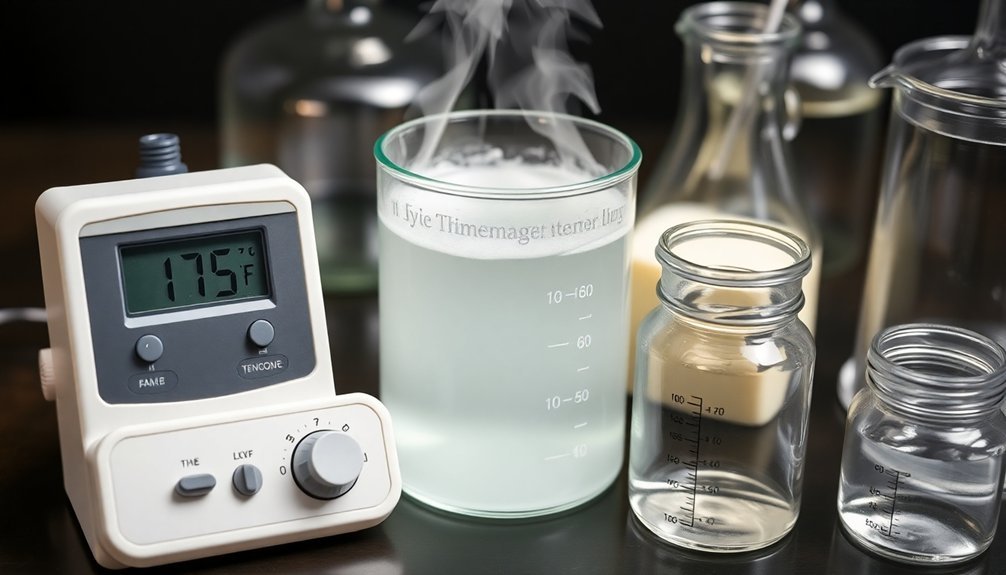

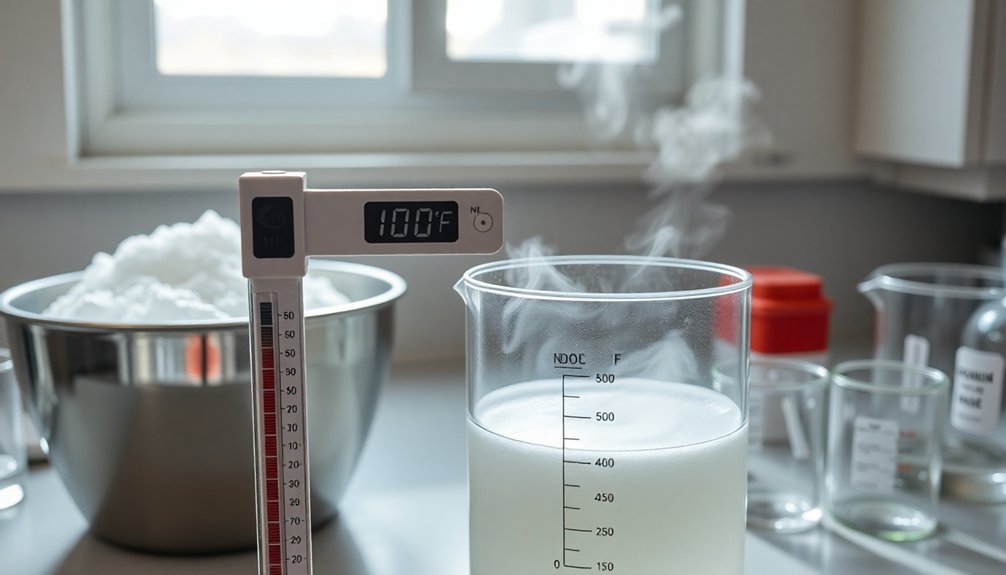

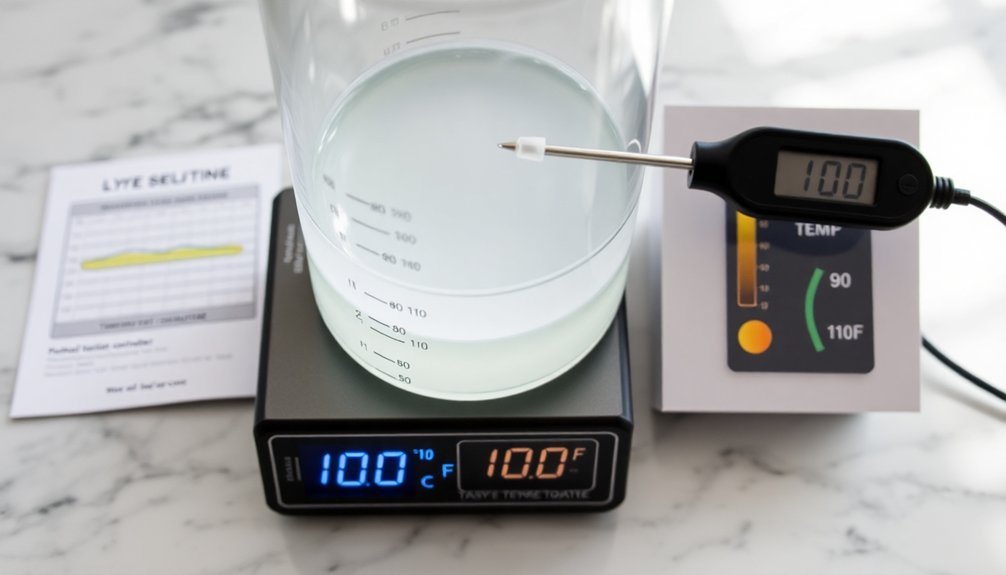

Maintaining your lye solution at 80-120°F (ideally around 100°F) is essential for successful soap making. Keep lye and oils within 5-10 degrees of each other to prevent false trace and separation. For best results, use a digital thermometer and gentle stirring to distribute heat evenly. You can utilize lye's natural heat to melt hard oils or rewarm solutions using hot water baths. Master these temperature controls to transform your soap from problematic to professional.

Numeric List of Second-Level Headings

While planning your lye solution temperature control strategy, you'll need to address several key areas.

Consider these essential headings for your soap making process:

- Best Lye Temperatures for Saponification

- Heat Transfer Methods for Warming Solutions

- Sodium Hydroxide Pure High Concentration Safety

- Managing the Exothermic Reaction

- Melting Point Considerations for Oils and Fats

- Temperature Correlation Between Lye and Oils

- Cold Process Temperature Monitoring Techniques

- Master-Batching Temperature Guidelines

- Maintaining Soap Batter Consistency

- Temperature Troubleshooting for Experienced Soap Makers

Each heading addresses a critical aspect of controlling your lye solution temperature, helping you maintain the ideal range of 98.6°F to 100°F for perfect saponification.

Remember that proper temperature management guarantees your soap making process advances smoothly without hazardous reactions or poor emulsification.

The Science Behind Lye Solution Temperatures

Now that you have a framework for temperature control strategies, let's explore the chemistry that makes these guidelines so significant.

When you combine NaOH with water temperature, an exothermic reaction occurs, naturally raising the solution's temperature. This heat release is vital for achieving proper concentration in your lye water mixture.

