When creating a safe soap making station, you'll need proper ventilation to remove fumes, complete PPE (goggles, gloves, protective clothing), an emergency response kit for accidents, secure chemical storage for lye, organized workspace zones to prevent cross-contamination, dedicated equipment solely for soap making, and visible safety documentation. Following these seven essential rules minimizes risks while handling caustic ingredients, protecting both you and your household from potential soap making hazards.

Proper Ventilation: Setting Up Your Air Quality System

Fumes from soap making, particularly when working with lye, can pose serious health risks if not properly managed. Your workspace requires proper ventilation to prevent the buildup of harmful vapors.

Set up your soap making station in a well-ventilated area with excellent air circulation. Install an exhaust fan near your work surface to draw away fumes generated during the lye mixing process.

Whenever possible, mix lye solutions outdoors or near open windows to minimize exposure to caustic vapors. For added protection, invest in quality air purifiers with HEPA filters to capture lingering particulates that might escape during the soap making process.

Regularly evaluate your ventilation system's effectiveness, especially when scaling up production. Your respiratory health depends on maintaining excellent air quality throughout the entire soap crafting journey.

Personal Protective Equipment: Essential Gear For Every Soap Maker

When handling caustic materials like lye, wearing appropriate personal protective equipment (PPE) isn't optional—it's absolutely essential for your safety.

Always wear safety goggles that properly seal around your eyes to prevent splashes during the soap-making process. If you wear glasses, choose over-the-glass models for complete protection.

Protective gloves are non-negotiable—nitrile gloves offer excellent protection against lye exposure and should fit well to prevent any skin contact.

Don't forget to cover the rest of your body with long sleeves, pants, and closed-toe shoes to minimize exposure risks.

Regularly inspect your personal protective equipment for damage and replace worn items immediately.

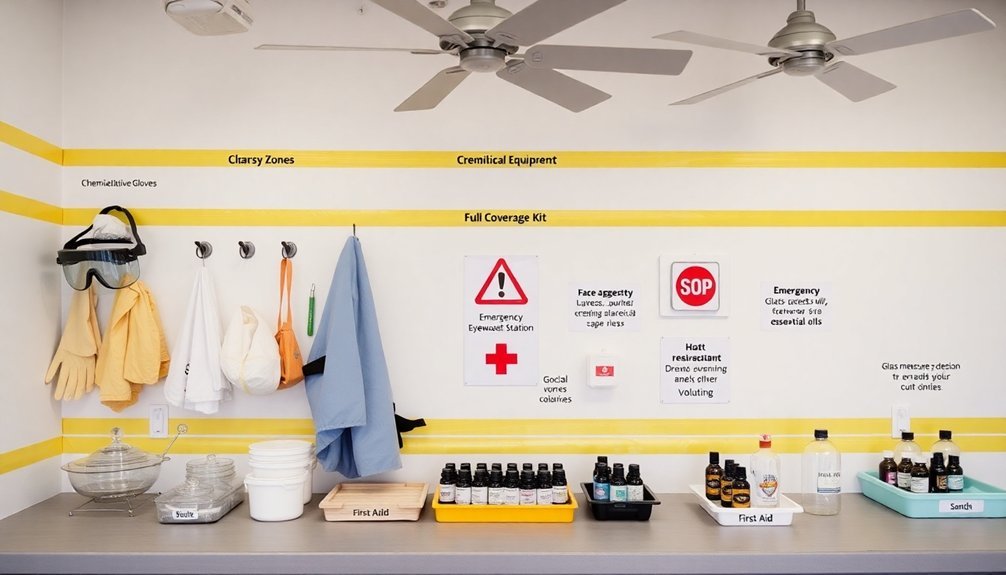

Emergency Response Kit: Preparing For Potential Accidents

Three critical components form the foundation of any soap maker's emergency response kit: a well-stocked first aid kit, emergency contact information, and appropriate spill containment supplies. Even with careful handling and safety glasses, accidents can happen during soap making.

| Emergency Item | Purpose |

|---|---|

| First aid kit | Treats minor burns and skin exposure |

| Emergency contacts | Guarantees quick access to poison control |

| Granular absorbent | Contains lye spills safely |

| Eyewash stations | Provides immediate eye flushing |

| Burn cream | Treats minor burns from raw soap |

Keep your emergency response supplies within arm's reach of your work area. Regularly check expiration dates on medical supplies and update contact information. Remember that quick access to these resources can mean the difference between a minor incident and a serious injury.

