When cooling lye for soapmaking, you'll find several safe methods: water bath with ice, adding ice cubes made from distilled water, pre-chilling your container, masterbatching lye solution, outdoor cooling for better ventilation, indoor cooling with proper protection, and using frozen liquid components. Always wear protective gear including goggles and gloves, and guarantee proper ventilation regardless of your chosen method. These techniques not only enhance safety but also improve your soap's quality and production efficiency.

7 Safe Methods to Cool Lye for Soapmaking

Four effective methods can help you safely cool your lye solution when making soap.

First, place your lye container in an ice water bath to accelerate cooling time while maintaining lye safety.

Second, use frozen water cubes when mixing your lye—this immediately lowers the temperature without compromising the chemical reaction.

For standard batches using about 32 ounces of oil, your lye solution will typically cool within an hour.

If you're working with larger batches, consider preparing your lye solution the night before to guarantee proper cooling.

The Water Bath Method: Cooling Without Compromising Safety

When safety is your priority, the water bath method offers an efficient solution for cooling lye without risking contamination or dangerous temperature fluctuations. This technique accelerates the cooling process by placing your lye solution container in a larger vessel filled with ice water.

- Use sturdy, heat-resistant containers for both your lye solution and the outer water bath.

- Monitor the temperature lye solution closely, aiming for the best 100-120 degree range.

- You'll typically achieve ready-to-use lye in under an hour, compared to natural cooling.

- The ice water insulation prevents direct exposure to air contaminants while controlling cooling rate.

This method gives you better temperature control throughout the entire process, making it ideal for soapmakers who need consistent results without compromising safety standards or waiting hours for natural cooling.

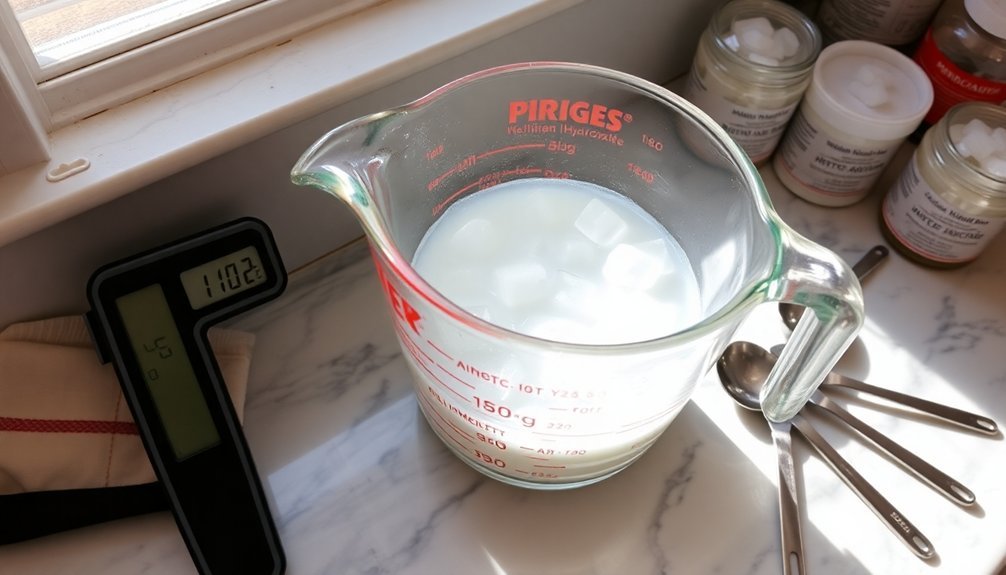

Ice Cube Technique: Accelerating the Cooling Process

The ice cube technique offers soapmakers a remarkably fast cooling method that can transform your lye solution from dangerously hot to workable temperature in minutes. Instead of waiting an hour or more, you'll achieve handling temperatures in just 10-20 minutes—particularly beneficial for larger batches.

To implement this method, prepare ice cubes using only distilled water. This prevents impurities from affecting your soap quality.