The chemistry is fascinating—a 50% NaOH solution isn't fully ionized and releases additional energy when diluted further.

Maintaining temperatures near body temperature (98.6°F) optimizes your soap-making process by preventing false trace while ensuring effective saponification.

Effective temperature management isn't just about safety—it directly impacts your soap's quality. The heat generated helps oils with higher melting points incorporate smoothly into your mixture.

Remember that controlling this natural warming process is essential for consistent, high-quality soap production.

Optimal Temperature Ranges for Cold Process Soap Making

Although experienced soap makers often develop personalized temperature preferences, beginners should focus on consistent temperature ranges for reliable results. The ideal target for your lye solution is around 100°F, which effectively supports the saponification process without complications. You don't need to match your oils and lye solution within 10-15 degrees—both can function well between 80-120°F.

| Temperature (°F) | Lye Solution | Oils | Effects |

|---|---|---|---|

| 80-90 | Cool | Low | Slower trace, gentler |

| 90-100 | Ideal | Ideal | Balanced process |

| 100-110 | Warm | Warm | Faster trace |

| 110-120 | Hot | Hot | Very quick trace |

| 120+ | Too hot | Too hot | Risk of false trace |

When monitoring temperatures during beginner soap making, remember that consistency matters more than precision. Properly melted oils help avoid false trace issues.

Heat Transfer Method: Utilizing Lye's Natural Heat

The Heat Transfer Method harnesses your lye solution's natural heat to efficiently melt hard butters and oils, eliminating the need for separate heating equipment.

You'll need to carefully monitor temperatures, keeping the mixture around 100°F to prevent false trace while ensuring complete melting of all ingredients.

When implementing this technique, stir gently as you combine the hot lye with your pre-measured oils to maintain ideal control throughout the saponification process.