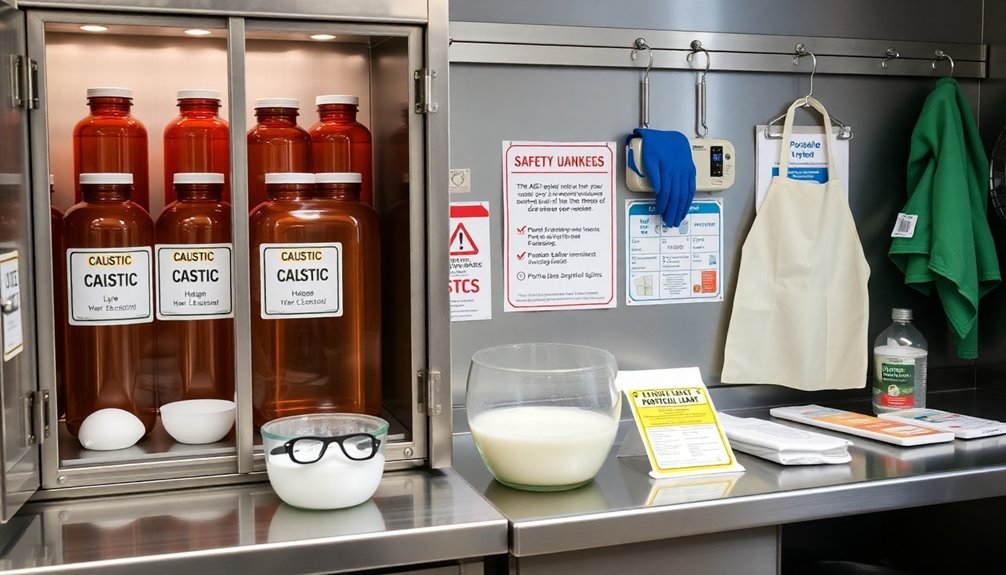

Chemical Storage: Safe Handling Of Lye And Other Ingredients

Proper chemical storage forms the backbone of soap making safety, extending beyond emergency preparedness to prevention strategies. Always store lye in tightly sealed, labeled containers away from moisture, clearly marked as 100% sodium hydroxide.

For safe handling, use heat-safe plastic containers (recycling #5) for lye water mixtures, never glass which can shatter from the extreme heat generated during mixing.

Keep all ingredients, including lye and essential oils, in designated child-proof cabinets inaccessible to children and pets.

Maintain a clean, organized soap making station with chemicals stored separately to prevent accidental mixing.

Regularly consult your Safety Data Sheets for all ingredients to understand proper handling procedures and potential hazards.

This organized approach to chemical storage creates a foundation for safe, worry-free soap making.

Workspace Organization: Reducing Cross-Contamination Risks

Organizing your soap making workspace into separate supply zones creates essential boundaries that prevent dangerous cross-contamination between chemicals and ingredients.

You'll find that implementing a color-coding equipment system—using red tools for lye, blue for oils, and green for additives—provides instant visual cues that reduce handling errors.

Dedicated ingredient storage cabinets or shelves, clearly labeled and arranged by purpose rather than alphabetically, guarantee you're never grabbing the wrong container during the critical mixing phases.

Separate Supply Zones

Creating distinct zones for your soapmaking materials forms the foundation of a safe workspace. Designate specific areas for lye, oils, fragrances, and additives to prevent cross-contamination that could compromise your finished products. Always store ingredients in clearly labeled containers to eliminate confusion during the soapmaking process.

| Zone Type | Color Code | Purpose | Maintenance |

|---|---|---|---|

| Lye Station | Red | Measuring and mixing caustics | Clean after each use |

| Oil Station | Blue | Weighing and blending base oils | Wipe down to prevent residue |

| Additives Area | Green | Measuring fragrances and botanicals | Sanitize between different scents |

| Curing Space | Yellow | Storing finished soap | Keep dust-free and ventilated |

Use color-coded utensils that match your supply zones for visual reinforcement. Remember to thoroughly clean and sanitize all surfaces between production phases to maintain ingredient integrity.

Color-Coding Equipment Systems

While separate storage zones establish your workspace foundation, a robust color-coding system for your equipment takes safety to the next level. Assign bright, distinct colors to different categories—use red for lye handling tools to immediately signal their hazardous nature and prevent dangerous mix-ups.

Designate specific colors for mixing containers, fragrance applicators, and molds for finished products. This visual organization system dramatically reduces cross-contamination risks between ingredients and equipment. For example, blue utensils might be exclusively for oils, while green ones handle colorants.

Maintain your color-coding through regular inspection and cleaning of all tools. Equally important is education—ensure everyone in your soap making space understands the system and its safety implications.

When properly implemented, color-coding becomes an intuitive safeguard against potential hazards.

Dedicated Ingredient Storage

Proper ingredient storage forms the cornerstone of a safe soap making operation, extending far beyond simple organization.

Your dedicated ingredient storage system should feature clearly labeled containers for all supplies, preventing dangerous mix-ups. Store caustic lye in a safe place—locked away from children and pets—and always handle it wearing protective gloves.

Designate specific shelves exclusively for soapmaking materials to eliminate cross-contamination risks with household items. Invest in airtight containers for powdered colorants and additives to protect them from moisture and prevent accidental spills.

Your organization strategy should include regular inventory checks to discard expired products.

