For successful soap making, maintain your lye solution and oils between 120-130°F, keeping them within 10°F of each other. Adjust temperatures based on oil types—liquid oils work well at 120-130°F while solid oils need around 130°F. Avoid false trace by ensuring oils are completely melted before mixing. Try the heat transfer method to simplify your process by adding hot lye to solid oils. These temperature controls will help you achieve smooth, defect-free soap every time.

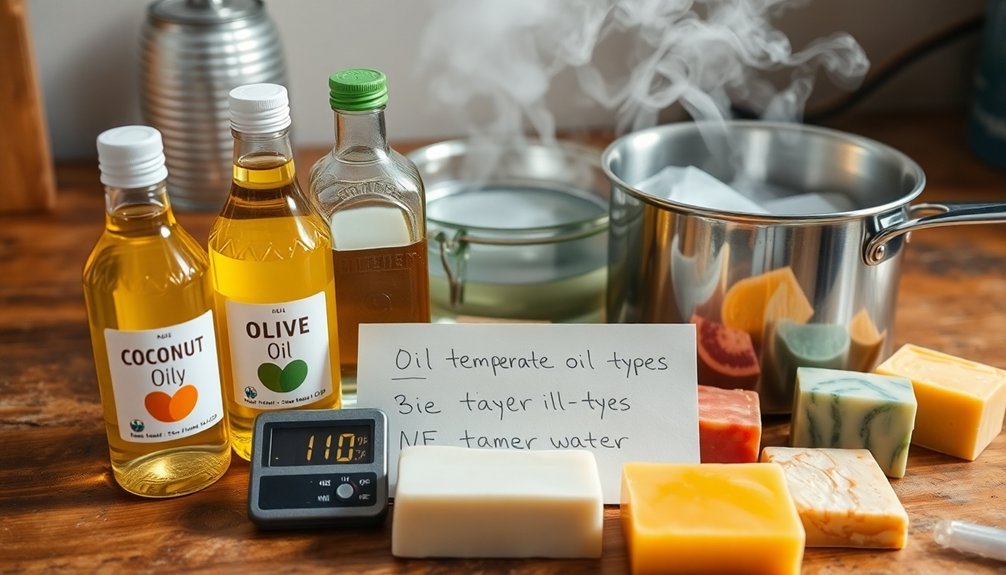

5 Essential Water Temperature Tips For Soap Making

When making soap, controlling your water temperature is essential for successful saponification. Your lye solution can reach temperatures up to 200°F during mixing, but should be cooled to 120-130°F before combining with oils. This temperature range guarantees proper chemical reactions without causing issues in your soap batter.

For both cold process soap making and hot process soap, maintain your lye solution and oils within 10 degrees of each other. This prevents problems like false trace, where soap batter thickens prematurely.

When working with hard oils or butters, confirm they're completely melted and your lye solution is at least body temperature.

Monitoring temperature throughout the process helps you achieve consistent trace and prevents common soap defects like soda ash or glycerin rivers in your finished products.

The Ideal Temperature Range for Cold Process Soap Making

Though many soapmakers develop their own unique techniques over time, the perfect temperature range for cold process soap making remains consistently between 120-130°F (49-54°C) for both your oils and lye solution. This temperature sweet spot guarantees peak saponification process while preventing complications.

| Temperature | Effect on Soap Making |

|---|---|

| Below 100°F | False trace may occur; oils solidify prematurely |

| 100-120°F | Acceptable but may slow trace occurs |

| 120-130°F | Ideal range for balanced saponification |

| Above 140°F | Can accelerate process too quickly |

Always keep your lye solution and oils within 10°F of each other to prevent issues during mixing. Remember that hard oils must be completely melted, while liquid oils integrate easily. Your lye solution naturally cools from about 200°F after mixing with water, so timing is essential.

How Oil Types Affect Your Water Temperature Requirements

Understanding how oil types affect your soap recipe is the next key factor in mastering water temperature control. Different oils demand specific temperature ranges for successful saponification.

Liquid oils like olive and sunflower remain fluid at room temperature, allowing you to work with water temperatures of 120-130°F.

However, solid oils and butters such as coconut oil and shea butter require higher water temperatures (around 130°F) to fully melt and incorporate into your mixture.

Keep your water temperature within 10 degrees of your oil temperature to promote proper emulsification and prevent separation.

When working with high coconut oil soap recipes, maintain water temperatures between 85-95°F to manage its quick saponification process.

If your water's too cool, you'll risk false trace with hard oils, as they may solidify prematurely before proper saponification occurs.

Preventing False Trace Through Proper Temperature Control

False trace, one of the most frustrating issues in soap making, occurs as your soap batter thickens prematurely, creating a deceptive illusion of proper trace. To prevent this, guarantee your oils are completely melted and maintained at 120-130°F before adding the lye solution.

When mixing lye with your oils, both components should be within 10 degrees of each other—ideally both in the 120-130°F range. Your lye solution should feel close to body temperature or slightly warmer. If it's too cold, solidified fats will harden upon contact; if too hot, saponification accelerates too quickly.

The recommended approach is simple: monitor temperatures carefully before bringing oils together with your lye solution. This temperature control guarantees a smooth soap mixture and prevents the grainy appearance of false trace, allowing the chemical reaction to progress correctly.

Mastering the Heat Transfer Method for Consistent Results

Three key advantages make the Heat Transfer Method a favorite among experienced soap makers. It simplifies your cold process workflow, reduces equipment needs, and guarantees ideal temperature control.

To use this technique, first weigh your soap making oils into a container, then add your hot lye solution (120-130°F) gradually while stirring until the solid oils melt completely.

This method works best when you're using soft or liquid oils combined with moderately hard oils. Always keep your lye temperatures and oil mixture within 10 degrees of each other to avoid false trace issues.

Pay close attention to the melting points in your recipe—if you're working with harder oils like coconut, confirm your lye to water ratio creates enough heat to melt solid oils effectively without requiring additional heating sources.

Frequently Asked Questions

What Is the Best Temperature for Soap Making?

You'll want to keep your oils and lye solution between 120-130°F (49-54°C) for standard recipes. If you're using lots of coconut oil, aim lower (85-95°F) to prevent fast trace and potential overheating issues.

What Temperature to Add Essential Oils to Soap?

Add essential oils to your soap between 120-130°F (49-54°C) for ideal scent distribution. You'll want to avoid temperatures above 160°F where oils degrade, and below 90°F where they won't incorporate properly.

What Is the Optimum Temperature for Saponification?

You'll achieve ideal saponification at 120-130°F (49-54°C). Keep your oils and lye solution within 10 degrees of each other to guarantee proper chemical reactions while preventing false trace or overheating issues.

What Thermometer Is Best for Soap Making?

You'll want either a digital infrared thermometer for quick, contactless readings or a probe thermometer for continuous monitoring. Choose one with a 0-200°F range and fast response time for accurate saponification temperatures.

In Summary

You'll find that mastering water temperature transforms your soap making from unpredictable to reliable. By keeping your water between 100-110°F for cold process soaps, adjusting for different oil types, and preventing false trace through proper temperature management, you're setting yourself up for success. Try the heat transfer method when you're ready to advance your skills. Temperature control isn't just a suggestion—it's essential for beautiful, consistent results.

Leave a Reply