For traditional soap stirring methods, you'll want to maintain temperatures between 100°F-120°F for ideal results. Keep your lye solution and oils within 10°F of each other to guarantee proper saponification. Hard oils like cocoa butter and coconut oil need thorough melting (76°F-93°F), while liquid oils work best at 100°F-110°F. Monitor temperatures frequently with an infrared thermometer to prevent overheating. These temperature guidelines form the foundation for achieving the perfect soap texture and appearance.

The Science Behind Optimal Soap Base Temperatures

While many crafters focus on ingredients and designs, temperature control actually forms the foundation of successful soap making. The ideal range typically falls between 90°F and 130°F, with specific techniques sometimes requiring up to 160°F.

Your success depends on thoroughly melting hard oils—cocoa butter at 93°F, shea at 84°F, and coconut at 76°F—to prevent false trace where your soap appears misleadingly thick.

Remember to keep your lye solution and oils within 10°F of each other when mixing for proper integration. Using a digital laser thermometer will provide the most accurate temperature readings for consistent results.

Higher temperatures accelerate saponification and enhance gel phase, intensifying natural colors. Conversely, cooler temperatures give you more working time for intricate swirls and designs.

The ambient room temperature also greatly impacts your process, especially when using alternative liquids like milk.

Essential Temperature Ranges for Different Oil Combinations

Because every oil behaves differently when heated, understanding the specific temperature requirements for various oil combinations is essential for successful soap making. You'll need to adjust your approach based on the oils in your recipe.

| Oil Type | Ideal Temperature Range |

|---|---|

| Liquid Oils | 100°F – 110°F |

| Hard Oils | 100°F – 122°F |

| Beeswax Blends | 140°F – 150°F |

| High Olive Oil | 100°F – 115°F |

| Tallow/Lard Based | 110°F – 120°F |

When working with primarily liquid oils like olive or sunflower, you can soap at lower temperatures (100°F). Hard oils like coconut and palm require warmer temperatures to prevent false trace. For recipes containing beeswax (melting point 149°F), you'll need to maintain higher temperatures throughout the process to keep the wax fully incorporated. Always ensure that your oils are completely melted and clear to avoid false trace issues in your final soap.

Monitoring and Adjusting Heat During the Saponification Process

Since temperature directly impacts the success of your soap, careful monitoring and adjustment throughout the saponification process is essential. Use infrared thermometers like EnnoLogic's eT650D for precise, non-contact readings while tracking temperatures in real-time.

Remember that saponification is exothermic—it generates heat. Keep temperatures between 100°F and 130°F to prevent issues like soap volcanos, which can occur above 122°F. Your room temperature also affects the reaction, so consider your environment when planning.

If your mixture overheats, employ cooling methods such as ice baths. For insufficient heat, pre-warm oils or lye solution before mixing. For many recipes with high liquid oils, exact temperature measurements are less critical than when working with hard fats.

Creating a temperature profile by recording readings at regular intervals helps you identify patterns and optimize your process for consistent, high-quality soap with proper texture and skin safety.

Cold vs. Hot Process Temperature Management Techniques

Understanding the stark contrast between cold and hot process methods is essential for successful soap making, as each requires specific temperature management techniques.

In cold process, you'll work at lower temperatures (room temperature to 120°F), using a digital thermometer for precision. This method offers greater design flexibility for creating intricate patterns and swirls. Combining lye solution with oils requires careful monitoring to ensure both components are around 100°F (38°C) before mixing.

Hot process operates at higher temperatures (50°C-100°C), using crockpots or double boilers to accelerate saponification. While you'll need additional equipment, your soap will be ready in 24-48 hours versus weeks for cold process.

When choosing between methods, consider that cold process yields smoother textures but requires patience during curing, while hot process creates rustic-textured soap that's ready faster and allows you to add heat-sensitive ingredients after cooking.

Temperature's Impact on Final Soap Texture and Appearance

While many soapmakers focus primarily on ingredients, temperature plays an equally crucial role in determining your final product's quality. Your soap's texture and appearance are directly influenced by how you manage heat throughout the process.

