Professional-grade multi-wire cutters will give you the cleanest slices for your artisanal soap bars. Top picks include the stainless steel precision cutters with adjustable tension settings, heat-treated steel models with drop-forged edges lasting through 12,000 cycles, and ergonomic designs featuring parallel cutting wires for uniform thickness. You'll get consistently smooth cuts up to 3.5 inches high and 4.25 inches wide. Discover how these essential features can transform your soap-making process.

Professional-Grade Wire Cutters for Artisanal Soap Making

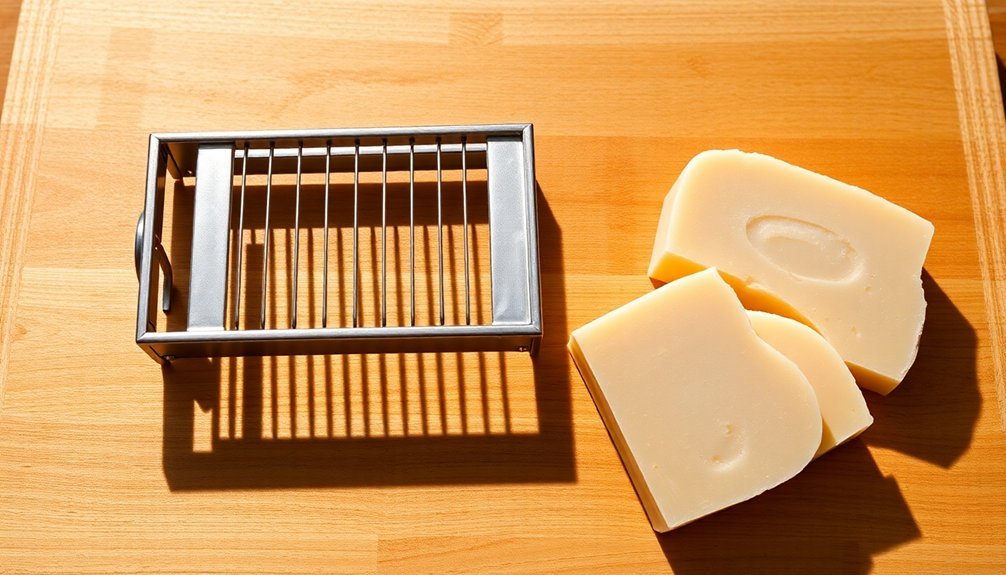

When crafting artisanal soaps, having the right wire cutter makes all the difference in achieving professional results.

Professional-grade wire cutters equipped with precision piano wire deliver clean cuts that'll guarantee your soap bars maintain uniform dimensions and flawless appearance.

Precision piano wire cutters create impeccably uniform soap bars, ensuring professional results with every slice.

You'll find these wire cutters are built to handle soap loaves up to 3.5 inches high and 4.25 inches wide, perfect for your small to medium production needs.

The heat-treated steel construction offers exceptional durability, while the ergonomic design with non-slip handles prevents fatigue during extended cutting sessions.

Most models feature adjustable settings, letting you customize bar thickness to match your specifications.

For professional soap makers focused on quality and consistency, these cutters' robust construction and precision capabilities make them an essential tool in your soap making arsenal.

Precision Features That Ensure Even Soap Bar Slices

Anyone seeking flawless soap bars needs to understand the critical precision features of quality multi-wire cutters.

You'll find that precision-engineered cutting wires made from stainless steel maintain their sharpness, delivering clean cuts consistently. The adjustable wire tension lets you customize the cutting force for different soap hardnesses.

Key features that guarantee perfect slices include:

- A sturdy base that stabilizes your soap loaf while maintaining even pressure across all wires

- Ergonomic handles that enable controlled operation without hand fatigue

- Parallel cutting wires positioned for uniform bar thickness

Your soap cutter should combine these elements to produce professional results every time.

With proper tension adjustment and the support of a stable base, you'll achieve precise, clean cuts that elevate your soap-making process to professional standards.