Melting Hard Butters Efficiently

One ingenious technique in soapmaking harnesses the natural heat generated by freshly mixed lye solution to melt hard butters, eliminating the need for separate heating equipment.

This Heat Transfer Method creates a smooth, consistent soap batter while simplifying your process.

To execute this method effectively, first weigh your hard butters into your mixing container.

Then pour your hot lye solution directly over the butters. As you gently stir the mixture, the heat distributes evenly, promoting complete melting.

Be mindful of different melting points among your chosen butters—some may require higher lye solution temperatures for proper melting.

Temperature Control Techniques

Mastering temperature control during soapmaking gives you incredible flexibility when using the Heat Transfer Method. By adding hot lye solution to pre-measured oils in your container, you'll harness the natural heat generated to melt your ingredients efficiently. This technique works particularly well with soft oils that have lower melting points.

| Oil Type | Melting Response | Best Practice |

|---|---|---|

| Liquid Oils | Immediate | Add first to container |

| Soft Butters | Quick melting | Add second to benefit from heat |

| Hard Butters | Requires more heat | Pre-cut into small pieces |

Gently stir the mixture until all oils have completely melted to create a homogenous soap batter. This careful temperature control helps prevent false trace, which can occur when harder oils solidify too quickly. You'll achieve a smoother mixture while simplifying your process by eliminating separate heating steps.

Preventing False Trace

When working with the Heat Transfer Method, you'll need to watch for false trace—a deceptive thickening that mimics real trace but actually results from cooled oils starting to solidify. This grainy texture disrupts proper saponification and leads to poor-quality soap.

To prevent false trace, make certain your oils are completely melted and homogenized before combining with the lye solution. The Heat Transfer Method leverages the natural heat from your fresh lye solution to melt and integrate with your oils effectively. Aim for a lye solution at or slightly above body temperature—this provides sufficient heat while avoiding overheating.

Stir your oils gently until fully melted before introducing the lye solution. This vital step creates a smooth soap batter with consistent temperature control throughout.

Preventing False Trace Through Temperature Management

Since temperature plays a critical role in the soap-making process, understanding how to manage it can help you avoid false trace—a frustrating issue where your soap batter appears to thicken prematurely.

Proper temperature management guarantees your lye solution and oils interact effectively during saponification.

- Maintain your lye solution at body temperature or slightly higher before mixing with oils

- Confirm all oils are fully melted and homogenized before adding the lye solution

- Consider using the heat transfer method, allowing the hot lye solution to melt solid oils

- Continue stirring the mixture until saponification generates enough heat to remelt any solidified fats

- Monitor both lye and oil temperatures with a reliable thermometer to verify they're compatible when combined

Master-Batching Lye: Temperature Considerations

Beyond preventing false trace, temperature control becomes even more significant when you're master-batching lye solutions. When preparing concentrated lye in advance, you'll need reliable methods to manage heat during both storage and reuse.

| Warming Method | Benefits | Safety Considerations |

|---|---|---|

| Hot Water Bath | Gentle, even heating | Monitor temperature closely |

| Double Boiler | Controlled temperature rise | Prevents direct heat contact |

| Microwave | Quick convenience | Use short pulses to avoid boilovers |

Always keep your master-batched lye solution within safe limits when reheating. A double boiler provides the safest approach to warm your lye without overheating. If using a hot water bath, place your lye container in warm water gradually. Remember that careful temperature control guarantees your master-batched lye performs consistently when combined with oils for soap making.

Safe Methods for Reheating Cold Lye Solutions

Three reliable methods exist for safely reheating cold lye solutions without compromising safety or soap quality. When you're working with pre-mixed solutions that have cooled, proper temperature control becomes essential for successful soapmaking.

- Create a hot water bath by placing your lye solution container in a pot of heated water, allowing for gradual warming without direct heat exposure.

- Use a double boiler setup to provide controlled, even heating that greatly reduces overheating risks.

- If using a microwave, apply short heating pulses (10-15 seconds) to prevent container breakage and dangerous boilovers.

- Always monitor the temperature with a reliable thermometer to avoid exceeding safe thresholds.

- Maintain proper ventilation during reheating, as fumes can release; wear protective gear (goggles, gloves) to prevent chemical exposure.

Hot Process Temperature Requirements and Adjustments

While hot process soapmaking requires careful temperature management, it offers more flexibility than cold process methods.

When making hot process soap, you'll want to warm and melt your oils in the cooking pot before introducing the lye solution. Unlike cold process, you don't need to cool your lye solution first—the hot lye actually accelerates saponification when combined with warm oils.

