Melting your soap oils at 120-130°F guarantees complete liquefaction of all fats, preventing cloudiness and false trace issues. At this temperature range, molecules achieve ideal mobility for efficient saponification, creating smoother emulsification and more vibrant colors in your final bars. You'll also avoid separation problems by keeping your lye solution within 10 degrees of your oil temperature. This sweet spot transforms your ingredients into the perfect canvas for beautiful, professional-quality soap every time.

The Science Behind the Ideal Soap Oil Temperature Range

While many soapmaking variables can be adjusted according to preference, the temperature at which you melt your oils isn't one of them. The 120-130°F range isn't arbitrary—it's chemistry at work. At this temperature, all solid fats fully liquefy, preventing cloudiness and false trace issues during saponification.

This ideal range creates the perfect consistency for blending with your lye solution. You'll want to keep your lye and oils within 10 degrees of each other to maintain a stable reaction and prevent separation problems.

The correct temperature also supports proper gel phase development, enhancing color vibrancy in your finished soap.

When you heat oils to 120-130°F, you're ensuring efficient heat transfer during the cold process, helping the chemical reaction proceed smoothly without premature thickening.

How 120-130°F Affects Saponification Chemistry

At 120-130°F, your soap oils achieve ideal molecular mobility, allowing fatty acid chains to move freely and react efficiently with lye hydroxide ions.

This temperature range creates the perfect environment for saponification chemistry, where triglycerides break down and recombine with sodium or potassium to form soap molecules.

You'll notice smoother emulsification as the heat energizes molecules just enough to promote complete reaction without accelerating the process too quickly or leaving unreacted portions behind.

Optimal Fatty Acid Reaction

The chemistry behind successful soapmaking hinges on maintaining oils at precisely 120-130°F during the saponification process. This temperature range guarantees all fatty acids remain in their liquid state, preventing premature solidification that can lead to false trace and incomplete soap formation.

When your oils reach 120-130°F, they'll appear clear and entirely free of cloudiness—a visual confirmation that all fatty acids are properly melted and ready for complete saponification.

For best results, keep your lye solution within 10 degrees of your oil temperatures. This temperature alignment enhances the efficiency of the saponification process, allowing oils and lye to react more uniformly.

The result? A smoother, more homogeneous soap batter that transforms into high-quality bars with consistent texture and appearance throughout.

Temperature-Dependent Molecular Mobility

Maintaining oils between 120-130°F fundamentally transforms their molecular behavior during saponification. At this temperature soap-making sweet spot, fatty acid molecules gain ideal mobility, allowing them to interact efficiently with lye molecules.

| Temperature | Molecular Effect | Impact on Soap |

|---|---|---|

| Below 120°F | Limited mobility | False trace risk |

| 120-125°F | Enhanced mobility | Smooth reaction |

| 125-130°F | Ideal mobility | Complete saponification |

| 130-140°F | Accelerated reaction | Potential overheating |

| Above 140°F | Excessive mobility | Quality degradation |

When lye and oils meet at matching temperatures, their molecular interactions occur uniformly throughout the mixture. The 120-130°F range provides enough thermal energy to keep solid fats fully melted while controlling the exothermic reaction. You'll achieve consistent saponification as molecules move freely enough to react completely without excessive heat generation.

Preventing False Trace Through Proper Heating

When you heat your oils to 120-130°F, you're creating ideal conditions for proper emulsification, allowing the oils to fully combine with lye without premature thickening.

This temperature range prevents crystallization of solid fats, which can mimic trace without actually completing the chemical reaction.

You'll notice smoother blending with fewer lumps or cloudiness, ensuring your soap batter reaches true trace rather than a deceptive false one that could lead to separation or inconsistent results.

Temperature's Effect on Emulsification

Because proper temperature control directly affects emulsification success, you'll need to monitor your oils carefully during the melting process. When oils remain within the 120-130°F temperature range, you'll experience smoother emulsification and avoid the frustrating problem of false trace.

