To control trace in soapmaking, use less concentrated lye solutions, maintain temperatures between 110-120°F, and select oils that saponify slowly (like liquid oils over solid ones). Hand stir instead of continuous stick blending, and add fragrance oils last, choosing varieties that don't accelerate reactions. Working with smaller batches gives you better control over the process. These techniques create the perfect balance for achieving beautiful soap designs while avoiding frustrating premature setting.

What Stops Trace From Setting Too Quickly?

When making soap, preventing your mixture from reaching trace too quickly allows you more time for creative designs and proper pouring.

To slow down saponification, use less concentrated lye solutions, as highly concentrated ones accelerate the process dramatically.

Keep your temperature under control—lower working temperatures reduce molecular activity that speeds up trace.

Consider your oil choices carefully; batches with higher percentages of liquid oils rather than solid oils will trace more slowly.

Be strategic with fragrance oils, as some are known to accelerate trace. Add them at the last possible moment and select varieties that don't cause rapid thickening.

Throughout the process, monitor your mixture constantly.

Gentle, intermittent stirring rather than continuous blending gives you better control over how quickly your soap reaches trace.

Understanding Trace in Soapmaking: Causes of Acceleration

Now that you know how to slow down trace, let's examine what actually causes it to accelerate in the first place. Certain fragrance oils can dramatically speed up the saponification process when they react with your lye solution.

The temperature of your ingredients is equally essential—higher heat increases molecular activity, resulting in faster trace.

Your lye solution's concentration matters too. A stronger solution accelerates trace and risks creating unsaponified pockets in your final soap.

Be vigilant about proper mixing techniques, as incomplete emulsification can lead to false trace, causing separation issues later.

For beginners, starting with smaller batches gives you better control over the process, helping you understand how different oils and temperatures affect trace development in your soapmaking journey.

The Science Behind Fragrance Oil Reactions

Although many soapmakers consider fragrance oils merely for scent, their chemical composition plays a crucial role in how quickly your soap reaches trace.

These oils contain compounds like vanillin that actively accelerate the saponification process, causing rapid emulsification when they interact with lye.

The concentration you use matters greatly—higher amounts of fragrance oils typically result in faster trace speed.

You'll notice this acceleration is more pronounced at elevated temperatures, as warmth enhances the chemical reaction between your oils and lye solution.

Don't overlook the importance of purity in your fragrance selections.

Lower-quality oils often contain unexpected additives that can dramatically alter trace behavior.

Temperature Management for Controlled Trace

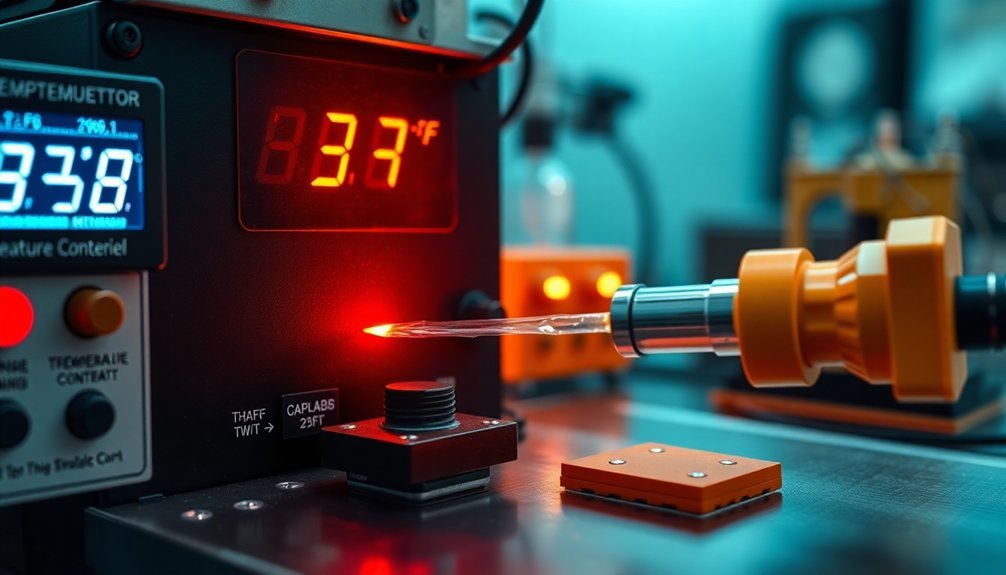

The temperature at which you combine your soap ingredients greatly impacts how quickly trace develops during the saponification process. Maintaining oils between 110-120°F creates ideal conditions for controlled trace, preventing the rapid saponification that occurs at higher temperatures.