Your lye solution can safely exceed body temperature, as this added heat enhances the reaction. Though you should monitor temperatures of both components, they don't need to match precisely.

Temperature adjustments during mixing aren't typically necessary since the heat generated by the lye reaction compensates for any variations. This forgiving nature of hot process soap making simplifies temperature control while still producing excellent results.

Factors Affecting Lye Temperature Stability

Your lye solution's temperature stability depends greatly on its heat transfer efficiency, which varies based on container materials and solution volume.

The storage environment you choose directly impacts temperature maintenance, with drafty areas causing faster cooling and insulated spaces preserving heat longer.

You'll notice that higher concentration lye solutions not only reach higher initial temperatures but also cool more gradually, requiring additional monitoring during the soap-making process.

Heat Transfer Efficiency

Efficient heat transfer forms the cornerstone of successful soap making, directly influencing how lye interacts with oils during saponification.

When your lye solution maintains peak temperature—around 100°F—you'll achieve better mixing efficiency and reduce false trace risks.

- Warmer lye solutions accelerate saponification rates, creating smoother shifts between phases.

- The Heat Transfer Method utilizes the exothermic reaction's natural heat to melt solid oils, ensuring even distribution.

- Consider your oils' melting points when preparing lye—higher melting point fats require warmer solutions.

- Additional water in your lye mixture can help manage heat by absorbing some of the exothermic reaction energy.

- Maintaining body temperature or slightly higher creates the ideal environment for chemical bonds to form between lye and oils.

Storage Environment Effects

Although often overlooked, storage conditions profoundly impact lye solution stability and temperature control. Your lye solution requires a cool, dry place away from direct sunlight to maintain its integrity.

Extreme cold can cause solidification or clumping, while excessive heat increases evaporation and alters concentration—both compromising your soap making process.

Store your solutions in insulated containers to buffer against external temperature fluctuations. This simple precaution maintains consistency and prevents degradation of your carefully prepared mixture.

Be vigilant about humidity levels as well; excess moisture can lead to caking of the lye and disrupt temperature stability.

Implement regular monitoring of both temperature and humidity in your storage environment. This proactive approach guarantees your lye solution remains stable, effective, and ready for use whenever your soap making projects demand it.

Concentration Impacts Cooling

Beyond storage environment, the concentration of sodium hydroxide in your lye solution plays a fundamental role in temperature stability. Understanding how NaOH concentration affects cooling rates will help you achieve consistent saponification results.

- Higher NaOH concentrations (like 50%) retain heat longer due to the exothermic reaction that occurs during dissolution.

- When diluting concentrated lye solutions, additional heat is generated as more NaOH molecules ionize in water.

- The heat capacity of both your lye solution and added water determines overall cooling time.

- Temperature monitoring becomes critical as concentration variations can lead to unpredictable cooling patterns.

- Proper concentration management directly impacts your final product quality by ensuring appropriate saponification temperatures.

Equipment for Precise Temperature Control

Proper tools for temperature control stand at the heart of successful soap making. A reliable digital thermometer is your most essential investment, enabling you to accurately monitor both lye solutions and oils throughout the process.

For heating your lye solution, you have several effective options. A double boiler setup provides gradual, controlled warming that prevents dangerous temperature spikes.

When mixing, always use glass or heat-resistant plastic containers that can withstand temperature fluctuations without compromising safety. The hot water bath method offers consistent heating by simply placing your lye container in heated water, ensuring even temperature distribution.

If you're short on time, a microwave can work—but only with extreme caution. Use brief heating intervals and check your temperature frequently to avoid potentially dangerous overheating incidents.

Troubleshooting Common Temperature-Related Issues

When your soap batter unexpectedly thickens and becomes grainy, you're likely experiencing false trace, which occurs when your lye solution is too cold and causes fats to solidify prematurely.

You can prevent this common issue by maintaining your lye solution around body temperature or slightly warming your oils to compensate for cooler lye temperatures.

If you notice soap separation beginning to occur despite your temperature control efforts, quickly remix your batch while adjusting the temperature to bring both phases back together for proper saponification.

Troubleshooting Common Temperature-Related Issues

Even experienced soapmakers encounter temperature-related challenges that can affect their final product. When your lye solution temperature isn't properly controlled, you might face several issues that can disrupt the saponification process.

- False trace occurs when soap batter prematurely thickens due to cooler temperatures, creating a grainy appearance—ensure oils are fully homogenized before adding lye.

- Aim for lye solution temperatures around body temperature (98.6°F) to enhance mixing and prevent false trace.

