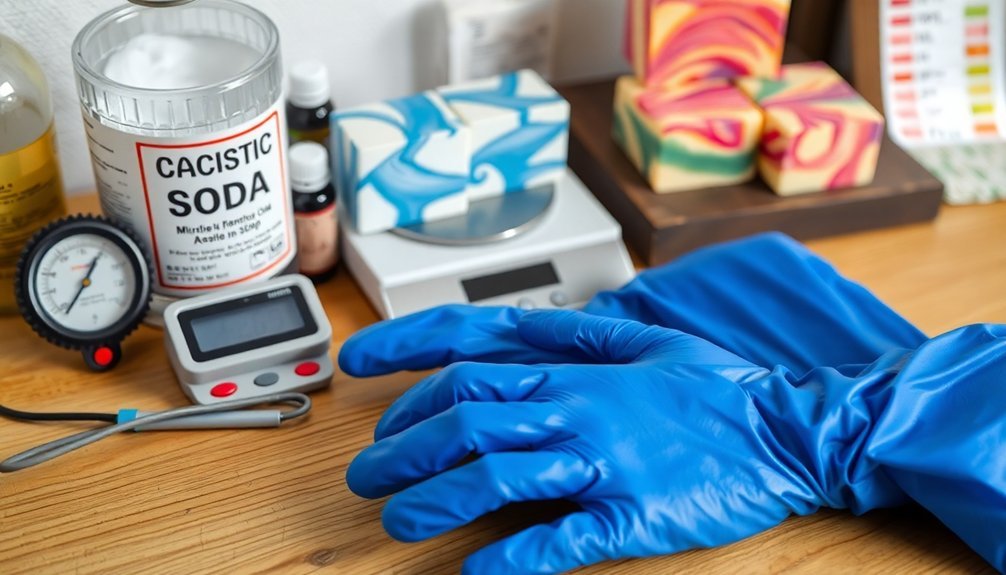

Soap making requires chemical-resistant gloves because lye can cause severe burns and permanent tissue damage on contact with skin. You'll need nitrile gloves specifically, as vinyl doesn't provide adequate protection against caustic substances. Properly fitting gloves prevent dangerous seepage around wrists and fingertips. Even if soap appears safe, it remains caustic during curing. Your hands' protection isn't just about safety—it's an essential investment in your long-term crafting journey.

The Dangers of Chemical Exposure in Soap Making

While soap making is a rewarding craft, it involves handling caustic substances that pose considerable health risks. The primary concern is sodium hydroxide (lye), which can cause severe burns and permanent tissue damage upon contact with your skin.

When you work with lye solution, even brief exposure can result in serious injuries if not immediately washed off. You must wear gloves that are specifically chemical-resistant to create an effective barrier between these harmful substances and your hands.

Beyond lye, the essential oils, fragrances, and colorants you use emit VOCs that may trigger respiratory issues and allergic reactions with repeated exposure.

Always protect your skin and don't forget safety glasses to shield your eyes from accidental splashes. These precautions considerably reduce both immediate and long-term health risks.

Types of Chemical-Resistant Gloves for Different Soap Ingredients

Because different soap ingredients require specific protection levels, selecting the right gloves becomes essential for your safety.

When working with sodium hydroxide (lye), choose nitrile gloves—they're specifically designed to resist this caustic chemical and prevent dangerous skin exposure. Soap makers should never substitute vinyl gloves when handling lye, as they don't provide adequate chemical resistance.

For more abrasive soap making tasks, consider black nitrile gloves, which offer enhanced durability thanks to their thicker construction.

While Marold gloves work for non-harmful cleaning, they're insufficient for lye-based processes.

At approximately two cents per glove, chemical-resistant nitrile options represent an affordable safety investment.

Remember to pair your gloves with proper eye protection—comprehensive safety requires protecting all vulnerable areas from chemical splashes.

Proper Fitting and Usage to Maximize Protection

Three critical elements determine the effectiveness of your chemical-resistant gloves: proper fit, condition, and application technique. When handling sodium hydroxide, verify your nitrile gloves fit snugly around wrists and fingertips—too loose invites dangerous seepage, while overly tight gloves restrict dexterity during the soapmaking process.

Before each use, carefully inspect your chemical-resistant gloves for tears, punctures, or wear that might compromise their protective capabilities. Even minor damage creates pathways for harmful substances to make direct skin contact, potentially causing burns or irritation.

Don't remove your gloves prematurely—raw soap remains caustic. Maintain protection throughout the entire process, from mixing lye solutions to molding.

Replace gloves regularly, especially after handling corrosive ingredients, to maintain ideal safety standards in your soapmaking practice.

When to Replace Your Soap Making Gloves

Even though your chemical-resistant gloves might look intact, invisible degradation can compromise their protective qualities over time.

Inspect your gloves regularly for tears, thinning areas, discoloration, or texture changes—these are clear signals that your protection has been compromised.

After handling sodium hydroxide or other harsh chemicals, consider replacing your gloves regardless of their appearance.

Chemical exposure can weaken the material in ways not immediately visible, putting your safety at risk.

For maximal hygiene and consistent protection, replace gloves after each soap making session, especially when switching between different fragrances or formulations.

Always maintain a backup supply of replacement gloves to guarantee you're never caught without proper protection during your creative process.

Beyond Protection: Additional Benefits of Wearing Gloves

While most soap makers prioritize chemical protection, properly selected gloves offer numerous additional advantages beyond safeguarding against sodium hydroxide burns.

Chemical-resistant gloves enhance your soap making experience in practical ways you mightn't have considered.

- Preserved skin moisture – You'll avoid frequent hand washing that leads to dryness and cracking, maintaining your skin's natural barrier.

- Improved hygiene – Gloves prevent contamination of your products, ensuring both your safety and the quality of your finished soaps.

- Enhanced dexterity – The right gloves provide better grip when handling slippery oils and raw soap, allowing for more precise movements.

These benefits make gloves a worthwhile investment beyond mere protection against skin irritation, contributing to both your crafting efficiency and long-term skin health.

Frequently Asked Questions

What Kind of Gloves to Wear for Soap Making?

For soap making, you'll need nitrile gloves because they protect against sodium hydroxide and harsh chemicals. Black nitrile gloves offer extra durability. Don't use vinyl gloves when handling lye as they provide insufficient protection.

Why Should You Wear Gloves When Working With Chemicals?

You should wear gloves when working with chemicals to protect your skin from burns, irritation, and long-term damage. They prevent harmful substances from directly contacting your hands, avoiding painful injuries and allergic reactions.

What PPE Is Needed for Soap Making?

You'll need safety goggles, chemical-resistant gloves, and a respirator for soap making. Don't forget to maintain a clean workspace and keep a first aid kit nearby for potential accidents.

What Are Chemical Resistant Gloves Used For?

You'll use chemical-resistant gloves to protect your skin from harmful substances that cause burns, irritation, or allergic reactions. They prevent direct contact with caustic ingredients while maintaining your dexterity during handling procedures.

In Summary

When making soap, you're not just creating a product—you're handling potent chemicals that can harm your skin. Don't compromise on proper gloves. They'll protect you from burns, shield against sensitizing ingredients, and guarantee your soap remains contamination-free. Remember, your safety isn't optional in this craft. Invest in quality chemical-resistant gloves, replace them when worn, and you'll enjoy soap making for years to come.

Leave a Reply