly impact your soap—summer heat naturally facilitates gel phase while winter requires additional warmth. In extremely hot environments, you may need to refrigerate soap immediately after pouring to prevent developing aesthetic issues like "alien brains" from excessive heat.

Humidity's Textural Effects

During the gel phase, high humidity can intensify heating issues, sometimes leading to unwanted textures like "alien brain" or glycerin rivers.

While this phase enhances color vibrancy, excessive heat from humid conditions may create cracks or surface irregularities.

To manage humidity's effects, store your soaps in well-ventilated areas with consistent environmental conditions. Proper ventilation helps prevent soap sweating, which is particularly problematic in humid environments.

Consider using dehumidifiers in particularly damp climates.

You'll also want to adjust your insulation techniques based on humidity levels—providing more cooling in humid conditions and more insulation in drier environments to achieve that perfect, uniform texture.

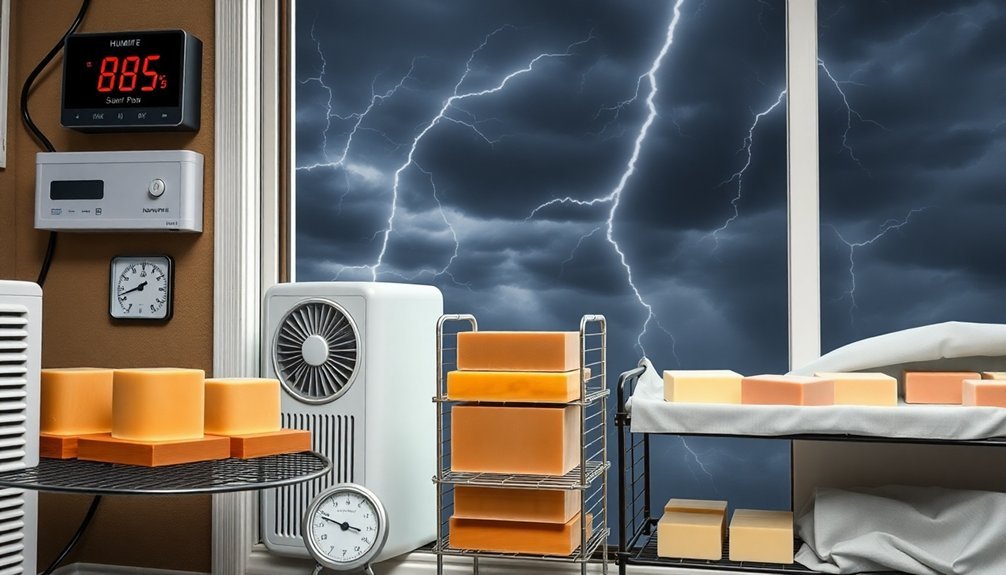

Humidity Hurdles: Managing Moisture During Soap Making

Crafting perfect cold process soap becomes considerably more challenging as humidity levels rise in your soap-making environment. High humidity slows water evaporation, extending unmolding and curing times while potentially causing glycerin sweat on your bars.

To overcome these hurdles, you'll need strategic interventions. Use a dehumidifier or guarantee proper ventilation in your work area. Additionally, maintaining oils and lye solution at body temperature can help you achieve proper saponification despite humid conditions.

Consider water discounting techniques to help your soap harden faster despite the moisture-heavy air. Adding sodium lactate can facilitate easier unmolding when humidity threatens to keep your soap soft.

For ingredients, be cautious with honey, sugar, and other humidity-sensitive additives that might exacerbate moisture issues.

Once your soap is made, store it in a cool, dry area to prevent post-production moisture problems that could compromise your carefully crafted bars.

Seasonal Soap Making: Adapting Your Process Year-Round

Successful soap makers understand that each season brings unique challenges and opportunities to the cold process method.

Temperature variations greatly impact saponification—spring and fall offer ideal moderate conditions, while summer heat can trigger unwanted gel phases requiring cooled lye solutions.

Winter's chill slows hardening but doesn't extend overall curing time.

Your ingredient selection should evolve with the seasons: honey works better in winter when scorching risks decrease; spring calls for fresh herbs and floral scents; summer benefits from invigorating citrus oils; and fall welcomes warm spices like cinnamon.