Temperature impacts your soap batter in several critical ways:

- Even distribution – Properly heated oils mix more thoroughly with lye solution, creating a stable emulsion.

- Prevention of solidification – Maintaining adequate warmth keeps fatty acids from reforming solid crystals that create graininess.

- Balanced reaction – Keeping lye and oils within 10 degrees of each other promotes proper chemical reactions.

- True trace recognition – Correct temperatures help you distinguish between genuine saponification and misleading false trace that only mimics thickening.

Avoiding Crystallization Problems

Proper heating of your oils stands as the primary defense against false trace, a frustrating phenomenon that can ruin an entire batch of soap. When melting soap oils to 120-130°F, you're ensuring all solid fats completely liquefy, which prevents crystallization during the saponification process.

Watch for visual cues—your oils should appear perfectly clear without any cloudiness. Cloudy oils indicate solidified fatty acids that haven't fully melted, which can trigger premature thickening that mimics true trace. This false trace leads to incomplete saponification and textural issues in your final product.

For best results, keep your lye solution and oil temperatures within 10 degrees of each other. This temperature harmony creates consistent soaping temperature conditions where ingredients blend smoothly, allowing you to recognize authentic trace and achieve properly saponified, high-quality soap.

Temperature's Impact on Soap Color and Texture

The relationship between oil temperature and soap aesthetics can't be overstated. When your soaping oils reach the ideal 120-130°F range, you're setting the foundation for beautiful, consistent results that will impress even seasoned crafters.

Properly melted oils deliver four key benefits:

- Prevents false trace – Fully liquefied fats guarantee your soap batter won't prematurely thicken and compromise texture.

- Promotes color uniformity – Clear, cloud-free oils create consistent coloration throughout your bars.

- Enhances gel phase helps – The right temperature in cold process soaping intensifies the gel phase, yielding vibrant, glossy soap.

- Eliminates glycerin rivers – Proper temperature management prevents those unattractive marbled streaks that can ruin your design.

Balancing Oil and Lye Temperatures for Perfect Trace

You'll want to keep your oil and lye solution within 5-10 degrees of each other, ideally both in the 120-130°F range, to achieve consistent trace formation.

Synchronized temperatures prevent false trace issues where the batter thickens prematurely rather than through proper saponification.

When temperatures are properly balanced, you can expect light trace within 5-10 minutes of mixing, giving you ample time to add colorants and fragrances before pouring.

Oil-Lye Temperature Synchronization

While many soapmakers focus on individual temperatures, achieving perfect trace depends heavily on synchronizing your oil and lye temperatures. Keep both components within 10 degrees of each other to promote even saponification and smooth blending.

The ideal approach to oil-lye temperature synchronization includes:

- Prepare your lye solution 1-3 hours before soaping to allow it to cool naturally to the 120-130°F range.

- Heat soap making oils until they're completely clear and free of cloudiness.

- Check that both components stay within the 120-130°F sweet spot where saponification occurs most efficiently.

- Adjust temperatures as needed—too-hot lye accelerates trace excessively, while too-cold lye won't properly melt oils.

This balanced approach prevents false trace, separation, and graininess while ensuring consistent results in your finished soap.

Trace Formation Timeframes

Once you've synchronized your oil and lye temperatures within the ideal 120-130°F range, predictable trace formation becomes possible.

Working in this temperature window gives you control over how quickly your soap batter thickens, allowing you to plan your design techniques accordingly.

At the higher end (closer to 130°F), your mixture will reach trace faster due to accelerated saponification. This can be advantageous when making simple soaps but challenging for intricate designs.

Conversely, maintaining temperatures at the lower end (around 120°F) extends your working time.

Hard vs. Soft Oils: Temperature Requirements Explained

Understanding the distinct temperature requirements for different soap oils is essential for successful soapmaking. When creating your soap, you'll need to properly heat both hard oils and soft oils to achieve proper saponification.