This methodical approach to storage not only streamlines your workflow but also creates essential safety barriers between hazardous materials and vulnerable household members.

Equipment Designation: Dedicated Tools For Soap Production

You'll need to set aside specific utensils exclusively for your soap making projects to eliminate dangerous cross-contamination with food preparation tools.

Label all your dedicated equipment clearly with "Soap Making Only" tags, as lye residue can remain on surfaces even after thorough cleaning.

Your soap-exclusive toolkit should include stainless steel pots (never aluminum), heat-resistant rubber spatulas, and designated wooden spoons that won't be used for any other purpose.

Exclusive Soapmaking Utensils Required

Every successful soap maker maintains a dedicated set of tools exclusively for crafting soap. When working with lye solution, you'll need stainless steel or heat-safe plastic containers—never aluminum, which creates hazardous fumes when they interact.

Designate specific utensils solely for your soap making process to prevent dangerous cross-contamination.

For ideal soap making safety:

- Choose rubber or plastic stirring utensils that resist lye's caustic effects and protect your hands from potential chemical burns.

- Clearly label all containers and tools to prevent accidental household use.

- Store your dedicated equipment away from children and pets in a designated area.

- Avoid wooden utensils that can absorb materials and contaminate future batches.

Prevent Cross-Contamination Risk

Cross-contamination poses a serious threat to both your safety and product quality, which is why designating specific tools solely for soap making is non-negotiable. When you clearly label all soap making tools, you prevent accidental cross-use with food preparation areas.

| Equipment Type | Dedicated Soap Making Practice |

|---|---|

| Containers | Use marked plastic with recycling numbers |

| Utensils | Designate exclusively for soap making |

| Wooden Tools | Mark specifically to prevent lye absorption |

| Storage | Separate from household/food items |

| Maintenance | Regularly inspect for residues |

Always maintain your dedicated equipment by checking for chemical residues that could compromise future batches. Remember that wooden utensils can absorb lye or other chemicals, so they require special attention. By establishing a system of designated tools, you'll prevent contamination and guarantee consistent, safe soap production.

Label Everything Clearly

Proper labeling serves as your soap making workspace's first line of defense against accidents and contamination.

When mixing lye, a caustic chemical, you need to designate specific tools exclusively for soap production. Using permanent markers or label makers, create durable labels that withstand exposure to soap-making materials.

- PREVENT DISASTERS – Mark all containers with "NOT FOR FOOD USE" to eliminate any possibility of dangerous mix-ups

- BUILD CONFIDENCE – Labeled tools remove uncertainty when working with caustic ingredients

- PROTECT LOVED ONES – Clear safety warnings keep family members from inadvertently using contaminated equipment

- ENSURE PRECISION – Label your accurate digital scale to prevent cross-contamination that could affect food preparation or soap quality

Regularly check that labels remain legible and update them as needed to maintain your safe soap making environment.

Signage And Documentation: Safety Protocols At A Glance

Clear, visible documentation serves as your first line of defense in a soap making station. Display thorough signage outlining safety protocols including proper protective gear requirements, lye handling procedures, and emergency response for spills. Position these instructions at eye level where they're impossible to miss.

Mount Safety Data Sheets in accessible locations so you can quickly reference essential information about each ingredient. Implement color-coded labels on all containers to indicate hazard levels and designate specific tools to prevent cross-contamination between projects.

Maintain a prominently posted emergency contact list featuring poison control, medical services, and hazardous waste disposal resources. Review and update your documentation regularly to incorporate new safety insights and procedural improvements.

This systematic approach guarantees everyone can access crucial safety information instantly when seconds count.

Frequently Asked Questions

What Are the Safety Precautions for Soap Making?

You'll need protective gloves and goggles, mix lye into water (never reverse), maintain ventilation, use heat-safe plastic containers, keep workspace organized, and guarantee hazardous materials stay away from children and pets.

What Are the Legal Requirements for Selling Handmade Soap?

To sell handmade soap legally, you'll need proper FDA-compliant labeling, business registration, a sales tax permit, and careful record-keeping of ingredients. Check your local health department regulations for specific requirements in your area.

Do I Need FDA Approval to Sell Homemade Soap?

No, you don't need FDA approval to sell homemade soap if you're marketing it solely as soap. However, if you make cosmetic or drug claims about your soap, FDA regulations will apply to your product.

What Are the Requirements for Making Soap?

You'll need oils, lye, water, equipment (scale, thermometer, molds, blender), and proper safety gear. Knowledge of saponification chemistry, accurate measurements, and patience are essential for successful soapmaking. Always prioritize ventilation and protective equipment.

In Summary

Don't overlook these seven essential safety rules when setting up your soap making station. By prioritizing ventilation, wearing proper PPE, maintaining an emergency kit, storing chemicals correctly, organizing your workspace, using dedicated equipment, and posting clear signage, you'll create a safe environment for your creative process. Remember, proper safety measures aren't just precautions—they're the foundation of successful and enjoyable soap making.

Leave a Reply