You'll achieve better results by cooling your oils before adding lye solution. This simple step prevents white spots in your soap while extending your working time. A properly diluted lye solution also helps manage trace outcomes—too concentrated and you'll face premature thickening.

Temperature control becomes easier when you gradually heat and monitor both components. For beginners, start with smaller batches where you can maintain consistent temperatures more effectively. This approach reduces the risk of false trace and gives you time to work with your soap before it sets too quickly.

Selecting the Right Oils for Slower Trace

When crafting handmade soap, your choice of oils directly determines how quickly trace develops during the mixing process. Oils with higher saturated fats, like coconut and palm oil, create stable emulsions that extend your working time.

Combining these with lighter oils that have lower saponification values—such as sweet almond or sunflower oil—further slows trace development.

- Incorporate oils rich in unsaponifiable matter (like olive oil) to greatly delay trace and increase your hands-on time

- Work with oil temperatures between 110°F-120°F to prevent rapid saponification

- Add natural butters (shea or cocoa) to your soap mixture as additives that require longer emulsification

Lye Concentration and Its Impact on Trace Time

Controlling your lye concentration provides perhaps the most direct method for managing trace development in soapmaking. Higher concentrations dramatically accelerate saponification reactions, potentially reducing trace time to less than a minute in extreme cases.

This speed can lead to unmixed lye pockets and texture issues like graininess if you're not careful.

Your choice of oils interacts considerably with lye concentration. Recipes containing higher percentages of fatty acids will trace more quickly at any concentration level.

Temperature plays an equally important role—warmer temperatures stabilize light trace by promoting faster saponification, while cooler environments slow the process.

For consistent soap quality, you'll need to balance these factors carefully. By adjusting your lye concentration based on your oil selection and working temperature, you'll gain precision control over your trace time.

Mixing Techniques to Prevent Premature Trace

You'll find that hand mixing offers greater control over the trace development process, allowing you to monitor changes in consistency more carefully than mechanical methods.

When using a stick blender, pulse it in short bursts rather than running it continuously to prevent rapid acceleration of trace.

Alternating between hand stirring and controlled stick blending gives you the perfect balance of efficiency and precision for achieving the ideal trace timing.

Hand Mixing Benefits

Though many soapers rely heavily on stick blenders, hand mixing offers superior control over the saponification process, particularly when you're working with finicky formulations.

When you hand mix oils and lye solution, you'll naturally incorporate them at a gentler pace, allowing you to monitor trace development closely. This measured approach gives you time to adjust if you notice the consistency changing too rapidly.

- Keep your oils and lye solution within the 110-120°F temperature range to further slow the saponification process

- Take brief pauses during mixing to assess how trace is developing before continuing

- Gradually introduce oils while stirring at a steady, moderate pace for even distribution without accelerating trace

The deliberate nature of hand mixing creates a meditative soapmaking experience while providing technical advantages for challenging recipes.

Controlled Stick Blending

While hand mixing offers excellent control, many soapers prefer the efficiency of stick blenders for their soap batches.

To prevent premature trace, you'll need to master controlled stick blending techniques that balance speed with precision.

Use a slow and steady motion when stick blending, pulsing rather than continuous operation. This approach minimizes excess air incorporation that can accelerate trace development.

Maintain a consistent temperature between 110-120°F for both oils and lye to moderate saponification rates. When combining ingredients, add your lye solution gradually to prevent local heat build-up that triggers quick setting.

Watch the mixture's viscosity carefully as you blend. If you notice rapid thickening, immediately switch to hand stirring.

These deliberate approaches let you harness the stick blender's efficiency while maintaining control over how quickly your soap reaches trace.

Essential Additives That Delay Trace Setting

When crafting handmade soaps, several key additives can greatly slow down the saponification process, giving you more control over trace development.

Distilled water dilutes your lye solution, creating a more gradual reaction that's easier to manage. Glycerin's humectant properties not only moisturize your final product but also extend working time by retaining moisture throughout the process.

- Castor oil has a lower saponification value, creating a more stable emulsion that resists quick setting.

- Natural sweeteners like sugar and honey require additional dissolution time, effectively delaying trace.

- Clays such as kaolin increase viscosity gradually rather than suddenly, providing measured thickening.

Recognizing False Trace vs. True Saponification

To recognize false trace from true saponification, you'll need to observe your soap mixture's visual cues, including whether it appears grainy or smooth when stirred.

The temperature of your oils directly impacts trace development—keeping temperatures between 110-120°F helps prevent rapid acceleration and promotes proper emulsification.

