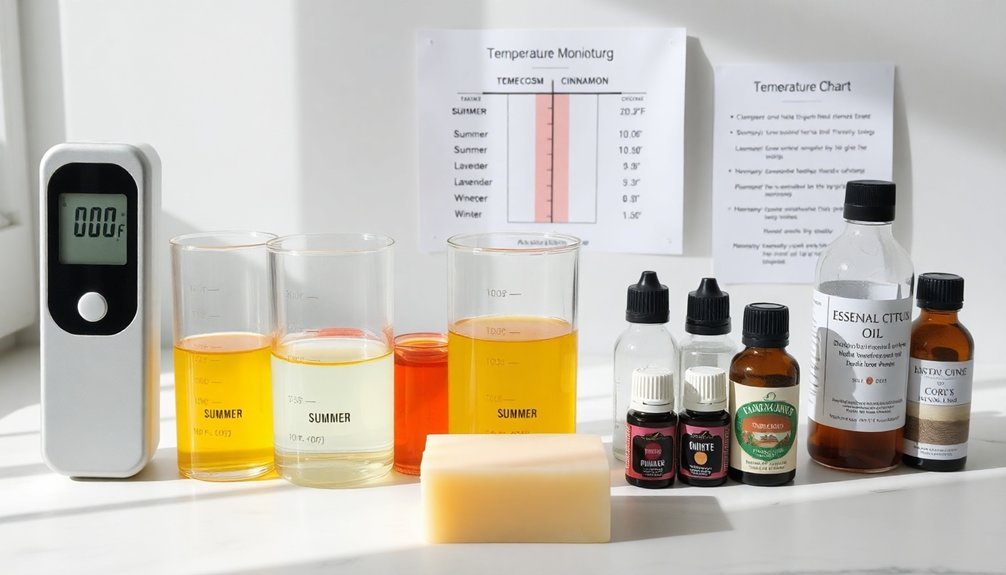

Successful seasonal soap-making requires adapting temperatures throughout the year. In winter, maintain oil and lye around 100°F and insulate molds. During summer, keep workspace below 120°F and use cooler lye solutions. For spring and fall, aim for 90-110°F with oils and lye within 10 degrees of each other. Always adjust for essential oil sensitivity: below 120°F in summer and monitor fragrance oils in winter. Control humidity levels year-round for ideal curing and quality outcomes.

5 Best Seasonal Soap-Making Temperature Guidelines For Success

While soap-making is a year-round craft, adjusting your temperature approach with the seasons can dramatically improve your results.

During colder months, keep your soap making temperatures between 90-110°F to guarantee hard oils fully melt and avoid false trace. The heat transfer method works exceptionally well in winter, using hot lye to naturally warm solid oils.

In summer, maintain temperatures around 100°F, keeping lye and oils within 10° of each other to control the saponification process. Never exceed 120°F, which can accelerate trace occurs too quickly and cause overheating issues like glycerin rivers or soap volcanoes.

Don't overlook seasonal humidity's impact on ideal soap quality. In humid conditions, cure your soaps in a dehumidified environment to prevent Dreaded Orange Spots and guarantee consistent results year-round.

Winter Soap-Making: Adjusting for Cooler Ambient Conditions

Because winter's chill poses unique challenges for soap makers, you'll need strategic temperature adjustments to achieve ideal results. Maintain oil and lye temperatures around 100°F (38°C) to prevent false trace in cold process soap making. Pre-warm your containers and use heating pads to maintain suitable temperatures throughout the process.

| Winter Challenge | Solution |

|---|---|

| False trace | Keep oils at 100°F |

| Soda ash formation | Control lye temperature (120-130°F) |

| Solidifying oils | Utilize heat transfer method |

| Slow saponification | Insulate molds with blankets |

The heat transfer method works particularly well in winter, as lye solution's heat helps melt solid oils. Remember to cool your lye solution adequately before combining with oils to prevent unwanted reactions while still leveraging its warmth to maintain workable temperatures.

Summer Heat Management: Preventing Acceleration and Overheating

As summer temperatures soar, you'll need to adapt your soap-making approach to prevent accelerated trace and overheating issues.

Keep your workspace temperatures below 120°F to guarantee proper saponification without rushing the process. Experienced soap makers recommend using cooler lye solutions (100-110°F) when combining with oils in hot weather.

- Work in air-conditioned spaces or during cooler morning hours to maintain stable temperatures

- Utilize the heat transfer method to let warm lye gently melt solid oils without excessive heating

- Monitor your soap mixture closely for unexpected trace acceleration during hot days

- Consider refrigerating your oils briefly before use to provide additional cooling

- Don't skip insulation during curing, as it helps prevent glycerin rivers despite the summer heat

Spring and Fall Temperature Balancing Acts for Perfect Trace

Spring and fall present ideal soap-making conditions where moderate ambient temperatures allow for greater flexibility in your process. Aim for soaping temperatures between 90°F and 110°F to achieve proper saponification without risking false trace.

Keep your lye temperatures and oil temperatures within 10 degrees of each other during these shifting seasons to guarantee even mixing. For cooler fall days, preheat oils and maintain your lye solution around body temperature to promote a smooth, perfect trace.

You'll find the heat transfer method particularly effective during spring and fall—the warmth from your lye solution helps melt oils naturally, creating a consistent mixture.

When working with hard oils, you may need slightly higher temperatures to keep your soap batter fluid and workable throughout the entire pouring process.

Essential Oil Temperature Sensitivity Across Seasons

Temperature management isn't just important for soap consistency—it's equally vital for preserving your essential oil fragrances throughout the year. Your seasonal soap making approach should adapt to protect volatile compounds from dissipating during the chemical reaction with lye.

- During summer months, embrace cooling temperatures below 120°F to prevent both overheating and essential oil evaporation.

- Citrus oils are particularly temperature-sensitive—keep your soap batter cooler to maintain their bright, zesty profile.

- In winter, monitor your fragrance oils carefully as cooler ambient conditions can create false trace when hard oils solidify.

- Temperature-sensitive fragrance oils perform better when incorporated at lower points, especially in cooler seasons.

- Consider how seasonal temperature fluctuations affect your workspace—adjust your process to maintain ideal conditions for fragrance retention.

Frequently Asked Questions

What Is the Best Temperature for Making Soap?

You'll want to keep your soap-making temperatures between 90°F to 110°F (32°C to 43°C) for both lye and oils. This guarantees proper saponification while preventing false trace during the process.

What Is the Optimum Temperature for Saponification?

For optimum saponification, you'll want to keep your soap mixture between 90°F and 110°F (32°C to 43°C). This temperature range prevents false trace and guarantees your oils and lye properly emulsify during the reaction.

What Thermometer Is Best for Soap Making?

You'll find digital laser thermometers best for soap making due to their accuracy and non-contact readings. Infrared models provide instant results, while probe thermometers are excellent for monitoring internal temperatures of oils and mixtures over time.

What Happens if Cold Process Soap Gets Too Hot?

If your cold process soap gets too hot, you'll risk alien brain formation, soap volcanoes, glycerin rivers, accelerated trace, soda ash development, and loss of fragrance notes due to essential oil volatility.

In Summary

As you adjust your soap-making temperatures with the seasons, you'll find your batches become more predictable and consistent. Remember, winter requires extra warmth, summer demands cooling strategies, and spring and fall need careful balancing. Trust your thermometer, but also develop your instincts. Over time, you'll naturally adapt to seasonal changes, creating beautiful soaps regardless of what's happening outside your window.

Leave a Reply