For handmade soap bars, you'll want to contemplate seven top-performing edge cutters: professional-grade wire cutters with welded steel construction, manual straight edge cutters for small batches, precision bar trimming tools, multi-wire systems for bulk processing, adjustable width cutters for custom sizes, heavy-duty stainless steel cutters, and ergonomic handle designs. Each option offers unique features to match your specific needs, from durability to precision. Let's explore which cutter will elevate your soap-making craft.

Professional-Grade Wire Edge Cutters for Commercial Production

Three key features distinguish professional-grade wire edge cutters in commercial soap production: durability, precision, and efficiency.

You'll find these tools are built with welded steel construction that lasts for decades in demanding soap making environments.

The proprietary wire used in professional-grade cutters is thicker than standard options, giving you enhanced strength and reliability during intensive soap cutting sessions.

You won't need to worry about frequent maintenance, as these advanced systems eliminate the need for constant re-tightening.

Whether you're working with cold process, hot process, or melt and pour soaps, these cutters adapt to handle various formulations effectively.

Professional-grade soap cutters excel at handling diverse soap types, from cold process to melt and pour, with consistent precision and reliability.

The ergonomic design lets you work longer without fatigue, maintaining your productivity throughout high-volume production runs.

This attention to user comfort makes professional-grade cutters essential for commercial operations.

Manual Straight Edge Cutters for Small-Batch Soaping

Precision and control define manual straight edge cutters for small-batch soap making. You'll find these essential tools feature durable stainless steel blades that deliver clean, professional cuts every time.

As a soap maker focusing on small-batch soaping, you'll appreciate how these cutters offer customizable settings to achieve your desired bar thickness.

Whether you're working with cold process or melt-and-pour soaps, manual straight edge cutters handle various consistencies with ease. The comfortable grip guarantees you maintain steady control throughout the cutting process, while the precise blade alignment helps you create uniform bars that'll catch customers' eyes.

When you're crafting handmade soaps in smaller quantities, these cutters prove invaluable for producing consistently sized bars with smooth, appealing edges that enhance your product's professional appearance.

Precision Bar Trimming Tools for Artisanal Makers

Building on the foundations of manual straight edge cutting, artisanal soap makers often turn to specialized trimming tools for that extra level of refinement.

Precision edge cutters equipped with proprietary wire offer superior control when you're working with every soap variety, from cold processed to melt and pour formulations.

You'll want to time your cuts perfectly—wait until your cold processed soap reaches 90°F for best results.

When using these specialized tools, maintain about 1/8 inch spacing between bars to guarantee proper air circulation during the curing process.

To extend your cutter's lifespan, regularly check wire tension and use a rubber mallet to guide the wire through your soap blocks.

The thicker-than-standard wire design helps prevent breakage and guarantees clean, consistent cuts across your entire production run.

Multi-Wire Cutting Systems for Bulk Processing

When you're scaling up soap production, multi-wire cutting systems offer parallel wire spacing options that let you customize cuts for different bar sizes in a single pass.

You'll find adjustable tension control systems that maintain consistent wire tightness, ensuring clean cuts across multiple bars without frequent recalibration.

While these systems dramatically increase your cutting speed compared to single-wire tools, you'll need to balance this efficiency against the slightly reduced precision that comes with processing multiple bars simultaneously.

Parallel Wire Spacing Options

Many soap makers find that parallel wire spacing systems revolutionize their bulk cutting operations. When you're launching a new product or running special offers, these systems let you efficiently cut large batches of soap with customizable spacing options.

These advanced cutting systems offer three key advantages:

- Process up to 546 bars from 42 loaves simultaneously, maximizing your production output.

- Adjust wire spacing to match your specific bar size requirements, ensuring consistency across batches.

- Utilize thicker, more durable wires than standard guitar strings for reduced breakage.

You'll find that proper wire tension is essential for maintaining cut quality. Most systems come with built-in tension adjustment mechanisms, making it easy to fine-tune your cuts without damaging the wires.