When you're ready to cool your lye solution, gradually add these frozen cubes directly to the mixture. The slow addition prevents violent reactions that sudden temperature changes might cause.

This approach considerably streamlines your soapmaking process by eliminating lengthy cooling wait times. You'll maintain safety while gaining efficiency—a perfect balance when you're keen to move forward with your creative soap formulations.

Pre-Chilling Your Container for Faster Results

You'll find significant time savings when you pre-chill your soap container before adding the lye solution.

Simply place your HDPE or polypropylene container in the freezer for 15-20 minutes prior to mixing your lye water.

This cold container technique, when combined with an ice bath surrounding your mixing vessel, can reduce cooling time by up to 50%, getting you to that ideal 100-120 degree range much faster.

Ice Bath Cooling

Accelerating your lye solution's cooling process can be achieved effectively through an ice bath method, especially when you've pre-chilled your container beforehand.

This technique allows cold water to rapidly absorb heat from your lye solution, reducing waiting time before you can begin soapmaking.

For ideal results:

- Confirm your ice bath is deep enough to surround the container's sides without allowing water to contaminate your lye solution.

- Add frozen water cubes directly to your ice bath to maintain consistently low temperatures.

- Monitor temperature carefully, as rapid cooling can create condensation that may lead to accidental lye splashes.

- Position your container securely in the ice bath to prevent tipping while maximizing surface contact for efficient cooling.

This method works particularly well when combined with pre-chilling techniques for maximum cooling efficiency.

Frozen Container Method

While ice baths provide external cooling, pre-chilling your mixing container offers a head start by lowering the initial temperature of your lye solution from the very beginning.

Simply place your mixing container in the freezer for a short time before you begin the mixing process.

When using a frozen container method, make sure your container is made from heat-resistant materials like HDPE #2 or Polypropylene #5, as these can safely withstand the high temperatures generated when lye meets water.

For even faster cooling, you can add frozen water cubes to your solution after the lye has completely dissolved.

Always monitor the temperature of your lye solution throughout this process, aiming for 100-120 degrees Fahrenheit for best soap-making results.

This technique greatly reduces your waiting time between mixing and pouring.

Masterbatching Lye Solution for Temperature Control

Masterbatching your lye solution in advance can revolutionize your temperature control strategy while saving substantial time during future soap sessions.

You'll need to store these pre-mixed solutions in appropriate chemical-resistant containers with secure, airtight closures away from children and pets.

When you're ready to use your masterbatch, you can easily adjust the concentration by weighing the precise amount needed for your recipe, ensuring consistently proper temperatures between 100-120 degrees without waiting for freshly mixed lye to cool.

Premaking Large Batches

For busy soapmakers who value efficiency, premaking large quantities of lye solution can revolutionize your production process. Masterbatching lye lets you prepare solution days or even weeks ahead, giving you immediate access whenever inspiration strikes.

This advanced technique provides exceptional temperature control since your lye solution will already be at room temperature.

When implementing this time-saving approach:

- Store your masterbatched lye solution in HDPE #2, Polypropylene #5, or Nalgene containers for safety and longevity

- Cool your lye solution quickly using ice water baths if you need it sooner

- Utilize the heat transfer method by pouring your masterbatched lye directly into hard oils to melt them efficiently

- Label containers clearly with concentration information and creation date for proper tracking

You'll appreciate the consistency and convenience that comes with having pre-mixed lye ready for multiple soap batches.

Storage Safety Considerations

The safe storage of masterbatched lye solutions requires strict adherence to five critical protocols.

First, always use containers made specifically from HDPE #2, Polypropylene #5, or Nalgene materials that resist degradation from the caustic solution. These containers must have tight-fitting lids to prevent leaks or evaporation.

Second, label each container clearly with "LYE SOLUTION," the concentration, and the date prepared.

Third, store your masterbatched lye solutions in a secure location that's cool, dry, and absolutely inaccessible to children and pets.