- If your lye solution is too cool, warm your oils slightly to balance temperatures.

- When reheating lye solutions, control temperature carefully to avoid hazardous reactions.

- Maintain consistency between oil temperatures and lye solution (ideally around 100°F) for smoother saponification.

Addressing these temperature-related issues promptly will help you create smoother, more consistent soap batches with fewer problems.

False Trace Prevention

False trace stands as one of the most frustrating temperature-related challenges in soapmaking.

You'll recognize it by the premature thickening and grainy appearance that mimics true trace but is actually just solidified fats.

To prevent this issue, guarantee all oils are fully melted and thoroughly homogenized before combining with your lye solution.

Maintain your lye solution temperature around body temperature or slightly higher for effective mixing and proper saponification.

Stir gently until all oils completely melt before using your immersion blender.

If you do encounter false trace, don't panic.

Continue mixing until saponification generates enough heat to remelt those solidified fats.

Establishing a uniform temperature throughout your batter is essential—it's the key difference between a successful batch and one plagued by false trace issues.

Soap Separation Solutions

Distinguishing between false trace and actual soap separation requires careful attention to temperature management throughout your process.

When soap separation occurs due to temperature imbalances, you can implement several effective remedies to salvage your batch and guarantee successful saponification.

- Keep your lye solution around body temperature or slightly higher to prevent false trace and separation

- Maintain fully melted, homogenized oils before introducing the lye solution for consistent temperature

- If separation occurs, continue mixing until the heat from saponification remelts any solidified fats

- Aim for both components to be around 100°F for best temperature control

- Confirm your lye and oils temperatures stay within 5-10 degrees of each other for a successful soap batch

These temperature control strategies will help you overcome separation issues and produce smooth, homogeneous soap consistently.

Adapting Temperatures for Different Oil Combinations

When creating soap with various oil combinations, you'll need to adjust your lye solution temperature strategically based on the properties of your chosen oils.

For recipes using only liquid oils like olive or sunflower, room temperature works perfectly for both oils and lye solution, preventing false trace and simplifying handling.

However, solid oils require heating to their melting point for proper incorporation. When working with mixed oil types, warming your lye solution to approximately 100 degrees Fahrenheit helps melt harder oils effectively, enhancing saponification.

This temperature management approach guarantees all components reach equilibrium regardless of their individual melting points.

Understanding each oil's melting characteristics allows you to adapt your process accordingly.

For mainly solid oils, maintain higher temperatures; for primarily liquid formulations, cooler temperatures suffice.

This tailored approach guarantees consistent, successful batches every time.

Seasonal Adjustments for Lye Solution Preparation

Seasonal temperature variations considerably impact your lye solution preparation process, requiring thoughtful adjustments throughout the year.

Your approach to mixing lye and water needs to adapt as ambient conditions change to maintain ideal saponification temperatures.

- During winter months, preheat your water slightly before adding lye to counteract faster cooling rates and prevent false trace.

- In summer, use cooler water or ice in your initial mixture to manage the exothermic reaction and avoid excessive temperatures.

- Consider insulated containers in extreme weather to maintain stable solution temperatures.

- Adjust your water volume seasonally—more in winter, less in summer—to reach your target temperature.

- Continuously monitor room temperature and humidity as these factors directly affect your lye solution's cooling curve.

Frequently Asked Questions

What Temperature Should Lye Solution Be Kept At?

You'll want to maintain your lye solution between 98-100°F (body temperature) for ideal saponification. You can use it at room temperature, but warming to around 100°F improves mixing and prevents false trace.

How to Use Master Batch Lye?

To use master batch lye, you'll need to weigh your concentrated solution accurately, warm it to around 100°F using a water bath, and then combine it with your oils according to your specific recipe's requirements.

What Temperature Do You Combine Lye and Oils?

You should combine lye and oils when they're both around 100°F, though a 5-10°F difference between them is fine. You can work within 80-120°F as long as both components reach a workable consistency.

Why Isn't Lye Used in Soap Anymore?

Your premise is incorrect. Lye is still used in soap making today. It's essential for saponification, though you don't find it in the final product as it's transformed during the chemical reaction with oils.

In Summary

You've now mastered the critical aspects of lye temperature control in soapmaking. By understanding the science, optimizing your ranges, and using proper equipment, you'll consistently create beautiful soaps without temperature-related flaws. Remember, every oil blend and season brings new challenges, but with the techniques you've learned, you're equipped to adjust confidently. Trust your thermometer, respect the chemistry, and enjoy the predictable results of your newfound expertise.

Leave a Reply