- Hard oils like shea butter and coconut oil must reach 120-130°F to fully melt and integrate with other ingredients, preventing cloudiness that indicates incomplete melting.

- Soft oils such as olive and sunflower remain liquid at room temperature but still need heating to the same 120-130°F range to avoid false trace.

- Maintaining this temperature range guarantees a homogeneous mixture, preventing oil separation during the soap-making process.

- For ideal saponification, keep your lye solution within 10 degrees of your oil temperature to enhance stability and improve your final soap quality.

Troubleshooting Common Temperature-Related Soap Defects

Temperature control can make or break your soap project, as even small deviations from the ideal 120-130°F range often lead to frustrating defects. When your oils are too cold, you'll risk false trace—a premature thickening that doesn't represent true saponification, leaving you with unusable soap.

| Temperature Issue | Resulting Defect | Prevention Strategy |

|---|---|---|

| Too Hot (>130°F) | Alien Brain/Soap Volcano | Keep oils under 130°F, avoid over-insulation |

| Too Cold (<120°F) | Soda Ash Formation | Maintain proper oil temperature, insulate properly |

| Temperature Imbalance | Partial Saponification | Keep lye and oils within 10°F of each other |

| Inconsistent Heating | False Trace | Thoroughly melt all oils, stir continuously |

Monitor both your lye solution and oils carefully. By maintaining consistent temperatures and addressing any temperature imbalance immediately, you'll greatly reduce these common defects, ensuring your soap turns out both beautiful and properly saponified.

The Role of Room Temperature in Your Soap Making Process

While you carefully monitor your oil temperatures, the ambient conditions of your workspace play an equally essential role in successful soap making. Room temperature directly impacts how your soap oils behave during the process, potentially creating challenges or advantages.

For ideal results, consider these room temperature factors:

- Maintain your workspace between 70-80°F to keep oils in their proper liquid state for easier blending with lye.

- Cold rooms can cause solid oils and butters to solidify prematurely, leading to false trace issues.

- Excessively warm environments may cause soap to overheat during saponification, resulting in soda ash or alien brain formation.

- Using primarily liquid oils reduces temperature-related complications, as they remain fluid at most room temperatures.

When your workspace temperature cooperates, your soap making process becomes more predictable and successful.