Your stirring technique matters too; gentle, consistent stirring helps you distinguish between a temporary false thickening and the permanent chemical reaction of true saponification.

Visual Assessment Techniques

Since the success of your soap depends on proper saponification, you'll need to develop a keen eye for distinguishing between false trace and true saponification.

True trace shows consistent texture throughout the mixture without separation, while false trace may appear thick but lacks proper emulsification.

Careful visual assessment helps you identify uniform consistency, the hallmark of successful saponification.

Watch for white, flaky edges—they signal temperature control issues affecting your trace quality. Monitoring both oil and lye temperatures is essential as higher temperatures accelerate trace, potentially leading to improper mixing.

- Look for a smooth, pudding-like texture that holds its shape when drizzled onto the surface

- Check for uniform color without streaks or oil slicks on top

- Observe how the mixture moves—true trace has a consistent flow pattern throughout

Temperature Impact Factors

Temperature serves as the primary catalyst in determining whether you'll achieve true saponification or merely false trace in your soap making process. When your oils and lye solution aren't properly temperature-controlled, you risk creating unsaponified pockets that compromise your final product.

| Temperature Range | Trace Behavior | Monitoring Needs |

|---|---|---|

| Below 100°F | Slow, may separate | Frequent stirring |

| 110-120°F | Ideal consistency | Regular checking |

| 121-130°F | Accelerated trace | Constant vigilance |

| Above 130°F | Risk of false trace | Immediate intervention |

Keep your oils between 110-120°F to guarantee proper emulsification with your lye solution. If temperatures climb too high, you'll notice rapid thickening that might seem like proper trace but actually indicates incomplete saponification. By carefully monitoring temperature throughout the process, you'll avoid the disappointment of discovering lye pockets in your finished soap.

Stirring Method Distinctions

While temperature plays a crucial role in soap making, your stirring technique ultimately determines whether you'll achieve true saponification or be misled by false trace. Your stirring method directly impacts trace speed—vigorous mixing accelerates emulsification, while gentle stirring allows for more temperature control.

- Gentle circular motions promote even saponification without excessive air incorporation.

- Intermittent high-speed bursts help identify true trace through sustained thickness.

- Consistent stirring patterns prevent lye pockets that lead to grainy texture.

When your mixture maintains stability without separating, you've achieved true saponification. False trace occurs when the soap appears thick but hasn't fully emulsified, typically because of improper mixing or temperature fluctuations.

You'll recognize true trace by its pudding-like consistency that holds its shape when drizzled across the surface.

Batch Size Considerations for Better Control

When you're struggling to control trace in your soap making process, reducing your batch size can be a game-changer.

Starting with smaller batches of around 2 pounds (32 ounces) gives you better control over the saponification process while making troubleshooting considerably easier.

With smaller batches, you'll notice improved attention to detail as you can closely monitor for issues like false trace or incomplete mixing.

You'll also gain the confidence to experiment with different techniques and ingredients without risking large quantities of materials or creating excessive waste.

As you develop your skills, you can gradually increase your batch size, but don't rush this progression.

Mastering control in smaller batches builds the foundation you'll need when handling larger volumes, ensuring consistent results throughout your soap making journey.

Frequently Asked Questions

Why Does Traceroute Keep Timing Out?

Your traceroute times out when routers block ICMP packets, ignore your requests, face congestion, or use asymmetric routing. Firewalls and security configurations that don't respond to your probes also cause these timeouts.

Why Does Traceroute Not Complete?

Traceroute doesn't complete because routers may block ICMP/UDP packets, networks use load balancing across multiple paths, firewalls filter traffic, or high congestion causes packet loss. You'll often see timeouts displayed as asterisks in the output.

How Do I Make Traceroute Faster?

You can make traceroute faster by using the '-d' option to disable DNS resolution, specifying fewer hops with '-h', reducing timeout with '-w', and using ICMP packets with '-I' instead of UDP.

What Can Affect Tracert Results?

Your tracert results can be affected by network configurations blocking ICMP/UDP packets, asymmetric routing paths, high router traffic loads, security-configured routers that don't respond, and variable network paths due to QoS policies or routing changes.

In Summary

You'll achieve better control over trace setting by managing temperatures, choosing slow-moving oils, blending at minimal emulsion, and avoiding fragrance oils known to accelerate. Don't rush your stick blending—pulse briefly and stir by hand when possible. Remember that batch size affects heat distribution, so adjust your process accordingly. With these techniques, you'll confidently create soap designs that require extended working time.

Leave a Reply