Top Multi-Wire Cutters and Their Performance Results

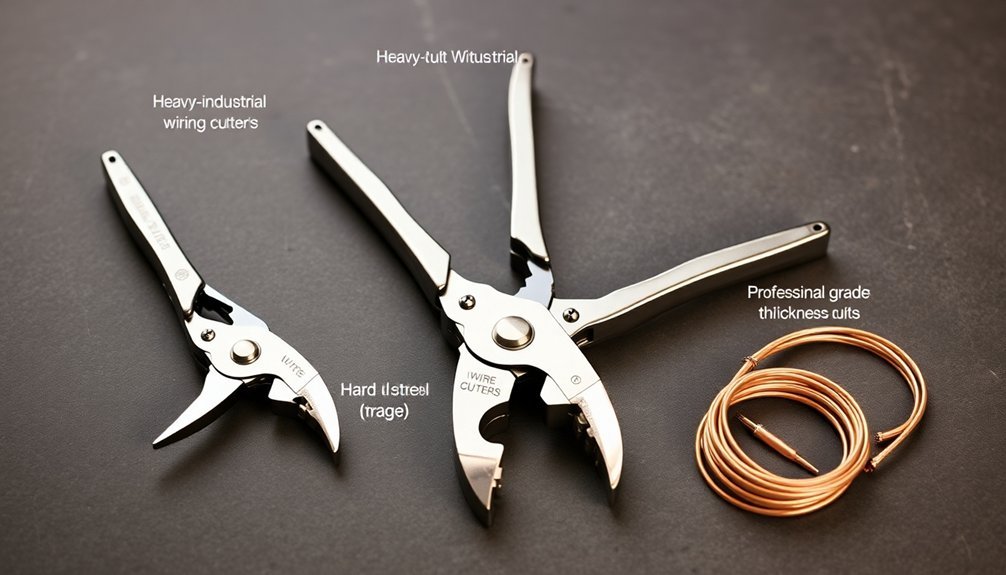

Through extensive testing and user feedback, top-performing multi-wire cutters consistently demonstrate superior cutting precision and durability.

You'll find that high-quality models featuring drop-forged, heat-treated steel cutting edges maintain their effectiveness even after thousands of uses.

The best performers come equipped with spring mechanisms that'll last through 12,000 cycles, ensuring reliable operation for your frequent cutting tasks.

You'll appreciate the adjustable stoppers and customizable stripping strength that give you enhanced control over your cuts.

When you're working on multiple projects, the ergonomic design prevents hand fatigue, making these tools comfortable for extended use.

For precise cutting in soap making and electrical work, look for multi-wire cutters that combine these essential features.

They'll deliver clean, consistent results while maintaining their durability throughout repeated use.

Frequently Asked Questions

Can Multi-Wire Cutters Be Used for Cutting Frozen Foods?

You shouldn't use multi-wire cutters on frozen foods as they're designed for non-food items. Instead, use proper kitchen tools like a sharp knife or food-specific wire cutter to safely slice frozen foods.

How Often Should the Cutting Wires Be Replaced?

You'll need to replace cutting wires when they become dull, frayed, or stretched, typically every 3-6 months with regular use. If you notice uneven cuts or resistance while cutting, it's time for replacement.

Are Stainless Steel Wires Better Than Nylon Ones?

You'll find stainless steel wires are more durable and provide cleaner cuts than nylon ones. They're also rust-resistant and won't stretch over time, though they're typically more expensive and less flexible.

What Maintenance Steps Keep Multi-Wire Cutters in Optimal Condition?

You'll need to regularly clean and oil the wires, check for tension, wipe down the frame after use, and store your cutter in a dry place. Don't forget to inspect for rust or damage.

Can These Cutters Work With Non-Traditional Soap Base Materials?

You'll find multi-wire cutters work well with alternative materials like melt-and-pour bases, lotion bars, and clay-based products. However, you should avoid cutting extremely hard substances that could damage the wires or frame.

In Summary

You'll find these three top-rated multi-wire cutters transform your soap-making process with professional results. Whether you're a beginner or experienced artisan, each model offers precise cutting capabilities and durable construction. The adjustable wire spacing lets you customize your bar sizes, while the stainless steel wires deliver clean, consistent slices every time. Choose any of these tools to elevate your soap-making craft.

Leave a Reply