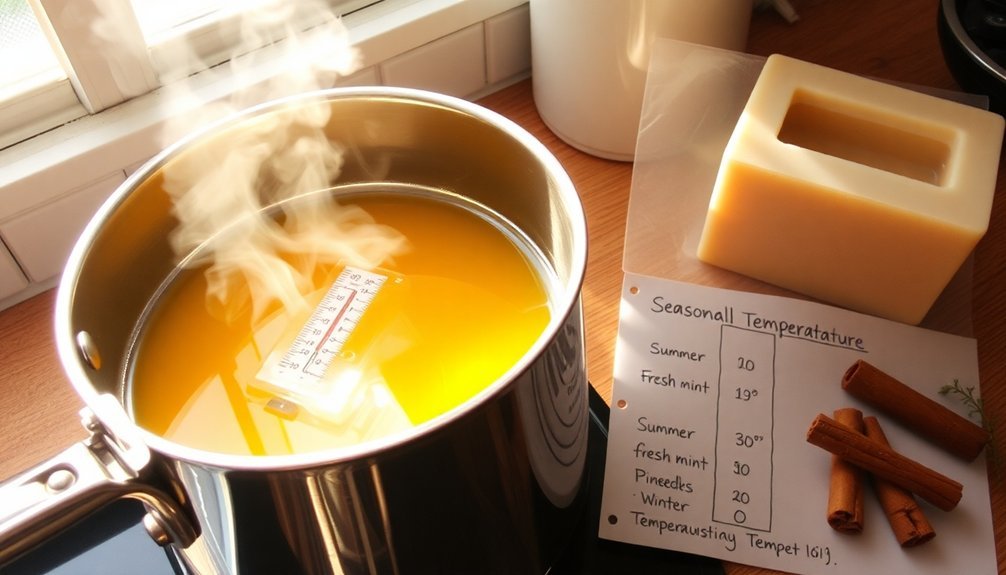

Seasonal Adjustments to Your Oil Melting Technique

Seasons dramatically alter how you'll approach the oil melting process, requiring thoughtful adjustments to maintain that critical 120-130°F range. Your melting point challenges vary throughout the year, with solid oils behaving differently as ambient conditions change.

| Season | Challenge | Solution | Temperature Strategy |

|---|---|---|---|

| Summer | Lower melting point | Monitor closely | Check every 2-3 minutes |

| Winter | Stubborn solidification | Double boiler method | Preheat equipment |

| Spring | Fluctuating humidity | Adjust cooling time | Use thermometer consistently |

| Fall | Cooling workspace | Insulate containers | Maintain 5° above melting point |

During high seasonal humidity, oils cool more slowly, potentially causing false trace issues. Conversely, in dry winter conditions, you'll need additional heating methods like microwave bursts to fully melt solid oils before combining with lye.

Essential Equipment for Maintaining Optimal Oil Temperature

Successful soap making hinges on your ability to precisely control oil temperatures, which requires investing in the right tools. When combining oils and lye at the ideal temperature of 120-130°F, precision becomes your greatest ally in achieving perfect saponification.

Your essential equipment toolkit should include:

- Reliable scale – Accurately weigh both oils and lye for proper chemical ratios

- Digital or infrared thermometer – Monitor temperatures throughout the process with pinpoint accuracy

- Heat-resistant containers – Use glass or stainless steel vessels that won't react with your ingredients

- Insulated containers – Maintain consistent temperature during the curing process

Don't underestimate the importance of quality equipment—proper temperature control directly impacts your soap's texture, appearance, and effectiveness.

Temperature Records: Documenting Your Soap Making Success

Three essential habits separate novice soap makers from masters—measuring precisely, controlling temperature consistently, and documenting meticulously. Your temperature records serve as a roadmap to repeatable success in soap making.

| Temperature Element | What to Document |

|---|---|

| Oil Temperature | 120-130°F ideal range, variations by oil type |

| Lye Solution | Temperature at mixing, cooling trend |

| Room Temperature | Ambient conditions affecting trace time |

| Combined Temperature | Reading when oils and lye meet |

Frequently Asked Questions

What Temperature to Melt Soap?

You'll want to melt your soap oils between 120-130°F. This range guarantees all oils fully melt without cloudiness, prevents false trace, and creates ideal conditions for the saponification process when combined with your lye solution.

What Is the Best Temperature for Saponification?

For ideal saponification, you'll want to maintain both your oils and lye solution between 120-130°F. Keep them within 10 degrees of each other to prevent false trace and guarantee a successful chemical reaction in your soap.

What Is the Best Temperature to Cure Soap?

The best temperature to cure your soap is room temperature (70-80°F). You'll want this consistent environment to allow proper hardening without issues like soda ash. Don't worry about speeding up the process with heat.

What Temperature to Add Essential Oils to Melt and Pour Soap?

Add essential oils to your melt and pour soap base at 120-130°F. You'll get the best scent distribution at this temperature range without degrading the oils' fragrance or therapeutic properties. Always use a thermometer.

In Summary

You'll find that melting your soap oils at 120-130°F creates the sweet spot for successful saponification. This temperature range prevents false trace, guarantees proper chemical reactions, and gives you better control over color and texture. By maintaining this ideal heat and balancing it with your lye temperature, you'll create consistent, high-quality soap every time. Remember to adjust for seasonal changes and keep records of your temperature success stories.

Leave a Reply