Fourth, never repurpose food containers for storage, regardless of how well you've labeled them.

Finally, regularly inspect your storage containers for signs of degradation or leakage. While properly stored solutions can last for months, storage safety should never be compromised for convenience.

Concentration Adjustment Methods

Once you've mastered basic lye handling, creating a masterbatched solution can revolutionize your soapmaking workflow while providing superior temperature control.

Preparing concentrated lye in advance allows you to dilute it precisely when needed, streamlining your production process.

When working with masterbatched solutions, consider these concentration adjustment methods:

- Calculate your desired final concentration by determining the water-to-lye ratio needed for your specific recipe

- Cool your concentrated solution rapidly using an ice bath to accelerate the cooling process

- Dilute the masterbatch with room temperature or cool distilled water to achieve your target concentration

- Mix thoroughly but gently to guarantee even distribution without splashing

This approach gives experienced soapmakers greater control over temperatures throughout the saponification process.

Your masterbatched solution can be stored safely for months, guaranteeing consistency across multiple batches of soap.

Indoor vs. Outdoor Cooling: Environmental Considerations

When deciding where to cool your lye solution, safety considerations should dictate your choice between indoor and outdoor environments. Cooling lye solution outdoors offers superior ventilation, greatly reducing your exposure to harmful lye fumes during the exothermic reaction.

If you must cool indoors, open windows and run fans to maintain adequate airflow. Never mix in confined spaces where fumes can concentrate quickly.

| Location | Advantages | Safety Requirements |

|---|---|---|

| Outdoor | Better ventilation, faster cooling | Basic protective gear |

| Indoor | Convenience, temperature control | Enhanced ventilation, full protective gear |

| Ice Bath | Rapid temperature reduction | Can be used in either location |

Remember that proper safety precautions—including goggles, gloves, and long sleeves—are essential regardless of where you cool your solution. Prioritize ventilation to minimize inhalation risks.

Using Frozen Liquid Components in Your Lye Solution

Why struggle with long cooling times when you can accelerate the process using frozen liquid components? This technique revolutionizes your soapmaking workflow by considerably reducing wait times to under an hour.

When you add frozen cubes to your lye solution, you're effectively managing the exothermic reaction that causes high temperatures.

For best results:

- Use distilled water for both your solution and frozen components to guarantee soap purity

- Add the frozen liquid components gradually to prevent temperature shock

- Prepare extra frozen cubes for larger batches that require more cooling

- Monitor the temperature throughout the process to reach the ideal mixing point

This method is particularly valuable when working with temperature-sensitive ingredients or when you're enthusiastic to complete your soap project more efficiently.

Frequently Asked Questions

How to Cool Down Lye Water?

To cool down lye water, place your container in an ice bath. You can also add frozen water cubes directly to the solution. It'll typically cool in under an hour, so timing works well with your soapmaking schedule.

How Long to Let Lye Cool?

You should let lye cool for 30-60 minutes for standard batches. For larger amounts, prepare it the night before. Aim for 100-120°F and keep the lye within 10° of your oils' temperature for ideal results.

How to Handle Lye Safely?

Always wear protective gear, work in well-ventilated areas, add lye to water (never reverse), use appropriate containers, and have water ready for immediate rinsing if contact occurs. Don't inhale fumes and handle with extreme caution.

What Plastic Is Safe for Lye?

You'll want to use HDPE (#2) or Polypropylene (#5) plastics for lye storage. They're resistant to lye's corrosive nature. Nalgene containers work well too. Always avoid PETE as lye will degrade it quickly.

In Summary

You've now got seven reliable methods to safely cool your lye solution for soapmaking. Whether you're using ice baths, frozen milk, or masterbatching, always prioritize safety with proper protective gear. Don't rush the process—proper cooling guarantees better soap quality and safer handling. Remember, patience with lye cooling will reward you with consistent results and a more enjoyable soapmaking experience.

Leave a Reply