Color palettes can reflect seasonal themes too—festive reds and greens for winter, pastels for spring, vibrant hues for summer, and earthy tones for autumn.

With proper temperature monitoring and seasonal adjustments, you'll create perfect soap year-round.

Always prioritize safety by wearing appropriate protective gear when handling lye, regardless of the season you're making soap in.

Insulation Techniques for Different Climate Conditions

Your soap insulation methods should adapt to your local climate, with hot weather requiring minimal coverage and cold environments demanding extra layers.

You'll need to monitor temperatures closely in summer to prevent overheating, while winter soap making might benefit from heating pads or Styrofoam containers.

These seasonal adjustments guarantee ideal gel phase development regardless of whether you're making soap during December's chill or July's heat. Achieving the proper gel phase temperature of up to 180°F enhances the visual qualities of your soap, creating a more translucent and vibrant finished product.

Climate-Specific Insulation Methods

When making cold process soap in different climates, adapting your insulation techniques becomes essential for successful saponification.

In cold environments, apply additional warmth using heating pads under molds for 30-60 minutes, then wrap with blankets or towels. Styrofoam coolers and cardboard coverings help maintain temperatures above 70°F.

For warm climates, you'll need less insulation—sometimes none at all. Monitor soap temperatures carefully to prevent "Alien Brain" texture issues.

Consider smaller cavity molds that retain less heat and avoid heat-accelerating fragrances. Spicy fragrance oils can dramatically increase temperature during saponification, requiring special monitoring.

Your recipe ingredients also impact insulation needs. Milk soaps and high-sugar formulations require cooler conditions to prevent browning.

Loaf molds work best in colder regions, while transparent lids allow you to watch for overheating signs like wrinkling or separation.

Seasonal Adjustment Strategies

Adapting your soap making approach to match the shifting seasons requires strategic planning beyond basic insulation techniques.

In summer, start with cooler oil and lye temperatures (115-120°F) to compensate for ambient heat, while winter batches benefit from warmer starting temperatures (125-130°F) to encourage proper saponification.

Adjust your recipe seasonally by increasing hard oils in summer to maintain firmness when coconut and palm oils soften above 76°F.

For winter, incorporate extra moisturizing butters like shea and mango to combat dry skin concerns. Pre-temper these butters in any season to prevent graininess. Aim for a proper gel phase during curing to enhance color vibrancy and achieve a more professional finish.

Your fragrance choices should reflect seasonal preferences—lighter floral scents for spring/summer and richer, spicy notes for fall/winter.

These adjustments guarantee consistent quality despite weather fluctuations throughout the year.

The Science of Curing: Weather Variables That Matter

While often overlooked, weather conditions play an essential role in determining the success of your cold process soap. Temperature directly influences saponification speed—with ideal ranges between 120-130°F for lye water and oils ensuring effective chemical reactions.

Humidity greatly affects curing time. High moisture levels can double your wait before unmolding and may cause unsightly glycerin sweat on finished bars. Using sodium lactate or water discounting can help counteract these effects.

Your insulation choices should vary seasonally. In winter, insulating helps promote gel phase for brighter colors and reduced soda ash. However, during summer heat, you'll want to avoid over-insulation with milk-based recipes. Cold air temperatures can slow down saponification, making your soap take longer to reach trace and potentially affecting the final product quality.

Remember that environmental consistency matters—fluctuating conditions can lead to uneven curing, affecting your soap's final texture and quality.

Color and Fragrance Stability in Changing Weather

Weather conditions that affect curing also greatly impact color stability and fragrance retention in your cold process soap. Temperature fluctuations can either enhance or diminish your soap's visual appeal and scent performance. Maintaining temperatures between 90°F to 110°F during the soap making process ensures optimal color development and scent retention in your final product.

| Weather Factor | Color Impact | Fragrance Impact |

|---|---|---|

| High Temperature | Promotes gel phase for vibrant colors | Accelerates fragrance dissipation |

| High Humidity | May cause soda ash formation | Extends curing time, preserving scent |

| Cold Environment | Slows color development | Better retention of delicate scents |

Insulating your soap during cold weather helps maintain color vibrancy by encouraging gel phase. However, be cautious with fragrance oils that naturally heat soap, especially in warm conditions. For best results, store your curing soaps away from direct sunlight and in stable temperatures to preserve both color integrity and scent longevity.