This versatility allows you to adapt quickly to different production needs while maintaining efficiency.

Adjustable Tension Control Systems

Professional soap makers rely on adjustable tension control systems to maximize their multi-wire cutting efficiency. You'll find these systems feature specialized, thicker wires that resist breakage while handling large batches of handmade bars.

When you're processing multiple bars simultaneously, proper tension control becomes essential. You can easily adjust each wire's tension to prevent sagging and maintain precise cuts across your entire batch.

You'll appreciate the user-friendly mechanisms that let you modify tension settings quickly, whether you're new to soap making or an experienced artisan.

These cutting systems excel at bulk processing, letting you slice through several bars at once. You'll save significant time while ensuring consistent results.

The proprietary wires and adjustable settings work together to deliver clean, professional cuts every time you operate the system.

Speed Vs Precision Tradeoffs

Modern multi-wire cutting systems strike an impressive balance between speed and precision.

You'll find these systems particularly valuable when you're scaling up your soap production without sacrificing quality. The adjustable wire tension guarantees your cuts remain consistent across large batches.

Key benefits you'll experience with multi-wire cutters:

- Process up to 546 bars from 42 loaves simultaneously, dramatically reducing your production time

- Achieve uniform dimensions across all cuts, even with harder soap varieties

- Minimize quality issues through precise tension control and proper curing time management

When you're working with multi-wire systems, you won't have to choose between speed and accuracy.

Regular maintenance of wire tension keeps your production flowing smoothly, while delivering the professional finish your customers expect.

Adjustable Width Soap Cutters for Custom Sizes

You'll appreciate the intuitive width settings on modern adjustable soap cutters, which let you quickly switch between different bar sizes using simple control mechanisms.

The best models feature smooth-sliding guides and secure locking systems that maintain your chosen measurements throughout the cutting process.

Whether you're creating sample-sized bars or full-sized soaps, you can easily modify the spacing between blades without needing to stop your production workflow.

Width Settings And Controls

When selecting an edge cutter for handmade soap bars, adjustable width settings offer unmatched versatility for crafters who work with multiple bar sizes.

You'll find precise controls that let you customize your cuts from 1 inch up to several inches, perfect for both individual bars and larger loaves.

The best adjustable cutters include these essential features:

- Locking mechanisms to maintain your chosen width throughout the cutting process

- Clear measurement markings for quick, accurate adjustments

- Easy-to-use controls that help you switch between different sizes without changing tools

Don't overlook the importance of reliable width settings when choosing your cutter.

A dependable locking system guarantees you'll get consistent results every time, whether you're a beginner or an experienced soap maker working on various projects.

Quick Size Adjustment Features

Skilled soap makers rely heavily on quick size adjustment features to streamline their production process.

You'll find that modern adjustable cutters come equipped with intuitive mechanisms that let you switch between different bar dimensions instantly, without needing extra tools or setup time.

These efficient features include precise calibration markings that guarantee you'll achieve consistent results every time you cut.

You're able to minimize waste while maintaining uniform bar sizes, which is vital when you're packaging products for sale.

The best cutters offer smooth adjustment controls that you can quickly set to your preferred specifications, making it easy to adapt to various recipes and design requirements.

Many models also come with interchangeable blades that you'll appreciate when working with different soap types and creative projects.