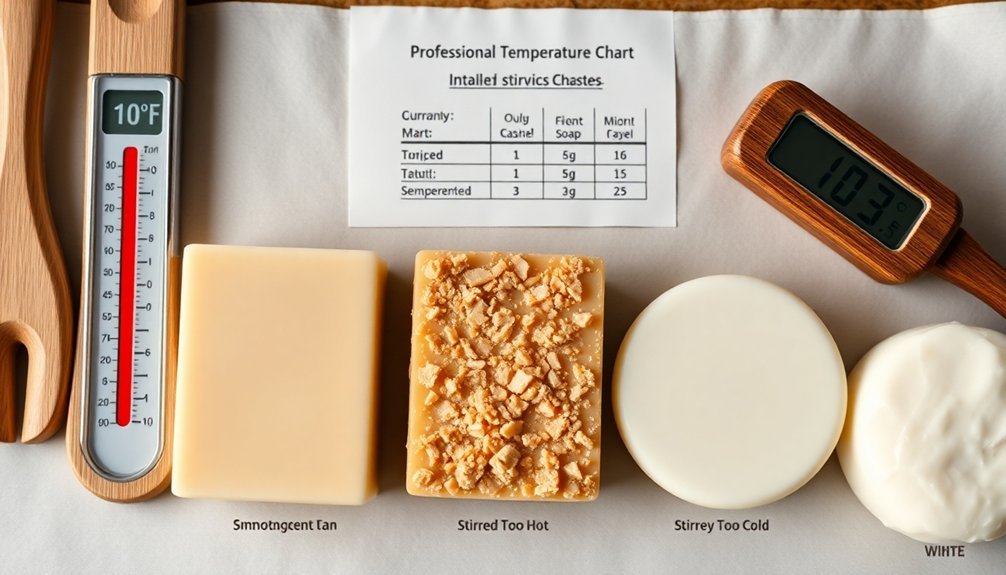

Gel phase, controlled by temperature, creates a smoother finish and enhances color vibrancy while reducing soda ash formation. When your soap gets too cold (below 85°F), you risk false trace and uneven saponification. Conversely, overheating produces brittle texture and irregular appearances like "alien brains." Some fragrance oils, especially spicy scents, can generate additional heat during saponification.

Your insulation choices—whether using heating pads or refrigeration—will determine whether you achieve full gel, partial gel, or no gel phase. This affects not only texture but also color intensity, with gelled soaps typically displaying more vibrant hues and a glossier finish than their ungelled counterparts.

Frequently Asked Questions

How Does Ice Quality Affect Stirring Temperature?

Ice quality affects your stirring temperature considerably. Clearer ice melts slower, maintaining colder temperatures longer. Larger pieces keep things cooler, while smaller ones melt faster, quickly cooling your mixture but diluting it more.

Why Are Stirred Cocktails Served in Chilled Glassware?

You'll want chilled glassware for stirred cocktails to prevent rapid warming, minimize further dilution, maintain the drink's carefully balanced temperature, and enhance presentation with attractive condensation on the glass surface.

Can Drink Temperature Affect Alcohol Potency Perception?

Yes, temperature does affect how potent you perceive alcohol to be. When drinks are colder, ethanol forms different molecular structures that can mask or enhance certain taste elements, changing your perception of the alcohol's strength.

How Does Stirring Speed Impact Final Drink Temperature?

Faster stirring speeds accelerate cooling by maximizing ice-liquid contact, helping you reach lower temperatures more quickly. You'll notice diminishing returns after about 30 seconds, regardless of how vigorously you stir your drink.

What Temperature Differences Exist Between Stirred vs. Built Cocktails?

Stirred cocktails reach -0.5°C to -7°C through active dilution, while built cocktails stay warmer initially then gradually cool. You'll notice built drinks evolve as ice melts, creating changing temperature and flavor profiles over time.

In Summary

You've now mastered the temperature fundamentals for successful soap making. Remember, your oils and lye solution should remain within their ideal ranges to achieve proper saponification. Whether you're working with cold or hot process methods, monitor carefully and make adjustments as needed. By controlling temperature throughout your soap making journey, you'll consistently create products with the texture and appearance you desire.

Leave a Reply