Troubleshooting Weather-Related Soap Making Issues

When environmental conditions shift unexpectedly, your cold process soap can develop various issues that affect its quality and appearance. Recognizing symptoms quickly allows you to take corrective action before permanent damage occurs.

- For overheating soap (wrinkly texture, rising from mold), immediately remove insulation and place in the freezer to halt the process.

- Combat false trace in cold environments by preheating solid oils or extending your mixing time.

- In high humidity, increase air circulation around curing soaps and extend curing time.

- Maintain temperatures between 30-50°C for both oils and lye to guarantee proper emulsification.

- Use insulation strategically—it promotes gel phase for vibrant colors but can cause problems in already warm environments.

Monitor your workspace temperature and humidity consistently throughout the soap-making process to anticipate potential issues before they arise. Remember that cold process soaps require a 4-6 week curing period, which can be affected by environmental conditions.

Equipment Adjustments for Extreme Weather Conditions

Adapting your soap making equipment for extreme weather conditions can mean the difference between success and failure in your creations. Monitor temperatures closely with reliable thermometers, maintaining lye and oils between 120-130°F for ideal results. Consider using a gelling box for improved heat retention when temperatures drop significantly.

| Cold Weather Solutions | Hot Weather Adaptations |

|---|---|

| Increase mold insulation with towels | Use cooling devices like fridges |

| Choose oils with lower melting points | Select heat-resistant equipment |

| Confirm room temperature stays 70-80°F | Improve ventilation systems |

| Add extra heat sources when needed | Reduce insulation to prevent overheating |

Don't forget your safety equipment—respirators and protective gear are essential regardless of weather. For seasonal adjustments, reduce insulation during summer months and increase it during winter. Store your materials in stable environments to maintain quality and consistency year-round.

Creating Your Ideal Soap Making Environment

Establishing the perfect environment for soap making requires attention to both temperature control and safety considerations. Your workspace should be cool and dry with good airflow to guarantee consistent results in both process and curing.

- Maintain oil and lye temperatures between 120-130°F, or use cooler 90-110°F ranges for delicate designs.

- Keep lye and oil temperatures within 10°F of each other for predictable saponification.

- Position your workstation near an open window for proper ventilation when handling lye.

- Use a temperature gun to monitor ingredients accurately throughout the process.

- Create a climate-controlled area if possible to minimize seasonal variations that affect trace time and gel phase.

Always wear appropriate protective gear when handling lye to prevent potential injuries from its corrosive nature.

Remember that room temperature greatly impacts your soap's development, particularly during the vital gel phase.

Frequently Asked Questions

Can Weather Affect Essential Oil Performance in Soap Recipes?

Weather can indirectly affect your essential oils in soap. While it doesn't change their properties, hot weather accelerates evaporation during curing, and cold weather helps preserve scents longer by reducing volatility.

Does Altitude Impact Soap Making and Curing Time?

Yes, altitude impacts your soap making and curing time. You'll face faster saponification due to lower pressure, drier air causing static electricity, and potentially different curing rates that require monitoring and adjustments to your recipes.

How Does Barometric Pressure Influence Trace Development?

Barometric pressure's influence on trace development is minimal. You'll notice more significant effects from temperature and humidity. Recipe composition and mixing techniques will impact your soap's trace development far more than atmospheric pressure changes.

Are Specific Colorants More Weather-Sensitive Than Others?

Yes, natural colorants are most weather-sensitive, followed by micas and oxides. You'll notice ultramarines are more stable, while titanium dioxide remains consistent. Humidity and temperature fluctuations will affect your colorants' vibrancy differently.

Should Recipe Water Discounts Change Based on Seasonal Humidity?

Yes, you'll need to adjust your water discounts seasonally. Use less water in humid months to prevent soda ash and soft spots. Increase water during dry winters to avoid brittle soap. Monitor humidity regularly for best results.

In Summary

You've now seen how weather affects every aspect of cold process soap making, from saponification to curing. By monitoring temperatures, adjusting insulation, and adapting your techniques seasonally, you'll create consistent, beautiful soaps regardless of climate challenges. Don't let unpredictable weather discourage you! With these strategies, you're well-equipped to maintain quality control and achieve professional results in any season. Your soap making journey won't be at the mercy of Mother Nature anymore.

Leave a Reply