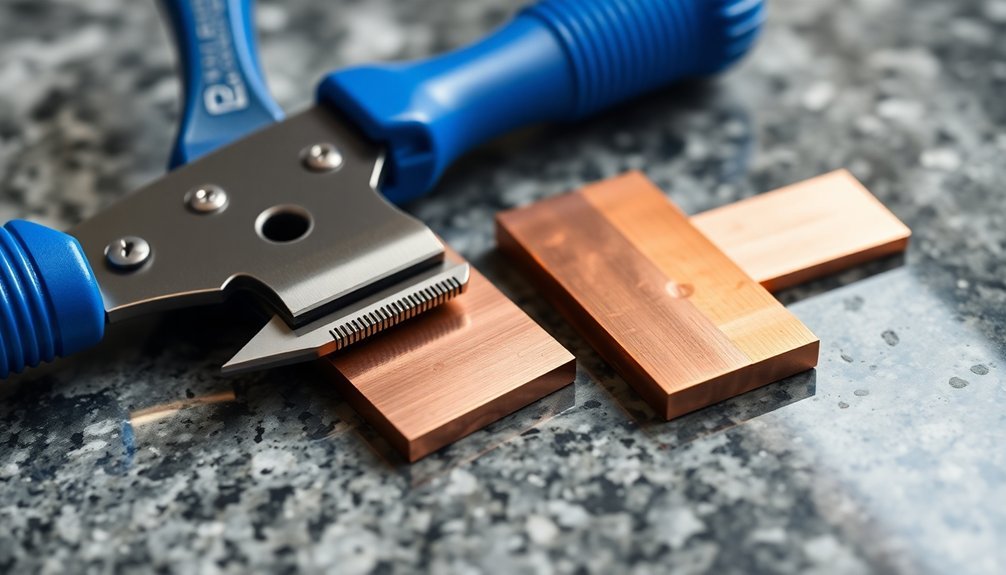

Heavy-Duty Stainless Steel Edge Cutters

Professional soap makers rely on heavy-duty stainless steel edge cutters as their go-to tools for achieving clean, precise cuts.

You'll find these durable tools excel in both wet and dry conditions, thanks to their corrosion-resistant properties. The ergonomic handles guarantee you can work comfortably through lengthy soap-cutting sessions without experiencing hand fatigue.

Key advantages of heavy-duty stainless steel cutters include:

- Adjustable blade settings for custom cutting depths

- Versatile compatibility with cold process, hot process, and melt-and-pour soaps

- Superior durability that prevents bending or breaking during frequent use

Whether you're trimming edges or creating uniform bars, these cutters deliver consistent results.

Their robust construction and adaptable features make them an essential investment for serious soap makers who demand precision in their craft.

Ergonomic Handle Designs for Extended Use

Building on the durability of stainless steel cutters, the handle design plays an equally important role in soap-making efficiency.

You'll find that ergonomic handles are specifically shaped to fit your hand's natural contours, distributing pressure evenly across your palm while you work.

Many edge cutters come with wooden handles that offer a natural, comfortable grip – perfect when you're cutting multiple soap bars.

You'll notice improved precision in your cuts since these ergonomic designs help you maintain better control and stability throughout the process.

If you're regularly making soap, these thoughtfully designed handles can protect you from repetitive strain injuries that often occur during extended cutting sessions.

The investment in an ergonomically designed cutter will make a significant difference in your soap-making comfort and productivity.

Frequently Asked Questions

What Is the Best Edge Band Trimmer?

You'll want to choose a trimmer with a stainless steel blade, ergonomic handle, and adjustable settings. The best ones feature easy-to-clean designs and work well on various materials for precise edge cutting.

What Is a Soap Cutter?

A soap cutter is a tool you'll use to slice handmade soap into uniform bars. It's designed with wires or blades that help you achieve precise, clean cuts while maintaining consistent sizes in your soap-making projects.

How to Trim Thick Edge Banding?

You'll need a sharp edge cutter set to match your banding's thickness. Apply steady pressure while trimming, maintain consistent movement, and finish by sanding any rough spots for a clean, professional look.

Can You Trim Edge Banding With a Router?

Yes, you can definitely trim edge banding with a router. You'll want to use a flush trim bit matching your banding's thickness, keep the router at 20,000-25,000 RPM, and guarantee your workpiece is firmly secured.

In Summary

You'll find the perfect edge cutter among these seven options to match your soap-making needs. Whether you're running a commercial operation or crafting small batches at home, there's a tool that fits your production scale and budget. Consider your daily volume, preferred bar sizes, and ergonomic requirements when selecting your cutter. Don't forget to factor in maintenance and durability for a long-term investment.

Leave a Reply